Multicomponent-system high-piezoelectric-activity piezoelectric ceramic material and preparation method therefor

A piezoelectric ceramic and high-voltage technology, which is applied in the field of multi-element high-voltage electroactive piezoelectric materials and their preparation, can solve rare problems and achieve improved piezoelectric strain constant, high yield rate, and reproducibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

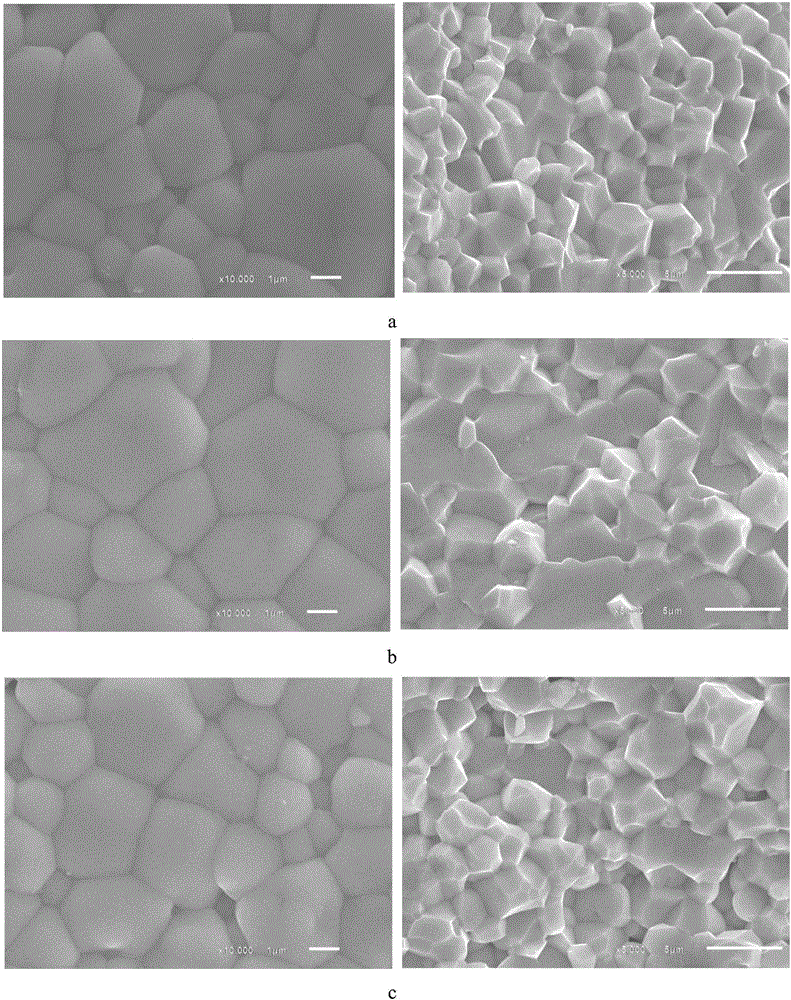

Embodiment 1

[0032] Taking the production of 0.25mol product of the present invention as an example, use the chemical formula

[0033] 0.01Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.01Pb(Zn 1 / 3 Sb 2 / 3 )O 3 -0.01Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.97Pb 1-m- n Ba m Sr n Ti 0.45 Zr 0.55 o 3 -pWO 3 Indicates that x, y, z are all 0.01, A is 0.45, 0.04≤m≤0.08, 0.08≤n≤0.12, p=0.003.

[0034] (1) According to the chemical formula NiNb 2 o 6 , ZnSb 2 o 6 , ZnNb 2 o 6 Weigh raw materials NiO, ZnO, Sb 2 o 3 , Nb 2 o 5 and some Pb 3 o 4 、BaCO 3 , SrCO 3 (the amount of lead, barium, and strontium added to the substance account for 16%, 14%, and 70% of the total molar amount of the respective elements respectively) and mix in the ball mill tank. The ball mill medium is deionized water and zirconia balls. The raw material and The mass ratio of zirconia is 1:3, ball milled at 380r / min for 4h, and dried at 150°C.

