Liquid storage tank with multiple oil return holes

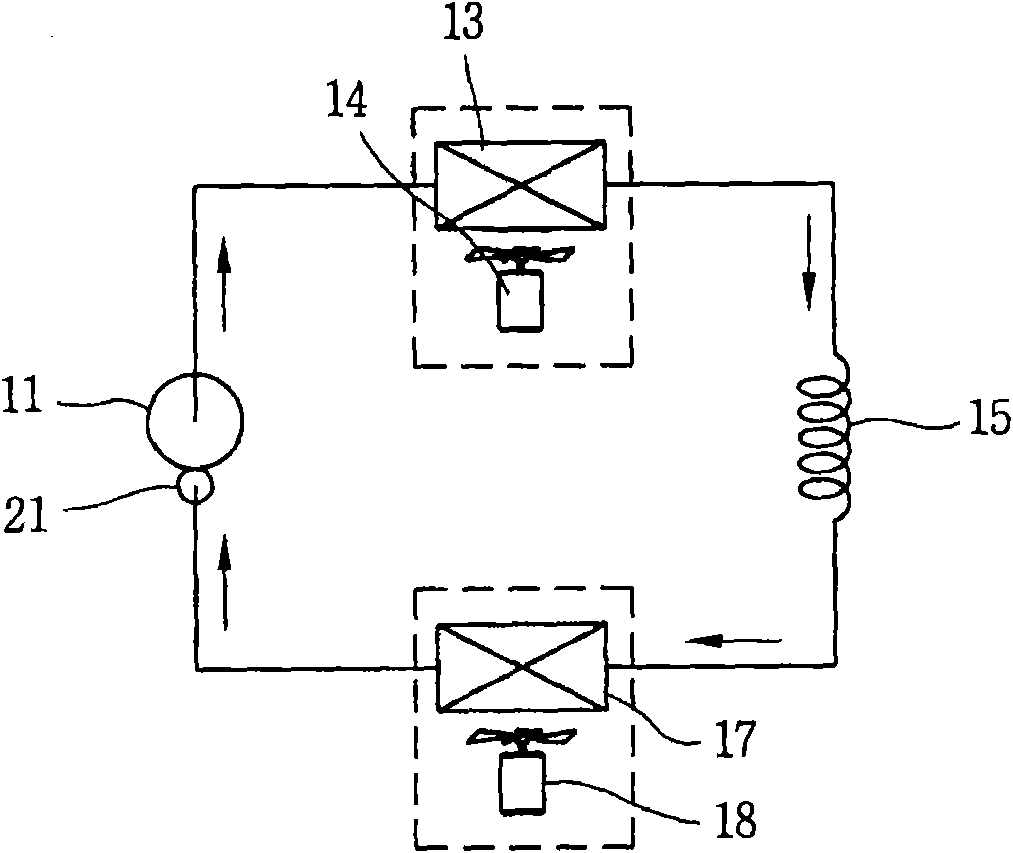

An oil return hole and liquid storage tank technology, applied in the field of liquid storage tanks with multiple oil return holes, can solve the problems of bad, oil can not flow back in time, compressor oil shortage, etc., so as to reduce the amount of oil replenishment , Inhibit oil shortage and avoid the effect of unable to return oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

