Patents

Literature

33results about How to "Consistent design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

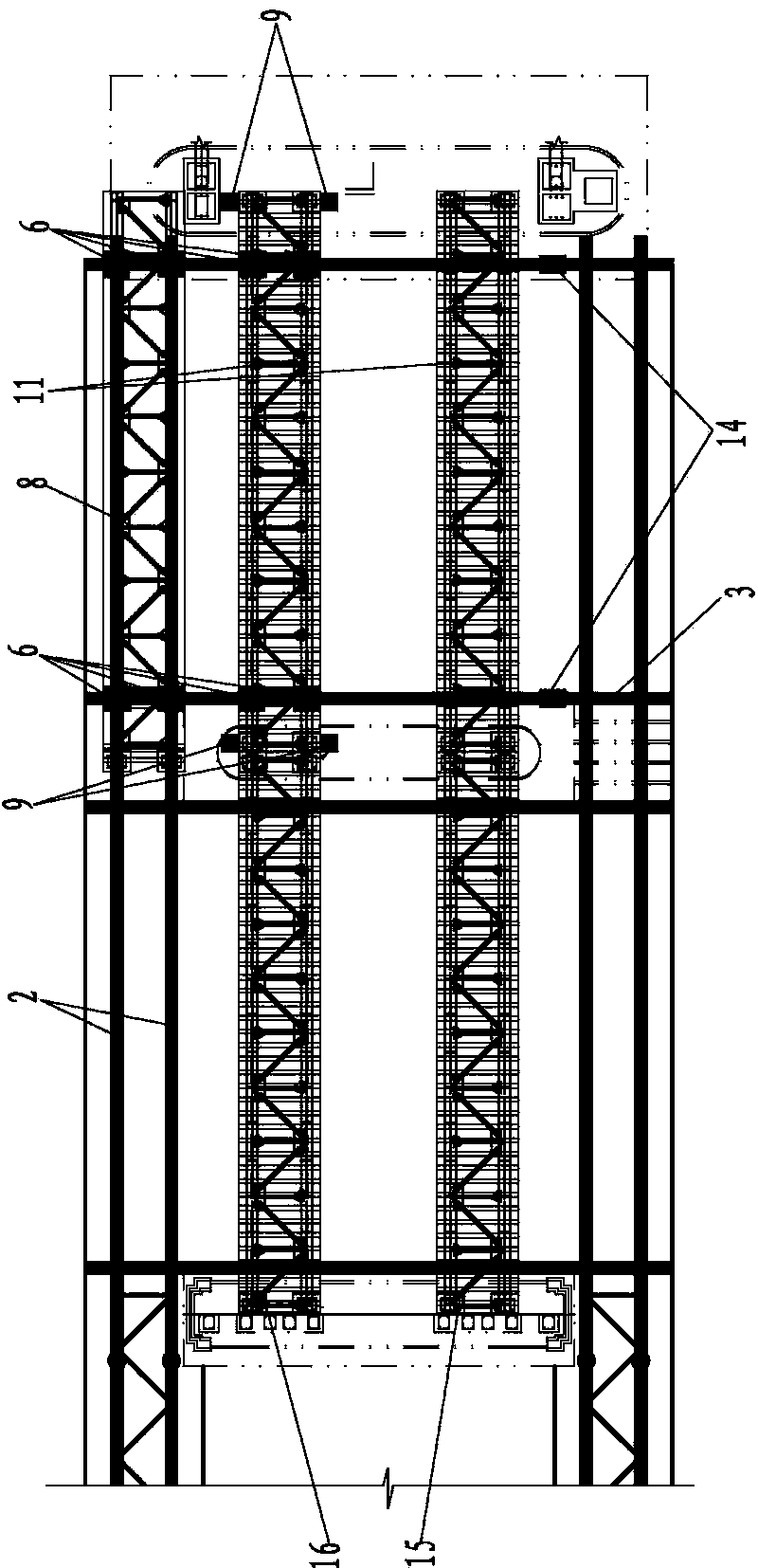

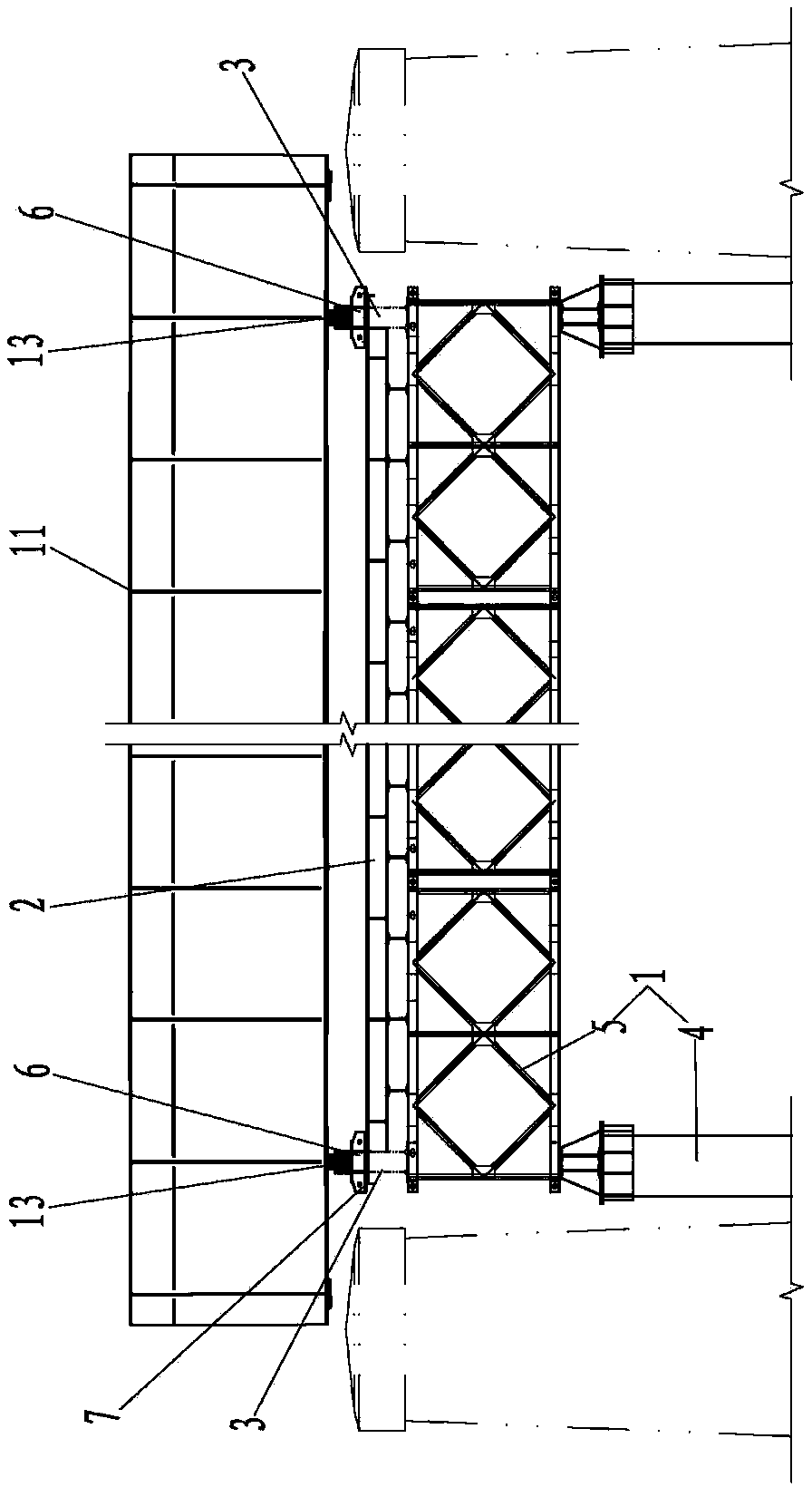

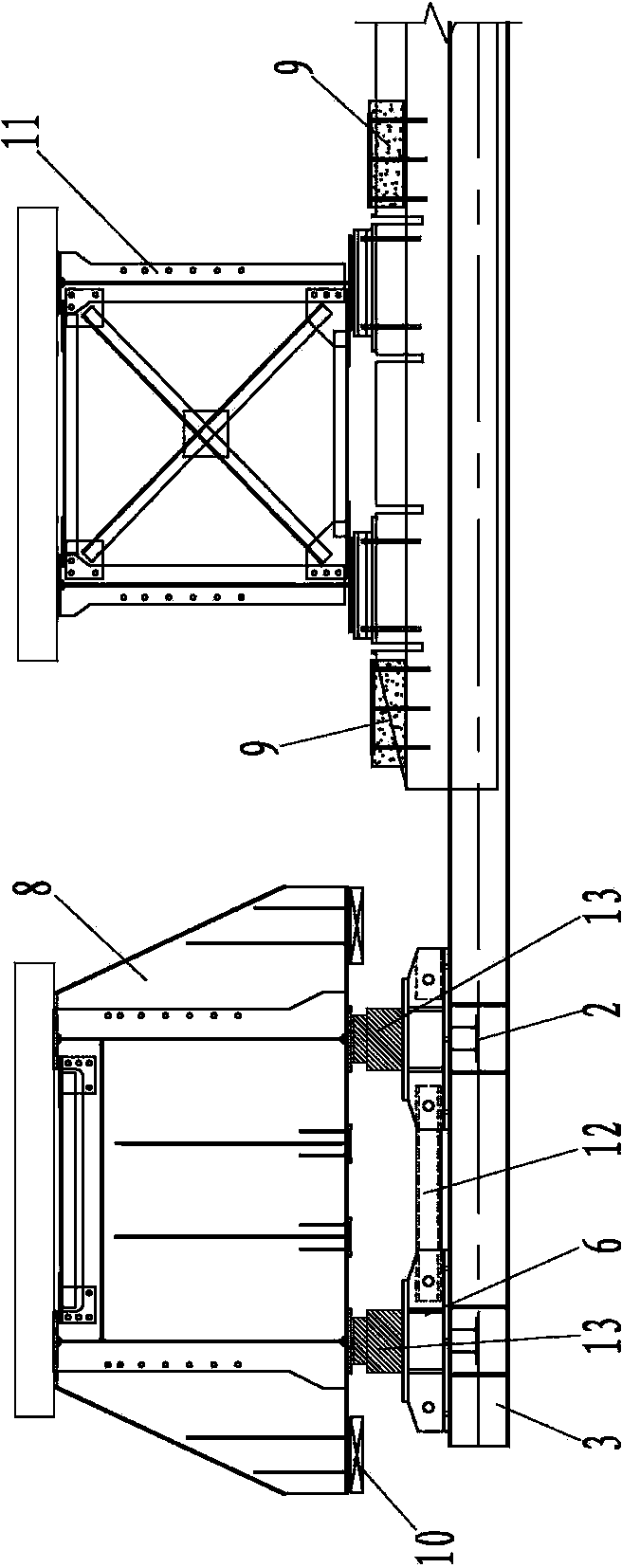

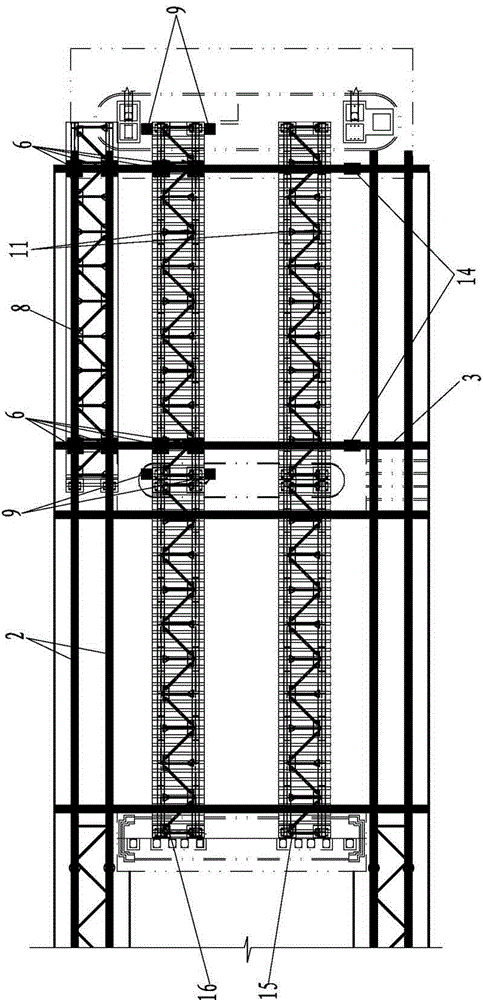

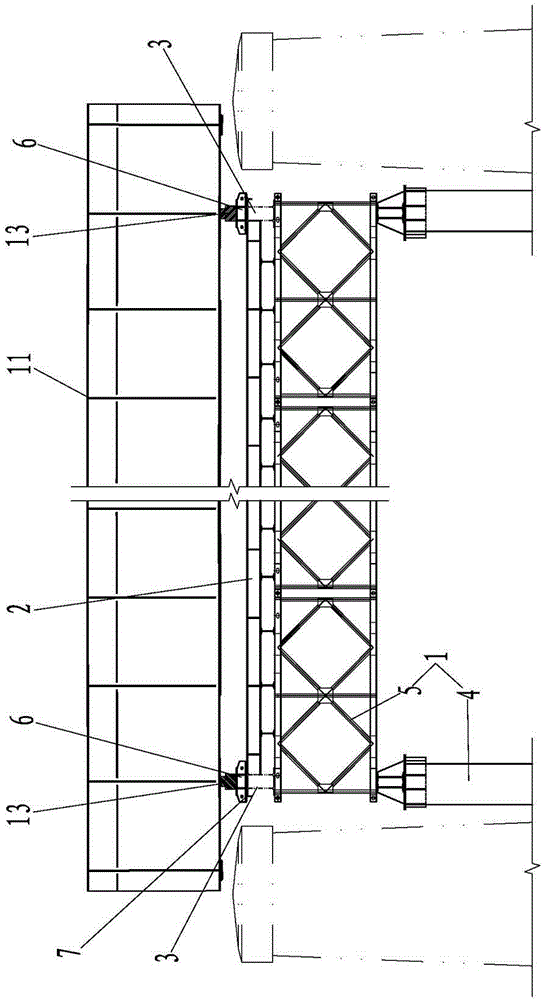

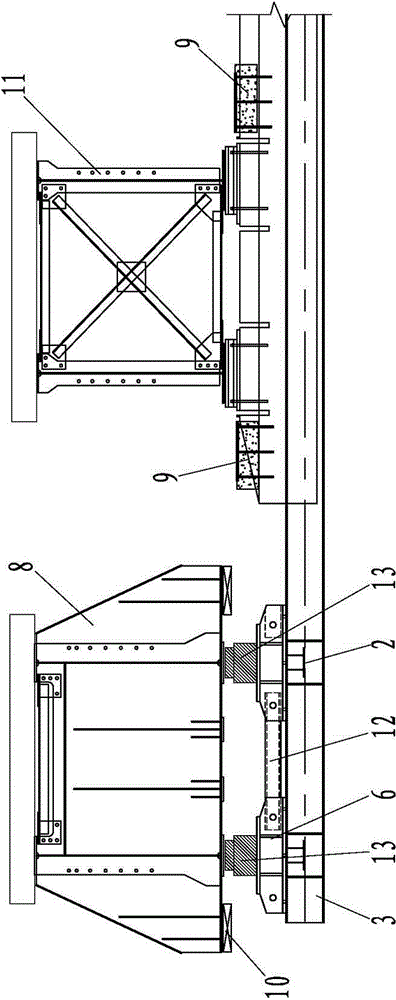

Quick-beam change construction method for existing railway line of railroad

ActiveCN103410103AReduced impact on normal operationsNormal operation impact is minimizedBridge erection/assemblyBridge strengtheningEngineeringCushion

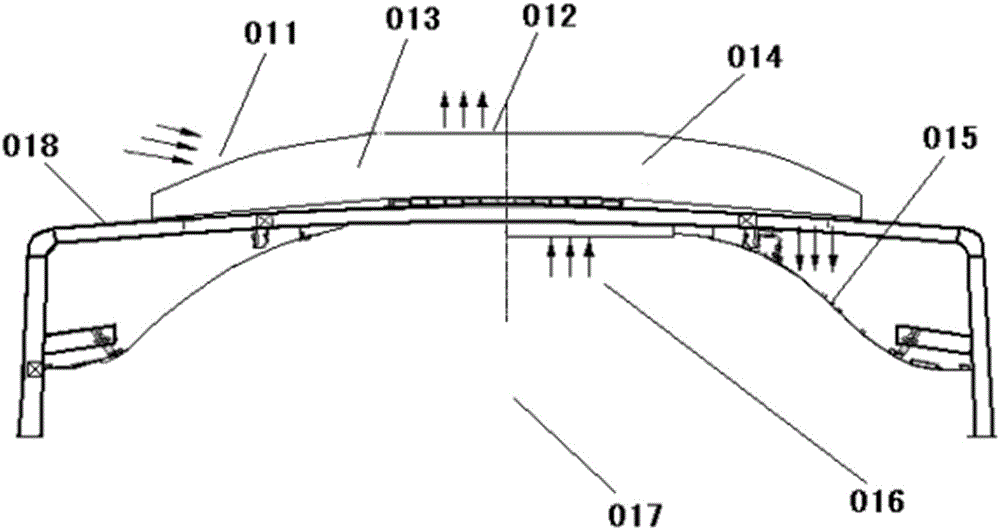

The invention discloses a quick-beam change construction method for an existing railway line of a railroad. The method comprises the following steps: first building a beam change construction bracket platform at the original place below an old beam, and then arranging a slideway system on the bracket platform; then, mounting a temporary support cushion on the outer side of an old beam support; afterwards, removing barriers for beam moving, and moving the new beam onto the slideway system outside the old beam; mounting a temporary support at the bottom of the new beam; lifting a seamless long steel rail in a blocking point, synchronously and transversally moving the new and the old beam so as to move the new beam to the original place of the old beam, fixing the temporary support on the temporary support cushion, and placing the seamless long steel rail down on the new beam for fastening, so as to restore traffic; finally, after the mounting of a permanent support, dismantling the temporary support at the skylight point, so as to allow the permanent support to be stressed. The method can realize the beam change of the existing railway line of the railroad, ensures beam change construction safety, is short in key point time, reduces the influence on the normal operation of the railroad to the utmost, and feasibly and effectively reduces the construction risk.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU

