Multifunctional hydraulic scribing and fissure cementing machine

A multi-functional, seam filling machine technology, applied in the direction of roads, road repairs, roads, etc., can solve the problems of difficult to meet the development requirements of road construction, high labor intensity, heavy workload, etc., to improve the construction quality and low labor intensity , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

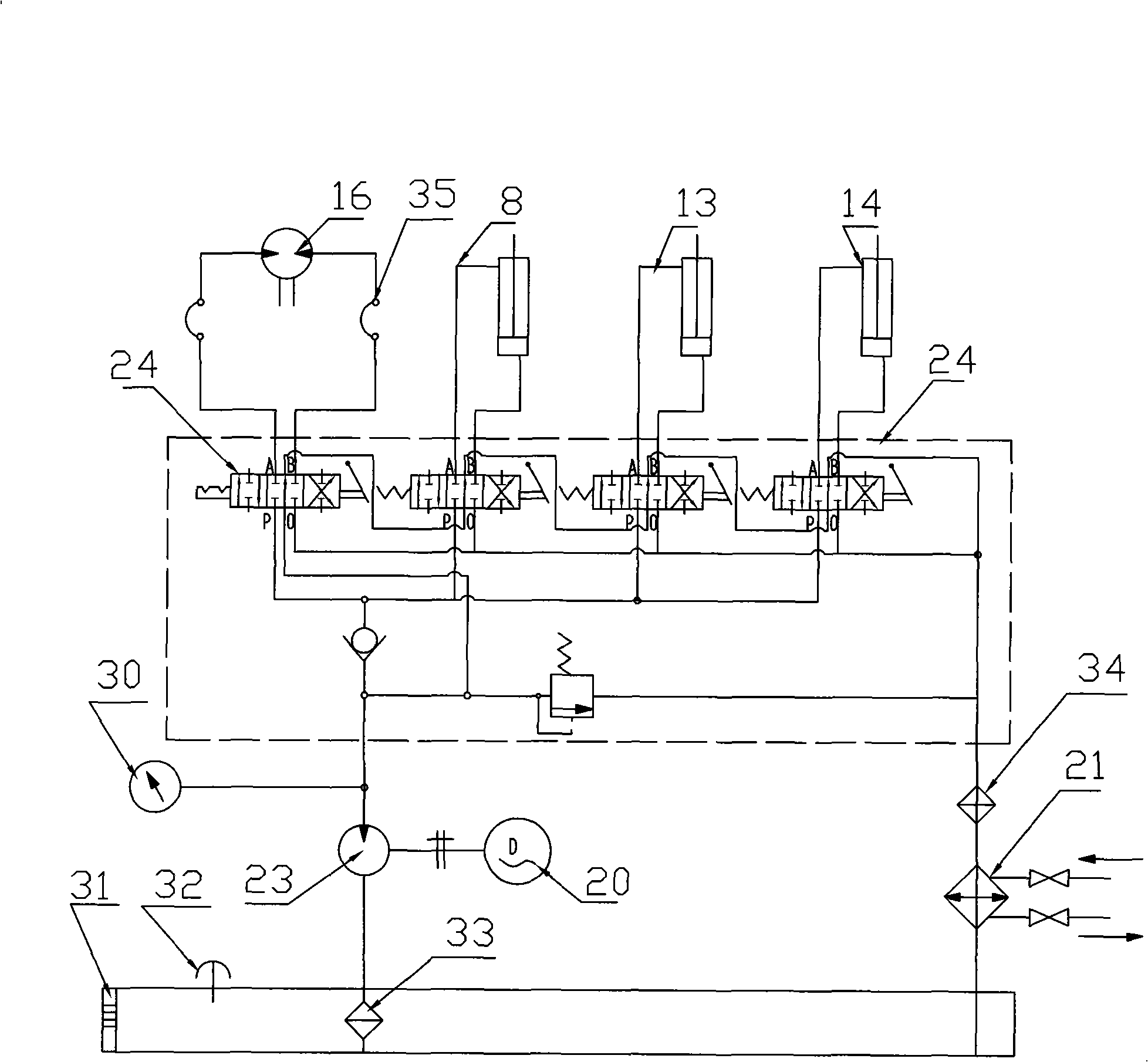

Method used

Image

Examples

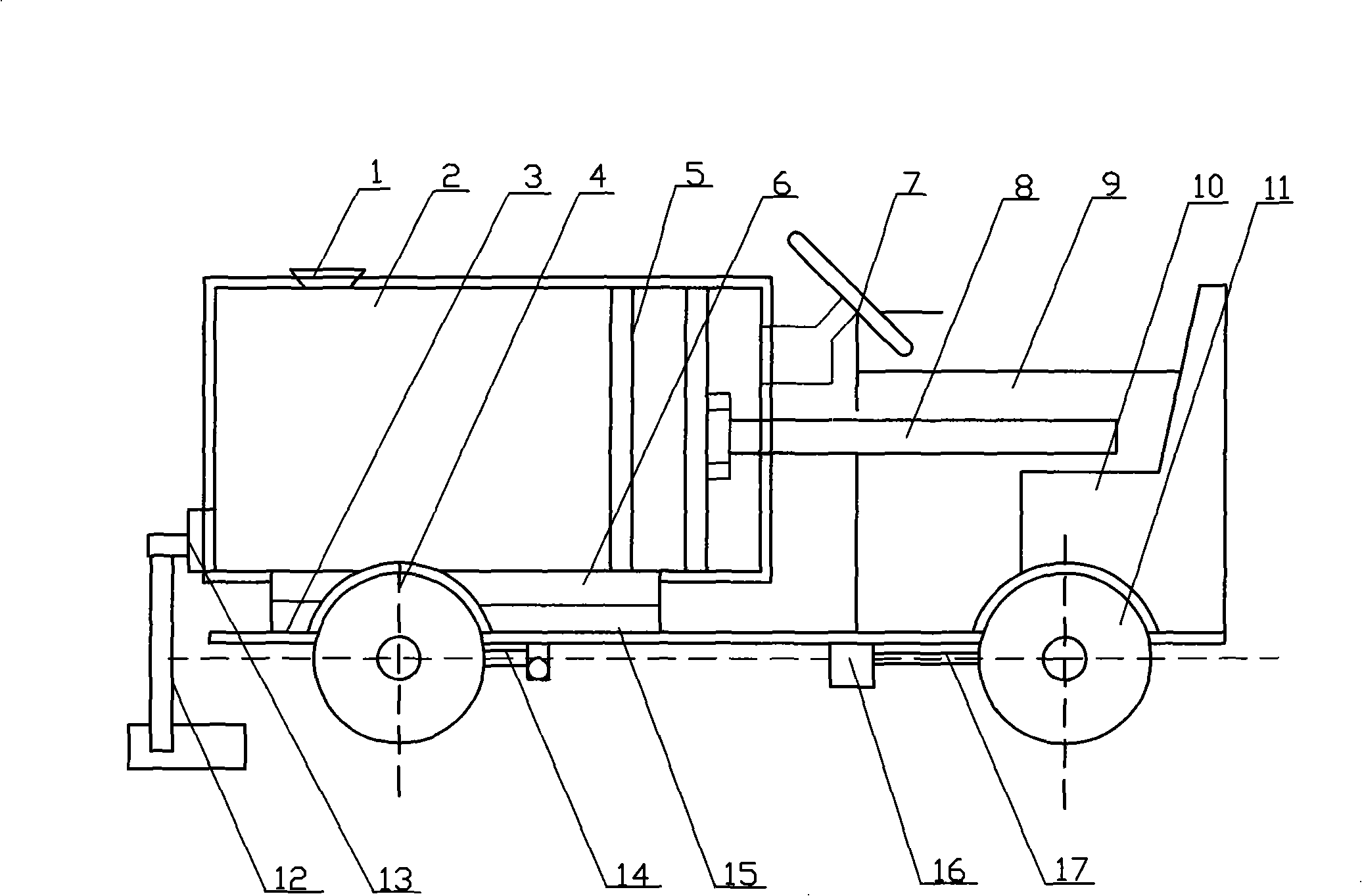

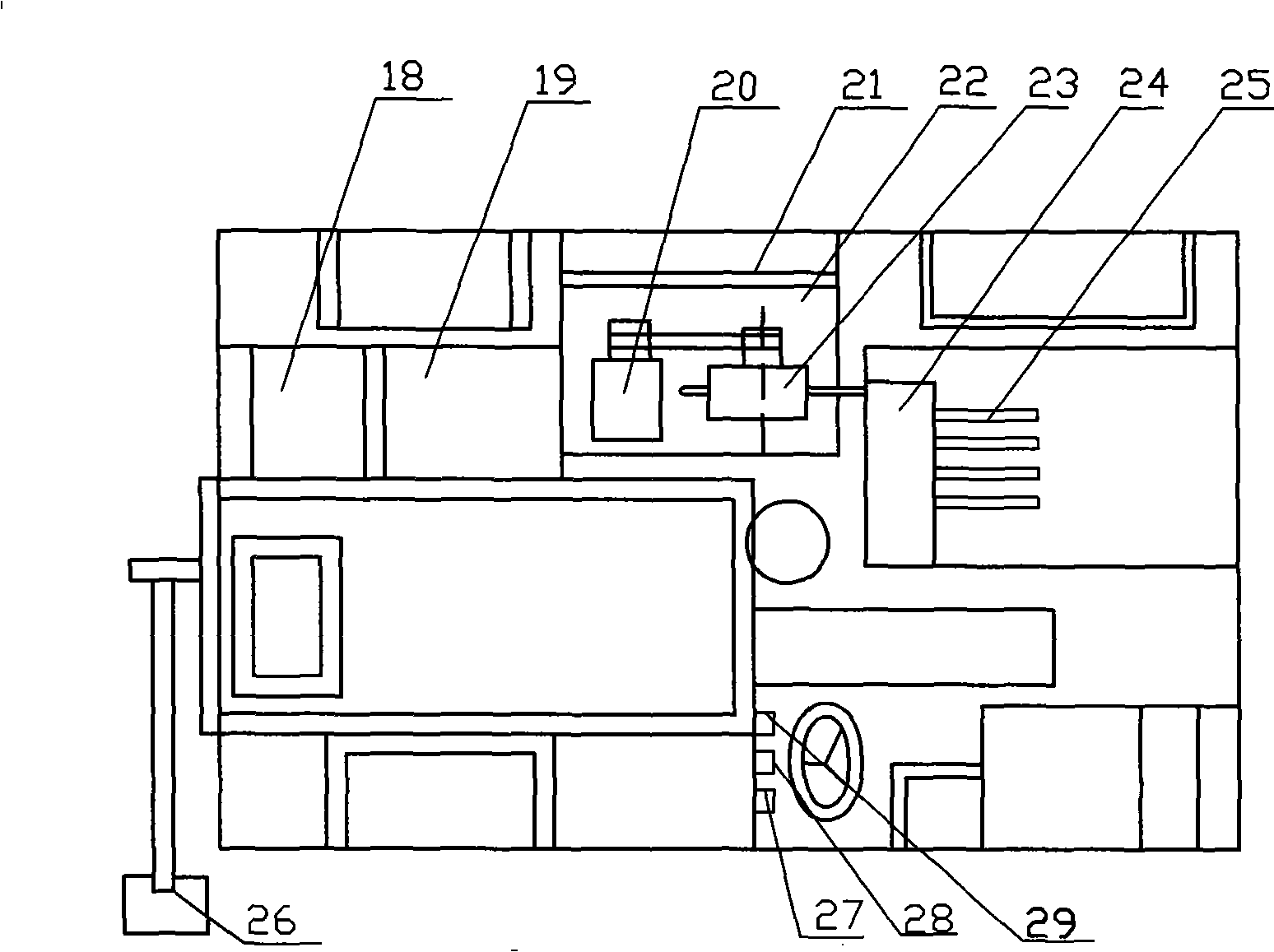

Embodiment 1

[0014] In Embodiment 1, the present invention is to install the front steering wheel 4 on the lower front end of the dedicated chassis 3, and the front steering wheel 4 is