Electro-hydraulic valve for engine and working system thereof

A technology of engine and valve, applied in the direction of engine components, engine control, machine/engine, etc., can solve the problems of high manufacturing cost, large driving loss, complex structure, etc., and achieve the effect of improving power performance, reducing emissions, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described below in conjunction with accompanying drawing.

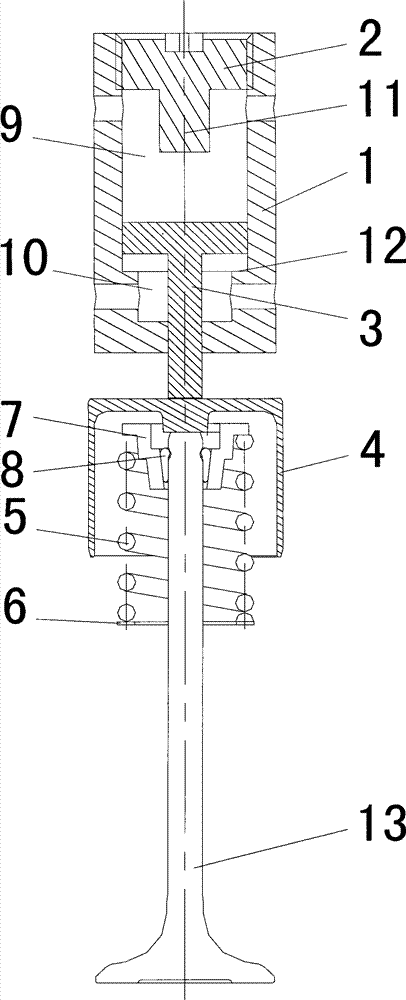

[0035] as attached figure 1Shown is a kind of electro-hydraulic valve for an engine according to the present invention, comprising an oil cylinder 1, a plunger 3, a tappet 4, a valve spring 5, and a valve 13; the top of the oil cylinder 1 is provided with an oil cylinder cover 2; the oil cylinder 1 is provided with No. 1 oil chamber 9 and No. 2 oil chamber 10 which communicate with each other; the inner diameter of No. 1 oil chamber 9 is larger than that of No. 2 oil chamber 10; the No. 1 oil chamber 9 is located in No. 2 oil above the cavity 10; the junction of the No. 1 oil cavity 9 and the No. 2 oil cavity 10 is formed with a step 12; the oil cylinder 1 is respectively provided with the No. Oil outlet hole of chamber (not marked), oil inlet hole of No. 2 oil chamber (not marked), oil outlet hole of No. 2 oil chamber (not marked); oil inlet hole of No. 1 oil chamber, No. 1 oil chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com