Oil return device and double-oil-return system for gearbox

A gearbox and guiding device technology, which is applied in the field of gearbox oil return device and gearbox double oil return system, can solve the problems of insufficient oil return and residual lubricating oil, achieve rapid oil return and improve oil return effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

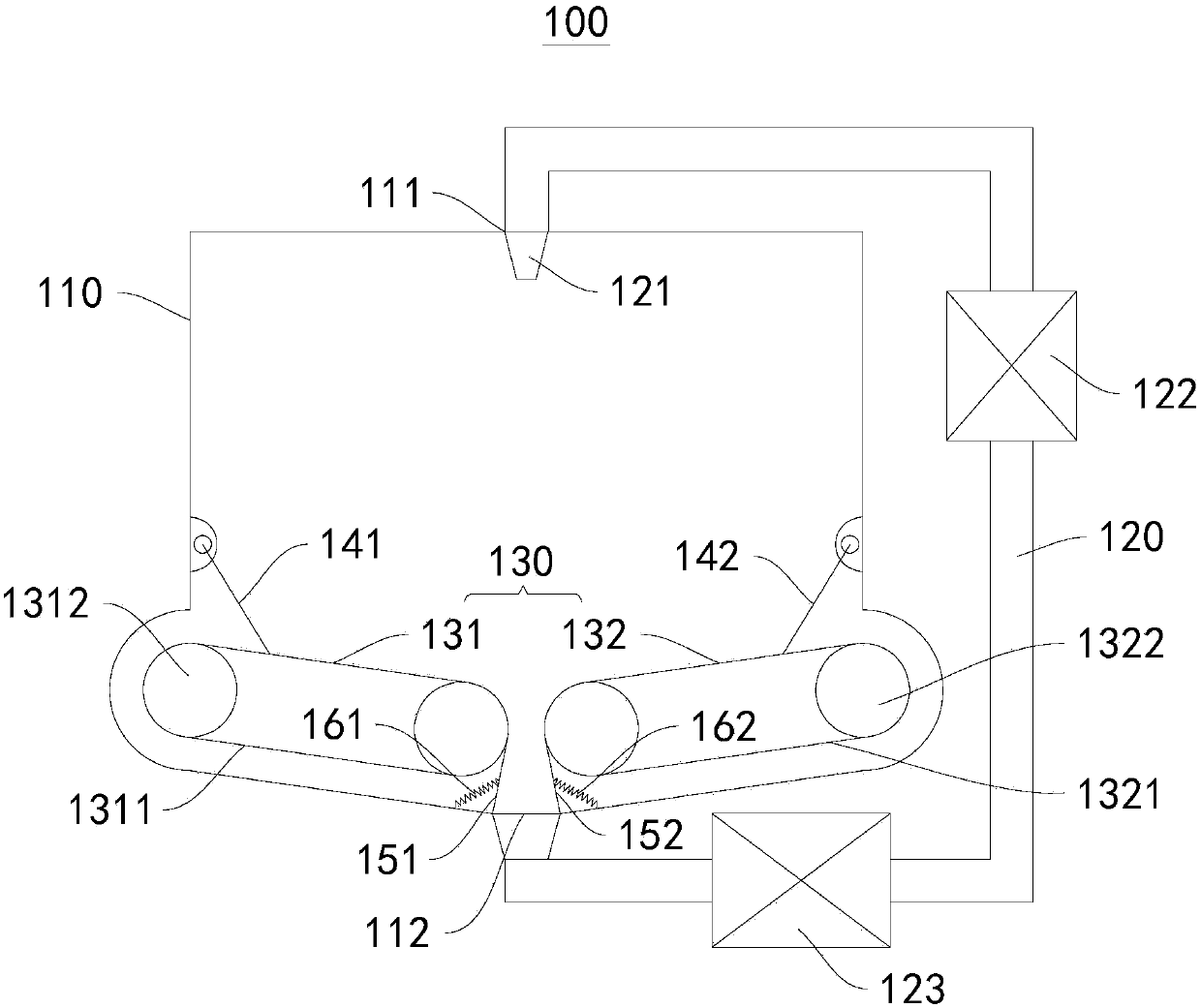

[0039] This embodiment provides a gearbox oil return device 100, please refer to figure 1 , figure 2 as well as image 3 , this gearbox oil return device 100 includes:

[0040] The box body 110, the box body 110 is set as a hollow structure, the box body 110 has a first through hole 112, and the first through hole 112 is used to discharge liquid;

[0041] A guiding device 130, the guiding device 130 is arranged inside the box body 110, and the guiding device 130 is used to guide the liquid inside the box body 110 to the first through hole 112;

[0042]The guiding device 130 includes a first guiding piece 131 and a second guiding piece 132, the first guiding piece 131 and the second guiding piece 132 are arranged oppositely, and the first guiding piece 131 and the second guiding piece 132 are distributed on both sides of the first through hole 112. side;

