Double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism

A precise adjustment, dual-flexibility technology, applied in optomechanical equipment, photo-engraving process of pattern surface, optics, etc., can solve problems such as installation space limitation, and achieve the effect of ensuring reliability, reducing input current and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

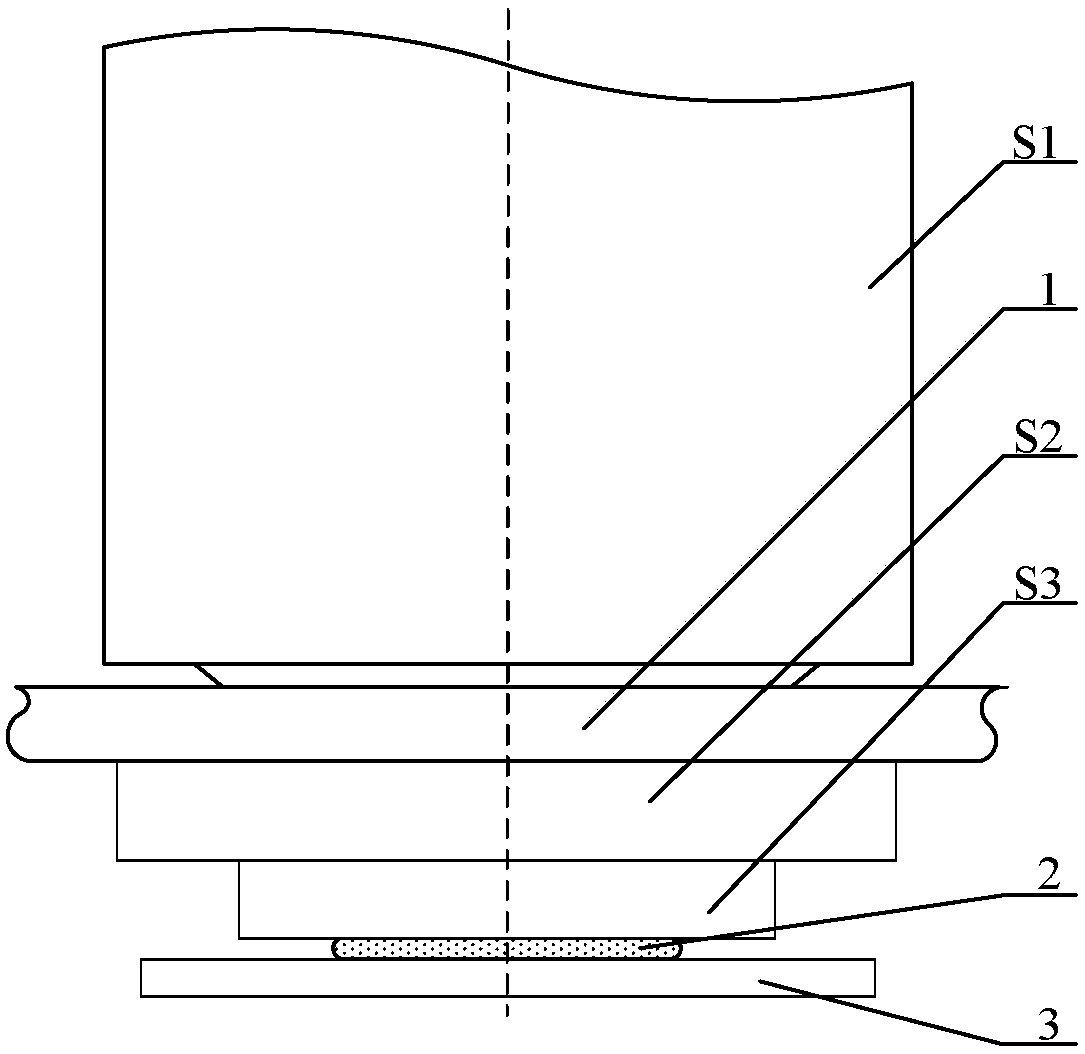

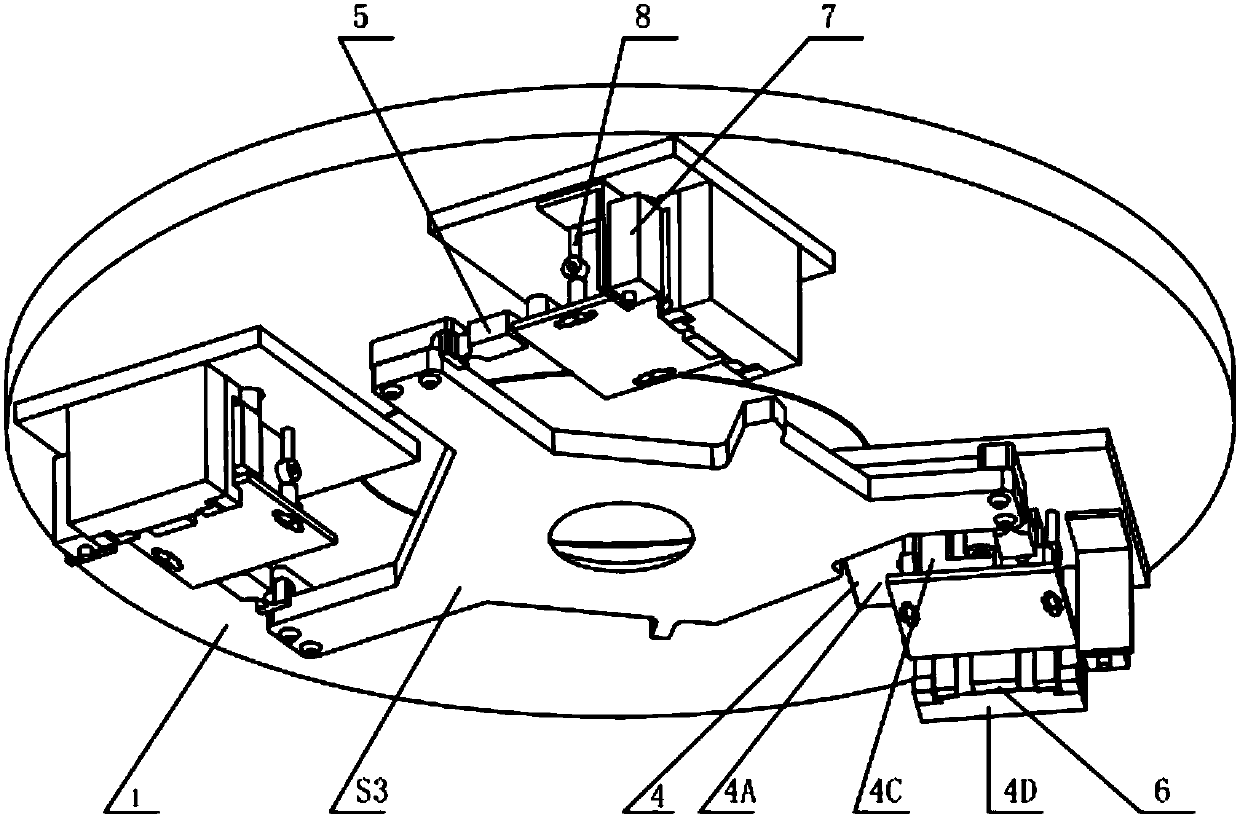

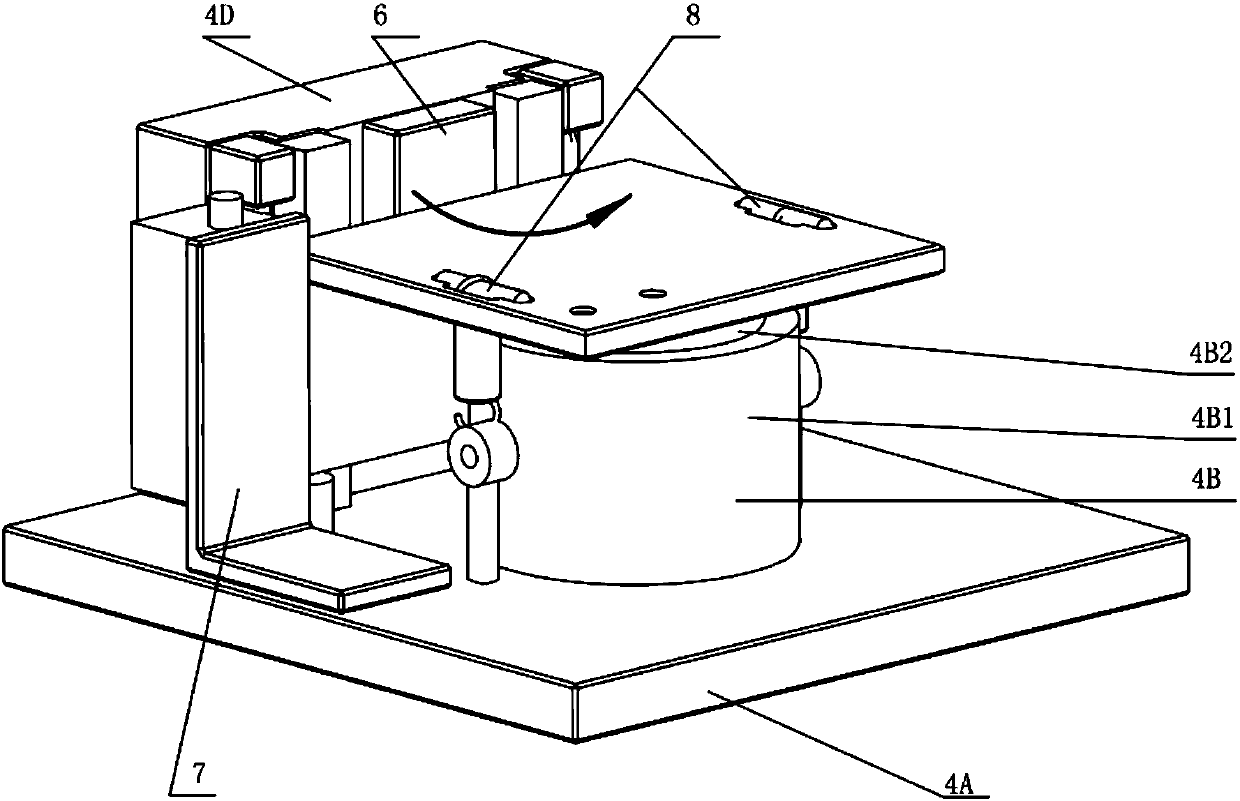

[0028] Such as figure 1 As shown, a three-degree-of-freedom precision adjustment parallel mechanism S2 based on double flexible pairs is installed between the main frame 1 of the immersion lithography machine and the immersion unit S3, and the optical system S1 of the immersion lithography machine runs through the main body of the immersion lithography machine. The frame 1, the three-degree-of-freedom precision adjustment parallel mechanism S2 based on the double flexible pair, and the immersion unit S3 expose the silicon wafer 3 at the bottom through the immersion flow field 2 . The main frame 1 of the immersion lithography machine and the immersion unit S3 pass through such as figure 2 The three groups of kinematic branch chains with the same structure are connected in parallel. The three groups of kinematic branch chains are unevenly distributed aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com