Oil return control mechanism and compressor

A technology of oil return control and compressor speed, which is applied in the field of compressors, can solve problems such as not being able to control the oil storage of compressors well, and achieve the effect of improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

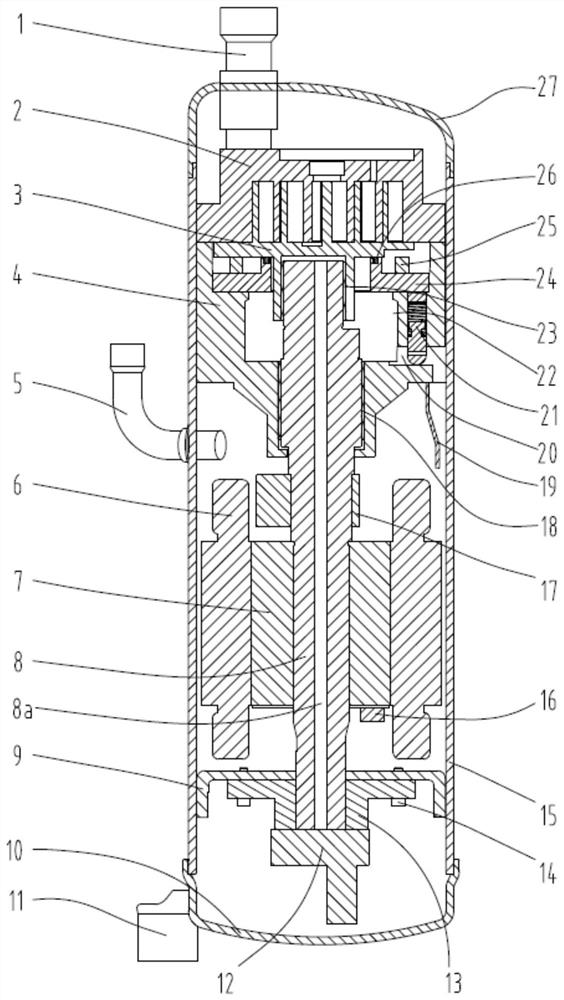

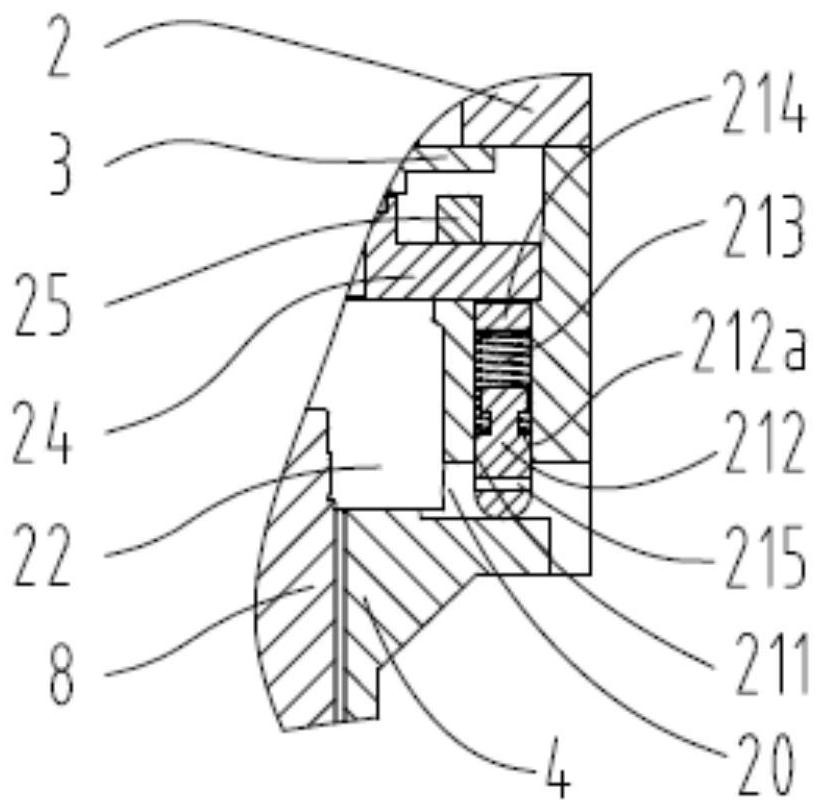

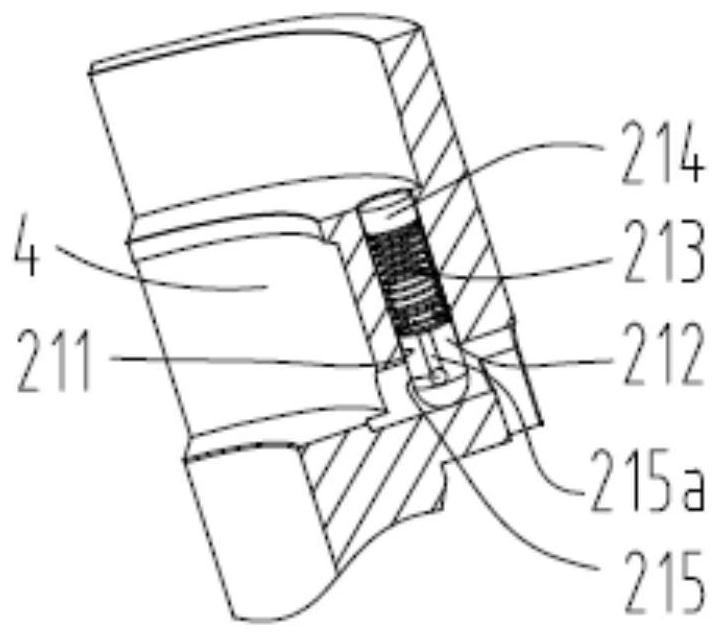

[0039] This embodiment describes in detail the first preferred implementation of the oil return control mechanism 21 of the present invention.

[0040] The oil return control mechanism 21 of this embodiment includes a housing part 211, a regulating valve 212 and an elastic member 213, such as Figure 1~5 shown. Preferably, the regulating valve 212 is provided with a channel assembly, and the channel assembly communicates with the oil return channel 20 on the upper support mechanism 4 . Preferably, the regulating valve 212 and the elastic member 213 are located in the housing portion 211 and can move along the axial direction of the housing portion 211 based on the compressor rotation speed, and the regulating valve 212 and the elastic member 213 have a second function of closing the oil return passage 20 One state and the second state of opening the oil return passage 20; and when the regulating valve 212 and the elastic member 213 are in the first state, the lubricating oil ...

Embodiment 2

[0053] This embodiment describes in detail the second preferred embodiment of the oil return control mechanism 21 of the present invention.

[0054] The difference between this embodiment and Embodiment 1 lies in the structure of the channel assembly on the regulating valve 212 . In this embodiment, only the parts different from those in Embodiment 1 are described in detail, and the same parts are not described again.

[0055] According to a preferred embodiment, the channel assembly includes an annular groove 218 and a second communication groove 218a, such as Figures 9 to 12 shown. Preferably, the annular groove 218 located in the circumferential direction of the regulating valve 212 communicates with the oil return passage 20 on the upper support mechanism 4; the second communication groove 218a communicates with the annular groove 218 and passes through the valve end surface 212a in the axial direction. The preferred technical solution of this embodiment said that the a...

Embodiment 3

[0059] This embodiment describes in detail the third preferred embodiment of the oil return control mechanism 21 of the present invention.

[0060] The difference between this embodiment and embodiment 1 or embodiment 2 lies in the arrangement position of the receiving portion 211 and the sealing member above the elastic member 213 . In this embodiment, only the parts different from those in Embodiment 1 or Embodiment 2 are described in detail, and the same parts are not described again.

[0061] According to a preferred embodiment, the receiving portion 211 is located on the upper supporting mechanism 4 and the cover plate 24, such as Figure 7 shown. Preferably, the oil return control mechanism 21 further includes an O-ring seal 216, and the O-ring seal 216 is located on the outer side of the housing portion 211 and between the upper support mechanism 4 and the cover plate 24, such as Figure 7 shown. The preferred technical solution of this embodiment can be sealed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com