Mixing device for multi-component systems

A mixing equipment and multi-component technology, applied in the direction of mixers, mixers with rotating stirring devices, fluid mixers, etc., can solve problems such as large volume, inability to achieve uniform distribution, and difficulty in compressed air operation. achieve smooth mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

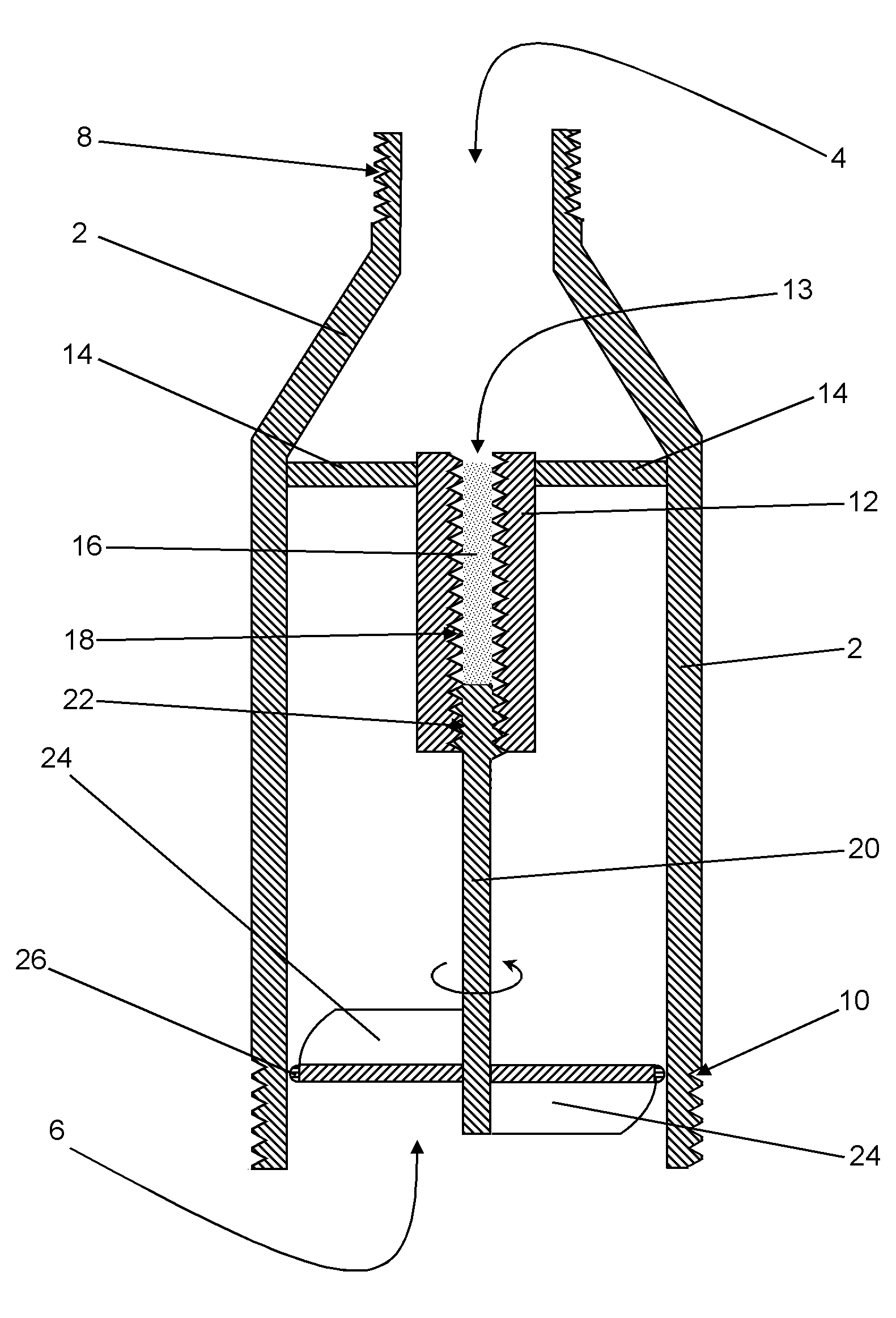

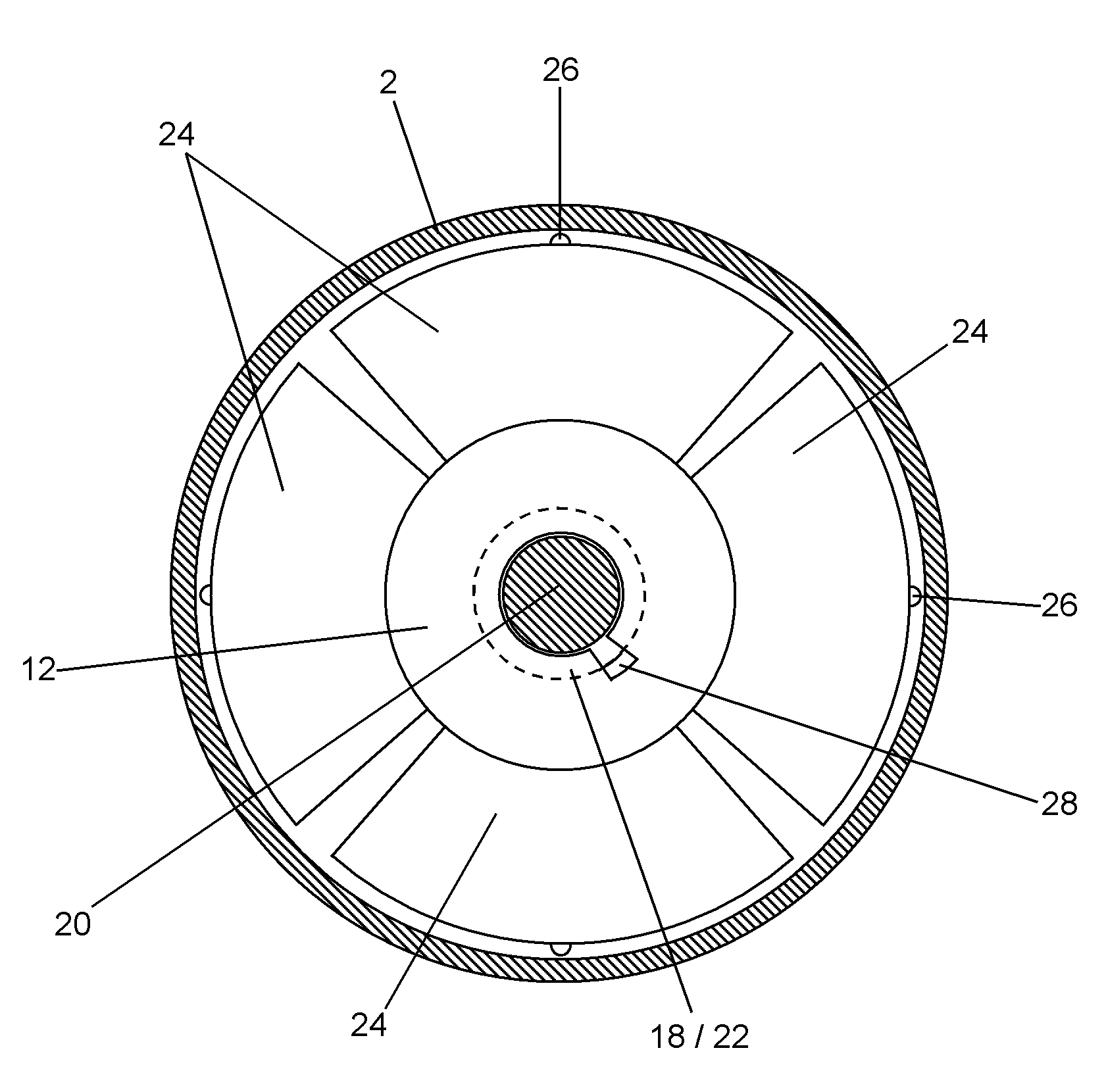

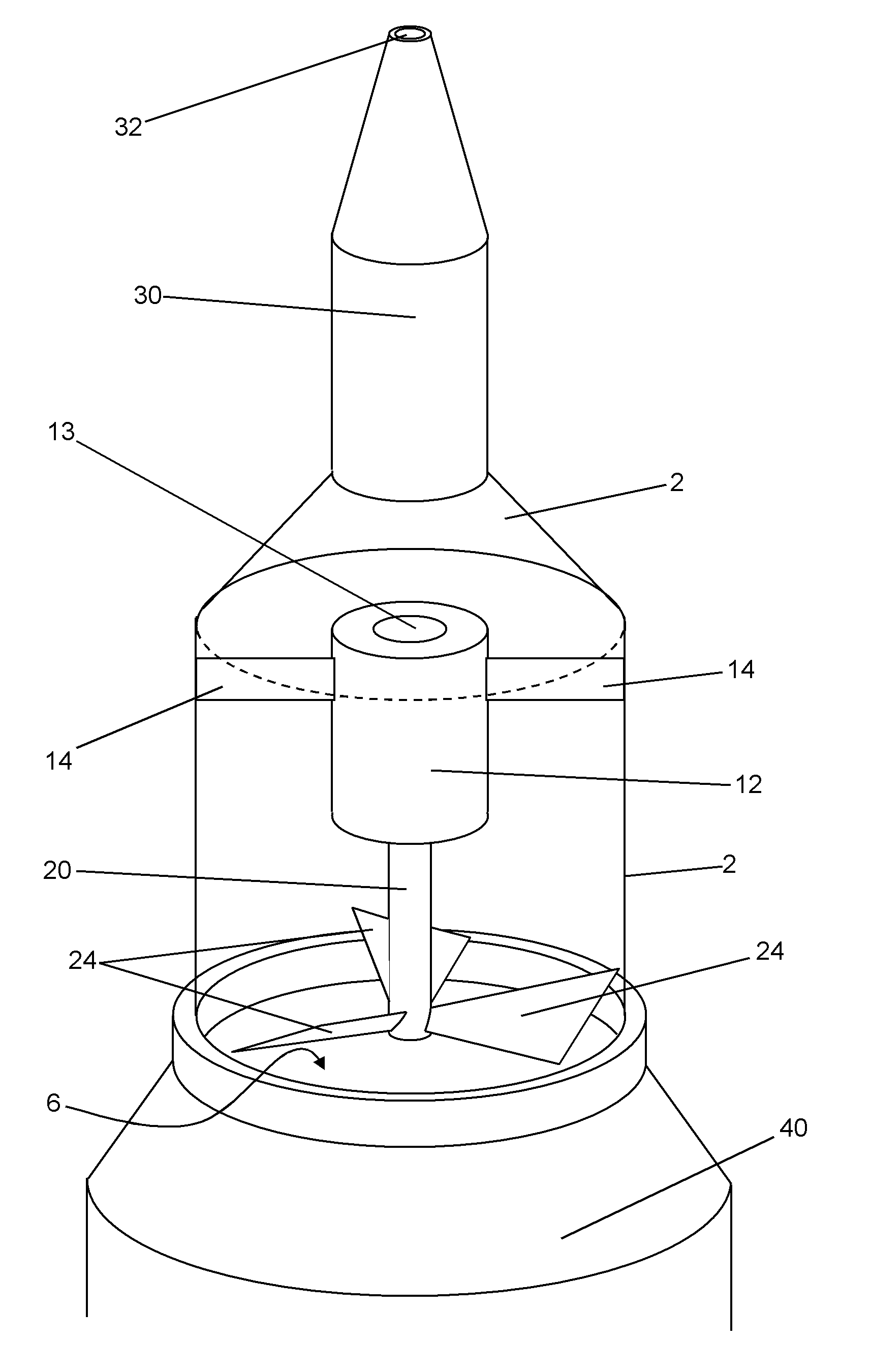

[0111] figure 1A schematic sectional view of a mixing device according to the invention is shown. The mixing device comprises a rotationally symmetrical housing 2 made of thermoplastic material. The housing 2 is produced as a cylindrical tube which tapers obliquely in the upward direction by means of a conical section and is then cylindrical again. Openings 4 , 6 are provided at both ends of the housing 2 . The multicomponent mixture (not shown) to be produced can be extruded through the upper opening 4, while the first component (not shown) is pressed into the housing 2 through the lower opening.

[0112] External threads 8 , 10 are provided on both ends of the housing 2 . A distribution tube (not shown) with a static mixer can be screwed / screwed onto the upper thread 8 . A cartridge (not shown) containing the first component is fastened to the lower thread 10 . The cartridge includes a plunger operable to force the first component into the housing. The cartridge and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com