Low-GI meal replacement rod for diabetes patients and preparation method and applications thereof

A diabetes and meal replacement technology, which is applied in the field of low GI meal replacement bars and their preparation, can solve the problems of not being able to verify whether the product is suitable for diabetics, not satisfying diabetics, and lack of scientific support, so as to enrich food types and promote The effect of virtuous cycle adjustment and slowing down blood sugar fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] At the same time, the present invention also provides a method for preparing a meal replacement bar, which mainly includes:

[0056] According to the recipe requirements, control the temperature of boiling sugar, add liquid raw materials, granular raw materials, and powder raw materials, stir evenly, press and shape, and cut to obtain semi-finished products with consistent specifications and weights;

[0057] The resulting semi-finished product is cooled to about 8°C through a tunnel under sterile conditions to avoid water mist after packaging to affect product quality;

[0058] The cooled product is inner-packaged and outer-packaged, and then stored in the warehouse, which is a finished meal replacement bar that can be sold.

[0059] The meal replacement bar prepared by the above method of the present invention is suitable for use as a meal replacement food for weight loss, especially suitable for diabetic patients to eat as a meal replacement / nutritional weight loss f...

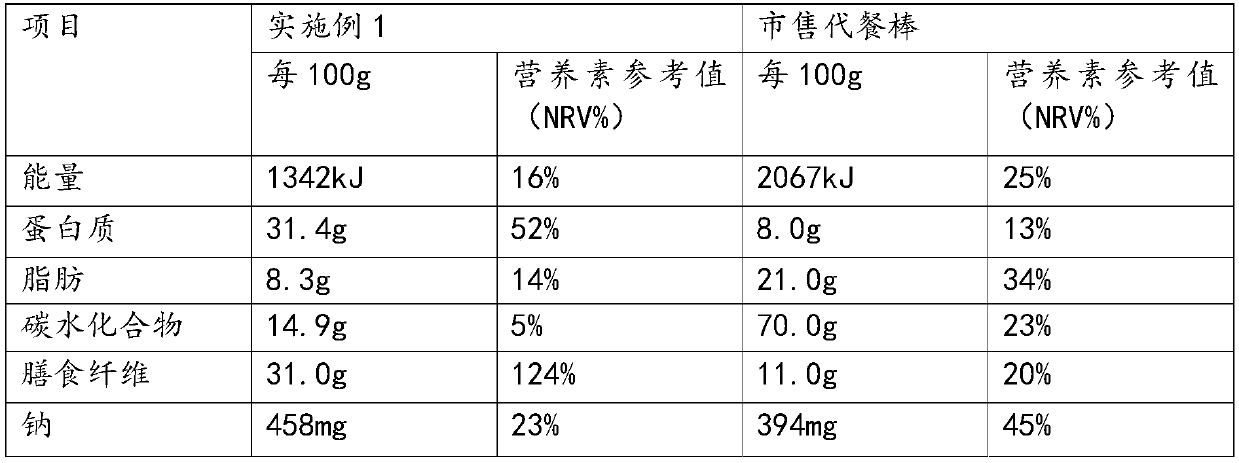

Embodiment 1

[0061] According to mass percentage, isomaltooligosaccharide 12%, polydextrose 5%, resistant dextrin 8%, oat β-glucan 3%, inulin 2%, konjac flour 1%, chia seeds 5%, oatmeal 5%, Puffed Quinoa 5%, Citrus Fiber 3%, Soy Grain Protein 18%, Soy Protein Isolate 5%, Whey Protein Concentrate 5%, Milk Protein Concentrate 3%, Maltitol 10%, Coconut Oil 3%, Glycerin 3.5%, 3% phospholipids, 0.45% salt, and 0.05% food essence, each raw material is weighed in right amount respectively.

[0062] Control the temperature of boiling sugar, add liquid raw materials, granular raw materials and powder raw materials, and stir evenly.

[0063] Then, use molding equipment to press the mixture into a flat, compact shape with uniform thickness, and cut semi-finished products with consistent specifications and stable weight to prevent pollution.

[0064] The semi-finished products after cutting are passed through the cooling tunnel in a sterile state, so that the temperature drops to about 8°C, so as to ...

Embodiment 2

[0069] According to mass percentage, 10% isomaltooligosaccharide, 10% polydextrose, 5% resistant dextrin, 1% oat β-glucan, 1% inulin, 0.5% konjac powder, 5% chia seeds, oatmeal 10%, Puffed Quinoa 15%, Citrus Fiber 1%, Soy Grain Protein 10%, Soy Protein Isolate 3%, Whey Protein Concentrate 5%, Milk Protein Concentrate 8%, Maltitol 10%, Coconut Oil 1%, Glycerin 1%, 3% phospholipids, 0.4% salt, and 0.1% food essence, each raw material is weighed in right amount respectively.

[0070] Then, referring to the method of Example 1, the low GI meal replacement bar of Example 2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com