coupled with the steering control system 7, so that the steering can be flexibly controlled. The rear drive wheel 11 is installed on the lower rear end of the dedicated chassis 3, the hydraulic motor 16 installed in the rear of the dedicated chassis 3 is matched with the drive shaft 17, and the drive shaft 17 is matched with the rear drive wheel 11; installed on the upper part of the special chassis 3 The diesel engine 9 is connected to a hydraulic oil pump 23, and the hydraulic oil pump 23 can also be connected to a low-power generator 20. The whole machine is driven by a diesel engine 9 to drive a hydraulic oil pump 23 and a low-power generator 20 to provide a power source to drive operation in various working conditions. The hydraulic motor 16 is connected with the hydraulic oil pump 23; the drive wheel 11 is...

Embodiment 2

[0018] In embodiment 2, the present invention can also provide a seat 10 in the middle of the dedicated chassis 3. The steering control system 7 is installed in front of the seat 10. The operator controls the steering control system 7 on the seat 10, watching the front working surface, and driving at a low speed. , You can easily operate the machine. Refer to Figure 1 to Figure 3 , The rest is the same as in Example 1.

Embodiment 3

[0019] In Embodiment 3, the two ends of the hot melt tank 2 of the present invention can be connected by a flange plate, which is convenient for installation and maintenance. Refer to Figure 1 to Figure 3 , The rest is the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com