Mechanical switch valve oil-well pump

A technology for opening and closing valves and oil pumps, which is applied in mechanical equipment, liquid variable displacement machinery, pumps, etc., and can solve problems such as reducing the fullness of the pump chamber, lagging the opening of the oil pump valve ball, and frequent operations of pumping wells, etc. To achieve the effect of avoiding air lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

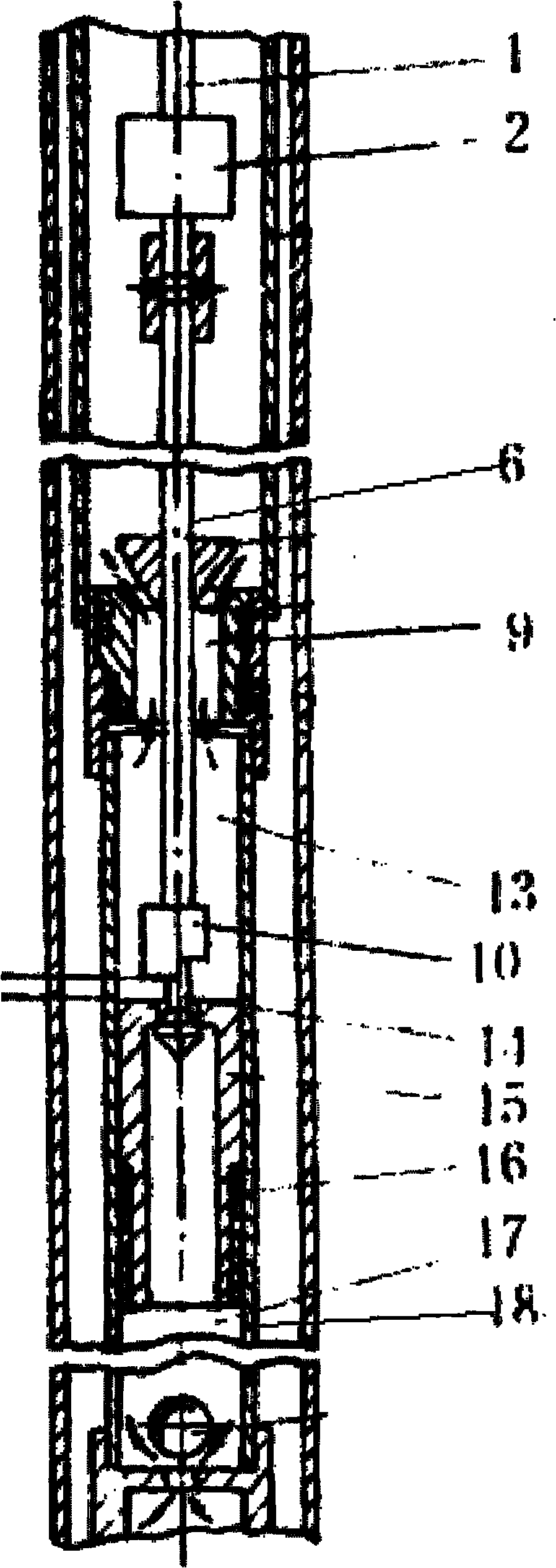

[0024] The mechanical opening and closing valve oil well pump that the present invention relates to is as figure 1 As shown, it is mainly composed of a pump barrel 18, a valve stem 9 inside the pump barrel 18, and a plunger body provided with the lower end of the valve stem 9. The plunger body divides the inside of the pump barrel 18 into an upper chamber 13 and a lower chamber. Chamber 17.

[0025] The plunger body includes a hard plunger body 15 and a soft plunger body 16 .

[0026] The hard plunger body 15 is arranged on the upper part of the soft plunger body 16 .

[0027] A plunger oil outlet valve 14 is arranged above the plunger body.

[0028] The valve stem 9 is provided with an air release hole 6 .

[0029] The upper end of the valve rod 9 is connected with the oil pushing rod 1 through the disconnector 2 .

[0030] A push block 10 is arranged on the valve stem 9 .

[0031] The working principle of the present invention is: the oil outlet valve on the plunger is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com