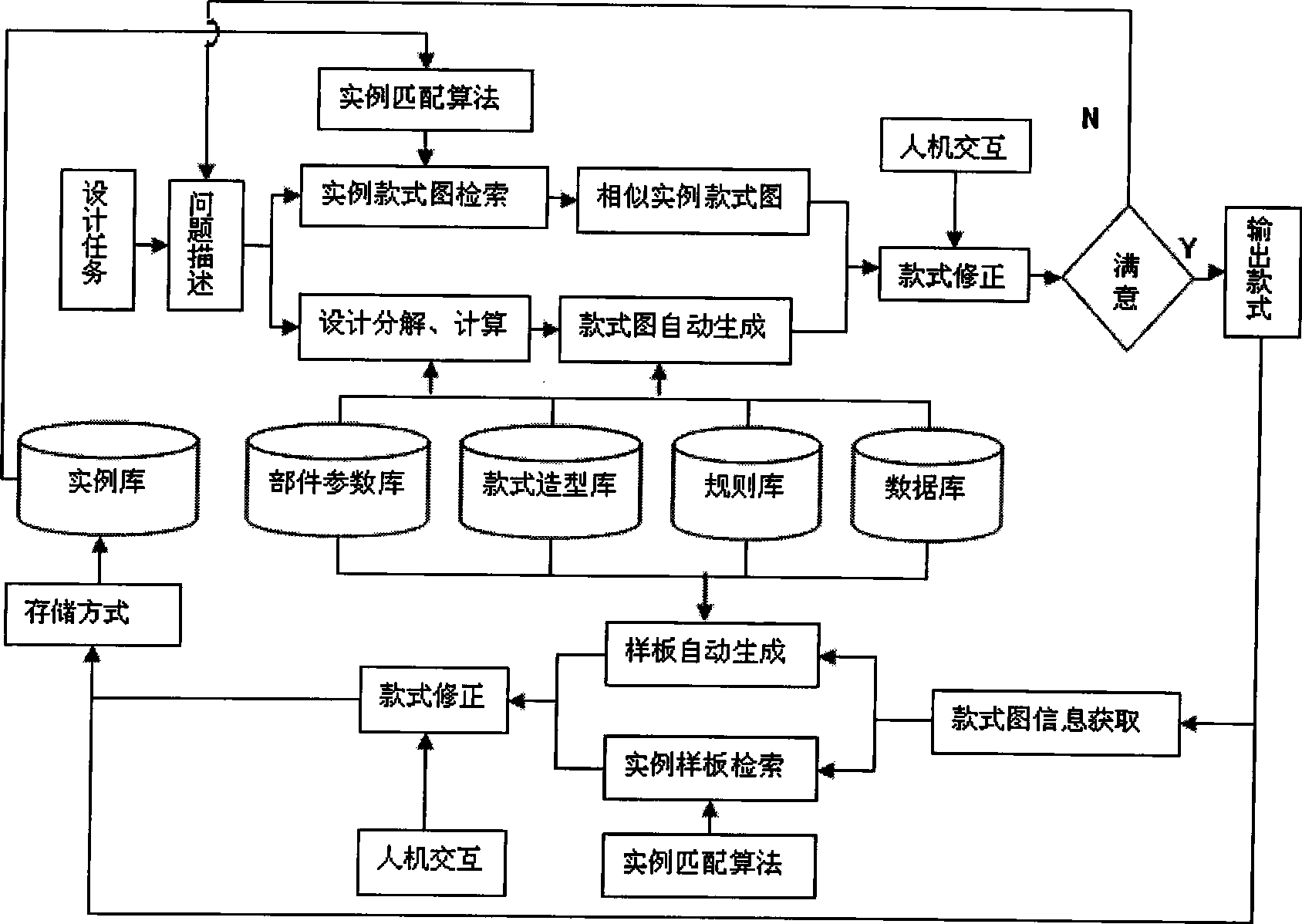

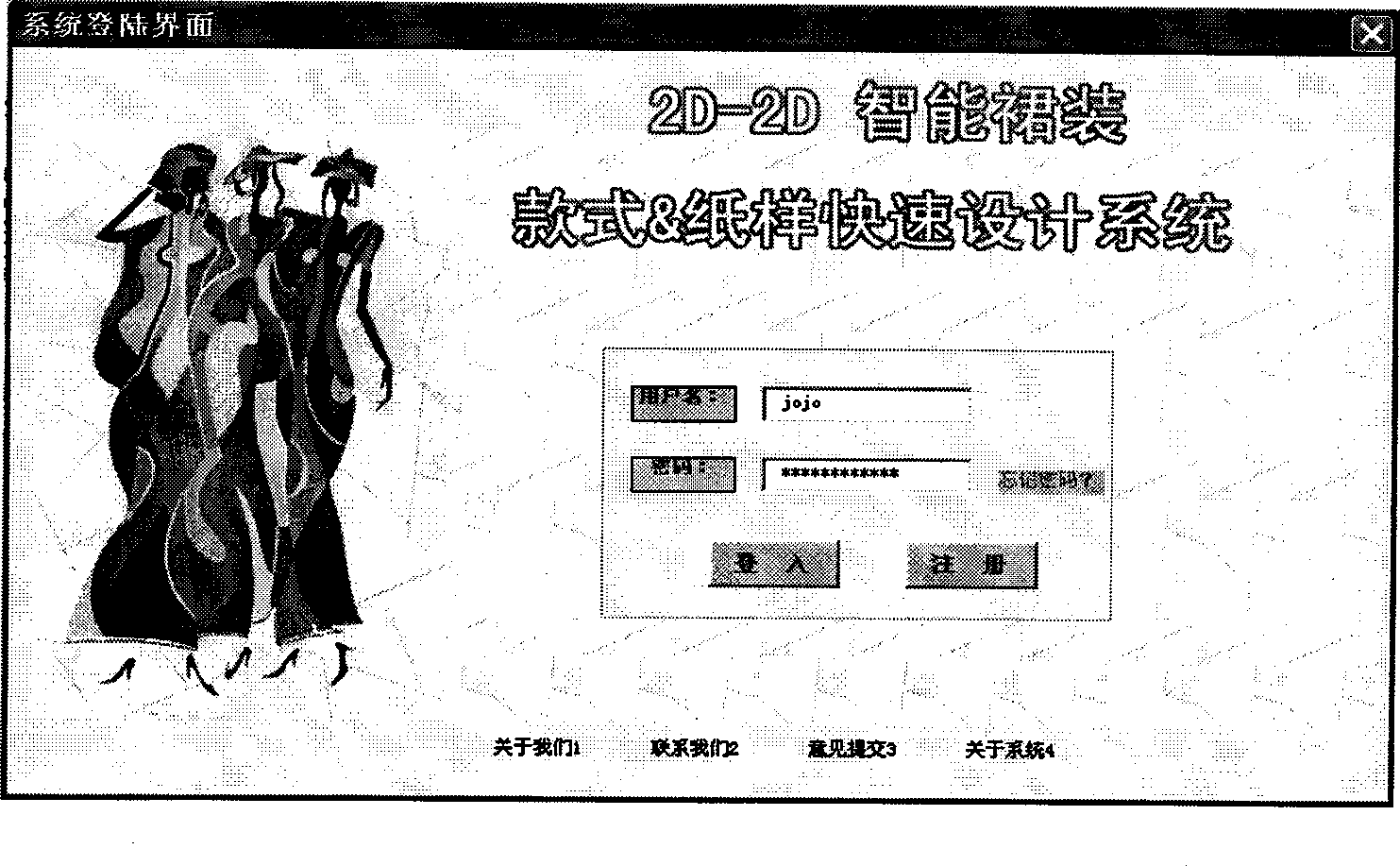

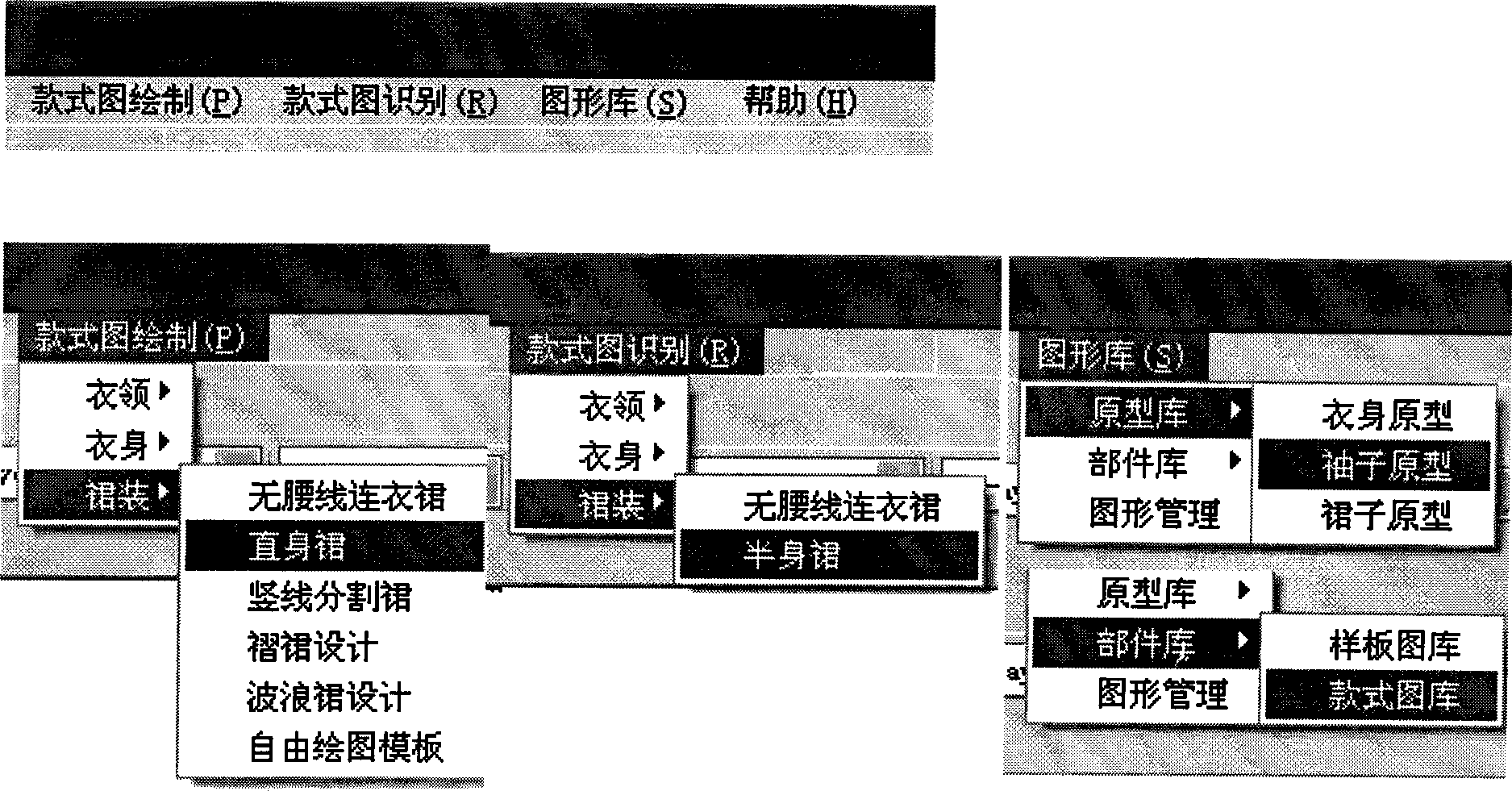

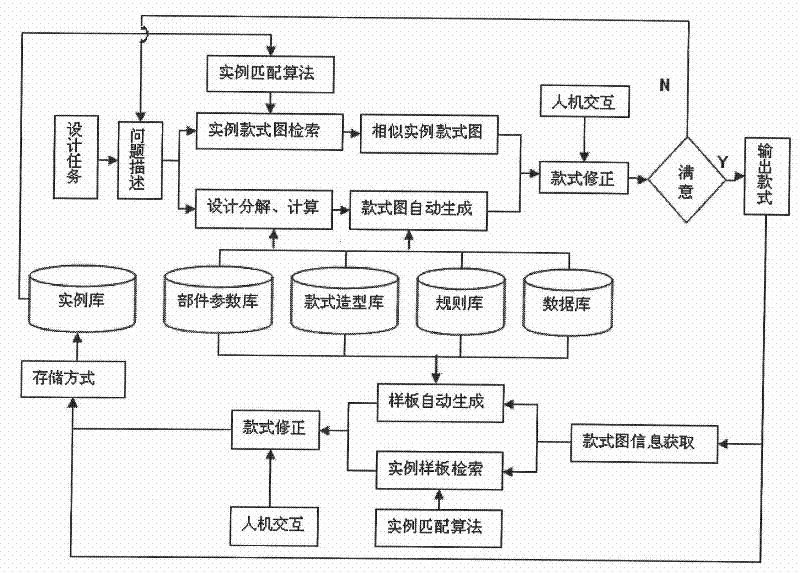

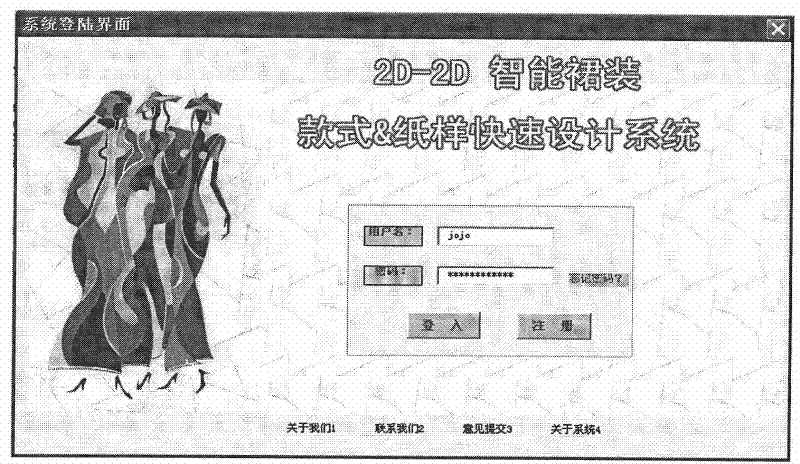

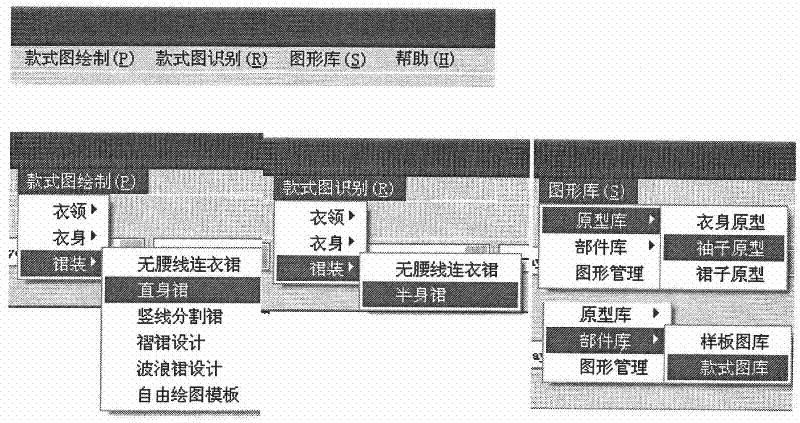

Intelligent skirt style and pattern design system

InactiveCN101482897AReduce the need for technical expertiseSmart addSpecial data processing applicationsSmart technologyEngineering

The invention relates to an intelligent skirt style and pattern design system. The system obtains and describes skirt styles and pattern knowledge through the rule-based and case-based reasoning technology, establishes a skirt design rule base and a skirt design case base which integrate expertise and professional skills, breaks through the bottleneck of knowledge obtaining and description of the production expert system, and realizes to rapidly design a skirt style drawing, intelligently identify the style drawing and automatically and intelligently generate a corresponding templet. The invention provides two design modes according to the characteristics of the styles, and expands the applied range of the system. The reconstruction and reusing function can enrich the CAD system, effectively simplify the operation, improve the design efficiency, realize to reuse technology and experience of the enterprises, makes the designers liberate from simple and repeated work, and reflects the superiority of combining the dress and the artificial intelligence technology.

