Engine exhaust system, air valve oil supply exhaust comprehensive control system and control method

An engine valve and exhaust system technology, applied in engine control, electrical control, engine components, etc., can solve the problems of reduced exhaust gas processor function, increased fuel injection volume of working cylinder, increased fuel injection time, etc. Longer service life, lower fuel consumption and lower emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

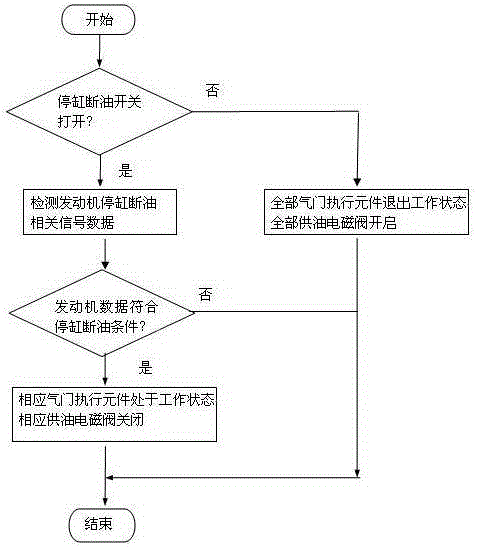

Method used

Image

Examples

Embodiment Construction

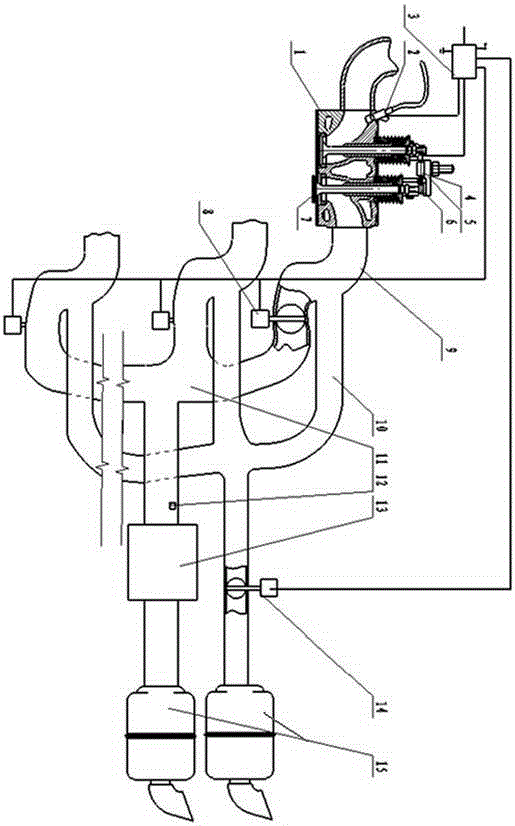

[0026] Such as figure 1 As shown, a kind of engine exhaust system, it comprises the exhaust manifold 9 that is connected with the air outlet of engine cylinder, a plurality of exhaust manifolds 9 are aggregated into exhaust pipe 11 and output through exhaust gas processor 13, muffler 15 , each exhaust manifold 9 is connected to the cylinder outlet in parallel with the exhaust branch pipe 10, and the outlet end of all exhaust branch pipes 10 is connected to the rear end of the exhaust gas processor 13; 9 is provided with an exhaust manifold valve 8, and the intake end of the exhaust manifold 10 is connected to the exhaust manifold 9 in front of the exhaust manifold valve 8; an exhaust manifold valve 14 is installed on the assembled exhaust manifold 10; A sensor 12 is installed on the exhaust pipe 11 ; the exhaust manifold valve 8 and the exhaust branch valve 14 are both connected to the control module 3 .

[0027] The control module 3 controls the functions of the engine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com