Air bag fabric possessing improved packed volume and stable air permeability

a technology of air bag fabric and packed volume, applied in weaving, pedestrian/occupant safety arrangements, vehicular safety arrangements, etc., can solve the problems of increased space allocation, increased cost of use of coatings, and economic and functional disadvantages of such coatings, and achieve the effect of improving foldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]It is to be understood that the illustrated and described exemplary and potentially preferred embodiments are in no way intended as limiting the broader aspects of the present invention to such illustrated and described embodiments. On the contrary, it is intended to cover all alternatives, modifications and equivalents as may be included within the true spirit and scope of the invention as defined by the appended claims and equivalents thereto.

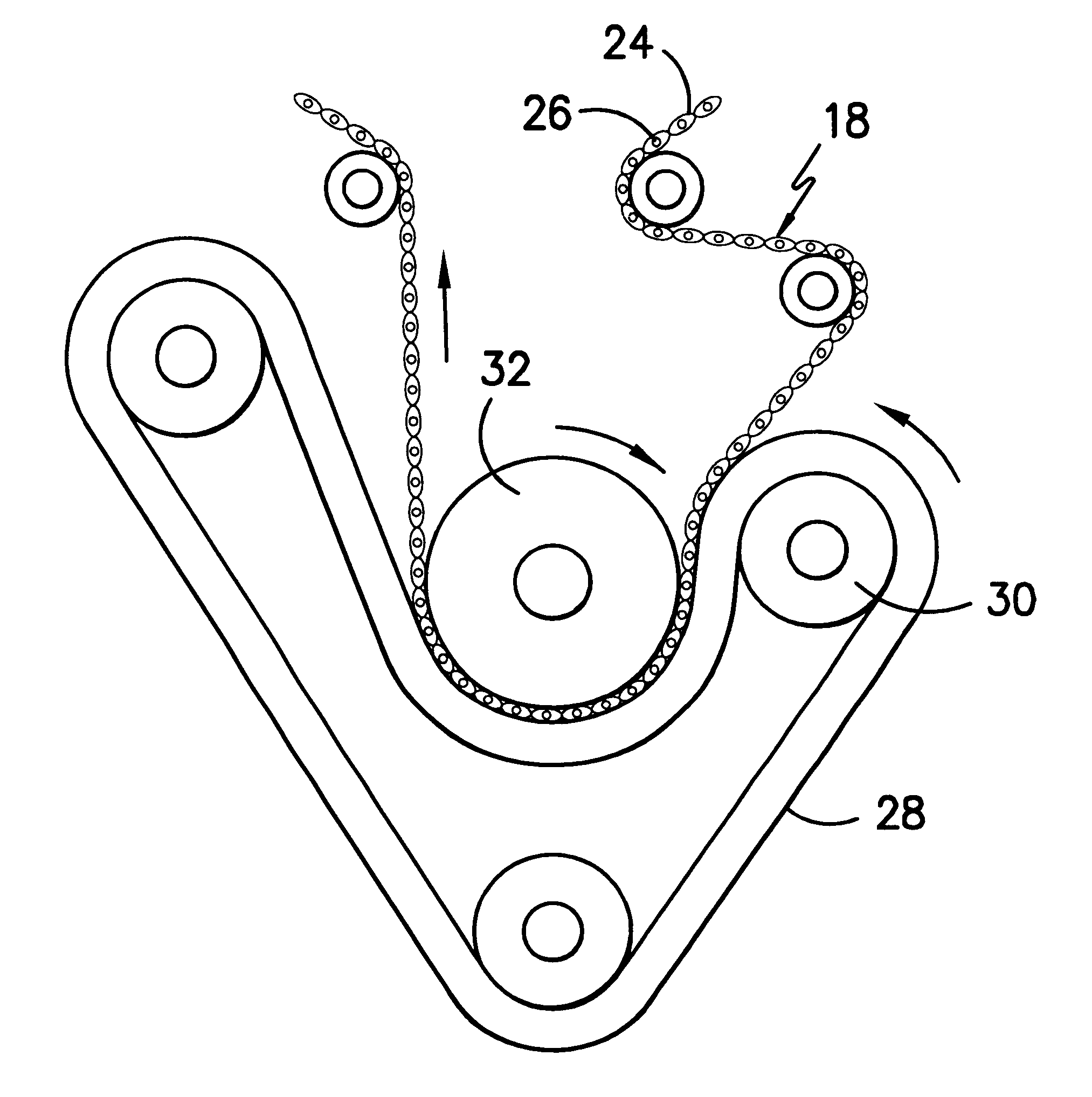

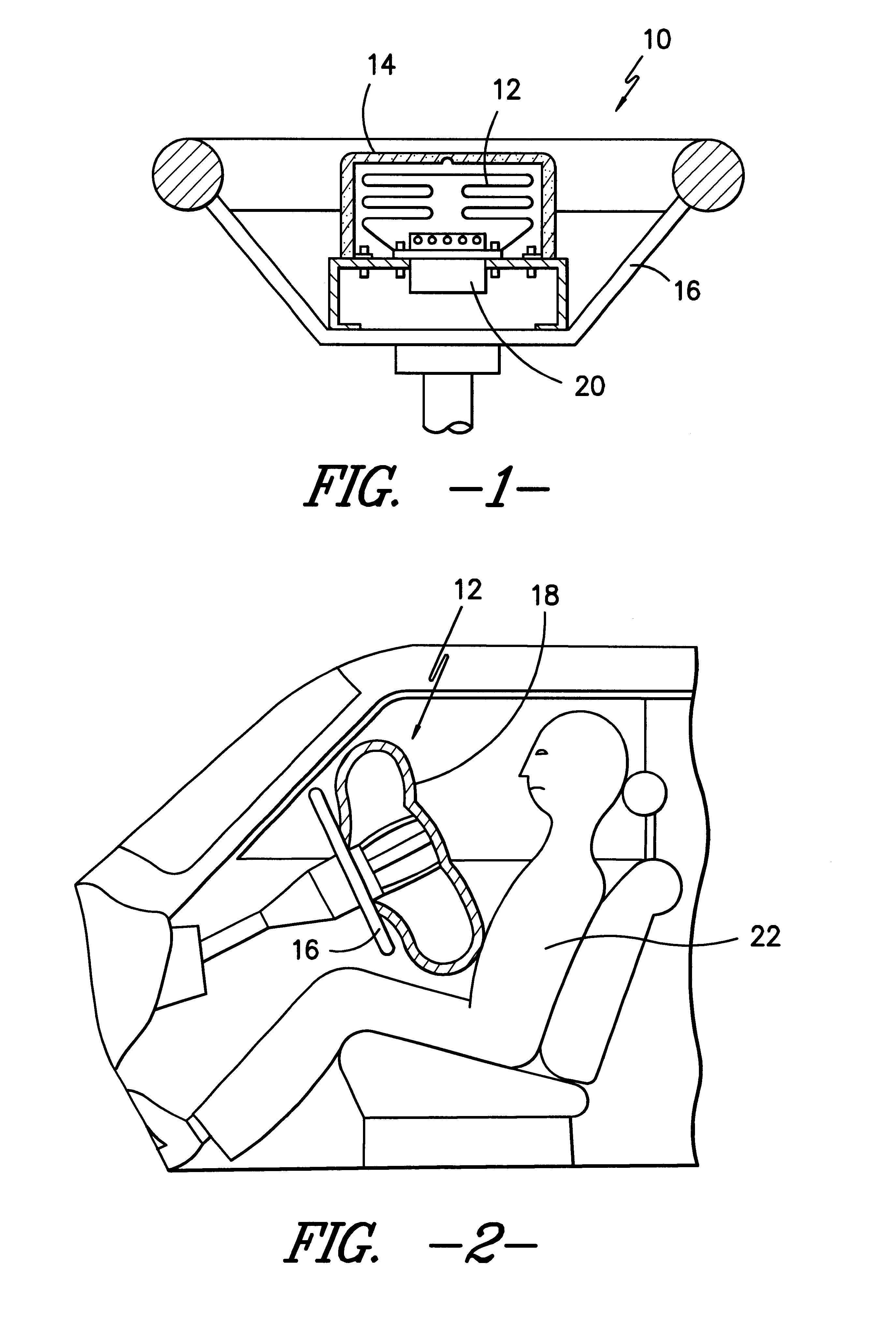

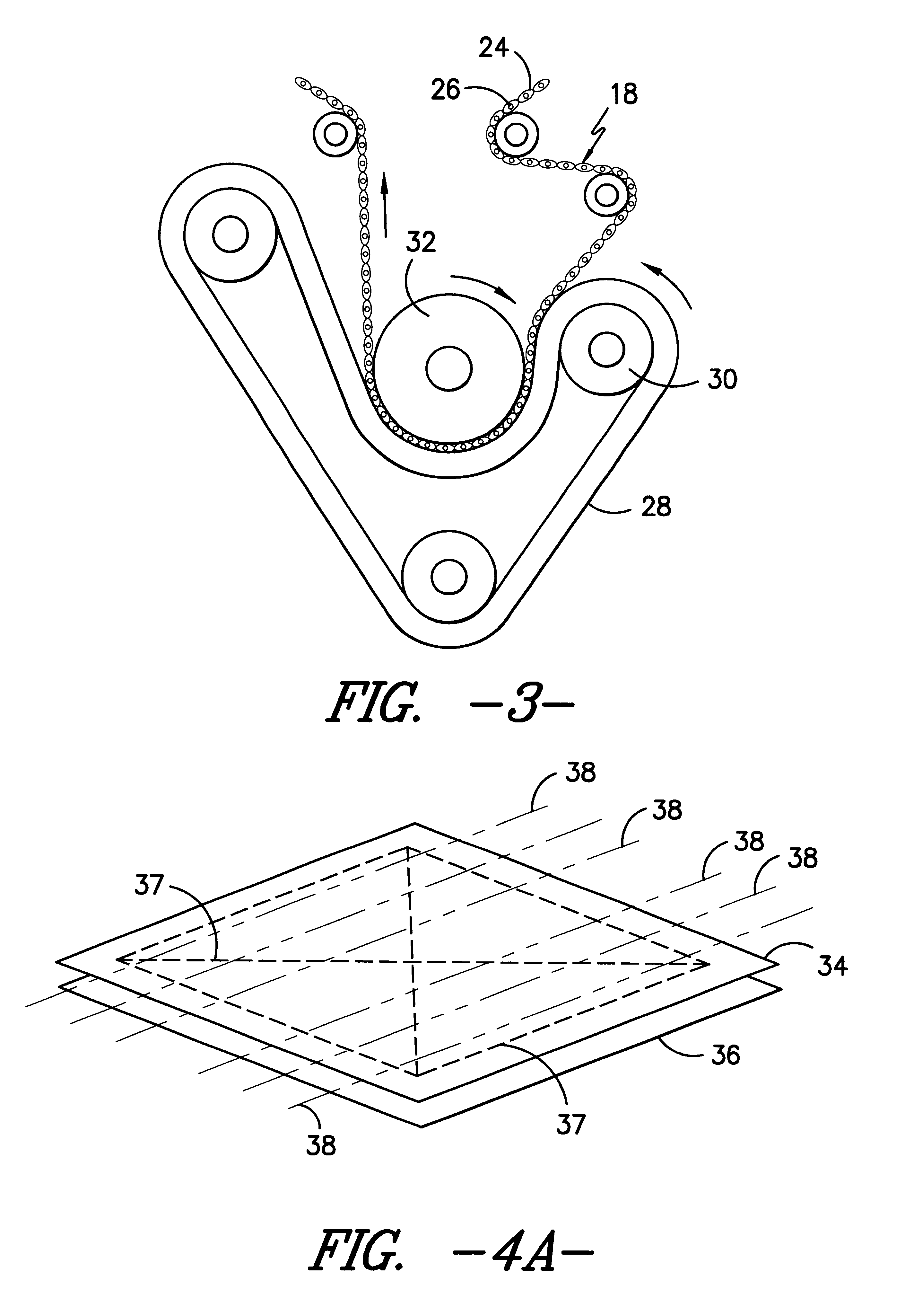

[0028]Referring now to FIG. 1, there is illustrated a schematic cross-sectional view of a typical driver's side air bag system 10. As shown, a typical system includes a folded inflatable air bag 12 disposed within a confined module 14 housed within the steering wheel 16 or dash panel if used for passenger side restraint. The air bag 12 is typically formed from a fabric 18 and is fixed to an inflater 20 which in turn is linked to a collision detection sensor (not shown). When the deceleration of the vehicle exceeds a certain level, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| linear densities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com