Manual-release electromagnetic brake of cam crankshaft

An electromagnetic brake and manual release technology, which is applied in the direction of brake parts, brake actuators, slack adjusters, etc., can solve the problems of slow speed and achieve the effects of high efficiency, convenient and clean operation, and fast braking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings:

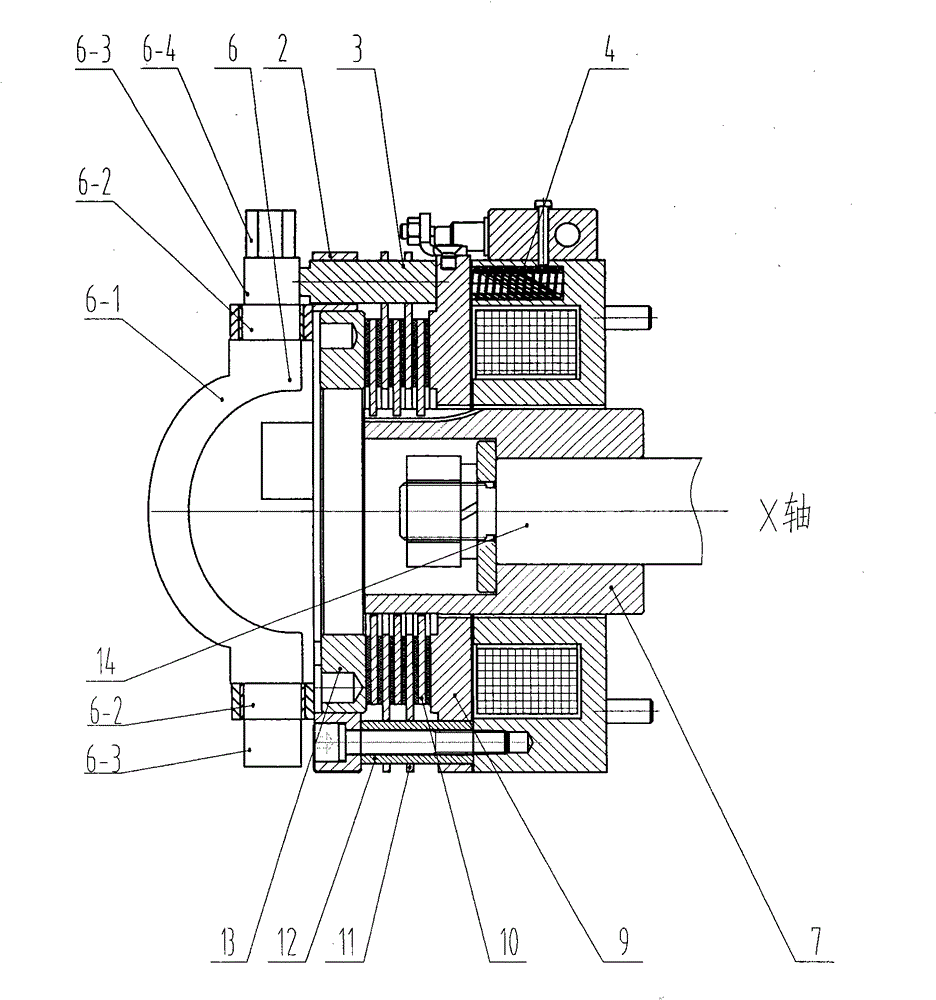

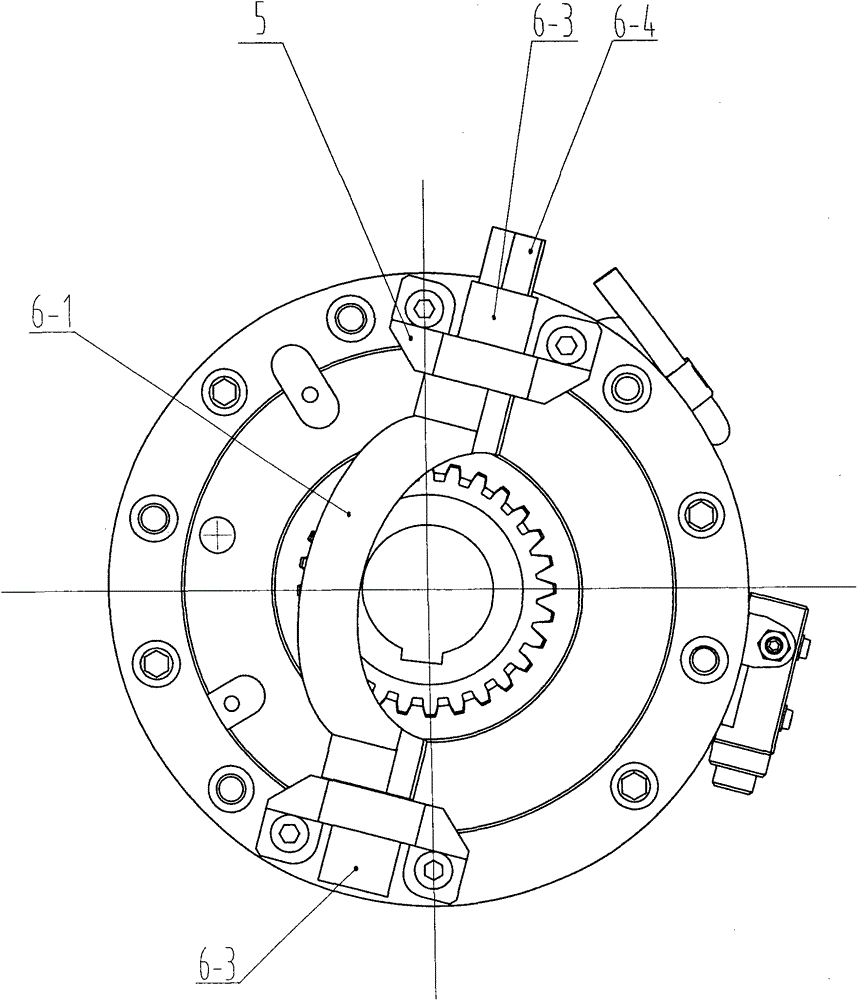

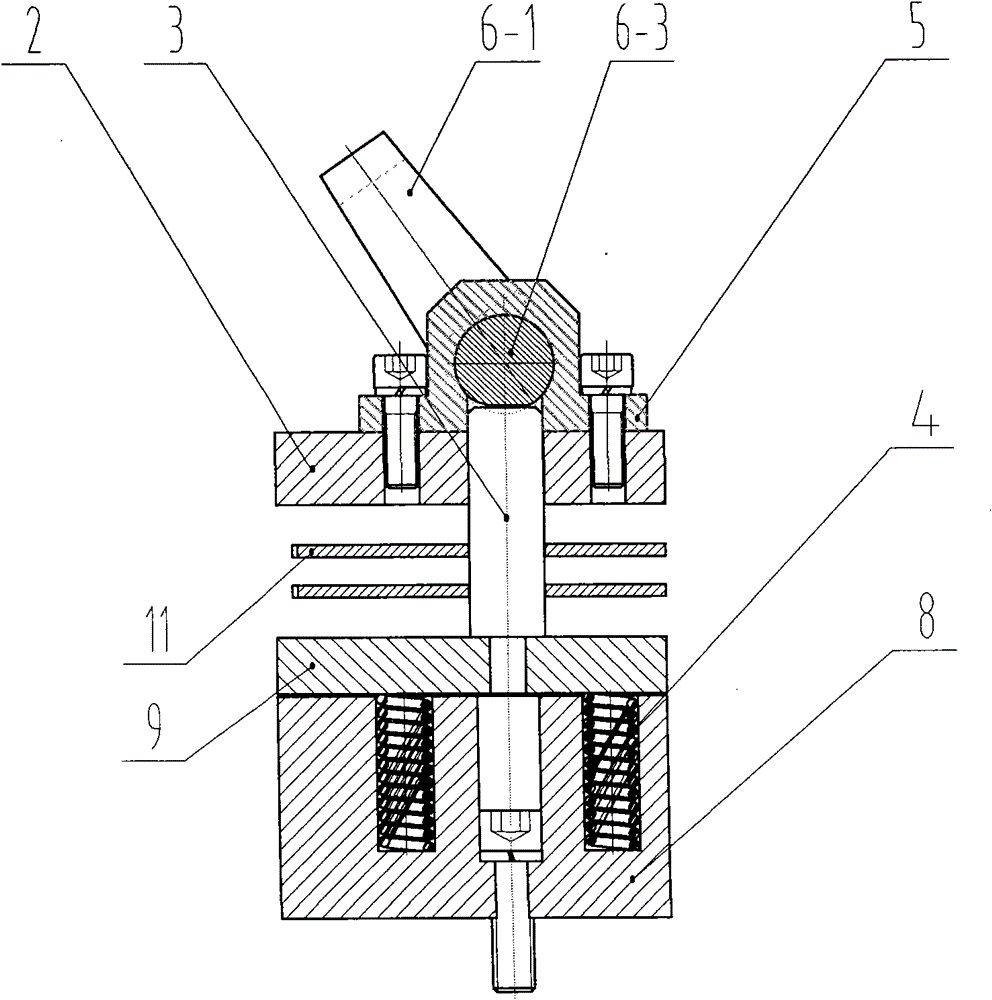

[0014] Referring to the accompanying drawings, the present invention is a normally closed electromagnetic brake, including a braking mechanism and a manual release mechanism. The brake mechanism consists of a power controller 1, an outer flange 2, a compression spring 4, an outer spline hub 7, an electromagnet 8, an armature plate 9, a moving friction plate 10, a fixed friction plate 11, a spacer 12 and an adjusting top ring 13 . The manual release mechanism is composed of a release top post 3, a release base 5 and a cam crankshaft 6. The outer flange 2 has two through holes, both of which are equipped with release top posts 3 , the release base 5 is installed on the outer plane of the outer flange 2 circles, and the cam crankshaft 6 is installed on the two release bases 5 . The cam crankshaft 6 comprises a semicircular crankshaft 6-1 positioned at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com