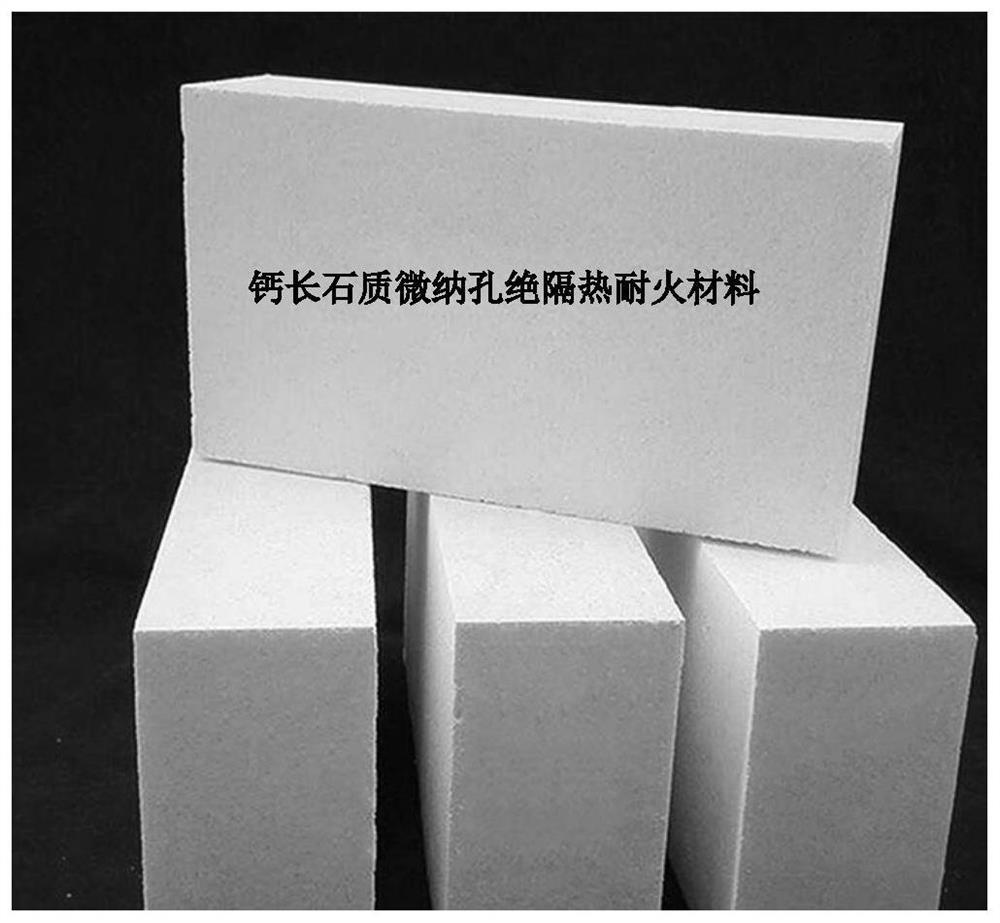

Aorthite micro-nano pore heat insulation refractory material and preparation method thereof

