Split electronic delay control fuel oil heating system

A technology of delay control and heating system, applied in the field of auto parts, can solve the problems of easy wax deposition, unsafe getting off operation, no delay function, etc., and achieve the effect of smooth manual valve switching, convenient operation and saving consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following specific examples illustrate the present invention in further detail.

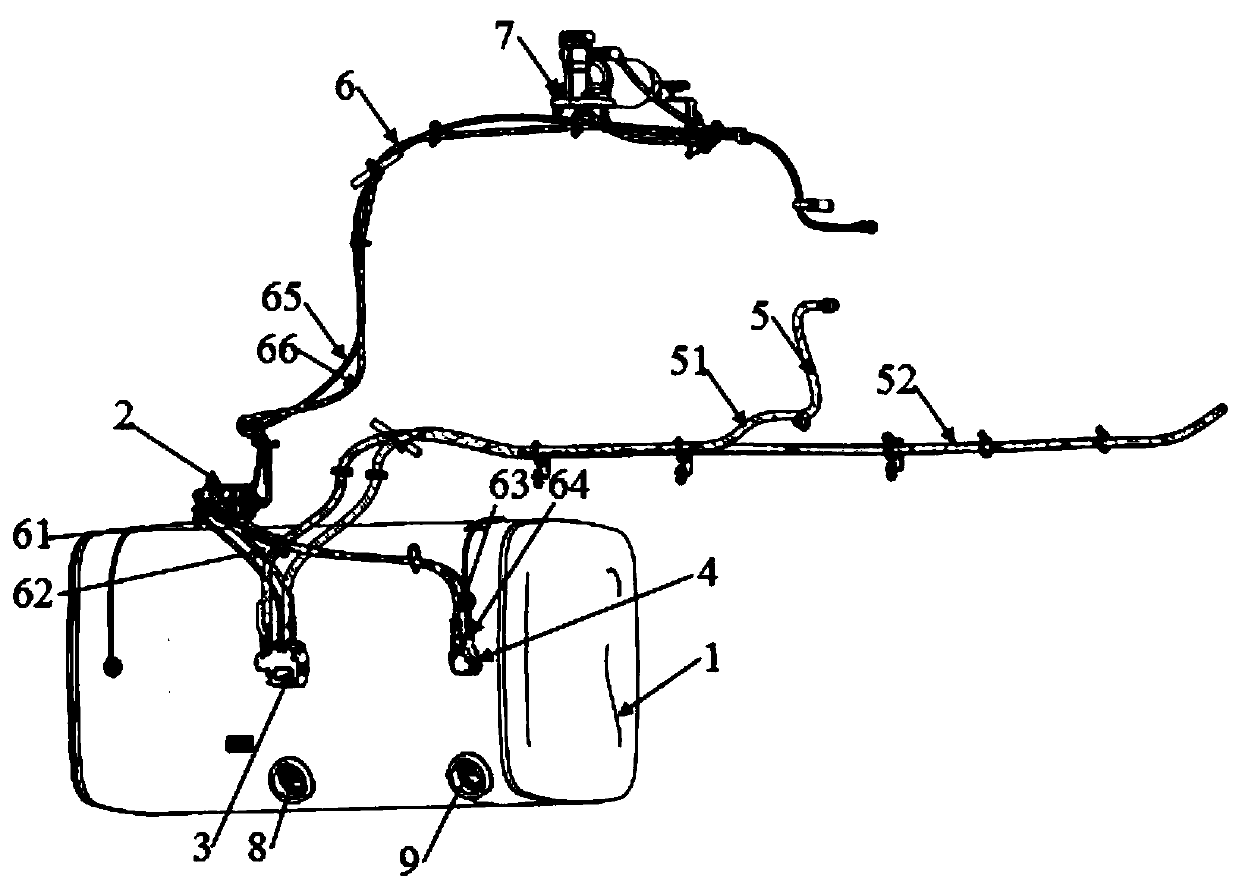

