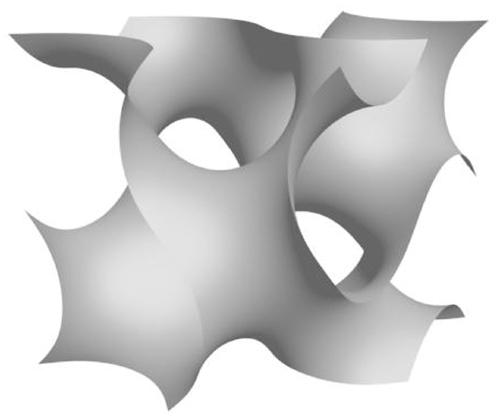

Preparation method of porous alumina ceramics based on Gyroid curved surface

A technology of alumina ceramics and curved surfaces, applied in ceramic products, applications, household appliances, etc., can solve the problems of difficult control of pore structure and pore size, difficulty in ensuring the mechanical properties of finished products, and unstable pore structure molding. The effect of more diverse applications, spatial arrangement, and better connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

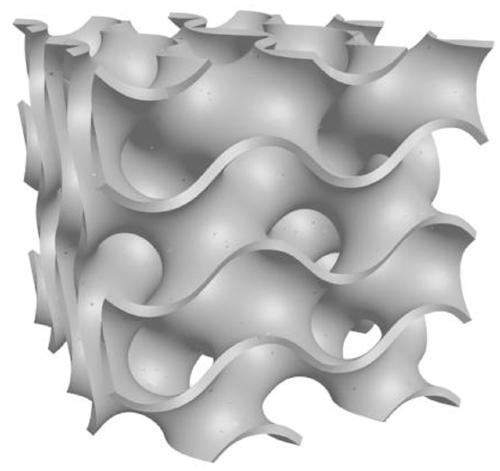

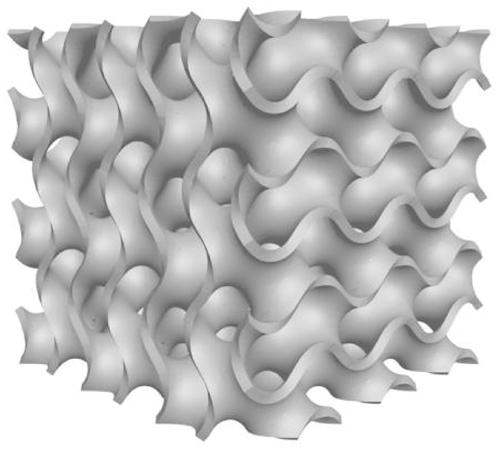

[0017] (1) Preparation of the PLA skeleton: use the fused deposition 3D printer to directly print the reverse three-dimensional structure of the Gyroid surface of the designed PLA material, with a layer thickness of 0.1mm, a cube with a side length of 4cm, a period parameter of 2, and a surface thickness 1mm.

[0018] (2) Preparation of ceramic slurry: Al 2 o 3 powder, CaO powder, MgO powder, SiO 2 Powder and TiO 2 The powder is weighed and mixed according to the ratio of 93.5:0.3:0.09:0.21:0.5. After ball milling for 4 hours, sieve to obtain ceramic powder with a particle size of ≤1 μm;

[0019] (3) Preparation of ceramic slurry: Pour the ceramic powder described in step (2) into deionized water, and the mass ratio of powder to deionized water is 1:1. Put it in a drum-type ball mill for mixing for 2 hours, the rotation speed is 100r / min, and finally add a dispersant of 1wt% gum arabic, stir, and obtain alumina ceramic slurry after aging for 24 hours;

[0020] (4) Prepara...

Embodiment 2

[0023] (1) Preparation of the PLA skeleton: Use the fused deposition 3D printer to directly print the reverse three-dimensional structure of the Gyroid surface of the designed PLA material, with a layer thickness of 0.1mm, a cube with a side length of 4cm, a period parameter of 3, and a surface thickness 1mm.

[0024] (2) Preparation of ceramic slurry: Al 2 o 3 powder, CaO powder, MgO powder, SiO 2 Powder and TiO 2 The powder is weighed and mixed according to the ratio of 93.5:0.3:0.09:0.21:0.5. After ball milling for 4 hours, sieve to obtain ceramic powder with a particle size of ≤1 μm;

[0025] (3) Preparation of ceramic slurry: Pour the ceramic powder described in step (2) into deionized water, and the mass ratio of powder to deionized water is 1:1. Put it in a drum-type ball mill for mixing for 2 hours, the rotation speed is 100r / min, and finally add a dispersant of 1wt% gum arabic, stir, and obtain alumina ceramic slurry after aging for 24 hours;

[0026] (4) Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com