All-bearing car body structure of new-energy urban bus

A full-load, new energy technology, applied in the direction of load-bearing body structure, passenger car superstructure, superstructure, etc., can solve the problem of poor local structure transmission effect, lack of closed force ring design for support column assembly, and reduce the overall body structure. Bearing uniformity and other issues to achieve the effect of avoiding compression, avoiding damage, and optimizing the interior of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

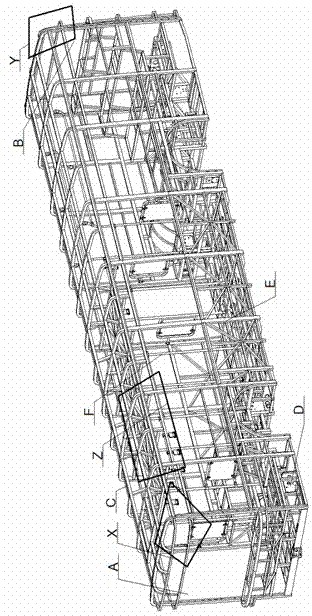

[0076] A full load-bearing body structure of a new energy bus, including a front wall assembly A, a rear wall assembly B, a top cover assembly C, an underframe assembly D, two side wall assemblies E and a support column assembly F , the two ends of the top cover assembly C are respectively connected with the upper ends of the front wall assembly A and the rear wall assembly B, and the lower ends of the front wall assembly A and the rear wall assembly B are respectively connected with the bottom frame assembly D The two ends are connected, the bottom frame assembly D is connected with the top cover assembly C through the side wall assembly E, and the upper and lower ends of the support column assembly F are respectively connected with the top cover assembly C and the bottom frame assembly D;

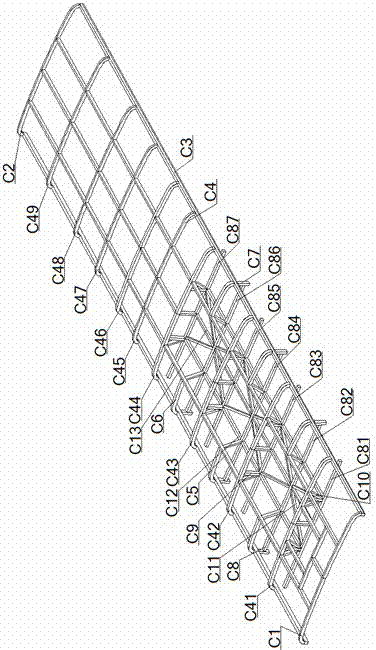

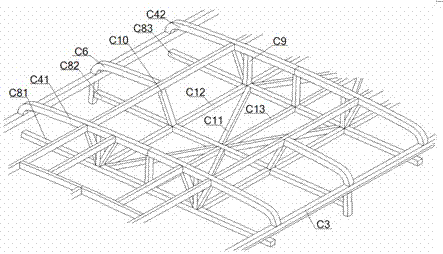

[0077] The top cover assembly C includes: a front curved beam C1, a rear curved beam C2 parallel to each other and two side window upper beams C3 arranged between them; the side window upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com