Opening type water cooling rail induction normalizing coil and use method thereof

An induction coil, opening and closing technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of circulating cooling water dripping, inconvenient disassembly and assembly, etc., to achieve uniform heating temperature, convenient assembly and disassembly, and improve electro-magnetic-thermal The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

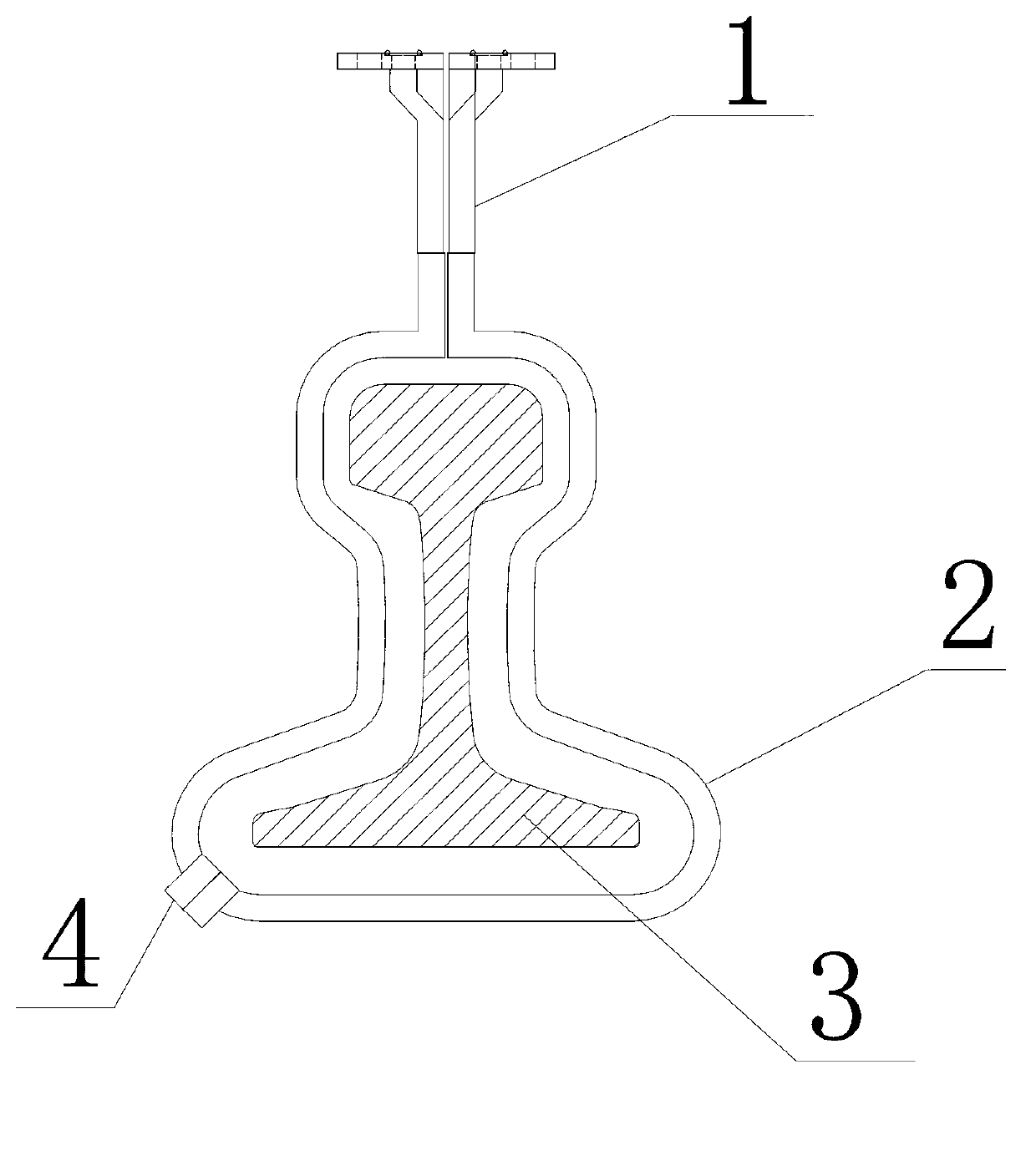

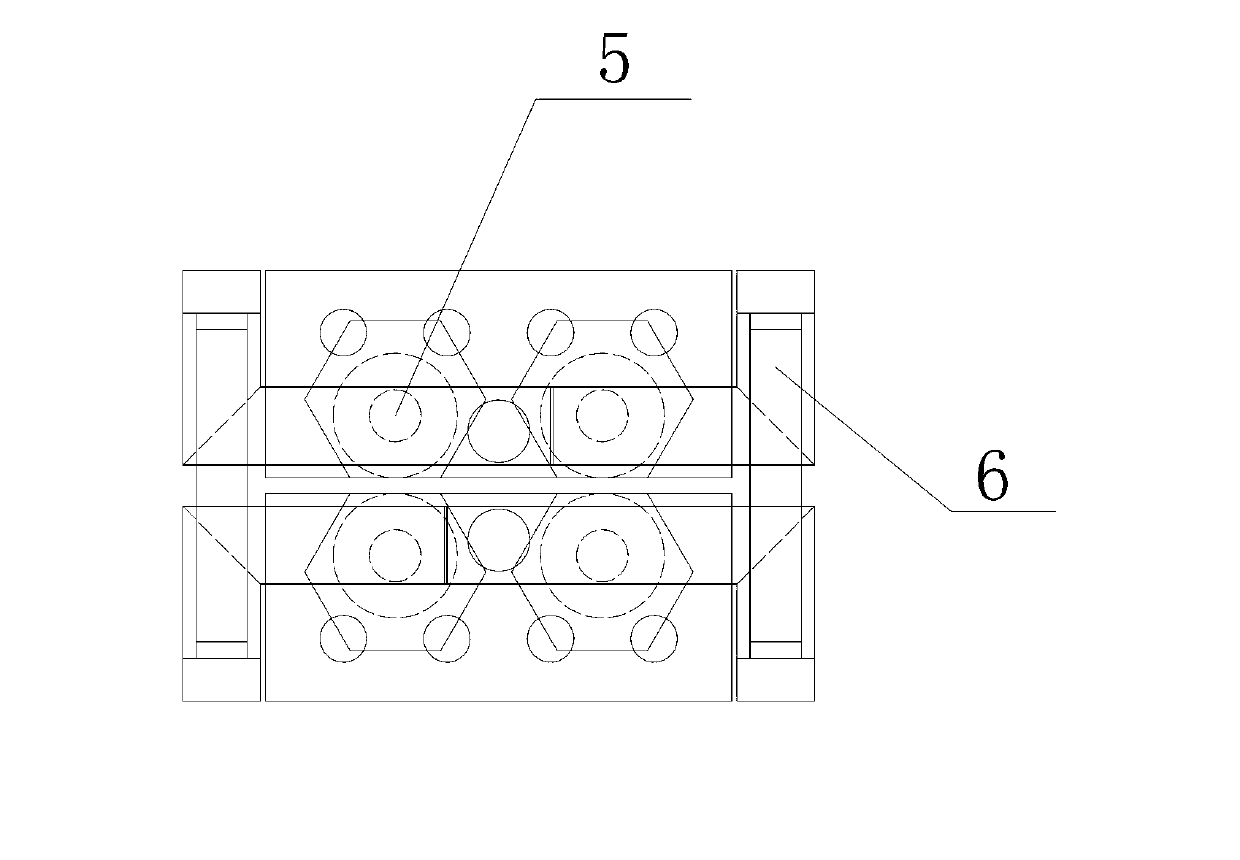

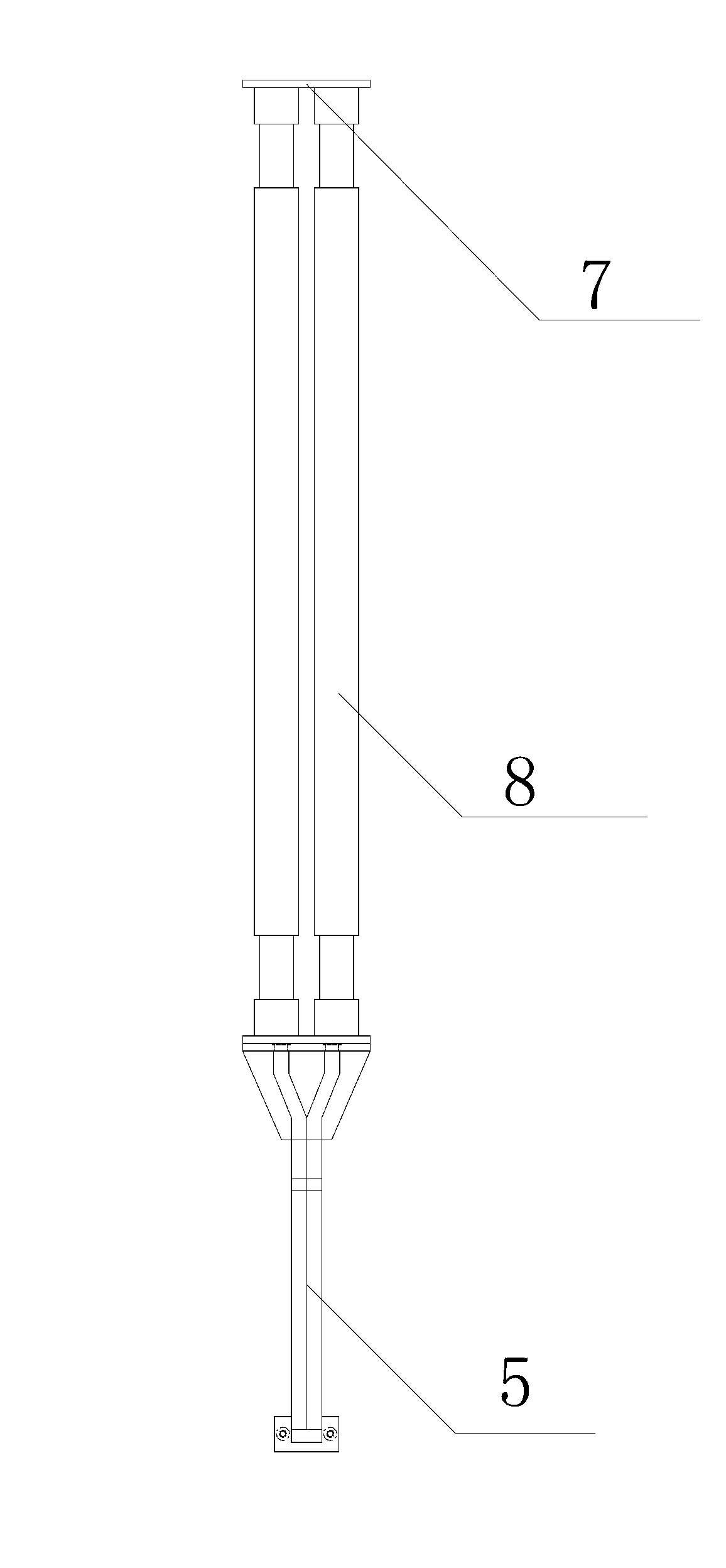

[0035] The induction normalizing coil of the present invention is composed of two parts on the left and right sides. The induction normalizing coil is made of an oxygen-free T2 copper tube, and the coils on both sides are independent pipe lines. , The current and water flow pass through the pipeline, and the water flow and current in the coils on both sides are not connected. There are two copper pipes connected in parallel in the two parts on the left and right sides, and the coils on both sides are insulated and bolted at the bottom corner of the rail on one side of the rail, and installed in a profiled rail, so that the rail is hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com