Bionic abrasion-resistant high-reliability guide rail of cast iron rolling machine tool and manufacturing method of bionic abrasion-resistant high-reliability guide rail

A reliability and guide rail technology, applied in the direction of manufacturing tools, metal processing machinery parts, coatings, etc., can solve the problems of complex rolling guide production process, poor reliability, production cost affecting work efficiency, etc., to achieve uniform force and failure rate. The effect of reducing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

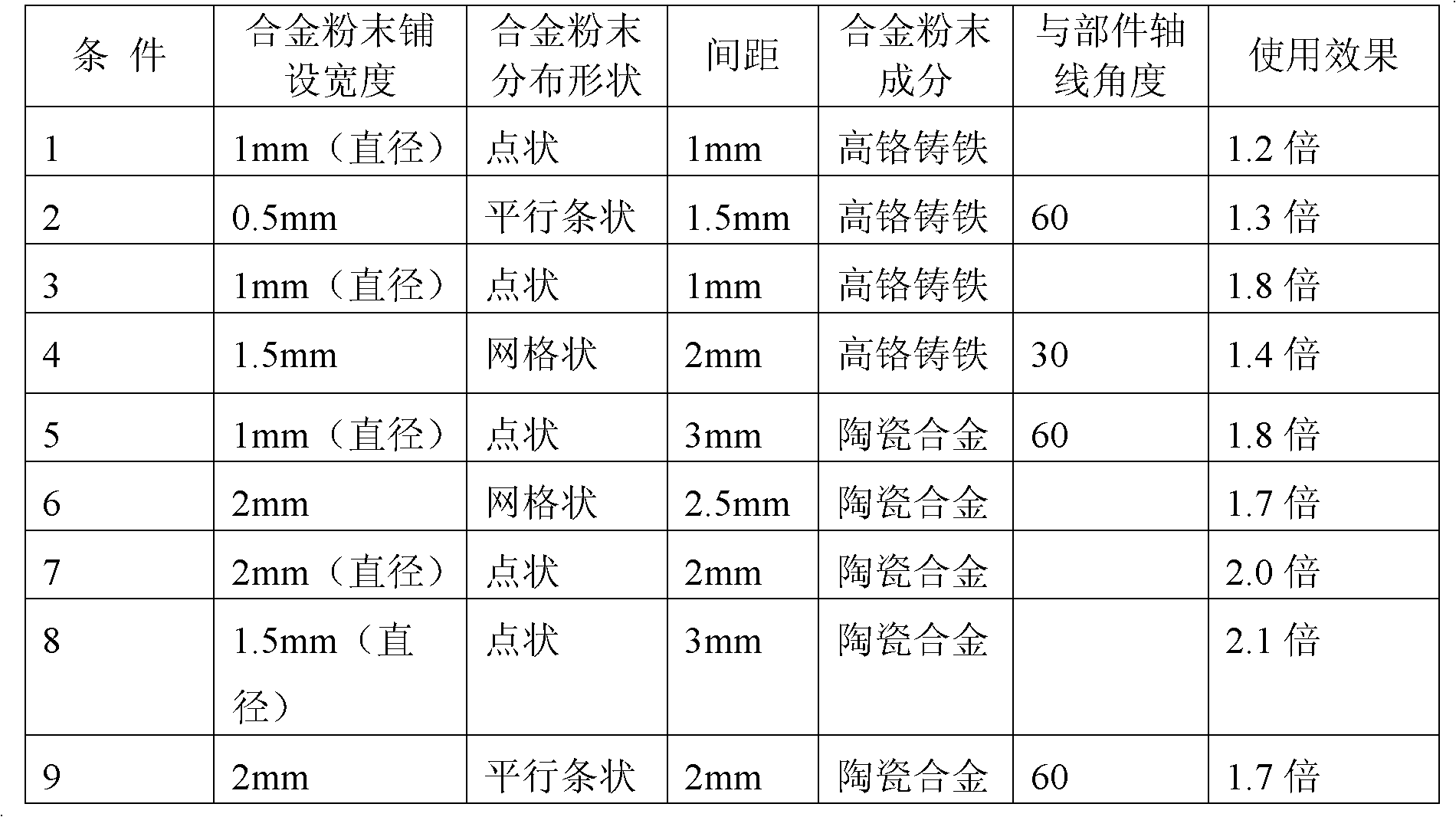

[0019] Below in conjunction with example further illustrate the specific content of the present invention.

