Air charging and exhausting valve oil seal inner flange gauge and detecting method thereof

A valve oil seal, intake and exhaust technology, applied in the inspection field of the inner flange of the intake and exhaust valve oil seal and its detection field, can solve the problems of inability to strictly control the quality of the valve oil seal, repeatability of measurement results, poor stability, and susceptibility to human factors to reduce the influence of human factors, facilitate operation and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

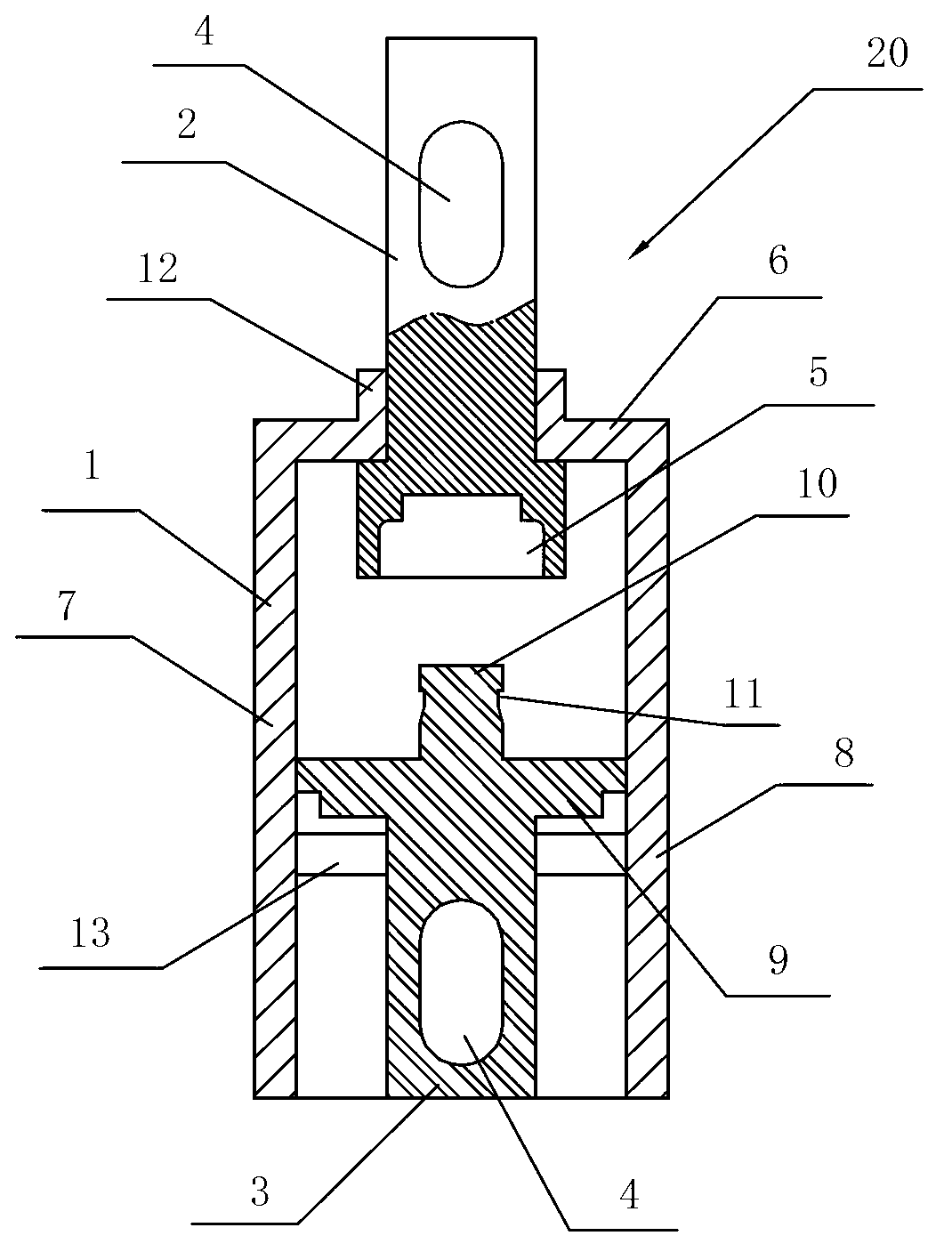

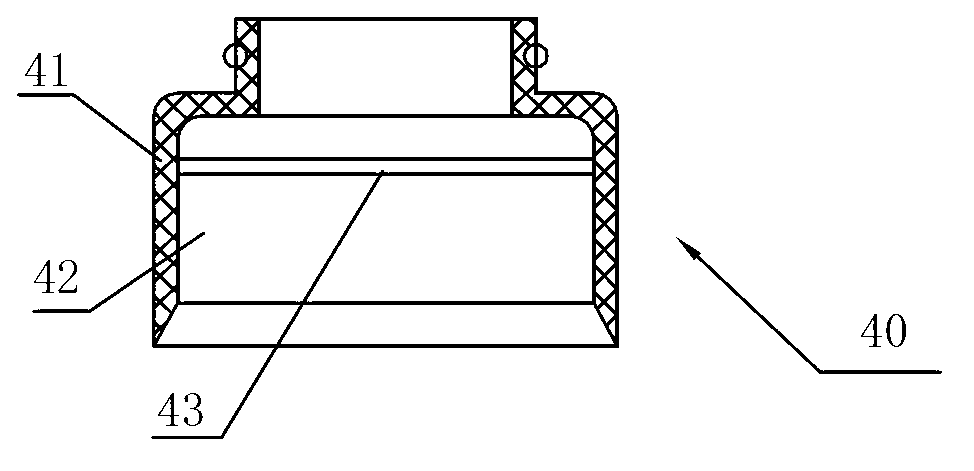

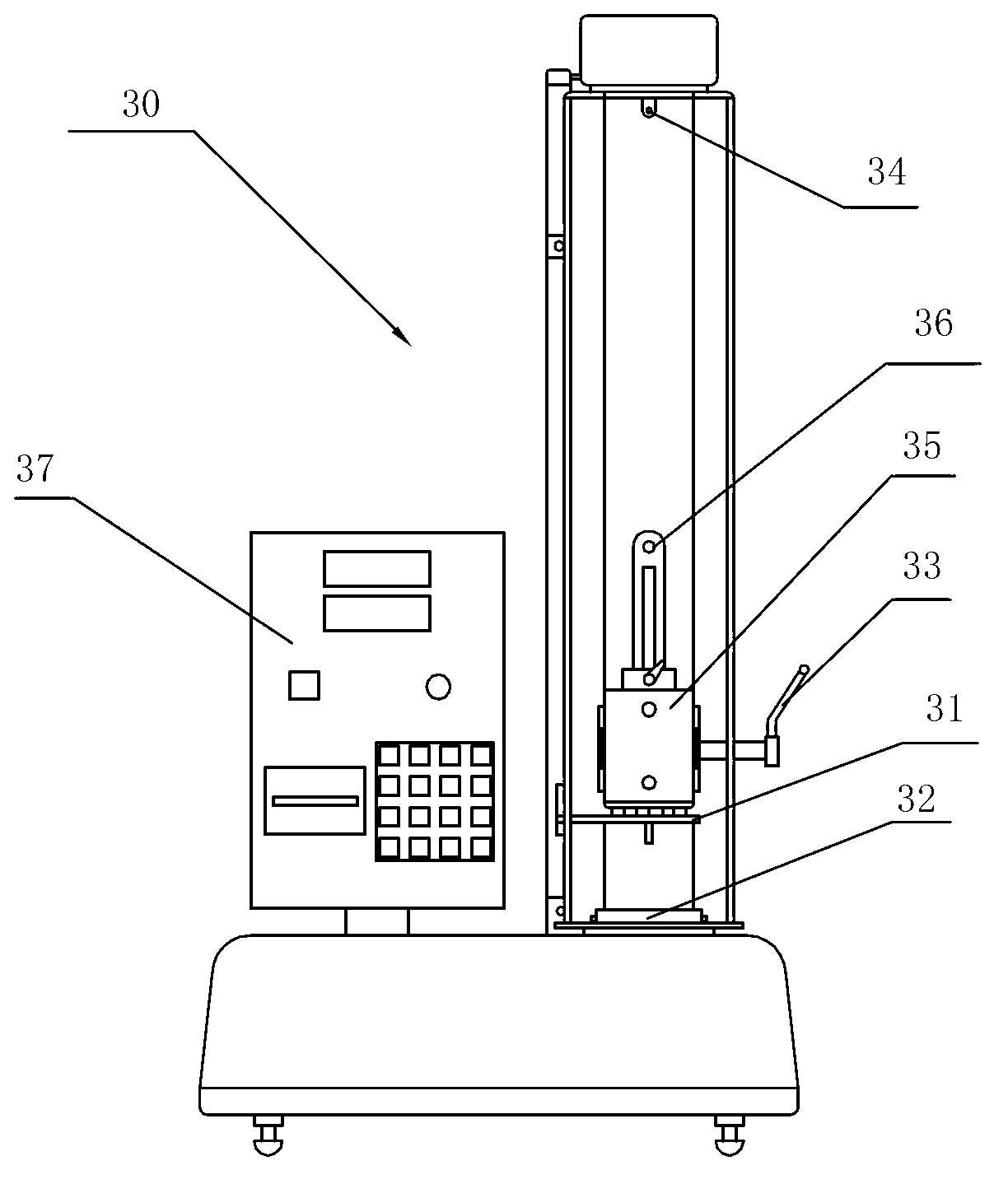

[0023] Embodiment: The inspection tool for the inner flange of the intake and exhaust valve oil seal of this embodiment, such as figure 1As shown, it includes a valve oil seal measuring tool 20 and a spring tester 30. The valve oil seal measuring tool 20 includes a base 1 and an upper rod 2 and a lower rod 3 that can slide up and down. The base 1 includes a top surface 6 and a left support frame 7 and a right support frame 8 connected to the bottom of the top surface 6. The top surface 6 is circular, the left support frame 7 and the right support frame 8 are arc-shaped, and the left support frame and the right support frame 8 are curved. A crossbeam 13 is connected between the right supporting frame, and a boss 12 is arranged on the top surface 6 of the base 1, and a through hole is opened in the boss. The upper tie rod 2 passes through the inner through hole of the boss 12 , and the bottom end of the upper tie rod 2 extends into the base 1 , and the upper tie rod 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com