Laser plasma shock wave surface nanocrystallization method for polycrystal metal material

A laser plasma and metal material technology, applied in the field of surface engineering technology and laser processing, can solve the problems of nanotechnology that have not been reported, and achieve the effects of easy control, small deformation of the workpiece, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

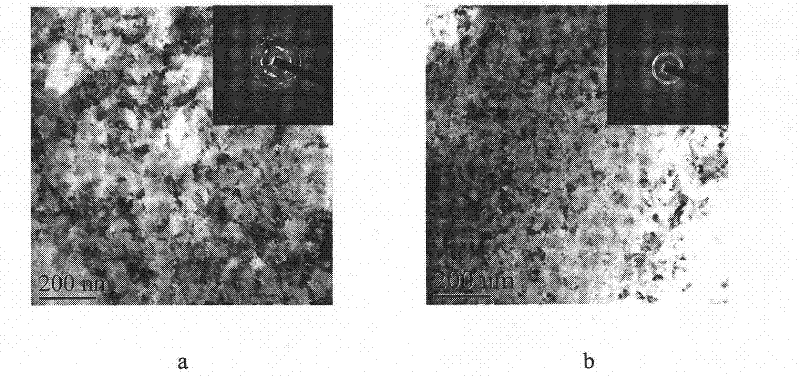

[0031] In this embodiment, a 20 nanosecond laser is used to process the titanium alloy (Ti-6.5Al-3.3Mo-1.5Zr-0.25Si) specimen, and the specific implementation steps are:

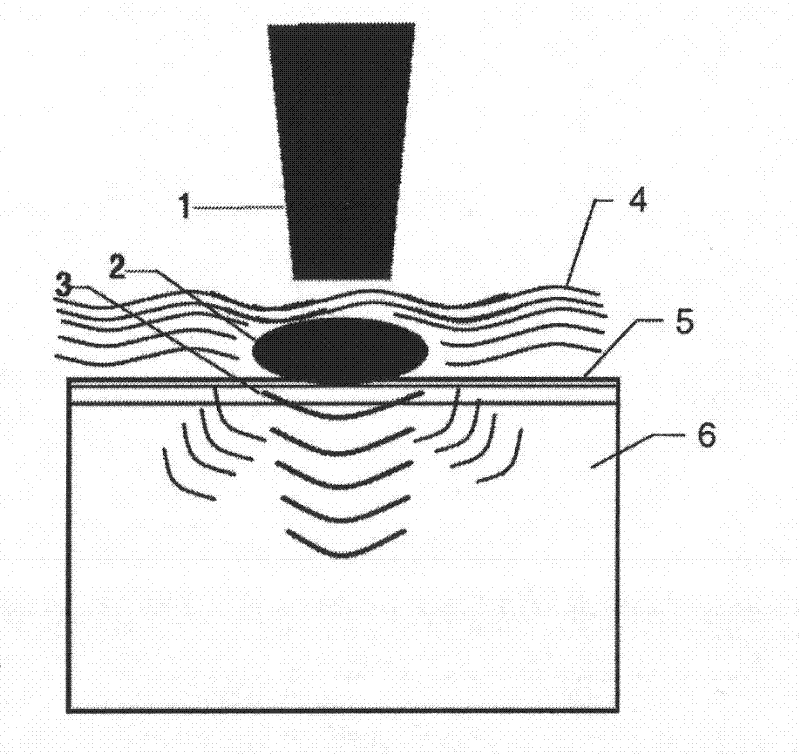

[0032] Step 1: Paste black tape on the surface of the Ti-6.5Al-3.3Mo-1.5Zr-0.25Si titanium alloy specimen to be processed. The thickness of the laser absorption layer is 0.1mm; see figure 1

[0033] Step 2: Using flowing water medium to form a 1mm thick water-constrained layer on the surface of the material to be processed;

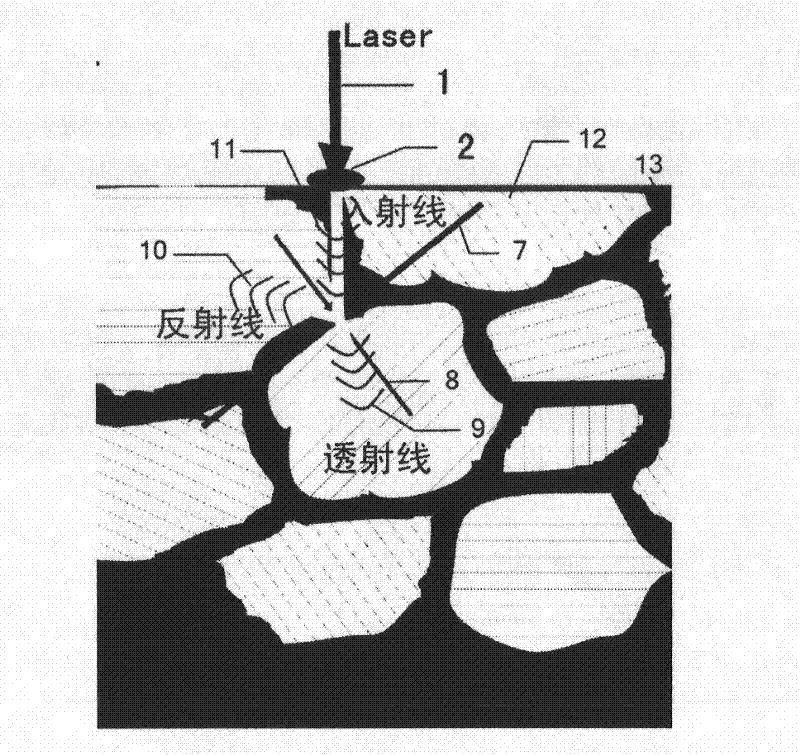

[0034] Step 3: Adjust the incident angle between the laser and the surface of the material to be processed to 0 degrees, and set the laser power density to 2.86GW / cm 2 , select the laser pulse magnitude as 20 nanoseconds;

[0035] Step 4: The laser performs 3 impact treatments on the surface of the material to be processed with a repetition frequency of 10 Hz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com