I-beam type vehicle dynamic weighing sensor

A dynamic weighing and sensor technology, applied in the field of sensors, can solve the problems of low accuracy and long-term service life, and achieve the effects of uniform force distribution, prolonging service life, and improving long-term insulation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

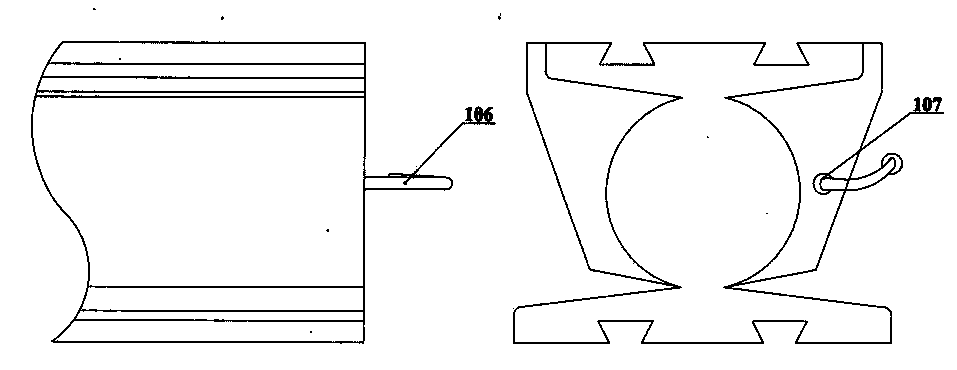

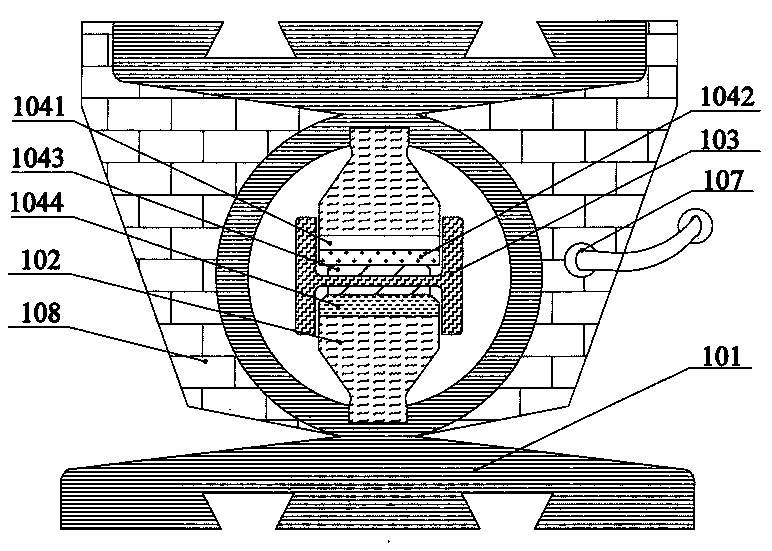

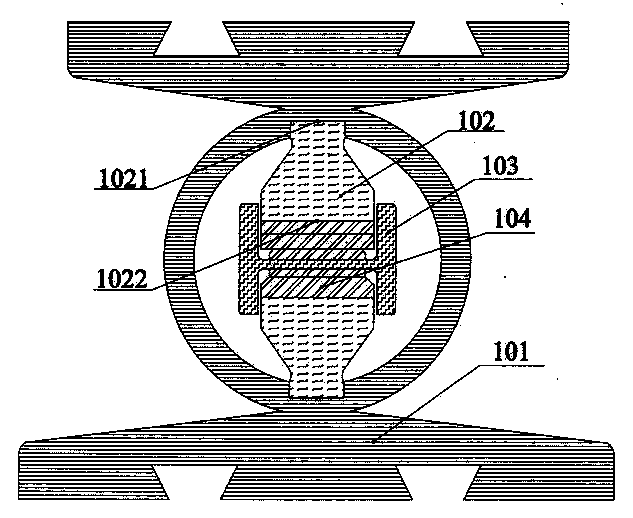

[0025] refer to figure 1 , the I-beam type vehicle dynamic load cell listed in this embodiment includes an I-beam type elastic body 101 , a measuring unit 104 , a force transmission block 102 and an insulating protective cover 103 . There is a cavity through the I-beam type elastic body, and a measuring unit 104 and a force transmission block 102 are arranged in the cavity, and the measurement unit 104 can be received between the force transmission blocks 102 and is in a pre-tightened state. In this way, the force distribution of the measuring unit 104 is made uniform, so that the weighing result is more accurate. The measurement unit 104 includes an upper electrode 1042 , a piezoelectric material 1043 and a lower electrode 1044 sequentially from top to bottom. In addition, the transverse surface of the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com