Owner:DONGHUA UNIV

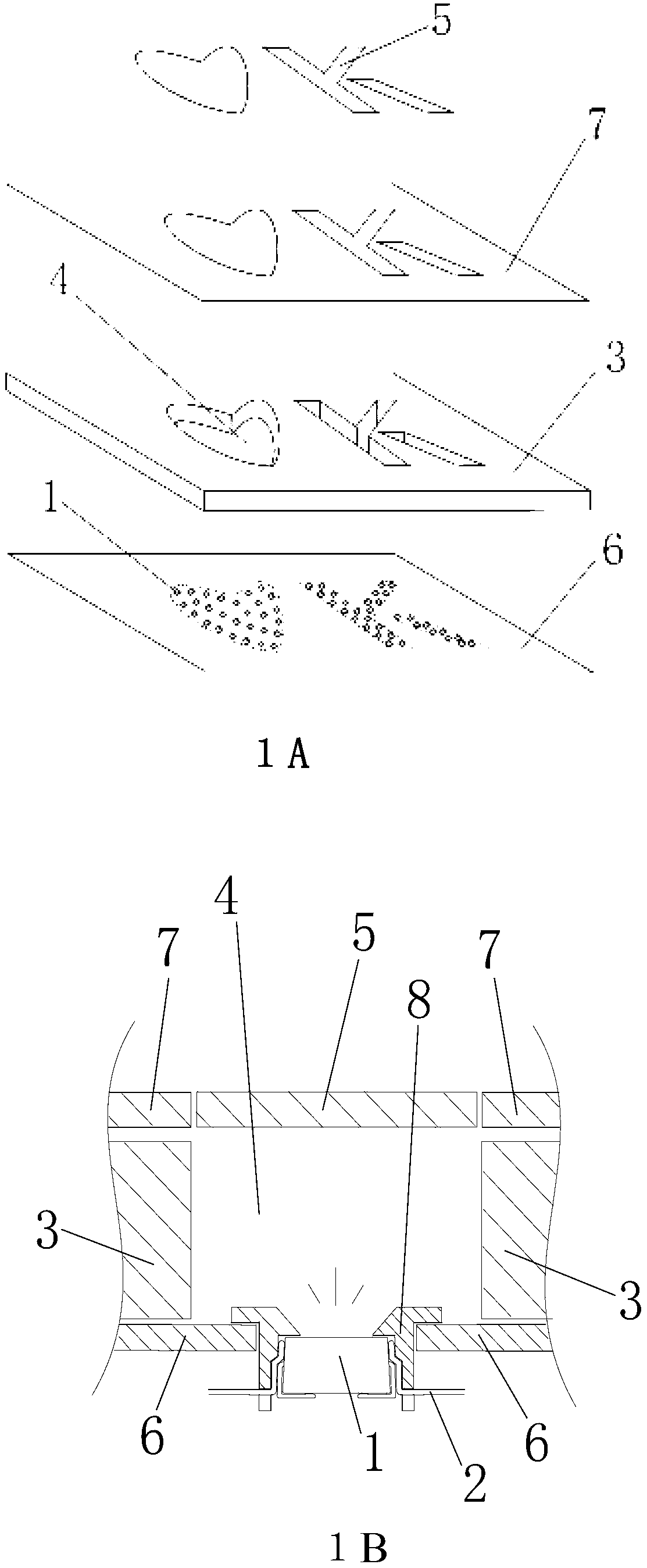

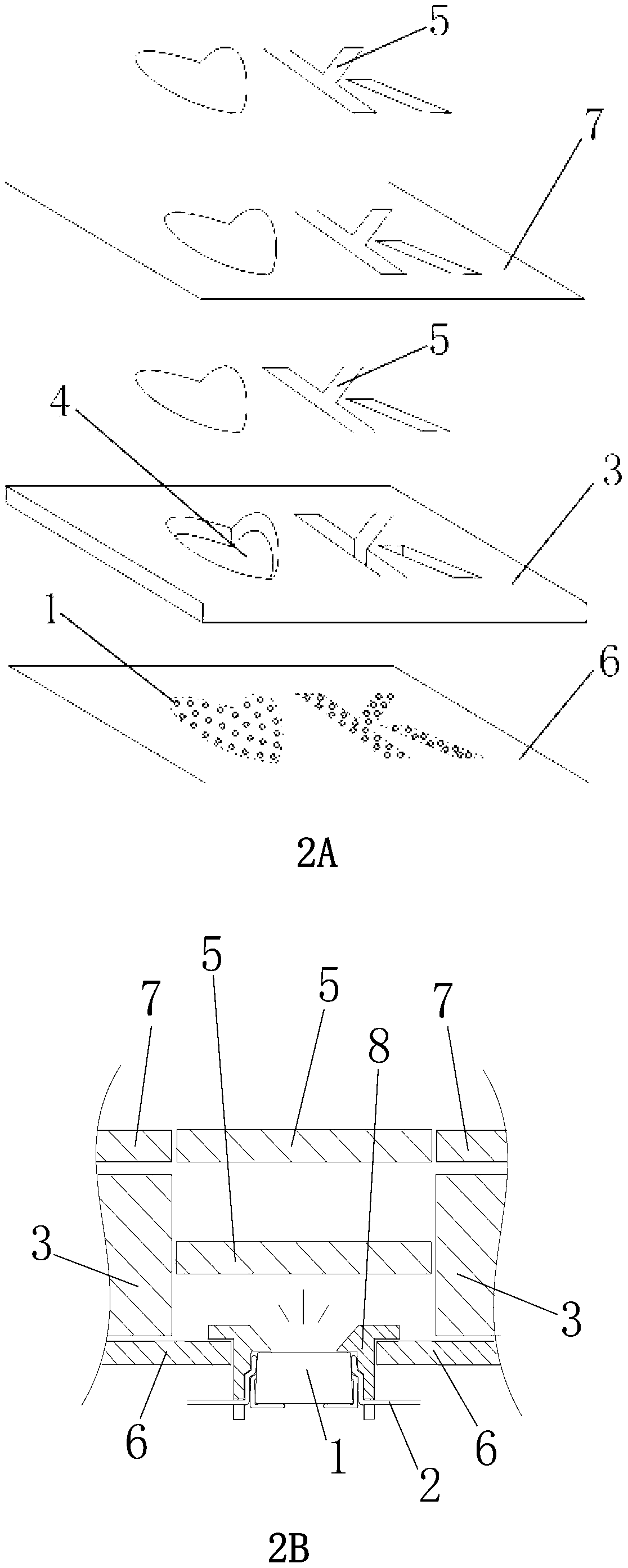

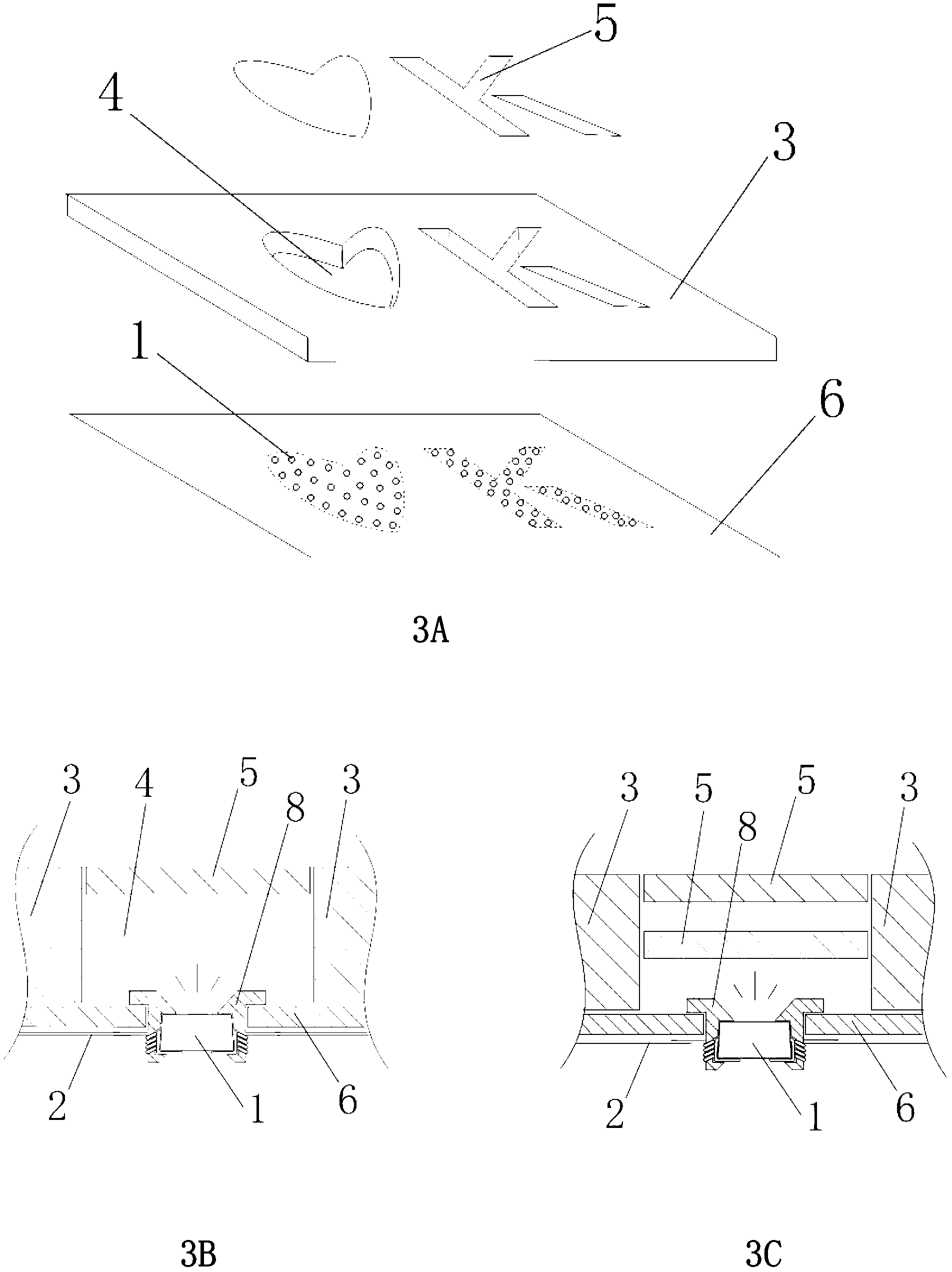

Light-emitting diode (LED) lighting plate

InactiveCN103175005ASimple structureStable structurePlanar light sourcesNon-electric lightingEffect lightEngineering

The invention discloses a light-emitting diode (LED) lighting plate which is formed by enhancing and improving an existing LED lamp box and lighting words and belongs to the field of LED decoration lighting. A special structure based on a plate-shaped lighting cavity body does not need to be enclosed like a traditional lamp box. Material cost is saved and at the same time, production machining procedures are reduced so that entire cost