Ore pulp sampling and iron grade signal collection device and method

A technology of signal acquisition and iron grade, applied in sampling devices, material magnetic variables, etc., can solve the problems of single sampling function and cumbersome process, and achieve the effect of avoiding measurement process, improving efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

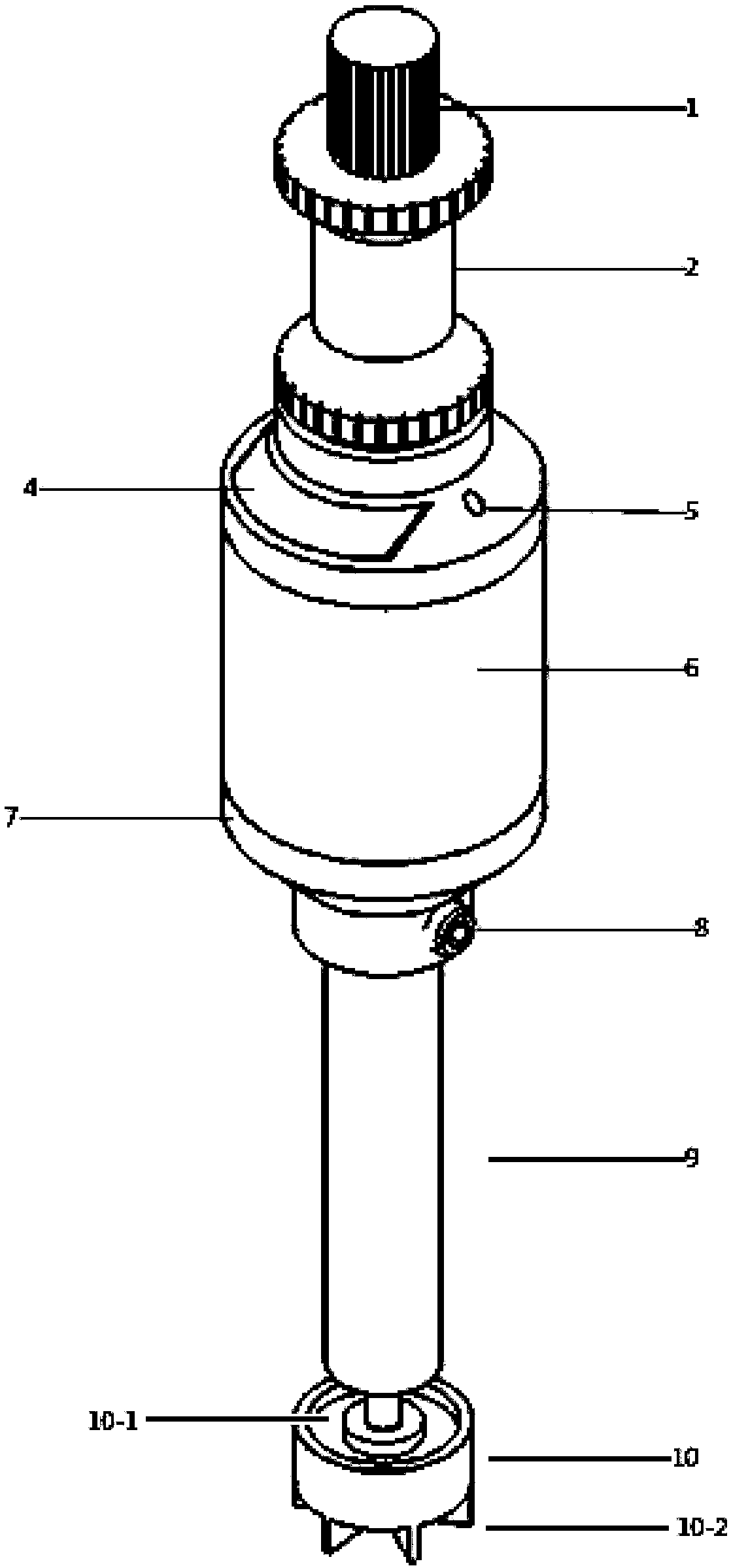

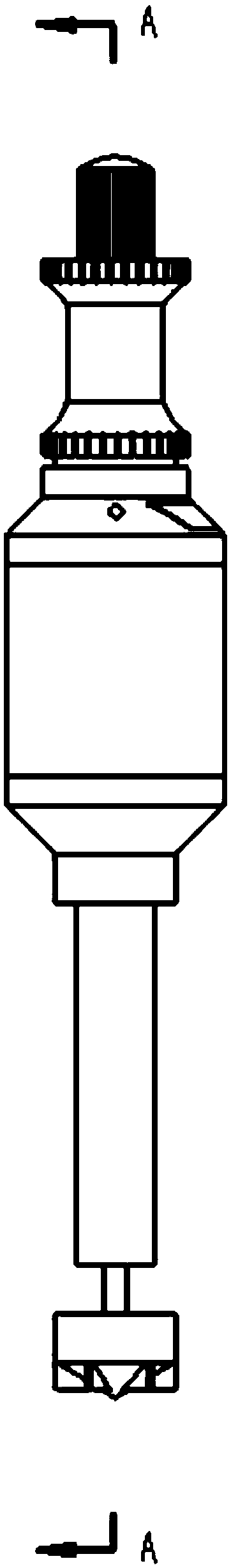

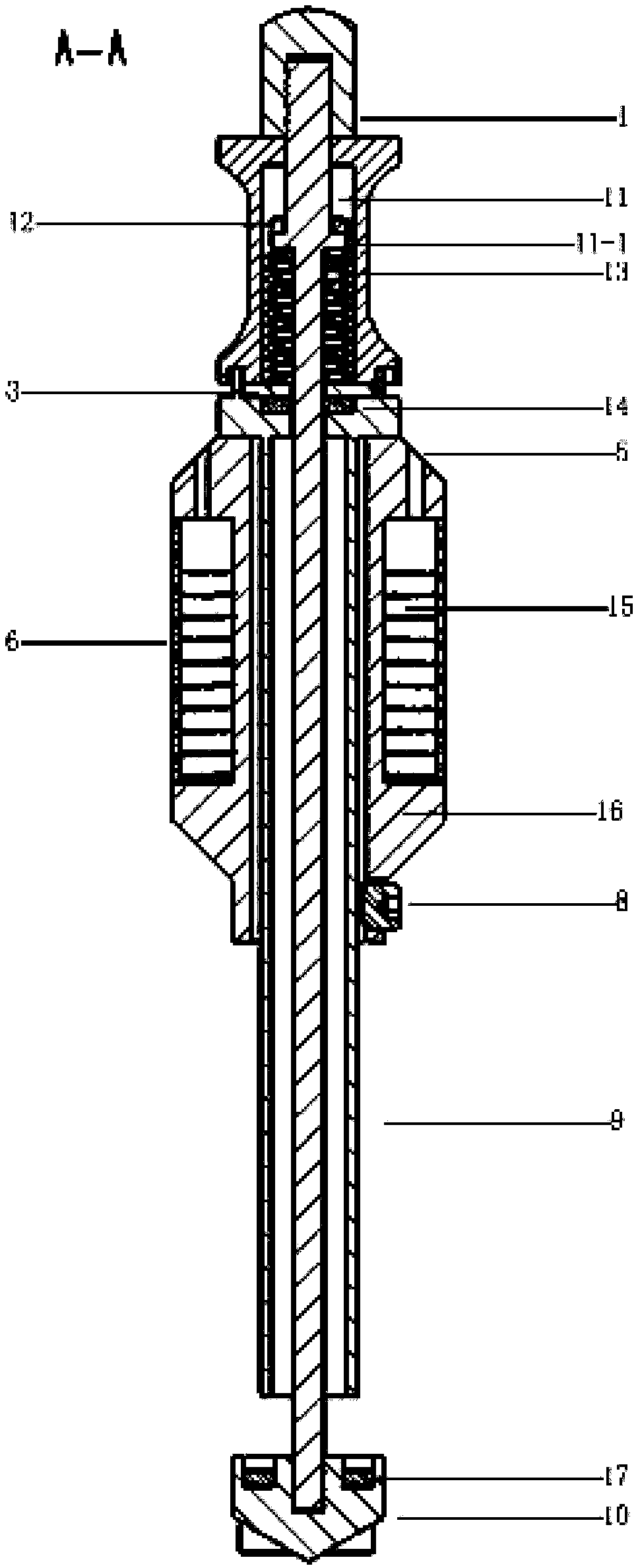

[0023] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a kind of ore pulp sampling and iron grade signal acquisition device described in this embodiment includes dustproof cap 1, handle 2, sampling cylinder 9, measuring rod 11, compression spring 13 and sampling cylinder lower end cover 10, handle 2 The lower end of the measuring rod 11 is connected to the upper end of the sampling cylinder 9, the measuring rod 11 runs through the handle 2 and the sampling cylinder 9 from top to bottom, and the lower end of the measuring rod 11 is inserted into the upper surface of the lower end cover 10 of the sampling cylinder, and the dustproof cap 1 is set On the upper end of the measuring rod 11; said a kind of ore slurry sampling and iron grade signal acquisition device also includes a sensor measuring head 7 and a set screw 8, said sensor measuring head 7 is set on the outer side wall of the sampling cylinder 9 top, and the sensor measuring The ...