Convenient efficient thermos bottle assembling machine

A thermos bottle and convenient technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of high workload of staff and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

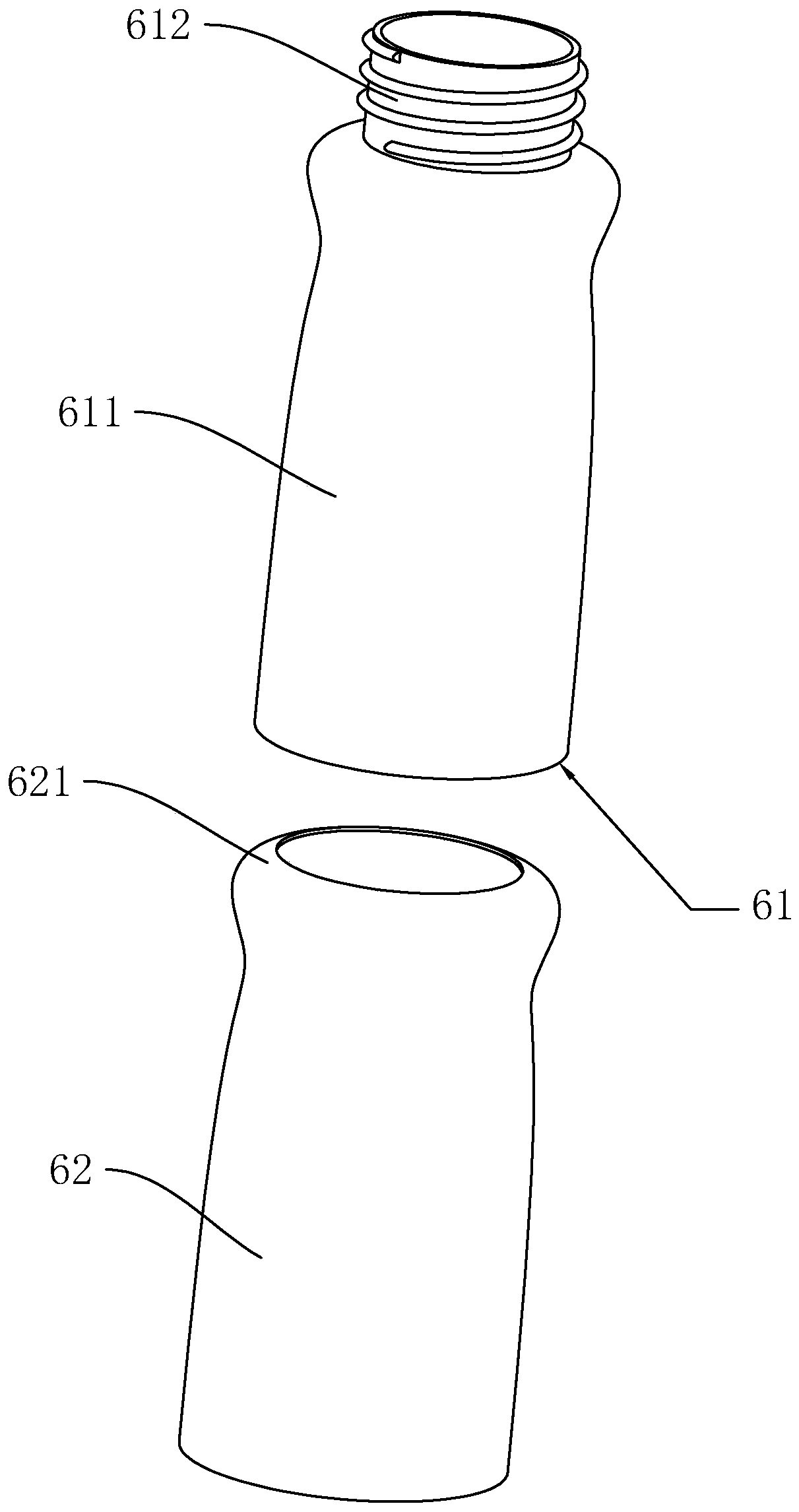

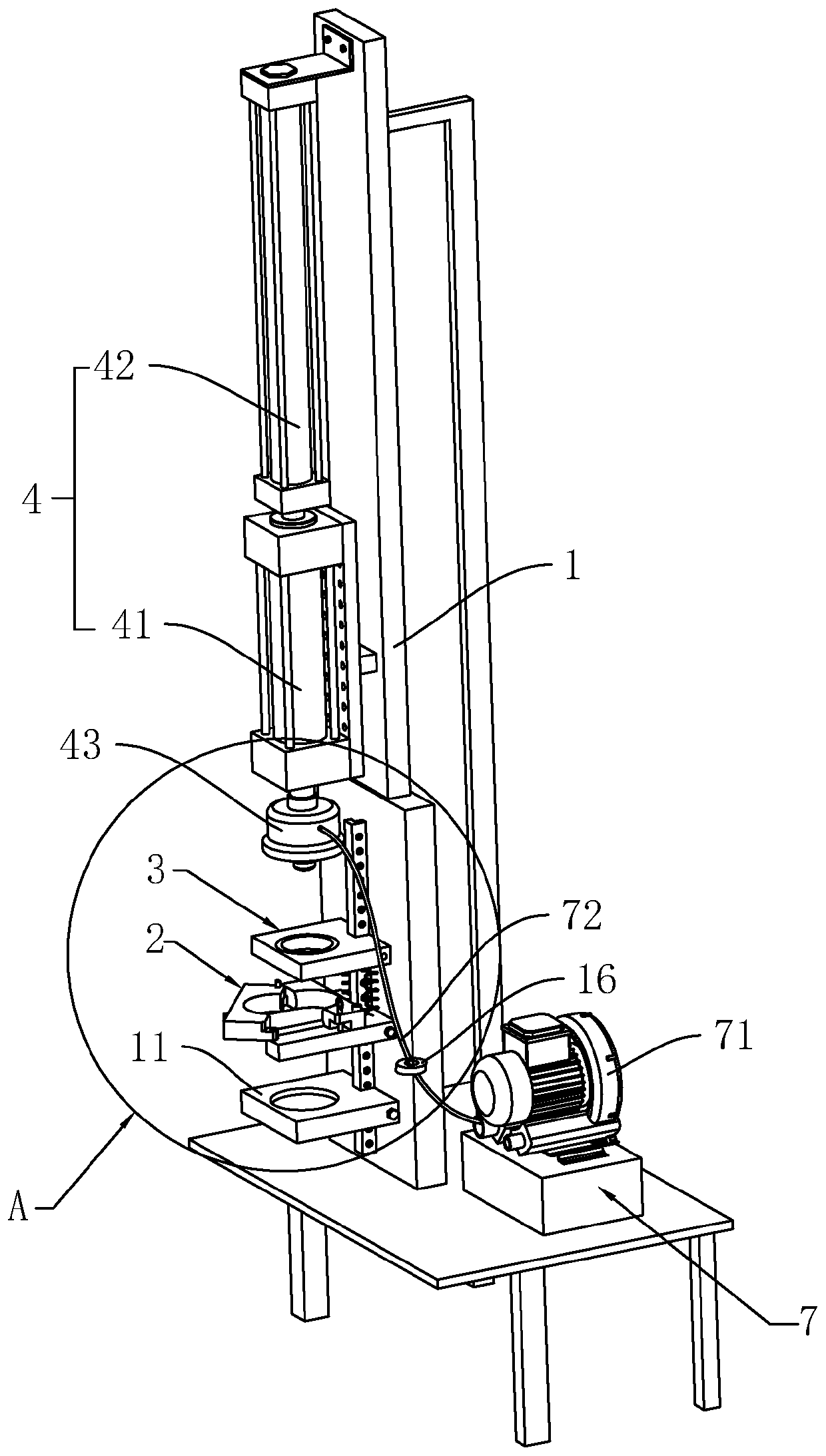

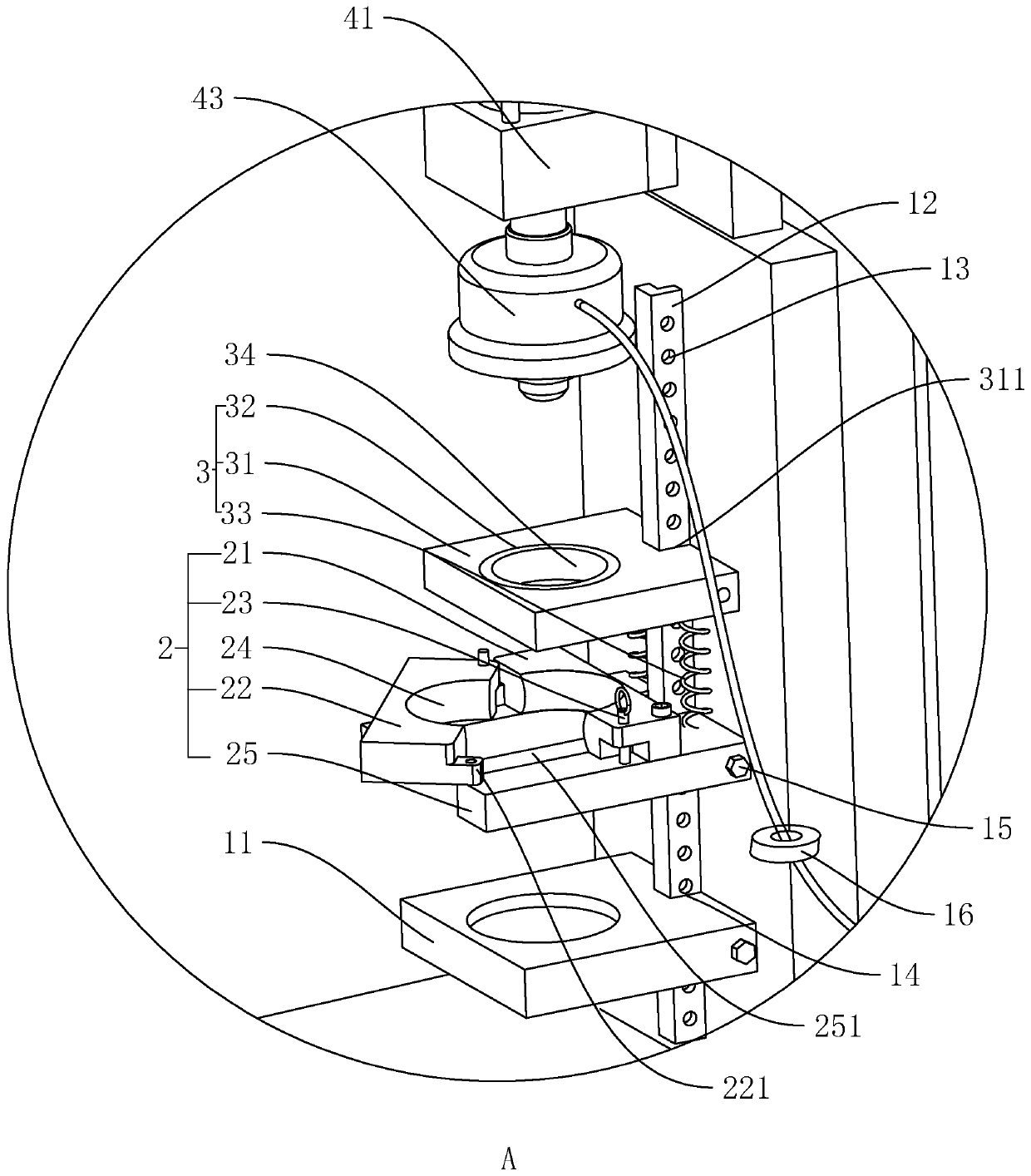

[0042] refer to figure 1 and figure 2 , is a portable high-efficiency thermos bottle assembly machine disclosed in the present invention, including a bracket 1 vertically fixed on the workbench. Enter component 4. When the outer bottle 62 and the inner bottle 61 are assembled, the worker places the outer bottle 62 vertically on the placement plate 11, and the fixing assembly 2 is sleeved on the side wall of the outer bottle 62 and the outer bottle 62 is laterally fixed. The inner bottle 61 is placed vertically on the top of the inner bottle 61 , and the positioning assembly 3 is sleeved on the outside of the inner bottle 61 and fixes the inner bottle 61 laterally. Specifically, after the inner bottle 61 and the outer bottle 62 are fixed, the press assembly 4 pushes down the inner bottle 61, and the inner bottle 61 is made of LDPE material with certain ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com