[0020] After hundreds of millions of years of evolution, organisms are not only able to adapt to nature, but also their evolution is close to perfection. Some of their wonderful functions far exceed the previous designs of human beings themselves, and gradually become the answer to difficult engineering problems. The present invention finds that they have the following characteristics by observing the organisms with excellent resistance to fatigue and wear in nature:

[0021] 1. They all have a soft and hard structure;

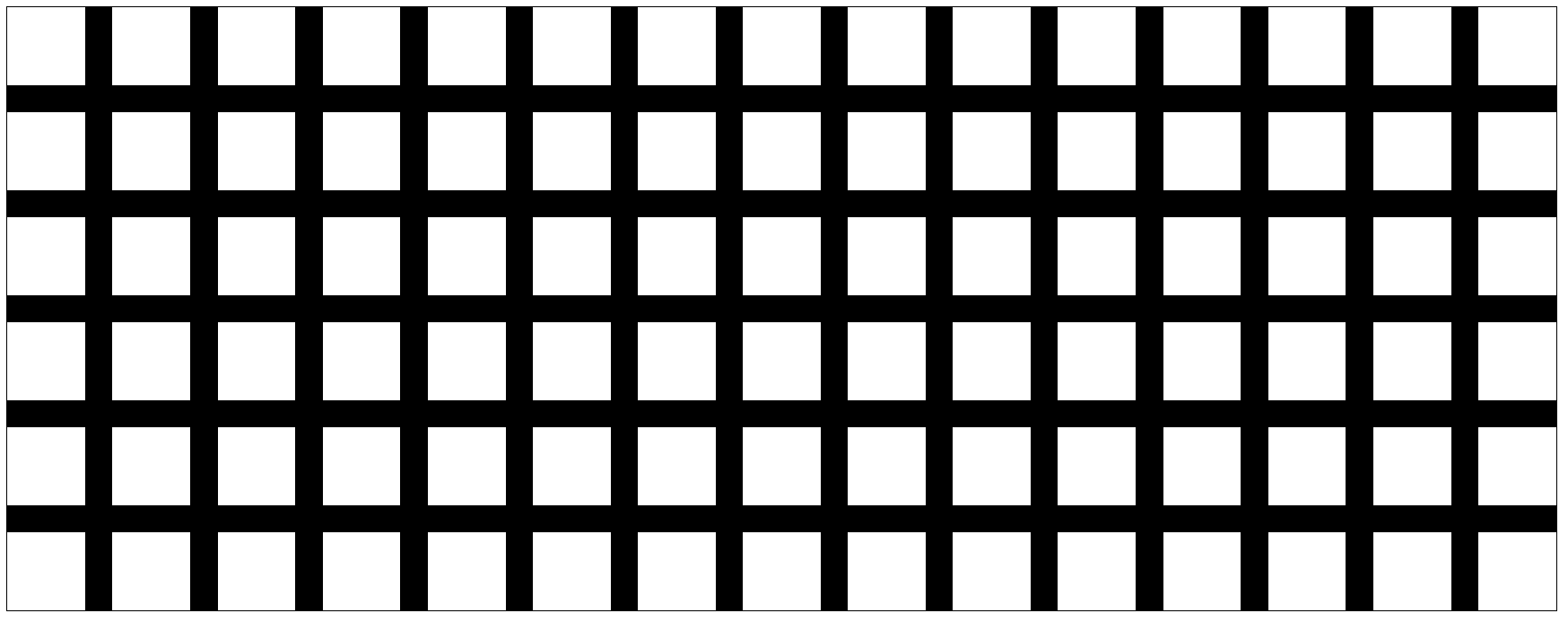

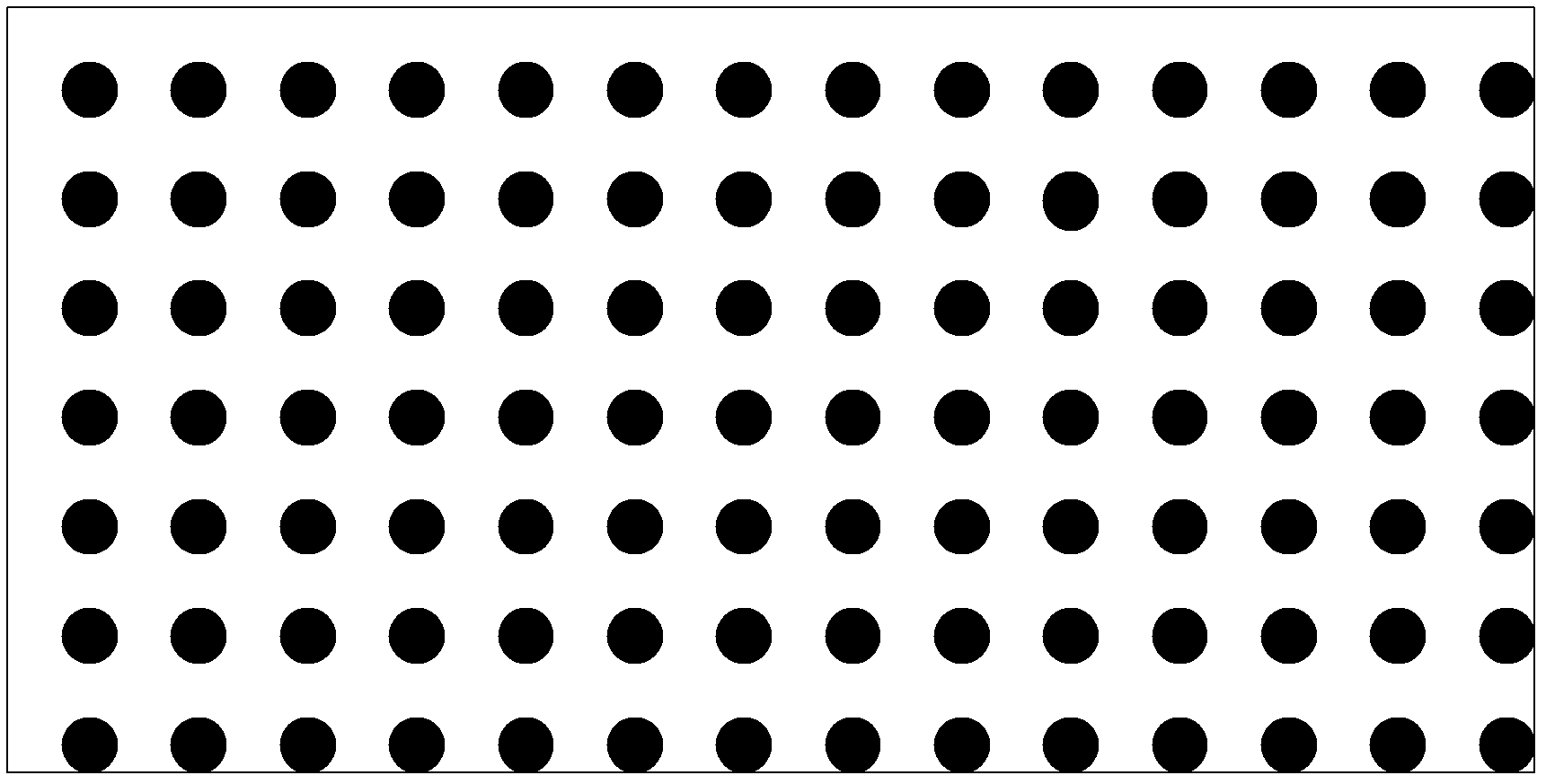

[0022] 2. The hard elements in the structure can have different distribution patterns;

[0023] 3. The relatively high hardness of the hard unit comes from the difference in the composition material or tissue structure of the hard unit and the soft unit. This organic coupling of morphology, structure, and constituent materials endows organisms with ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com