High-pressure oil pipe pressure relief circuit and method with quick-change connectors

A high-pressure oil pipe and pressure relief technology, which is applied in the direction of mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of hydraulic oil environmental pollution, hydraulic oil waste, and inability to connect high-pressure joints, etc., to achieve increased The effect of fast oil return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

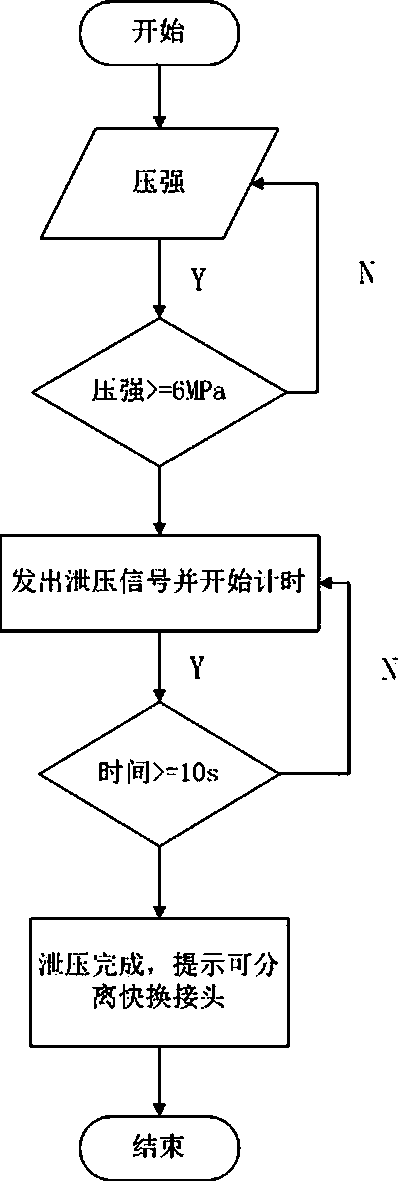

Method used

Image

Examples

Embodiment 1

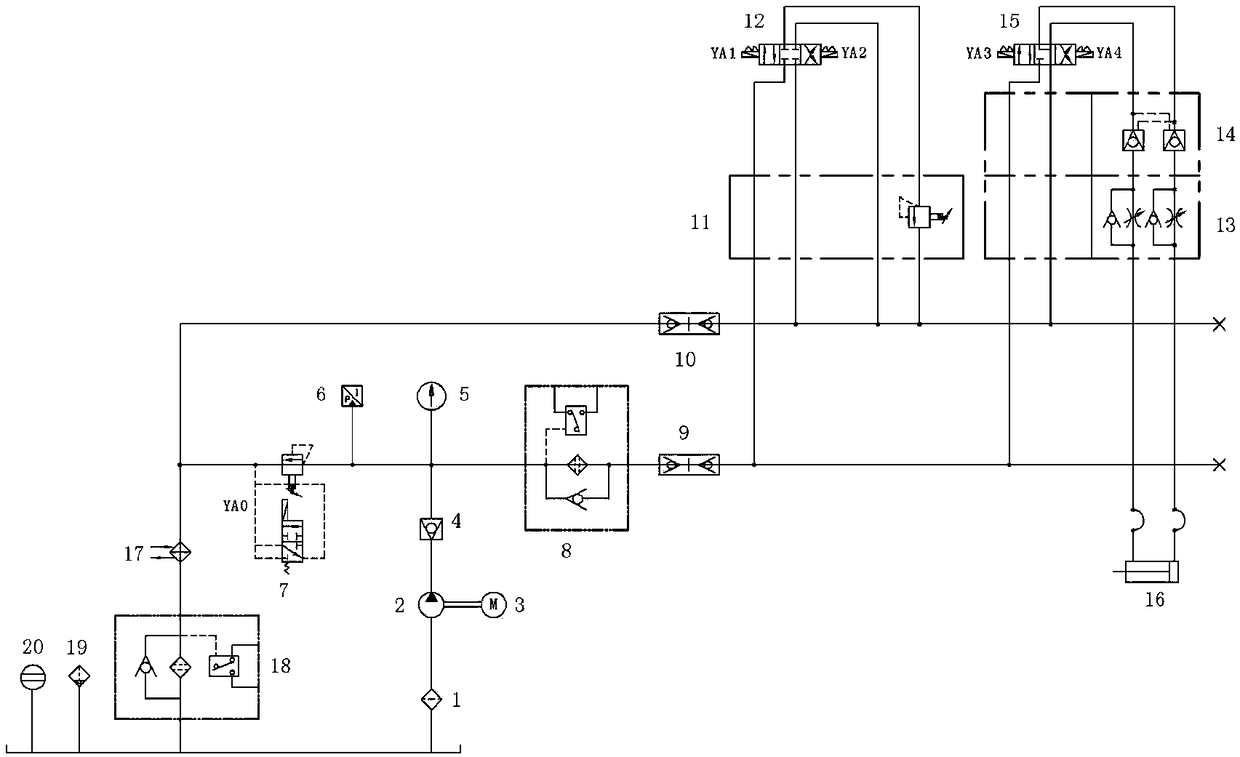

[0032] Provide a high-pressure oil pipe pressure relief circuit with a quick-change joint, including an oil inlet module, a first quick-change joint 9, a first reversing valve 12, a second quick-change joint 10 and an oil return module connected in sequence; wherein, The oil inlet module includes an oil tank 1, an oil pump 2, a check valve 4 and a fine filter 8 connected sequentially along the oil inlet route. The oil pump 2 is also connected to the motor 3, the check valve 4 is also connected to the pressure gauge 5, and the fine filter 8 The other end is connected with the left side of the first quick-change joint 9, and the first quick-change joint 9 is located at the oil inlet circuit, that is, connected with the high-pressure oil pipe. The oil return module includes a radiator 17, an oil return filter 18 and an oil tank 1 sequentially connected along the oil return route, and the oil tank 1 is also connected with an oil return filter 19 and an oil mark 20 respectively, and...

Embodiment 2

[0044] The difference between Embodiment 2 and Embodiment 1 is that the pressure relief circuit also includes a relief valve 11 connected to the first reversing valve 12 and a hopper control module, and the hopper control module includes a second reversing valve 15 connected in sequence, Two-way hydraulic lock 14, double one-way throttle valve 13 and material turning hydraulic cylinder 16. The relief valve 11 is used to adjust the high pressure of the oil inlet circuit to a set constant pressure. The hopper control module is used to control the rise and fall of the hopper further.

[0045]During normal operation, the pressure in the oil pipe of the main engine is 16MPa, but only 6MPa is required when the hopper is working, and the working time of the hopper is less than 1% of the working time of the whole machine, so the pressure in the oil pipe is only reduced during the working time of the hopper , which can save costs without affecting the normal operation of the whole mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com