Water containing plate for heat exchanger

A water tray and heat exchanger technology, applied in the field of heat exchangers, can solve the problems of large power consumption, leakage, spillage, etc., and achieve the effects of avoiding secondary freezing, reducing manufacturing costs, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the following examples.

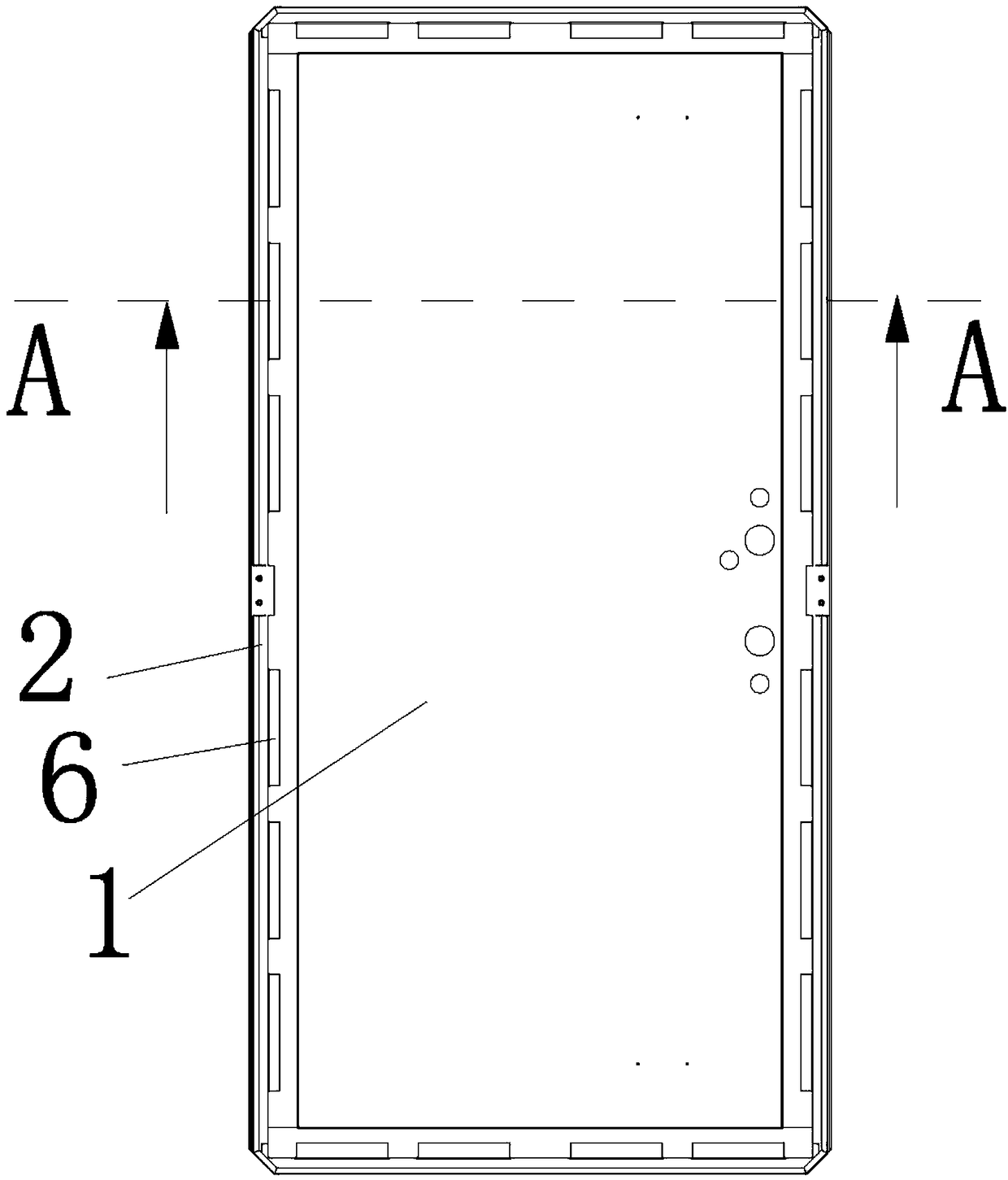

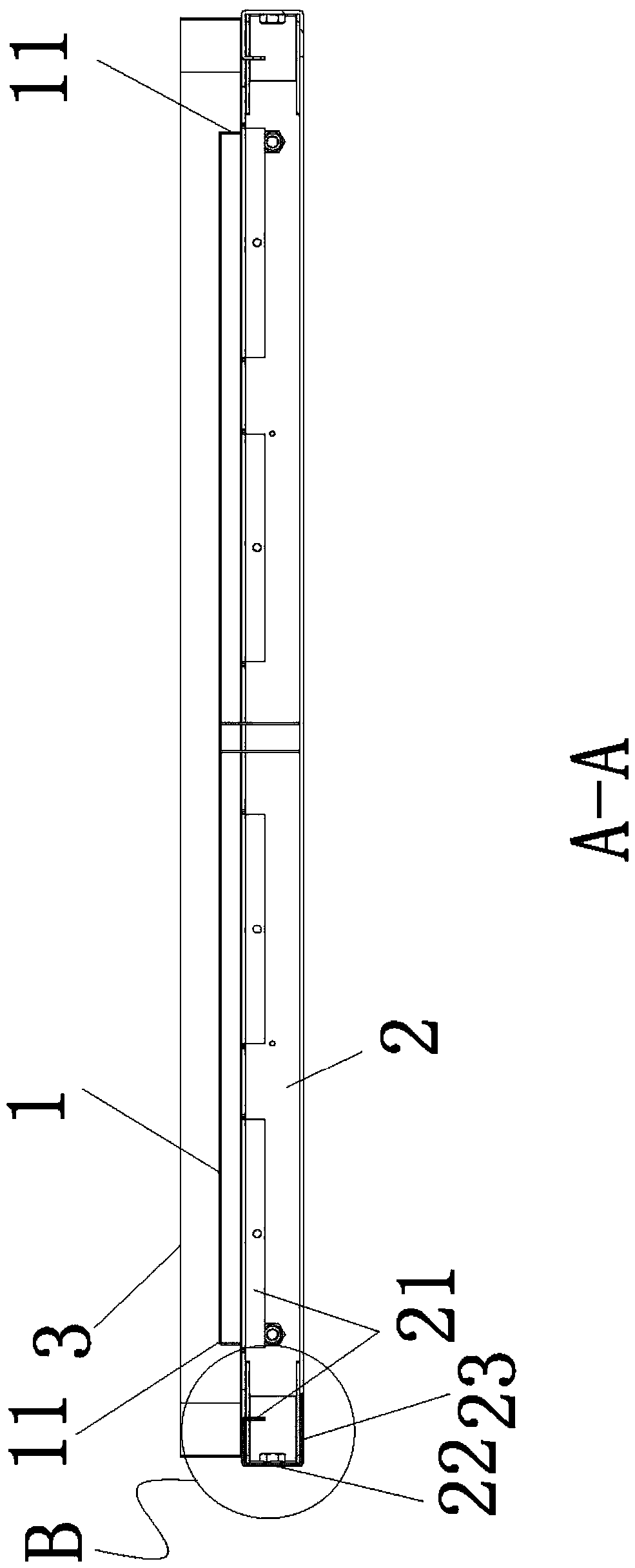

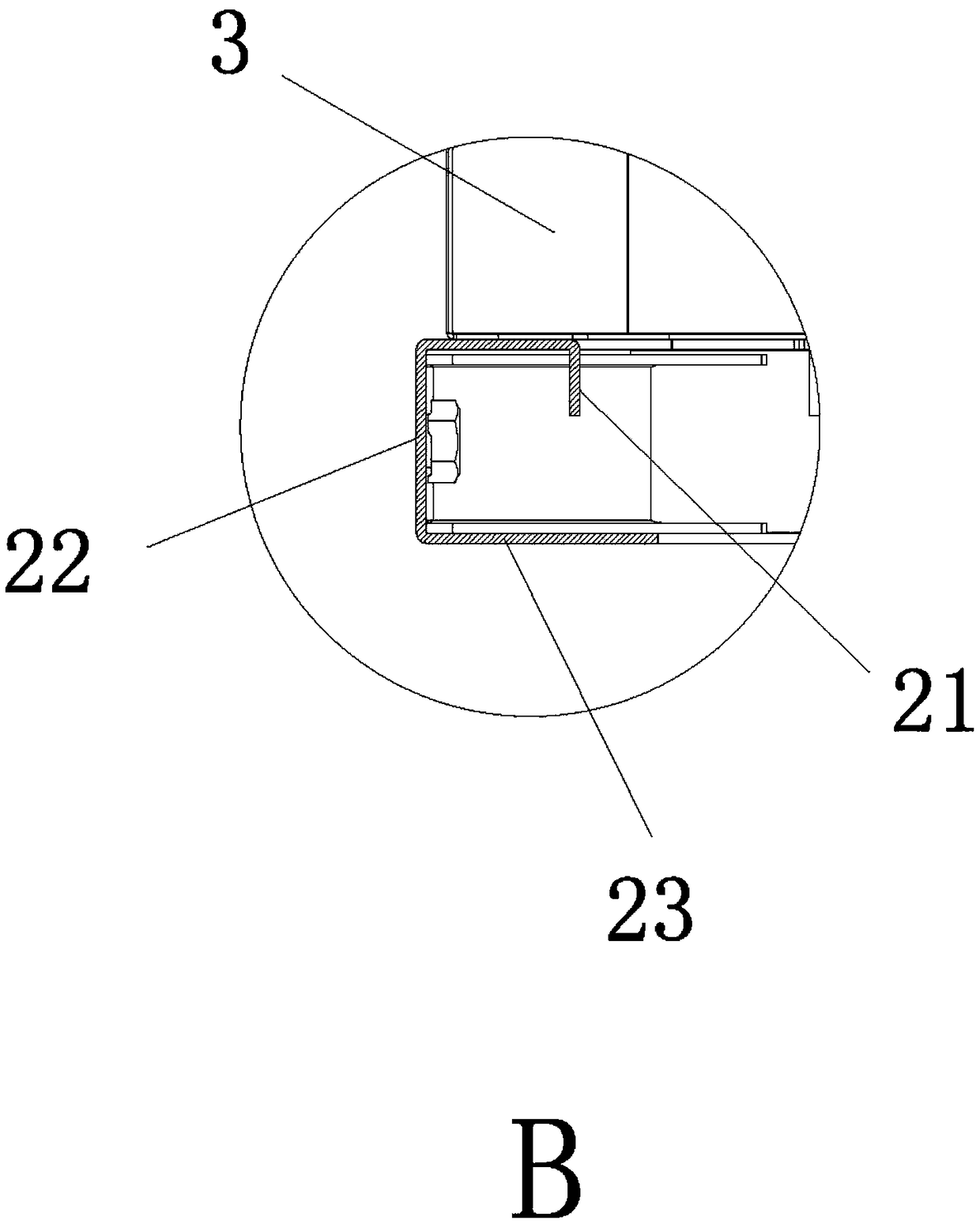

[0026] A specific embodiment of a water receiving tray for a heat exchanger of the present invention, as Figure 1 to Figure 6 As shown, it includes a bottom plate 1 and a water guiding plate 2, the water guiding plate 2 is arranged around the outer periphery of the bottom plate 1 and is detachably connected with the bottom plate 1. In this embodiment, the bottom plate 1 is arranged in a rectangular shape. Of course, the bottom plate 1 is also It can be called circular, triangular and other shapes, and the shape of the water guide plate 2 can be assembled according to the shape of the bottom plate 1. Among them, in order to facilitate the mass production of the water receiving tray, the difficulty of assembling and producing the water receiving tray is simplified , there are four water guide plates 2, and the four water guide plates 2 together form a rectangle. Of course, in additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com