Control logic coordination valve of undercarriage cabin door uplock

A landing gear hatch and control logic technology, which is applied to building locks, non-mechanical transmission-operated locks, chassis, etc., can solve problems such as complex pressure supply control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

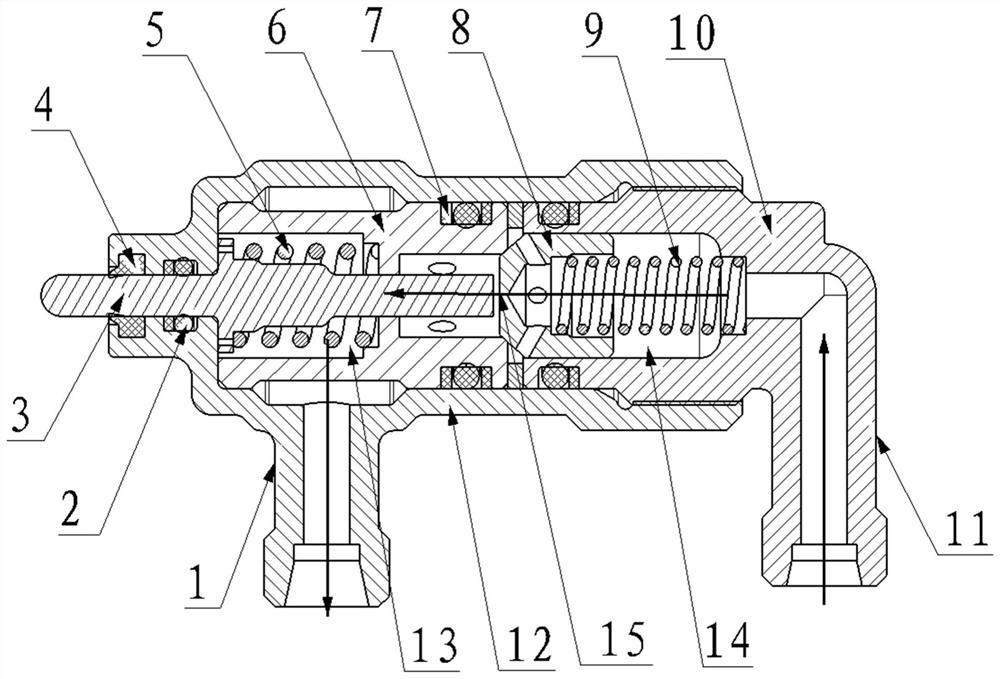

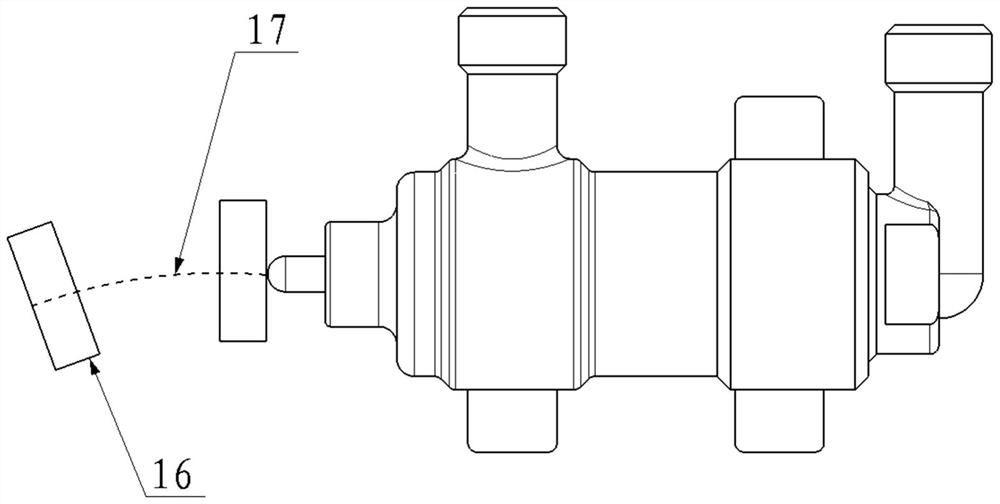

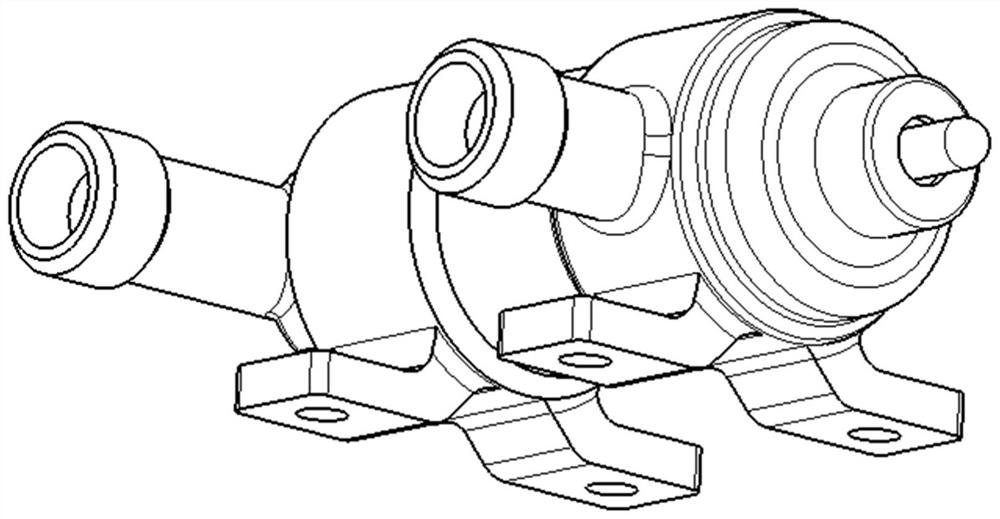

[0014] refer to Figure 1 ~ Figure 3. In the preferred embodiment described below, a landing gear door uplock trigger coordination valve includes: a coordination valve that integrates the installation interface of the uplock and is formed with an oil inlet nozzle 1 that is radially connected to the front coordination valve chamber The shell, the valve seat 6 and the valve core 8 assembled in the front coordination valve cavity, the pressure rod 3 with the pressure rod return spring 5 set, the end cover 10 of the oil outlet nozzle, wherein: the valve seat 6 The outside is formed with an assembly sealing ring 7 sealing grooves, the end cover 10 is connected to the valve seat 6 through the sealing ring, and the outer circle of the opening end is provided with a sealing ring 7 .

[0015] The pressure rod 3 passes through the dustproof ring 4 and the sealing ring 2 in sequence, passes through the spring seat plate of the valve seat 6, and is assembled on the bearing; The lock lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com