[0035] (2) Put the mixed powder obtained in step (1) into a corundum crucible, compact it,...

Embodiment 2

[0049] Taking the production of 0.25mol product of the present invention as an example, use the general formula

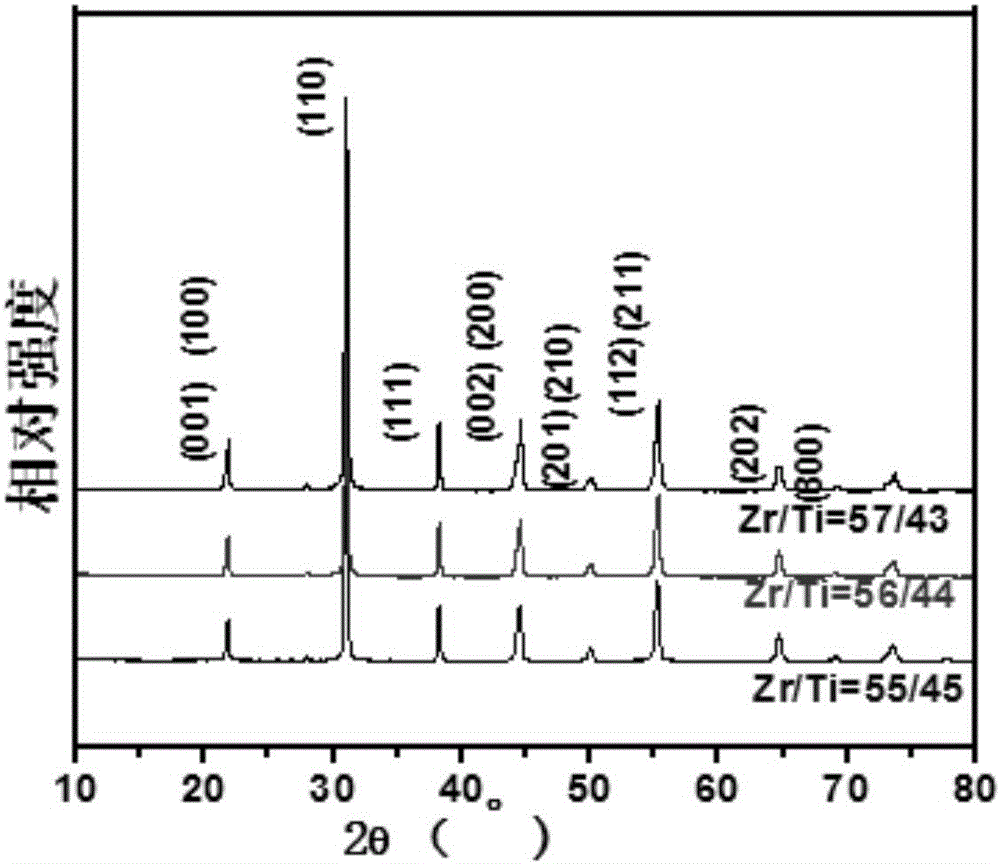

[0050] 0.01Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.01Pb(Zn 1 / 3 Sb 2 / 3 )O 3 -0.01Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.97Pb 1-m- n Ba m Sr n Ti A Zr 1-A o 3 -pWO 3 It means that x, y, z are all 0.01, m is 0.06-0.08, n is 0.10-0.12, A is 0.42-0.45, p=0.003.

[0051] Its preparation and testing methods are the same as in Example 1, and the properties measured are shown in Table 2.

[0052] Table 2. Electrical properties of ceramics with varying Zr / Ti ratios under different Ba and Sr contents

[0053]

[0054] It can be seen from Table 2 that when the contents of Ba and Sr are 0.08, 0.12, 0.08, 0.10 and 0.06, 0.12, respectively, as the Zr / Ti ratio moves toward the zirconium-rich direction, the bulk density ρ of piezoelectric ceramics decreases gradually. Relative permittivity ε r Then gradually increase; when Ba, Sr content is 0.06, 0.10, the relative permittivity ε r is gr...

