Anaerobic digestion multiphase sampling method

A technology of anaerobic digestion and sampling tubes, applied in the direction of sampling devices, etc., can solve the problems of affecting the mixing effect and clogging, and achieve the effect of accelerating the separation of dissolved biogas and material gas-liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

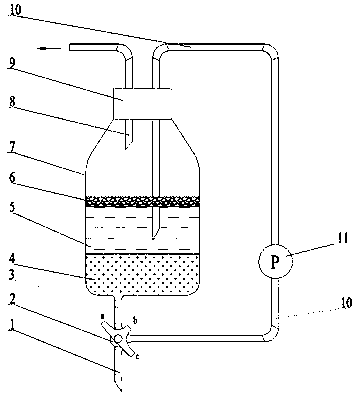

[0033] An anaerobic digestion multiphase sampling device based on an anaerobic digestion multiphase sampling method, as attached figure 1 As shown, it mainly includes an anaerobic digestion bottle, which contains materials, and materials with different specific gravity are naturally stratified under the action of gravity in a static state, and the material with the smallest specific gravity floats on the uppermost layer to form a scum layer. The lower layer is a clear liquid layer, and the lowermost layer is a solid phase layer; the top of the anaerobic digestion bottle is provided with a rubber stopper, and the rubber stopper is provided with double holes, which are respectively connected to the air guide tube and the catheter tube (10); The air guide tube leads into the anaerobic digestion bottle and its lower port keeps a certain distance from the scum layer; the liquid guide tube (10) leads into the clear liquid layer inside the anaerobic digestion bottle at one end, and co...

Embodiment 2

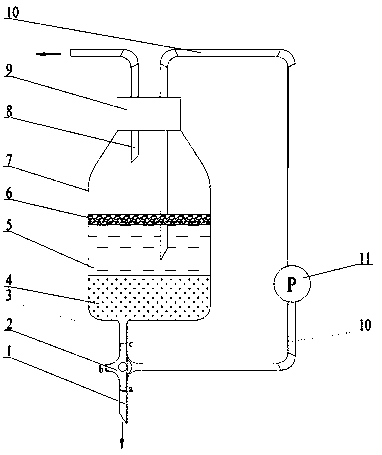

[0035] When the present invention carries out solid-phase sampling, as attached figure 2 As shown, the a and c ends of the three-way valve knob are respectively connected to the sampling tube and the leakage tube of the anaerobic digestion bottle, and the liquid pump (11) is in the closed state; at this time, the sampling tube and the leakage tube are connected, and the catheter ( 10) Close, the material in the solid phase layer flows out naturally under the action of gravity, and the solid phase sampling process is completed.

Embodiment 3

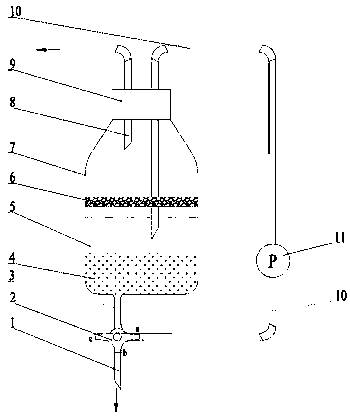

[0037] When the present invention carries out liquid phase sampling, as attached image 3 As shown, connect the a and b ends of the three-way valve knob to the catheter (10) and the sampling tube respectively, and the liquid pump (11) is in the open state; at this time, the catheter (10) is connected to the sampling tube, and the leakage The tube is closed, and the sample flows out from the supernatant layer under the action of the liquid pump (11), completing the liquid phase sampling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com