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the sensor measuring head 7 described in this embodiment includes a keel 16, a glass observation window 4, a sensor coil 15, two lead holes 5 and a shielding outer layer 6, the outer wall of the keel 16 has an annular gap, and two lead wires The holes 5 are arranged symmetrically on the outer side wall of the upper end of the keel 16, the sensor coil 15 is wound in the annular gap of the keel 16, the two ends of the sensor coil 15 are respectively derived from the two lead holes 5, and the glass observation window 4 is arranged on two Between the lead holes 5 , the shielding outer layer 6 covers the annular gap of the keel 16 .

[0026] The keel 16 is made of non-metallic insulating material, and the enameled wire is wrapped around the annular gap of the keel 16 to form a sensor coil 15. The two ends of the sensor coil 15 are respectively derived from the two lead holes 5, whic...

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the device described in this embodiment also includes a compression spring support plate 3 and a sealing washer 14, the compression spring support plate 3 and the sealing washer 14 are sequentially set on the measuring rod 11 from top to bottom, and the compression spring support plate 3 is located at the connection between the sampling cylinder 9 and the handle 2, and the sealing gasket 14 is located in the upper surface of the sampling cylinder 9.

[0029] It is set in this way to prevent the ore slurry from penetrating into the space where the compression spring 13 is located along the outer wall of the measuring rod 11 .

[0030] Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com