Engine cylinder closing valve control device and method

A control device and engine block technology, applied in the direction of engine control, engine components, machines/engines, etc., can solve the problems of difficult to meet engine cylinder closure, fast wear speed, low reliability, etc., to improve reliability and meet high Frequency response and reliability, the effect of simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

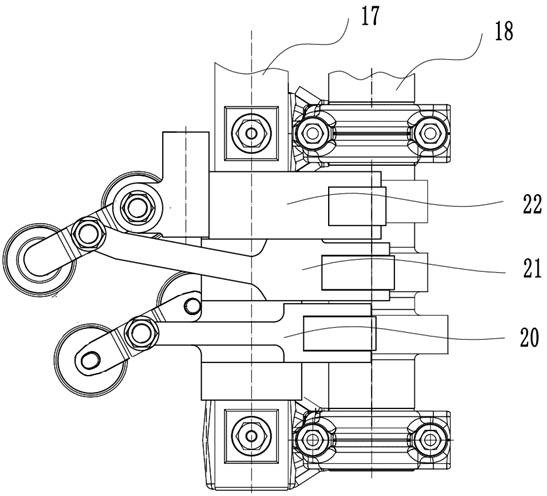

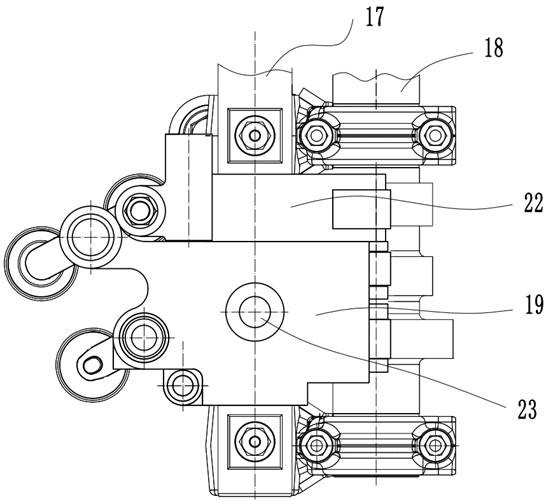

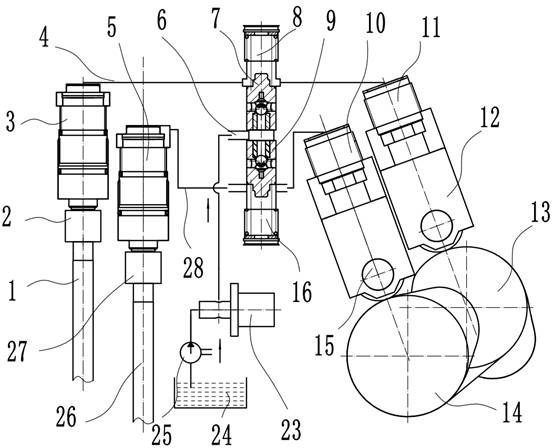

[0035] In a typical embodiment of the present invention, such as Figure 2-Figure 5 As shown, an engine cylinder deactivation valve control device is given.

[0036] Such as figure 1 Shown is a traditional engine rocker valve control structure, the intake rocker 20, exhaust rocker 21, brake rocker 22 are connected in series through the rocker shaft 17, the rocker is driven by the camshaft 18, and then the rocker is driven The valve bridge, and then the valve bridge drives the valves to work. Such as figure 2 As shown, the engine cylinder deactivation control device provided in this embodiment is used as the cylinder deactivation control mechanism 19 to replace the original intake rocker arm 20, exhaust rocker arm 21 and brake rocker arm 22, and is also connected in series on the rocker arm shaft 17. Driven by the camshaft 18, but integrally fixed on the cylinder head, it cannot swing around the rocker shaft 17 driven by the camshaft 18.

[0037] figure 2 , image 3 Sho...

Embodiment 2

[0059] In another typical embodiment of the present invention, such as Figure 2-Figure 5 As shown, a method for controlling the cylinder-closing valve of the engine is given, using the engine cylinder-closing valve control device as in Embodiment 1.

[0060] During normal engine block operation:

[0061] The control valve 23 obtains the medium supplied by the hydraulic pump 25 and inputs it to the control port of the spool valve, and the spool of the spool valve moves;

[0062] The spool valve core opens the middle passage, so that the valve oil circuit remains connected, and the external hydraulic tappet periodically transmits the driving force to the external hydraulic piston under the action of the camshaft 18, so that the hydraulic piston drives the valve to periodically move;

[0063] When the engine block is closed:

[0064] The control valve 23 obtains the medium supplied by the hydraulic pump 25 and inputs it to the control port of the spool valve, and the spool of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com