Adiabatic shearing failure temperature online detection method and system based on infrared thermal imaging

A technology of infrared thermal imaging and detection system, applied in the field of infrared thermal imaging, can solve the problem of not being able to obtain the temperature change history of the adiabatic shear zone, and achieve the effect of improving spatial resolution and temporal resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

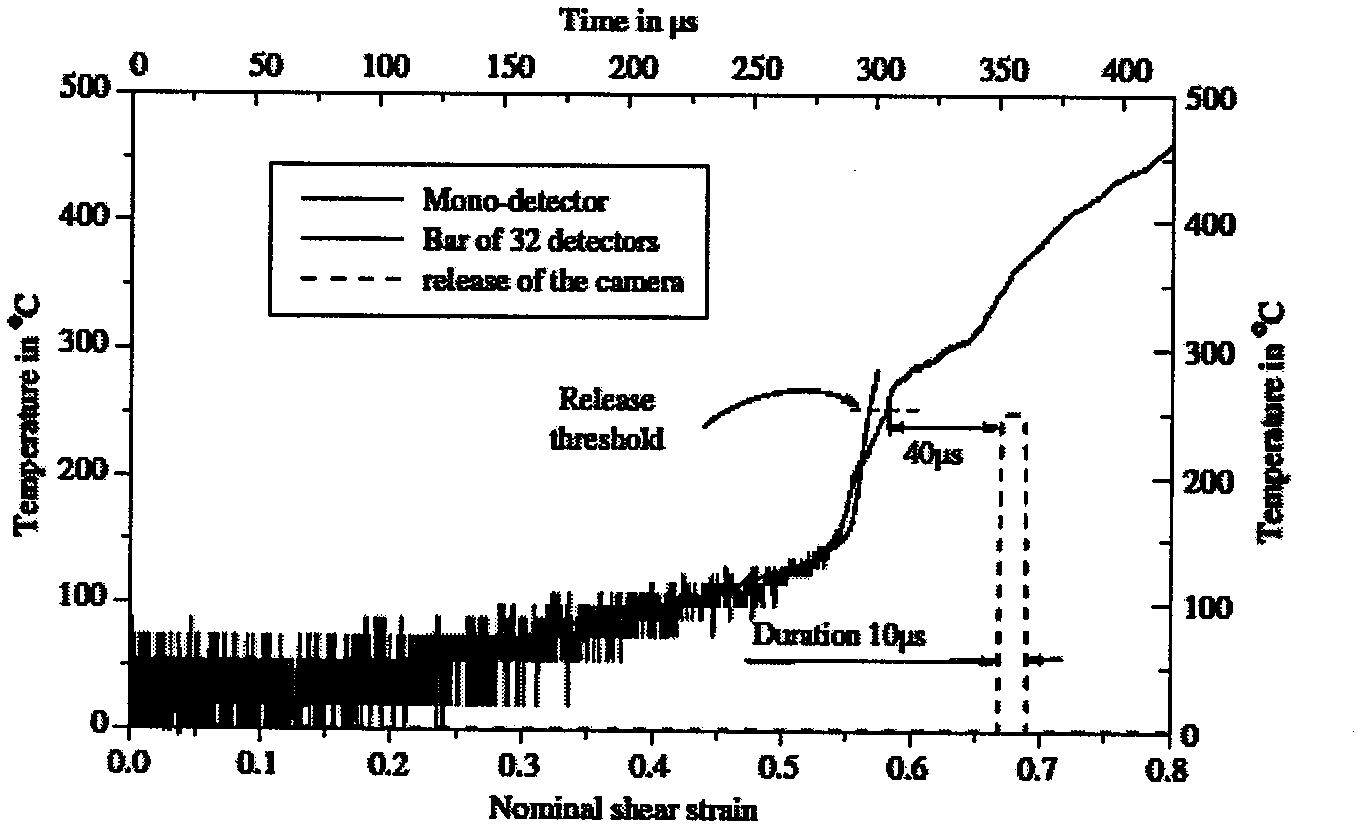

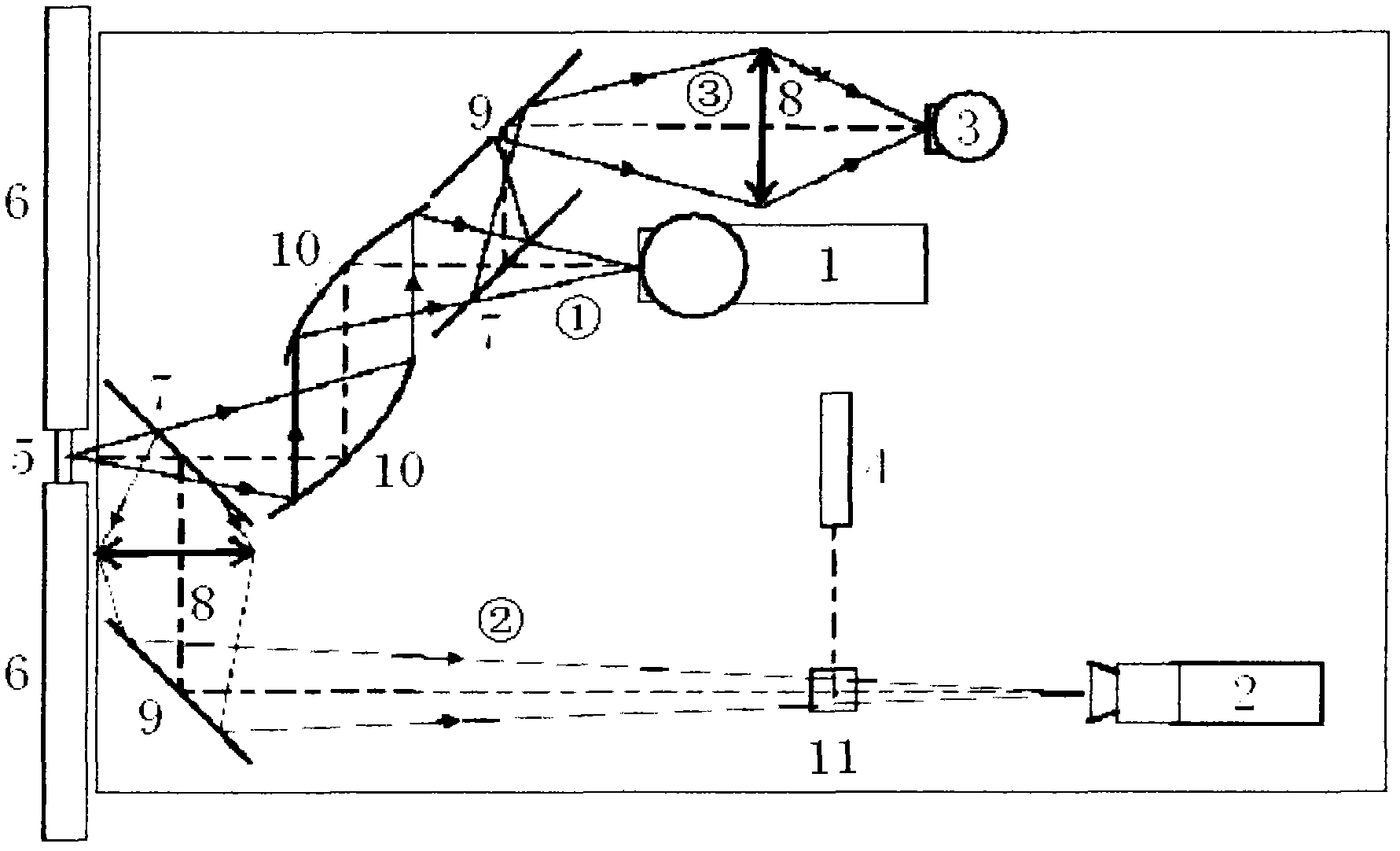

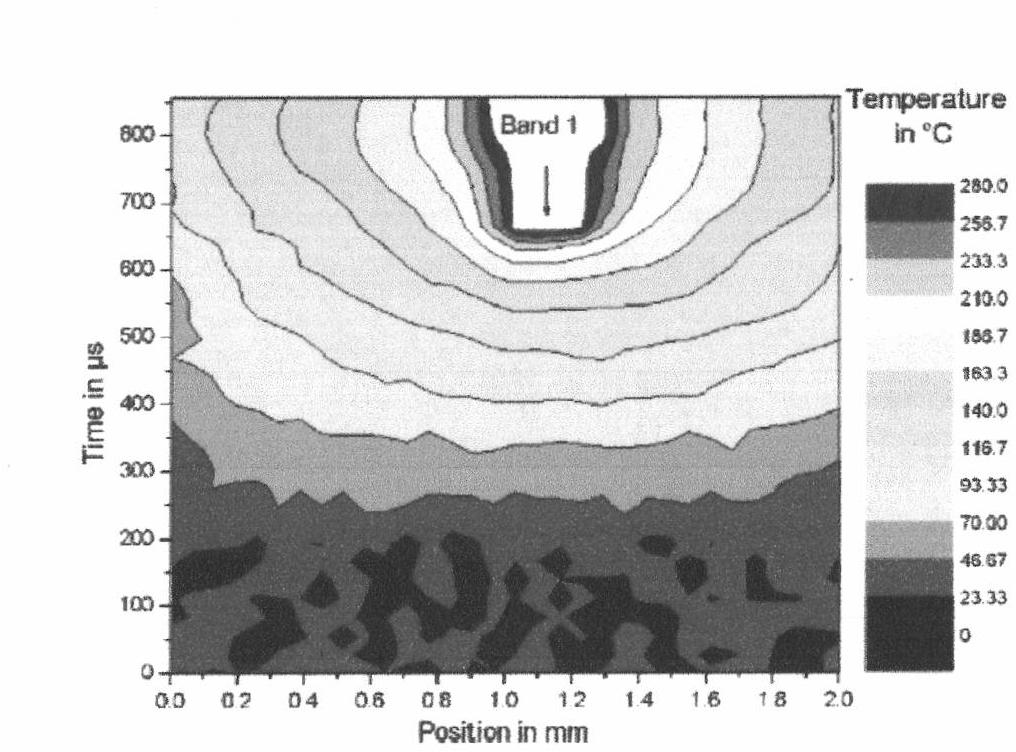

[0022] The present invention mainly solves the technical problem that the resolution of the infrared detector to measure the temperature of the formation and development stages of the adiabatic shear band is not high when metal materials and components are loaded by devices such as drop hammers, air guns, and Hobkinson pressure bars (SHPB). , so a fast-response, high-resolution infrared thermal imaging system is used to measure the temperature field during the development of the adiabatic shear band. Formation, especially in the area of interest, the generation and propagation of the adiabatic shear band is only a few microseconds; the second is that the adiabatic shear band in the material is extremely narrow, with a width ranging f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com