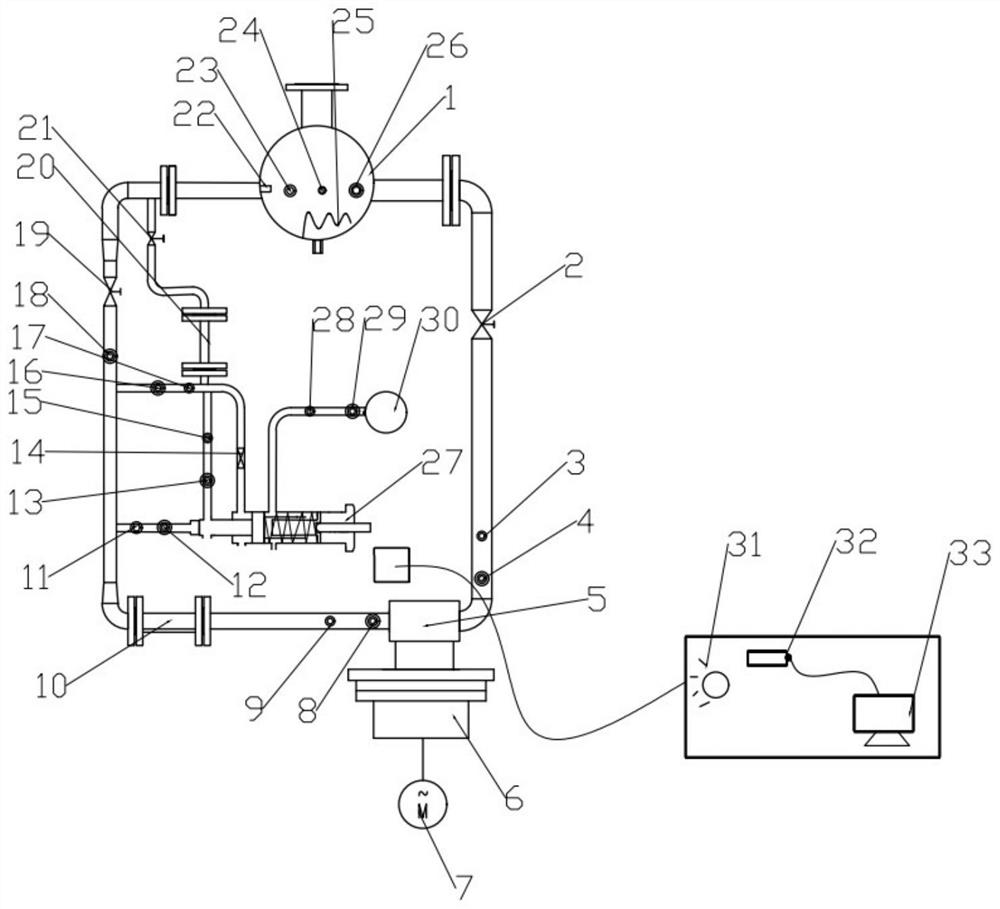

Differential pressure regulating valve dynamic performance test bench and measurement method thereof

A technology of dynamic performance and measurement method, applied in measurement devices, mechanical valve testing, instruments, etc., can solve the problems of lack of differential pressure regulating valve, affecting the accuracy and authenticity of calculation results, and high oil supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

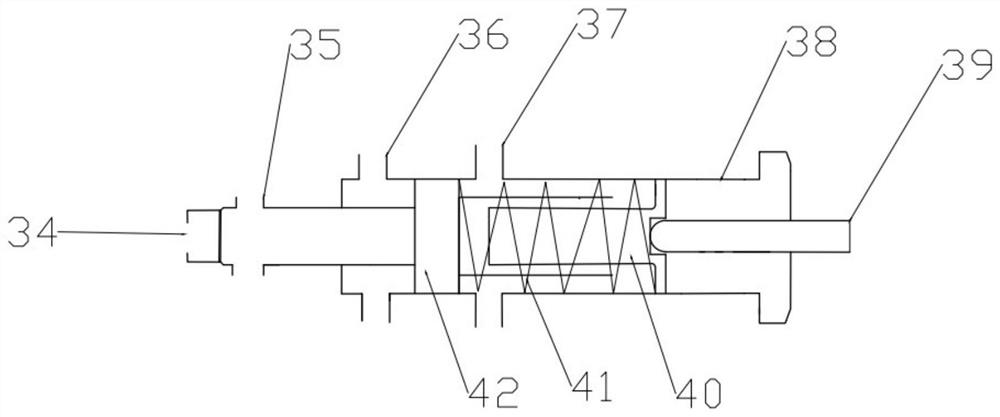

[0030] Such as figure 2 Said, the pressure differential valve 27 of the present invention comprises a valve inlet 34, an oil supply pressure inlet 36, a cavity pressure inlet 37, an overflow outlet 35, a screw plug 38, an adjusting screw 39, a guide rod 40, a spring 41 and The spool 42, because the pressure differential valve 27 is an existing structure, the installation method of the structure is no longer stated, only the working process is introduced. When the pressure differential valve 27 is in the closed state, the position of the guide rod 40 and the spring are fixed by the adjustment screw 39 41 compression amount, under the action of the pre-tightening force, the sliding valve is at the leftmost end of the valve body, and the opening of the overflow hole 35 is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com