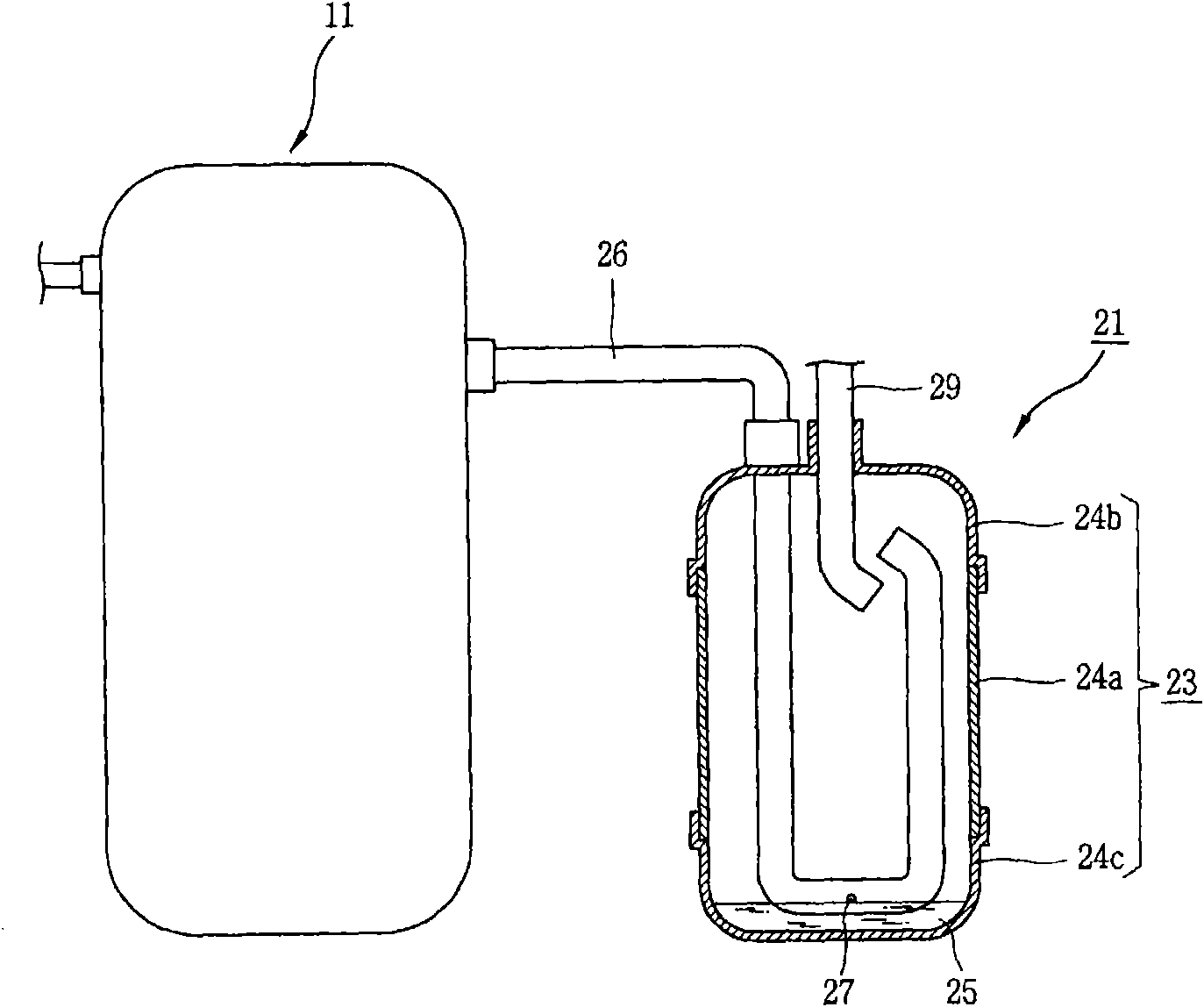

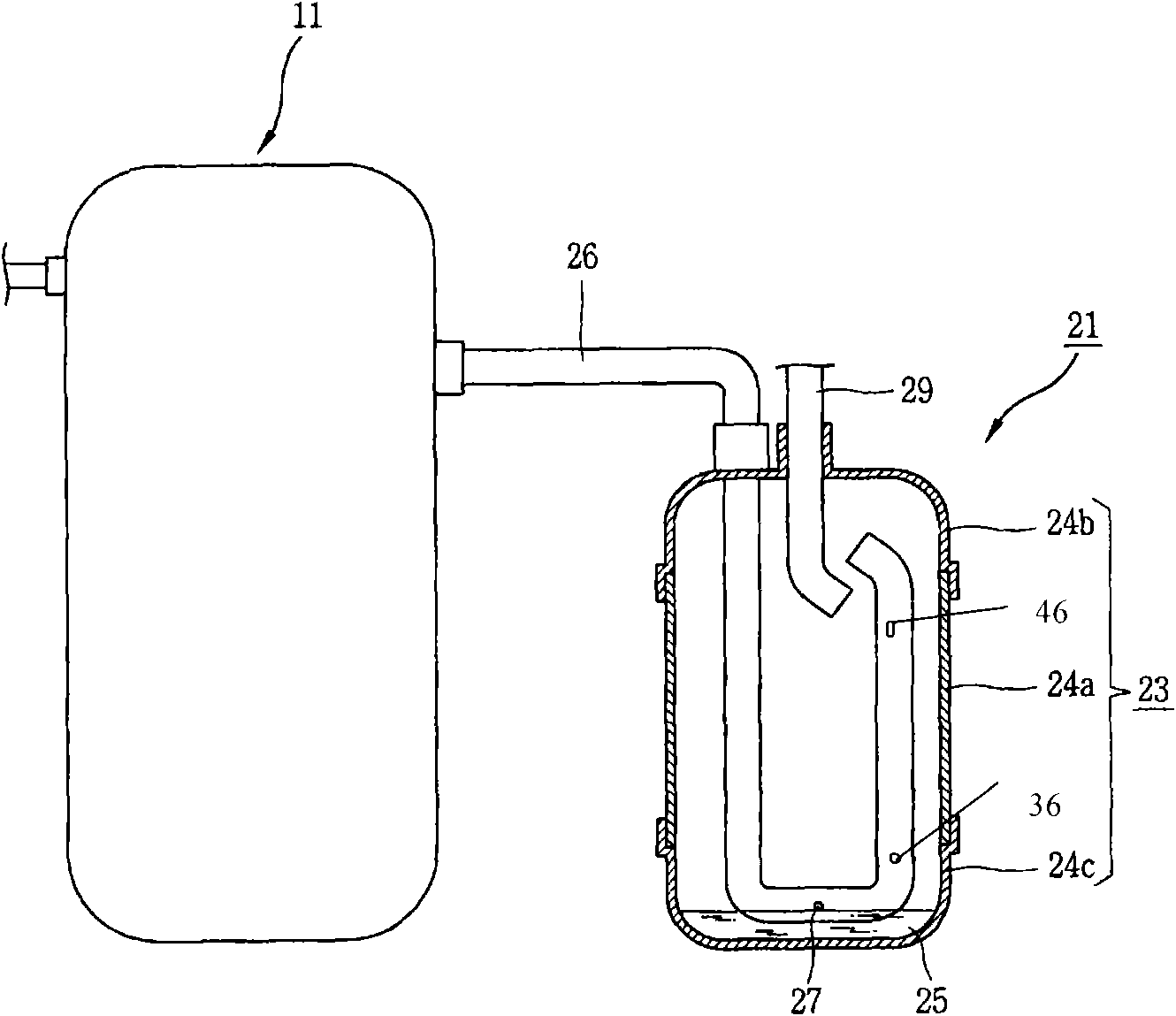

[0017] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0018] For the convenience of description, the same or similar parts with the previous configuration will be given the same reference numerals.

[0019] Such as image 3 As shown, the liquid storage tank 21 with an oil return pipe is a housing 23 that forms a space for the refrigerant inside; in order to allow the refrigerant in the housing 23 to flow out and be sucked into the compressor 11, one side is connected to the compressor 11 , The other side is inserted into the inside of the housing 23, and the inserted part passes through the bottom of the housing and then the outflow pipe 26 that is bent upward and extends; one side is connected to the bottom of the housing 23 and the lower side of the housing 23, and the other side is in the housing The outside of 23 and the outflow pipe 26 are connected to each other, and the oil at the bottom of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com