Engine cam shaft bearing cap integrated with VVT oilway

A technology for engines, camshafts, applied to shafts and bearings, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

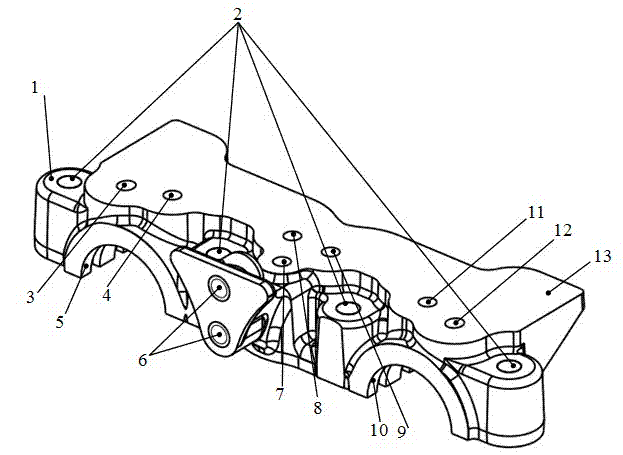

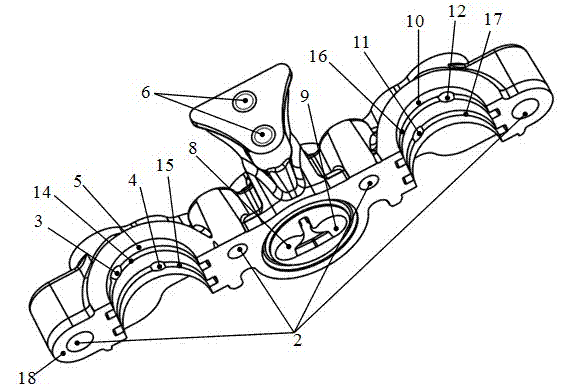

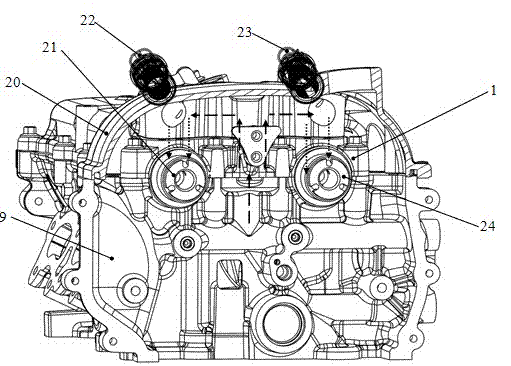

[0018] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0019] see figure 1 and figure 2 , the camshaft bearing cover 1 has the basic structure of the bearing cover, that is, the cover body is symmetrically provided with the half-shaft hole 5 on the intake side and the half-shaft hole 10 on the exhaust side, and the upper surface of the cover body is attached to the cylinder head cover. The upper sealing surface 13 that is combined, the lower surface is the lower sealing surface 18 that fits with the cylinder head. There are also bearing cap mounting holes 2 on the cover body, bearing cap and cylinder head cover assembly holes 7, and the front end of the camshaft bearing cap is provided with a chain guide rail mounting hole 6.

[0020] The VVT oil circuit integrated on the camshaft bearing cap is different from the existing oil circuit: a first oil groove 15 and a second oil groove 14 are arranged in parallel on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com