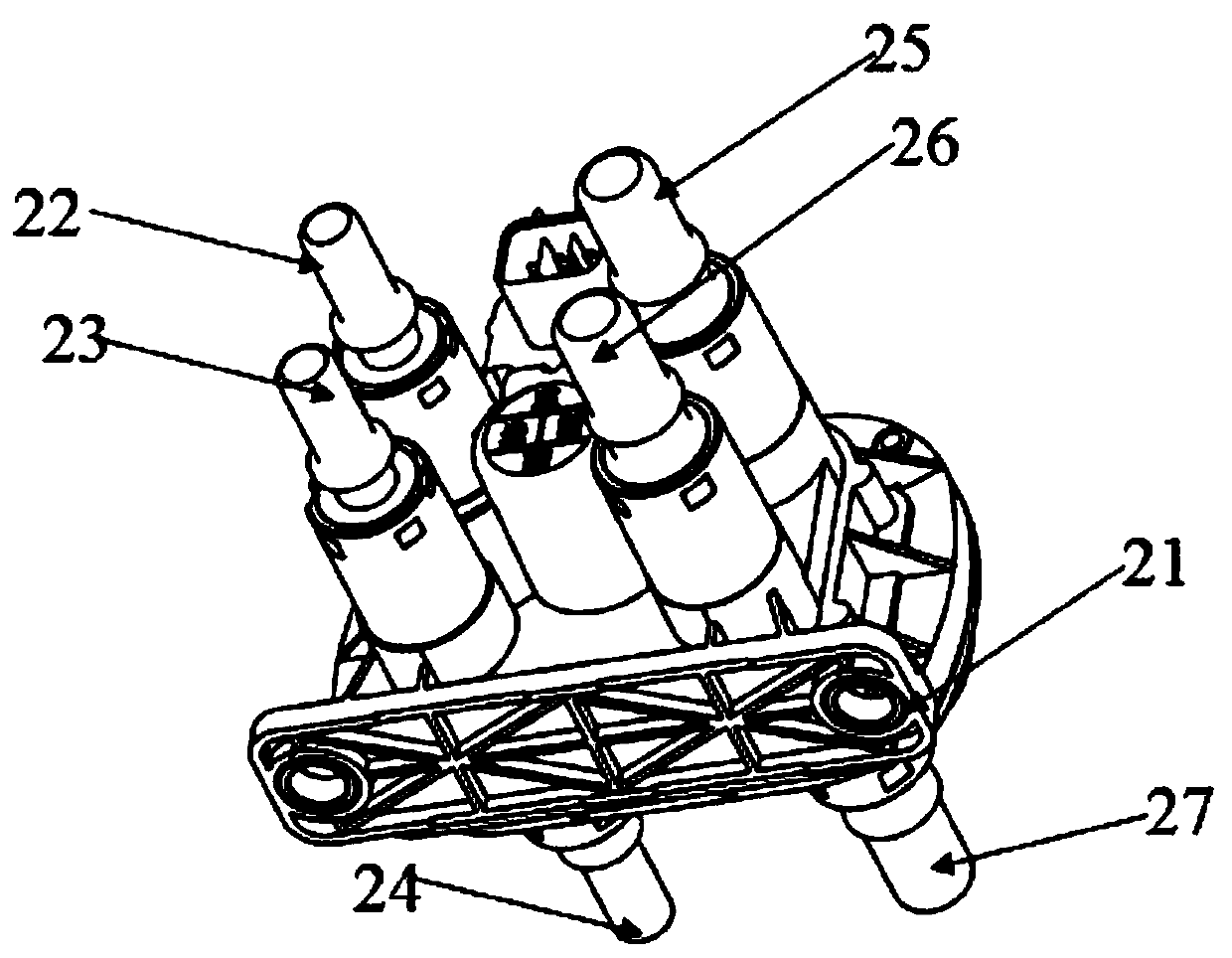

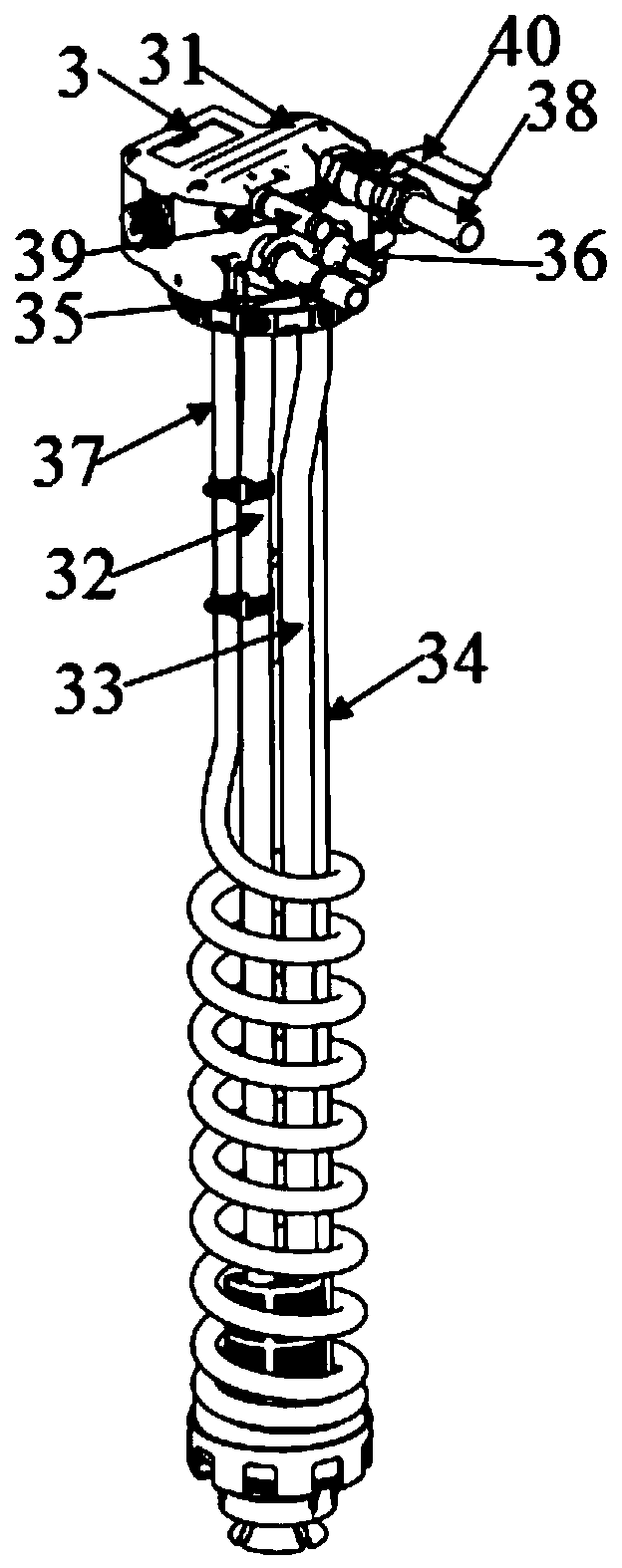

[0030] Such as Figure 1-4 As shown, a split-type electronic delay control fuel heating system provided by the present invention includes a dual-chamber fuel tank 1 with a main fuel tank 8 and an auxiliary fuel tank 9 inside, and also includes a delay fuel switching valve 2, a fuel quantity sensor 3 for the main fuel tank, Fuel quantity sensor 4 for auxiliary fuel tank, heating water pipe 5, and fuel pipeline 6; fuel quantity sensor 3 for main fuel tank and fuel quantity sensor 4 for auxiliary fuel tank are respectively fixed on main fuel tank 8 and auxiliary fuel tank 9; delay fuel switching valve 2 is fixed on the vehicle frame, The fuel quantity sensor 3 of the main fuel tank communicates with the heating water pipe 5 to the engine 10 to form a cooling water circulation; the delayed fuel switching valve 2 connects the fuel quantity sensor 3 of the main fuel tank and the fuel quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com