Flow-matched balance and energy recovery system

A flow matching and energy recovery technology, applied in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve problems such as difficult and difficult gravitational potential energy recovery and reuse, and achieve low processing difficulty and high energy utilization efficiency. , The effect of stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The above and other technical features and advantages of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, rather than all of them.

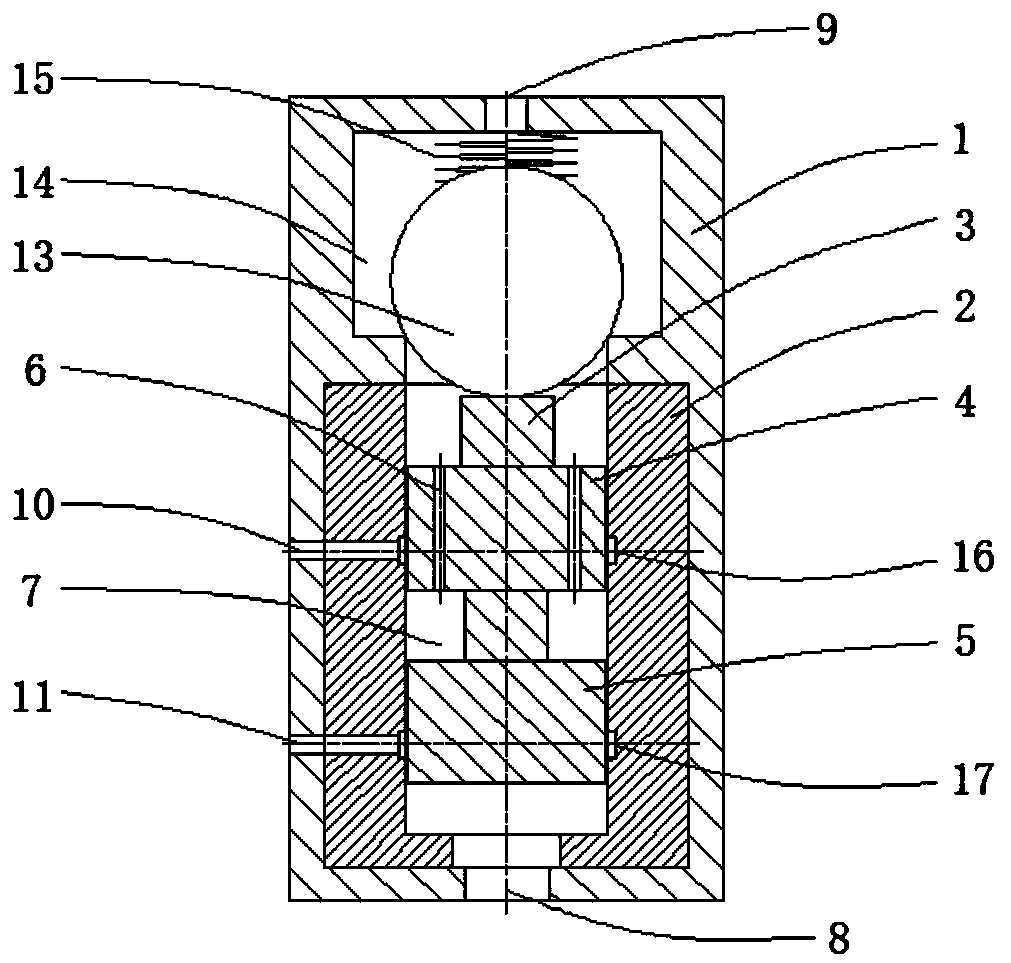

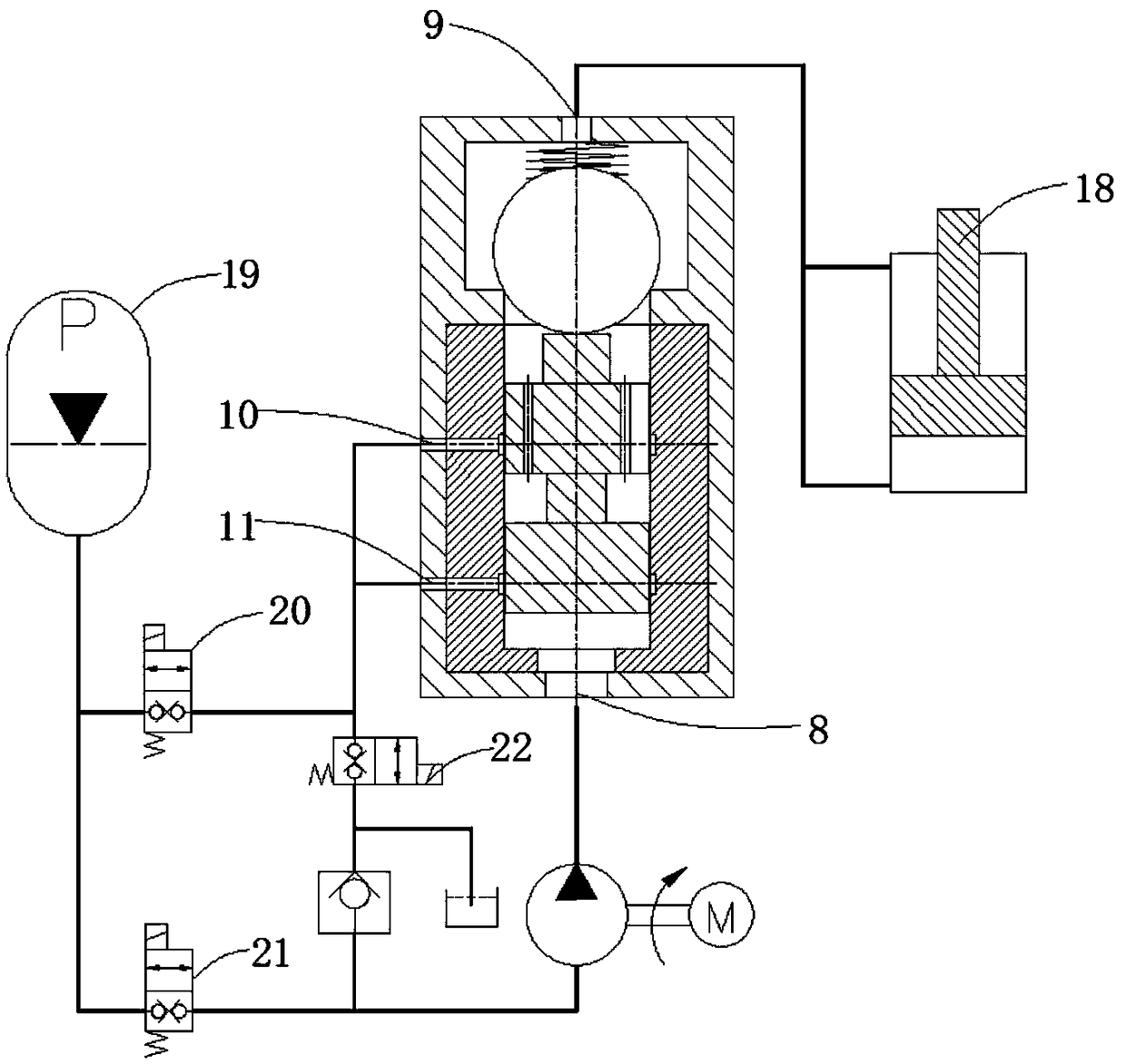

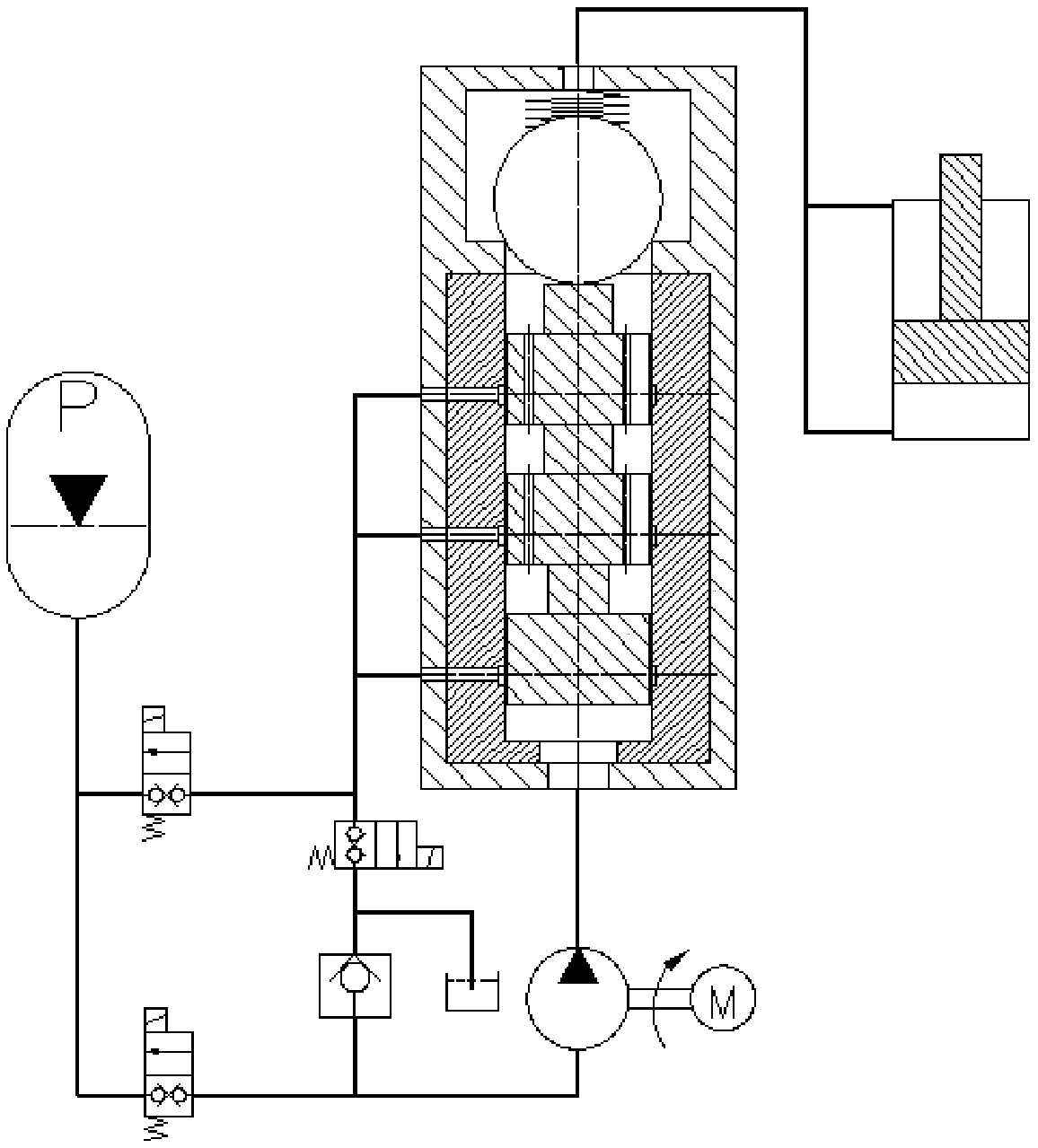

[0025] Such as figure 1 As shown, the flow matching balance valve (hereinafter referred to as "balance valve") provided by the embodiment of the present invention is a schematic structural diagram, which mainly consists of a valve body 1, a valve sleeve 2, a valve core 3, a ball valve core 13, a ball valve seat 14, and a pressure valve. Tighten the spring 15. Among them, the valve body 1 is provided with a valve hole and a ball valve seat 14; the valve sleeve 2 is installed in the valve hole; the ball valve core 13 is pressed on the valve seat by a compression spring 15 to function as a one-way valve, and the one-way valve seat The diameter of the opening is the same as that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com