Material for producing disposable tableware or industrial goods tray and production method thereof

A tableware and disposable technology, which is applied in the direction of textiles and papermaking, fiber raw material processing, pulp raw material addition process, etc., can solve the problems of low utilization rate of straw, waste of resources, environmental pollution, etc., and achieve low production cost and good crispness , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] 1. Preparation of straw mechanical pulp: use the "Environmental Protection Comprehensive Utilization System of Straw" disclosed by the authorized announcement number CN 2688744Y (utility model name: environmental protection comprehensive utilization system of straw) to grind and disintegrate wheat straw into slurry; the straw mechanical pulp of the present invention A conventional beater can also be used to grind the straw into a slurry;

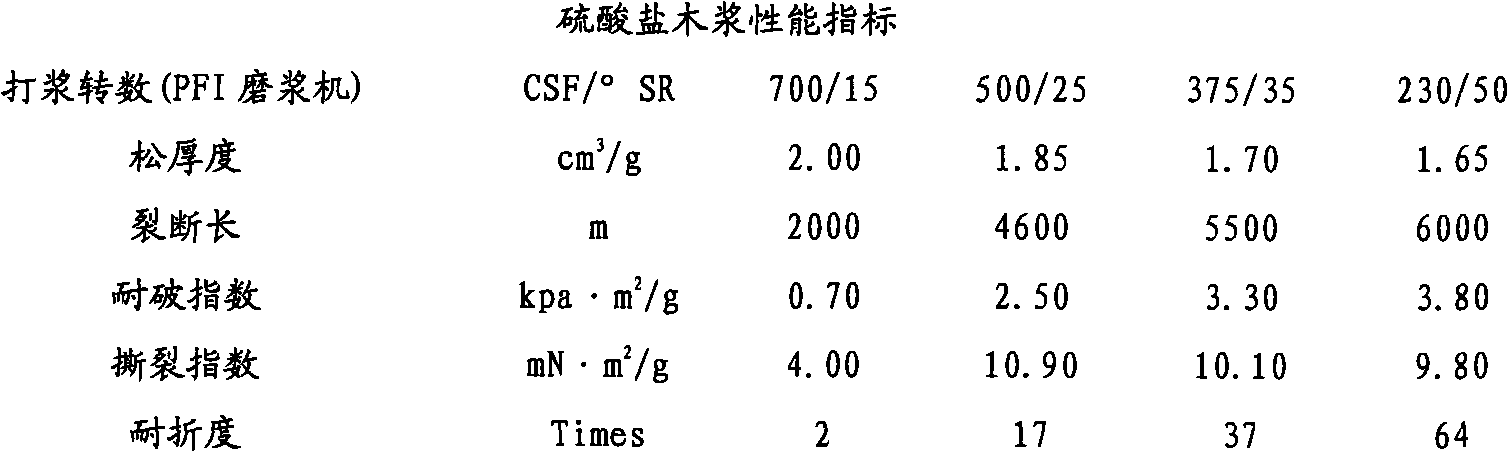

[0029] 2. Chemical wood pulp or straw pulp (also called "paper pulp"): chemical wood pulp or straw pulp of the present invention can be kraft wood pulp (kraft wood pulp is to adopt the mixed solution of sodium hydroxide and sodium sulfide as cooking agent) or sub Kraft wood pulp (using a mixture of sulfurous acid and acid sulfite as a cooking agent); specifically, the performance indicators of the kraft wood pulp can refer to Table 1. Kraft wood pulp or sulfite wood pulp used in the present invention can be purchased through commercia...

Embodiment 1

[0033] The preparation of embodiment 1 tableware

[0034] 1. Take 6Kg straw mechanical pulp, 2.5Kg chemical wood pulp (sulphate wood pulp), 0.4Kg oxide lake, 0.2Kg butyl acrylate, 0.1Kg ethyl acrylate and 0.05Kg polyvinyl fluoride and add them to the volume of 1000L Inside, add 500Kg of water again, at room temperature, stir at high speed (800-1500 rpm) for 30 minutes to make a uniform, flocculent slurry;

[0035] 2. Get 2Kg of the slurry prepared in the above steps and add it to the food tray mould, remove the obvious excess water in the slurry by the leaking method, so that the solid components in the slurry are evenly attached to the inner wall of the mold, and then the attached The mold with slurry is put into the outer mold of 180 ℃ and pressed for 20 seconds to make a food tray with a wall thickness of 2mm and a diameter of 160mm, and the tray weighs about 36g. (During the compression molding process, a small amount of water in the slurry is a natural foaming agent).

Embodiment 2

[0036] The preparation of embodiment 2 tableware

[0037] 1. Take 8Kg straw mechanical pulp, 4.0Kg chemical wood pulp (sulphate wood pulp), 0.6Kg cross-linked starch, 0.2Kg butyl acrylate, 0.3Kg propyl acrylate and 0.1Kg polyvinyl difluoride to a volume of 1000L Inside, add 650Kg water again, under normal temperature, high-speed (800-1500 turn / minute) stir 30min, make uniform, flocculated slurry;

[0038] 2. Get 2Kg of the slurry prepared in the above steps and add it to the food tray mould, remove the obvious excess water in the slurry by the leaking method, so that the solid components in the slurry are evenly attached to the inner wall of the mold, and then the attached The mold with slurry is put into the outer mold of 180 ℃ and pressed for 30 seconds to make a food tray with a wall thickness of 2mm and a diameter of 160mm, and the tray weighs about 38g. (During the compression molding process, a small amount of water in the slurry is a natural foaming agent).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com