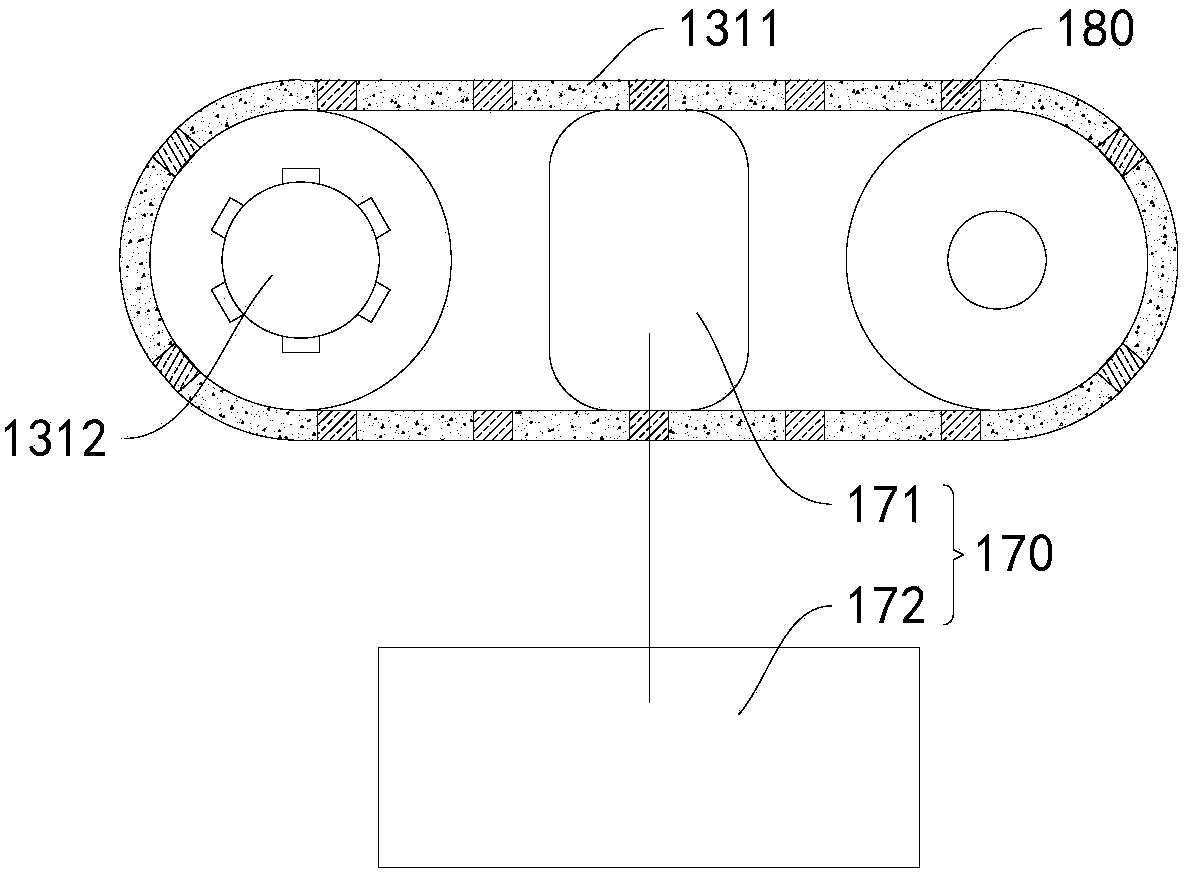

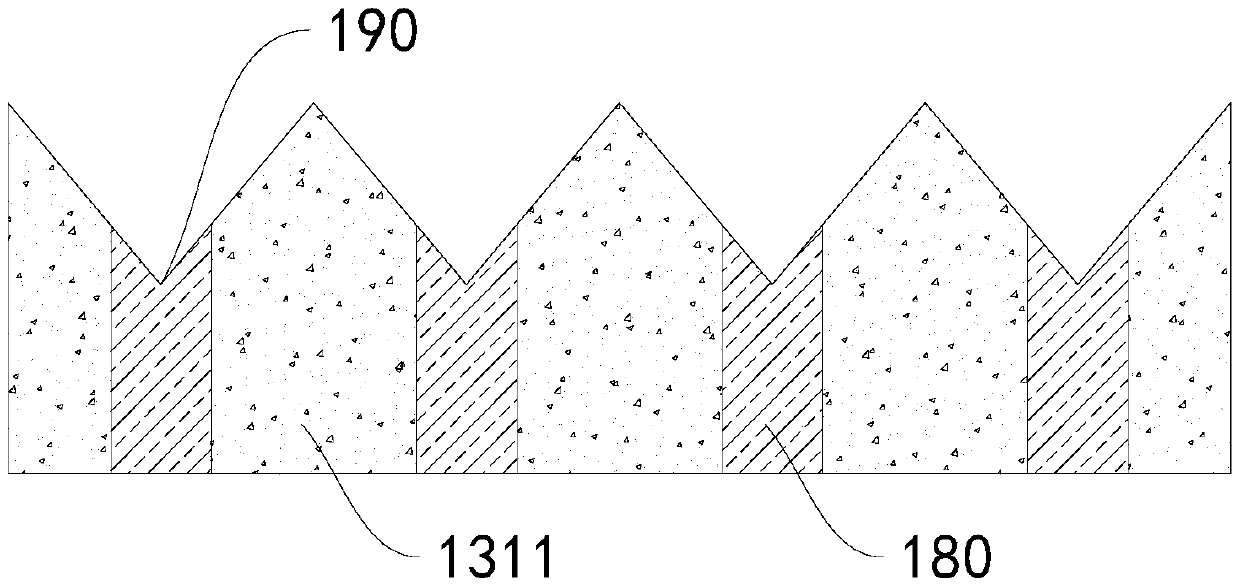

[0043] The first guide 131 includes a first roller 1312 and a first conveyor belt 1311, and the first roller 1312 driv...

Embodiment 2

[0072] This embodiment provides a gearbox double oil return system 200, please refer to Figure 4 , this gearbox double oil return system 200 includes a gearbox oil return device 100, the guide device 130 in the gearbox oil return device 100 is set to two, the two guide devices 130 are arranged at intervals, and the first through hole 112 is set There are two, and there is a one-to-one correspondence between the two first through holes 112 and the two guiding devices 130 .

[0073] The working principle of the gearbox double oil return system 200 provided in this embodiment is that during operation, the liquid in the gearbox can be quickly moved to the two second through holes 111 through the two guiding devices 130, Thereby, a faster oil return can be realized and the oil return effect can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com