Colored throttle valve oil-resistant rubber material

A technology of throttle valve and rubber compound, applied in the field of rubber, can solve the problems that the reinforcing performance of white filler is not as good as that of carbon black, the compression deformation is poor, the processing performance is not good, etc., and achieves good physical and mechanical properties, low compression set The effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0023] The preparation method of the colored throttle oil-resistant rubber material of the present invention is as follows: 1) putting nitrile rubber into a banbury mixer for masticating, and parking for use; 2) putting the masticated rubber material into a banbury mixer, and then adding reinforcement agent, calcined hard clay, environmentally friendly plasticizer, stearic acid, fully stirred, mixed evenly, and parked for use; 3) Put the banburyed rubber into the internal mixer, and then add sulfur and the remaining accelerator, zinc oxide , processing aids and other raw materials for banburying; 4) Extrude and granulate through an extruder to obtain a colored throttle valve oil-resistant rubber compound.

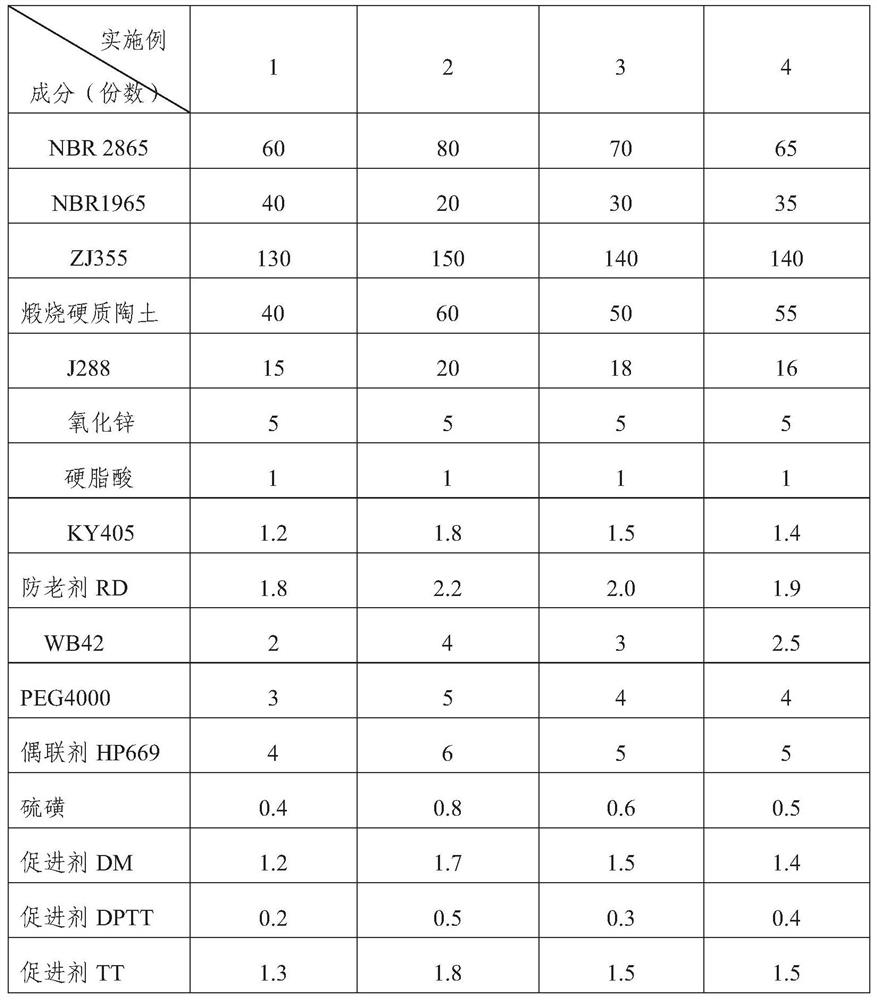

[0024] See Table 1 for the names and proportioning of raw materials in the rubber compound of the present invention.

[0025] Table 1

[0026]

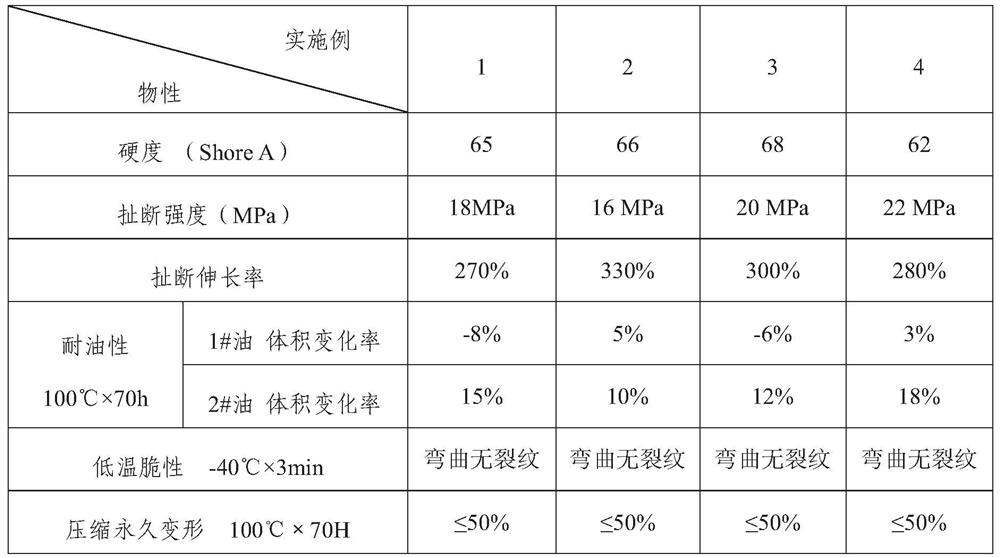

[0027] The performance parameters of the sizing compound made by the embodiment 1-4 of table 2

[0028]

[0029] As can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com