Austenitic stainless steel sheet and method for producing same

A technology of stainless steel plate and austenitic system, applied in the field of austenitic stainless steel plate and its manufacturing, can solve problems such as cracks and insufficient structural member characteristics, and achieve the effect of improving impact absorption capacity and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] A 17 kg block of stainless steel having the chemical composition shown in Table 1 was melted. In Table 1, steel grades A1 to A25 are chemical composition, (C+3×N) content, Md 30 Values satisfying the scope of the present invention, steel grades B1 to B14 are chemical composition, (C+3×N) amount, Md 30 At least one of the values is outside the range of the present invention. In Table 1, "-" means that it is not expected to be included (the content is less than the desired range or 0).

[0072] [Table 1]

[0073]

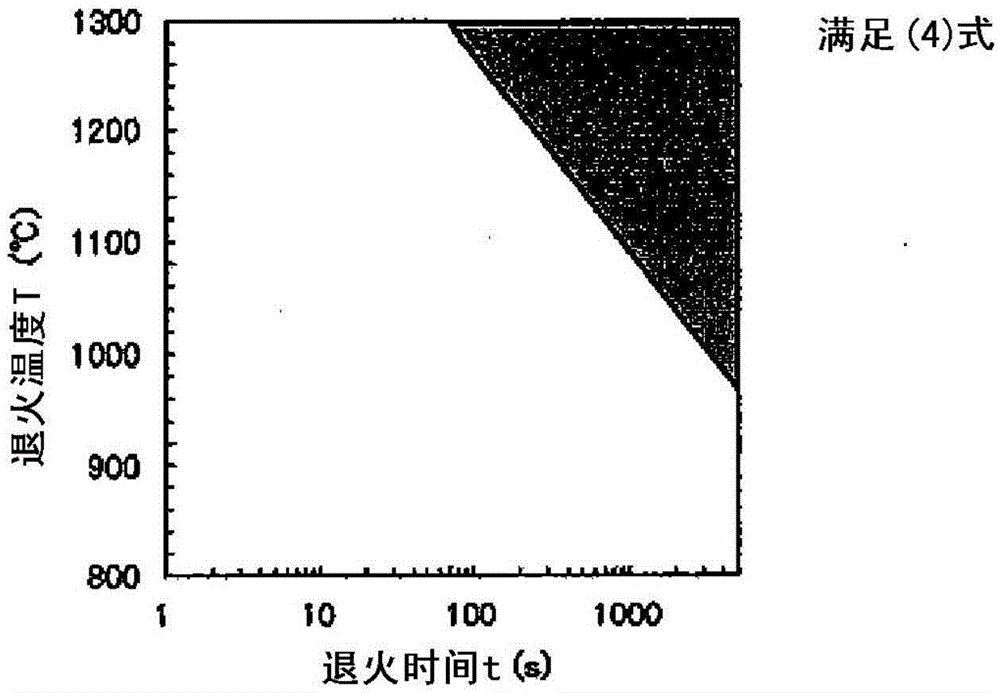

[0074] This stainless steel ingot was cut to form a raw material for hot rolling with a thickness of 45 mm. Thereafter, hot rolling was performed to form a hot-rolled steel sheet with a thickness of 6.0 mm, and then hot-rolled sheet annealing was performed on the hot-rolled steel sheet at the annealing temperature and annealing time shown in Table 2, respectively. The steel sheets 28, 34, 35, 43, and 44 are examples in which the annealing temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com