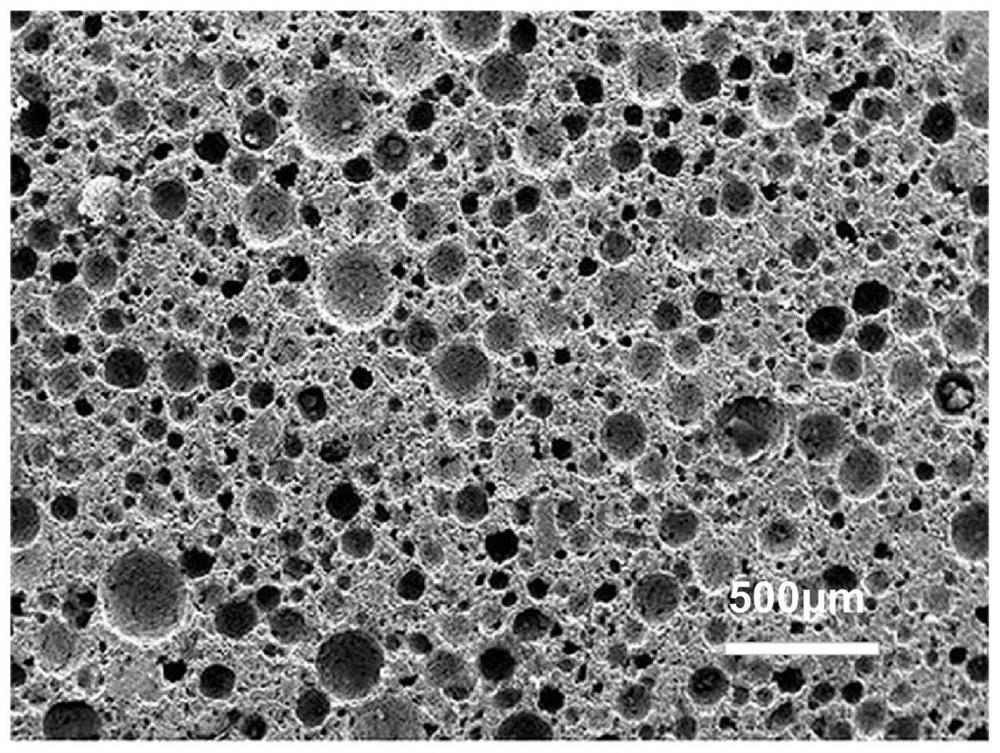

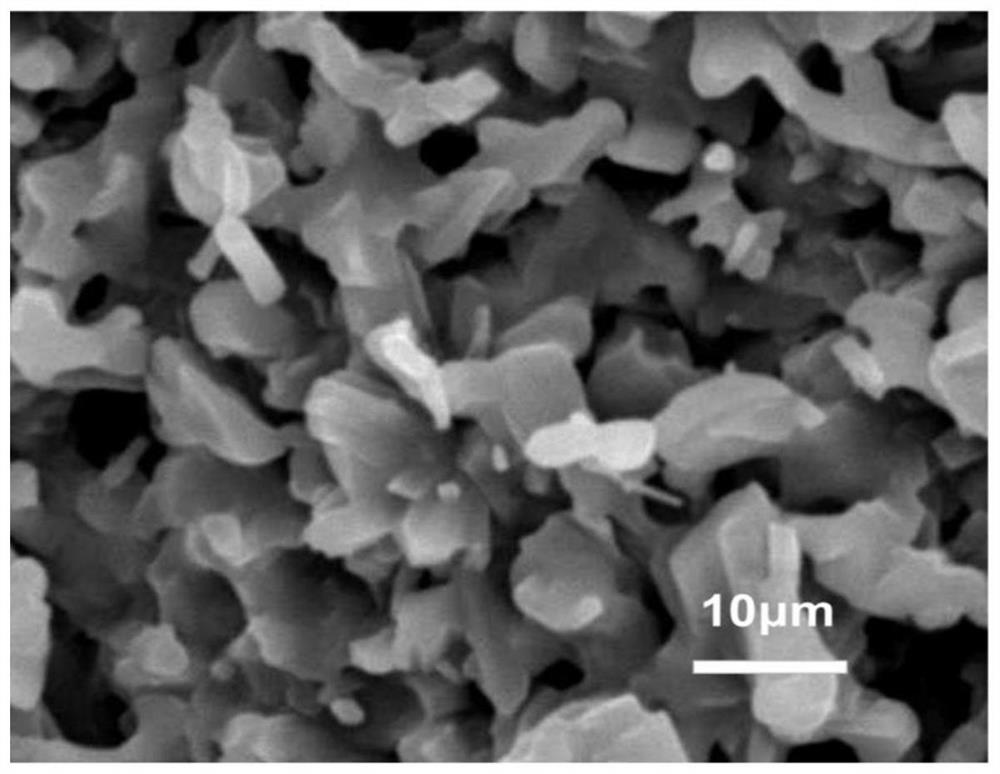

A technology of refractory materials and micro-nanopores is applied in the field of refractory materials, which can solve the problems of incompatible heat-insulating refractory materials, low thermal conductivity of materials, low bulk density, etc., and achieves short demoulding and drying cycles, high strength and simple process. easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] The calcium long stone micro-nodular separation thermal refractory material, a base material, a suspending agent, a mineralizing agent, an infrared sunscreen, a foaming agent, an inorganic curing agent, an organic curing agent, a biocomposite modifier, and water production. The type and amount of the raw materials in this embodiment will be described below:

[0096] Basic ingredients: 0.06 tons of gray, 0.3 tons of kaolin, 0.1 tons of potassium longite, 0.1 tons of sodium, 0.21 tons of industrial Al (OH) 3 0.05 tons of boehmite, 0.05 tons of water aluminum stone, 0.13 tons of diatomaceous earth. Kaolin in Al 2 O 3 The mass content is 32 ~ 35%, SIO 2 The mass content is 61 ~ 64%, the particle size is 0.6 ~ 1 mm; potassium longite in K 2 The mass content of O is 9 ~ 11%, Al 2 O 3 The mass content is 18 ~ 20%, SIO 2 The mass content is 64 ~ 66%, particle size 0.08mm; sodium fossil in NA 2 O The mass percentage content is 10 ~ 12%, Al 2 O 3 The mass content is 19 ~ 22%, SiO 2 T...

Embodiment 2~15

[0113] Example 2 to 15 The formulation composition of the calcium long stone micro-nodular separation heat refractory material is shown in Table 1, Table 2:

[0114] Table 1 Example 2 to 8 Formulations of the fine refractory material of calcium long stone micro-nodular

[0115]

[0116]

[0117]

[0118]

[0119] Table 2 Example 9 ~ 16 Calcium long stone micro-nodular separation heat refractory material formulation

[0120]

[0121]

[0122]

[0123]

[0124]

Embodiment 2

[0126] In Example 2, the base material obtained from step (1) was poured into the roller ball mill, plus 2.8 tons of water, spherical mill mixing for 10 h, and the ultrasonic oscillating (ultrasonic power 1500W) was obtained, and uniform suspension paste (wherein solid particles Particle size 30 μm); ball mill in grinding ball using aluminum oxide ball, big ball Mid-balloon small ball The weight ratio is 1: 1: 8, and the weight ratio of material / ball is 1: 0.9;

[0127] The suspended slurry was injected into the stirrer, first agload 1min (the line velocity of the stirring line was 5 m / s), and then the proximity obtained by the step (2) and a 120 kg silica sol, 80 kg alumina sol was added to the stirrer The mixing paddle is rapidly mixed with a line speed of 80 m / s to obtain a homogeneous foam slurry.

[0128] In the aluminum alloy mold, the air temperature and the relative humidity are maintained in an environment of 1 ° C, 40%, respectively, to be cured;

[0129] The so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com