Combined brake control device

A brake control and hydraulic technology, applied in the direction of fluid pressure actuation device, brake actuator, servo motor assembly, etc., can solve the problems of insensitive brake response speed, inability to handle emergencies, and no emergency braking function, etc. To achieve the effect of compact structure, saving installation space, and sensitive brake release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

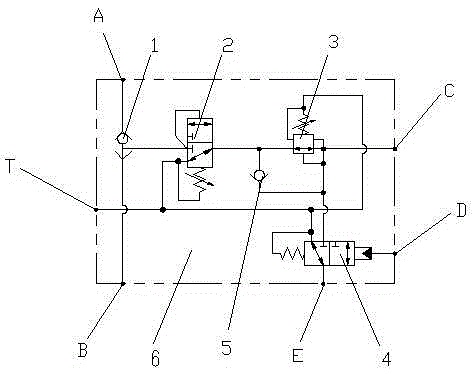

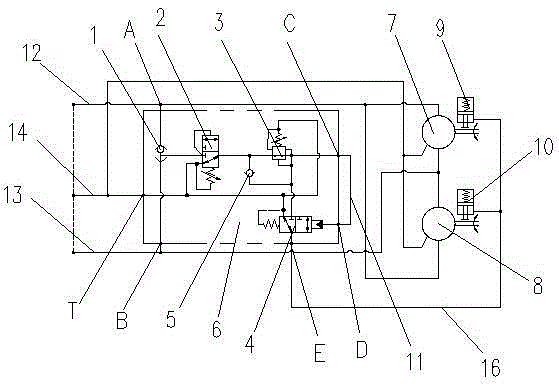

[0021] Connection status of control oil port C and control oil port D

[0022] see figure 1 and figure 2 , when the control oil port C and the control oil port D on the valve body 6 are communicated with the connecting oil line 11, the hydraulic oil entering from the No. 1 oil inlet line 12 and the No. And the oil inlet B flows into the shuttle valve 1, the shuttle valve 1 is opened under the action of the pressure difference, and then flows through the connecting oil circuit 11 through the hydraulic reversing valve 2, the pressure relief valve 3 and enters the pilot fluid through the control oil port C In the dynamic reversing valve 4, the pilot hydraulic reversing valve 4 is opened under the push of hydraulic oil, and the brake oil port E on the valve body 6 is connected with the brake oil circuit 16, and drives No. 1 brake device 9 and No. 2 brake device respectively. 10. Automatically release the brake on No. 1 injection head motor 7 and No. 2 injection head motor 8.

...

Embodiment 2

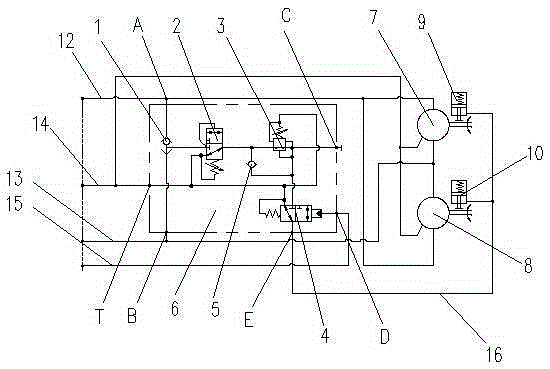

[0025] Control oil port C and control oil port D disconnected state

[0026] see figure 1 and image 3 , the control oil port D on the valve body 6 is connected with the external oil line 15, when the hydraulic oil entering the No. 1, the shuttle valve 1 opens under the action of the pressure difference and enters the hydraulic reversing valve 2 and pressure relief valve 3. Since the control oil port C on the valve body 6 is closed, the hydraulic oil reaches the pilot hydraulic reversing valve. In the valve 4, after oil is supplied to the external oil circuit 15 connected with the control oil port D at this time, the pilot hydraulic reversing valve 4 is opened and communicated with the brake oil circuit 16 through the brake oil port E on the valve body 6, Drive No. 1 brake device 9 and No. 2 brake device 10 respectively, and automatically release the brake on No. 1 injection head motor 7 and No. 2 injection head motor 8 .

[0027] When the pressure of the oil inlet A and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com