Multi-sampling-port insulating oil sampling valve

A sampling valve and sampling port technology, applied in sampling devices, measuring devices, instruments, etc., can solve the problems of increasing pipeline nodes, increasing leakage points, increasing hidden dangers, etc., to achieve oil circuit safety without affecting each other, and reduce installation. Rotation radius, the effect of simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

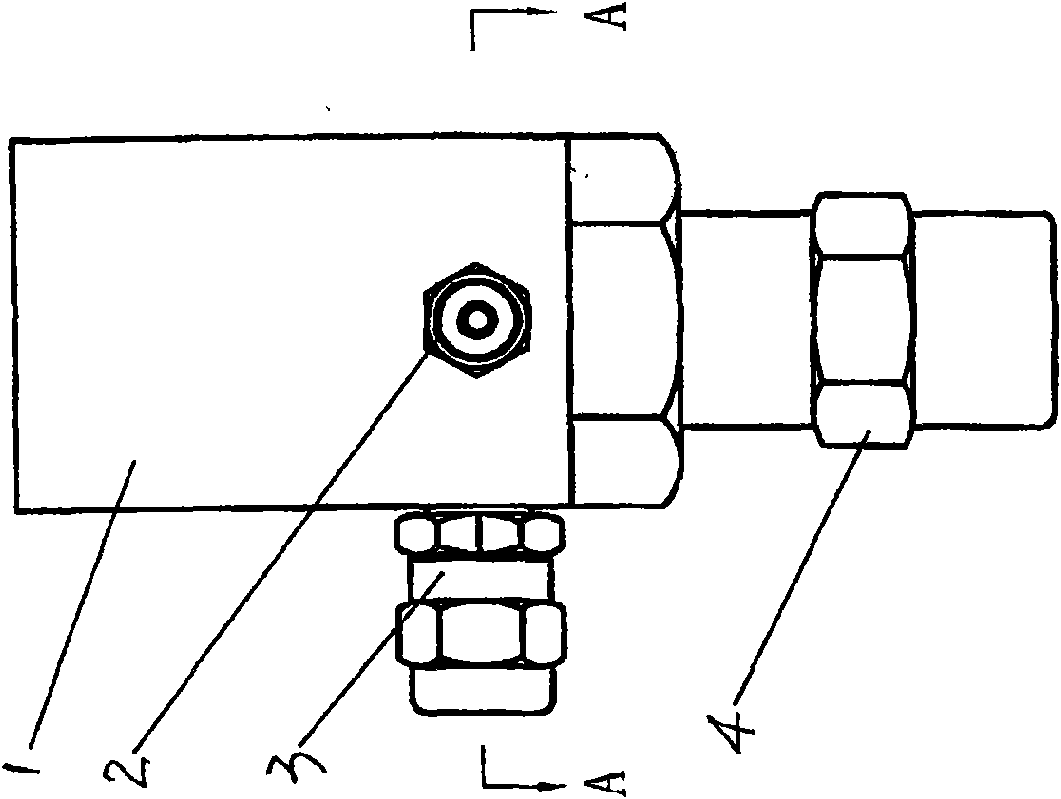

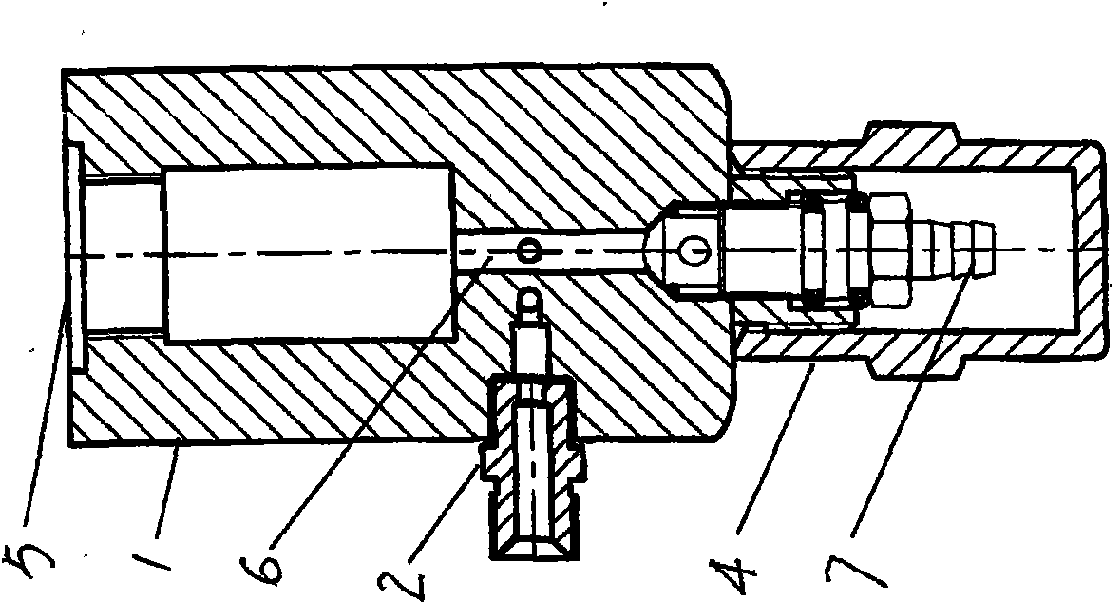

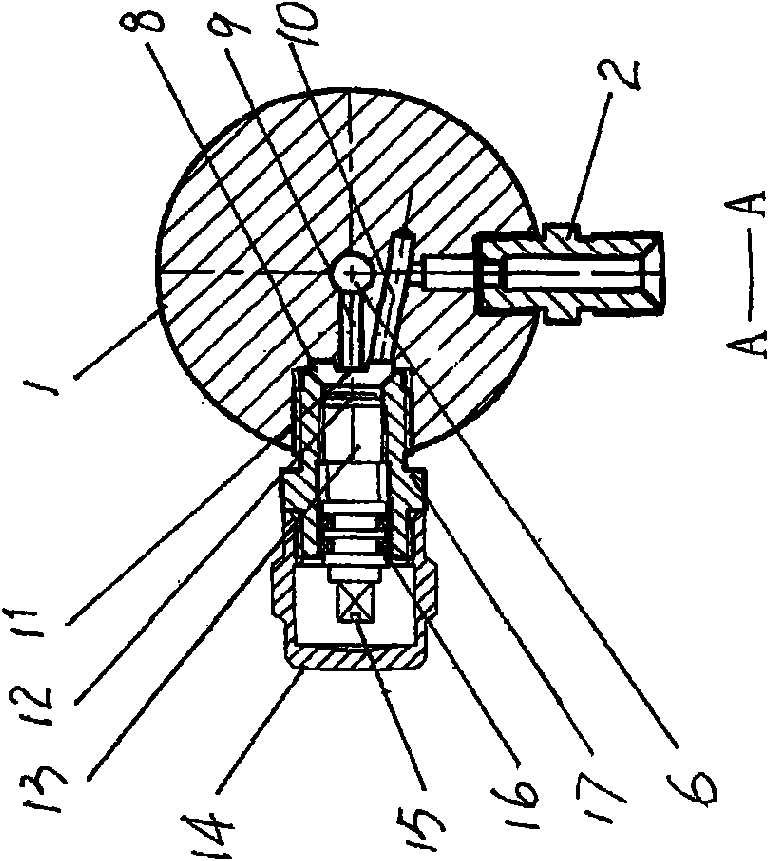

[0010] The invention is attached figure 1 As shown, it is a sampling valve with two sampling ports, one sampling port is used for laboratory oil chemical analysis sampling, and the other sampling port is used for sampling of insulating oil online monitoring system. The sampling port for laboratory oil chemical analysis and sampling is set at the lower part of the sampling valve body 1, and its sampling port 7 is directly connected to the oil-filled electrical equipment connection port 5 through the sampling valve oil passage 6, and a dust cover is provided outside the sampling port 7 4. The chromatographic online sampling connection port 2 is set on the side wall of the sampling valve body 1, the chromatographic online sampling connection port 2 and its cut-off valve 3 are respectively set at two different positions, and the chromatographic online sampling stop valve 3 is also set on the sampling valve body 1 On the side wall, the horizontal direction of the two is on the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com