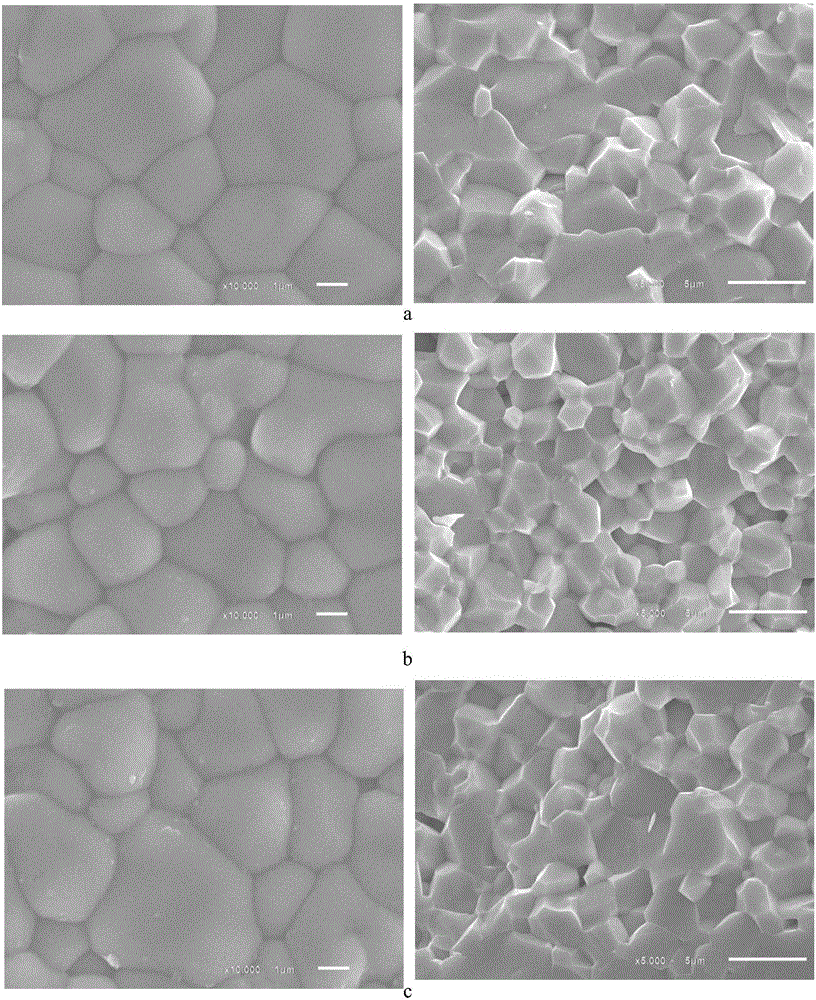

Embodiment 3

[0064] Taking the production of 0.25mol product of the present invention as an example, use the general formula

[0065] xPb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.01Pb(Zn 1 / 3 Sb 2 / 3 )O 3 -0.01Pb(Zn 1 / 3 Nb 2 / 3 )O 3 –(0.98-x)Pb 0.82 Ba 0.08 Sr 0.10 Ti 0.435 Zr 0.555 o 3 -pWO 3 It means that 0.01≤x≤0.04, y and z are both 0.01, m is 0.08, n is 0.10, A is 0.44, p=0.003.

[0066] (1) According to the chemical formula NiNb 2 o 6 , ZnSb 2 o 6 , ZnNb 2 o 6 Weigh raw materials NiO, ZnO, Sb 2 o 3 , Nb 2 o 5 and some Pb 3 o 4 、BaCO 3 , SrCO 3 (respectively accounting for 16%, 14% and 70% of the total amount of elements) into the ball mill tank for mixing. The ball milling medium is deionized water and zirconia balls. The mass ratio of raw materials to zirconia is 1:3. Ball mill for 4 hours at rpm, and dry at 150°C.

[0067] (2) Put the powder obtained in step (1) into a corundum crucible, compact it, cover it, pre-fire it at 1200°C, keep it warm for 3 hours, and the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Piezoelectric strain constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com