of a lamp is reduced and production efficiency is greatly improved. Meanwhile, flexibility in arranging light sources is greatly improved due to fixing structures of LED light balls and multiple light permeating layers on a base plate. Compared with an existing LED lighting module, lighting brightness is strong, density and distribution of light sources are flexible, the thickness of the whole lamp box is greatly reduced, the LED lighting plate can be competently applied to a lighting body combining functions of lighting and advertising due to randomness of lighting pattern design and the LED lighting plate has high cost performance in terms of visual aesthetics and lighting brightness.

Owner:马飞

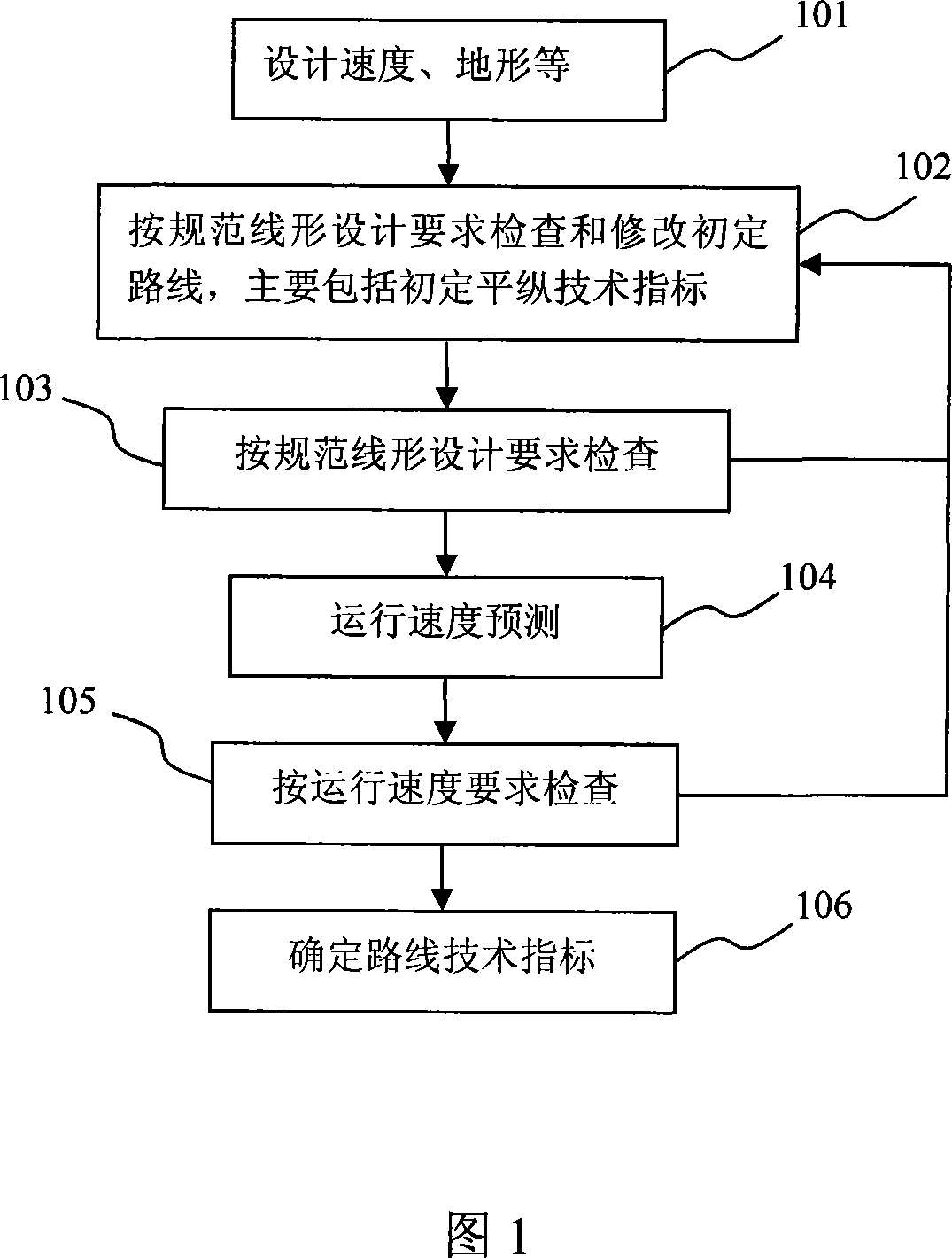

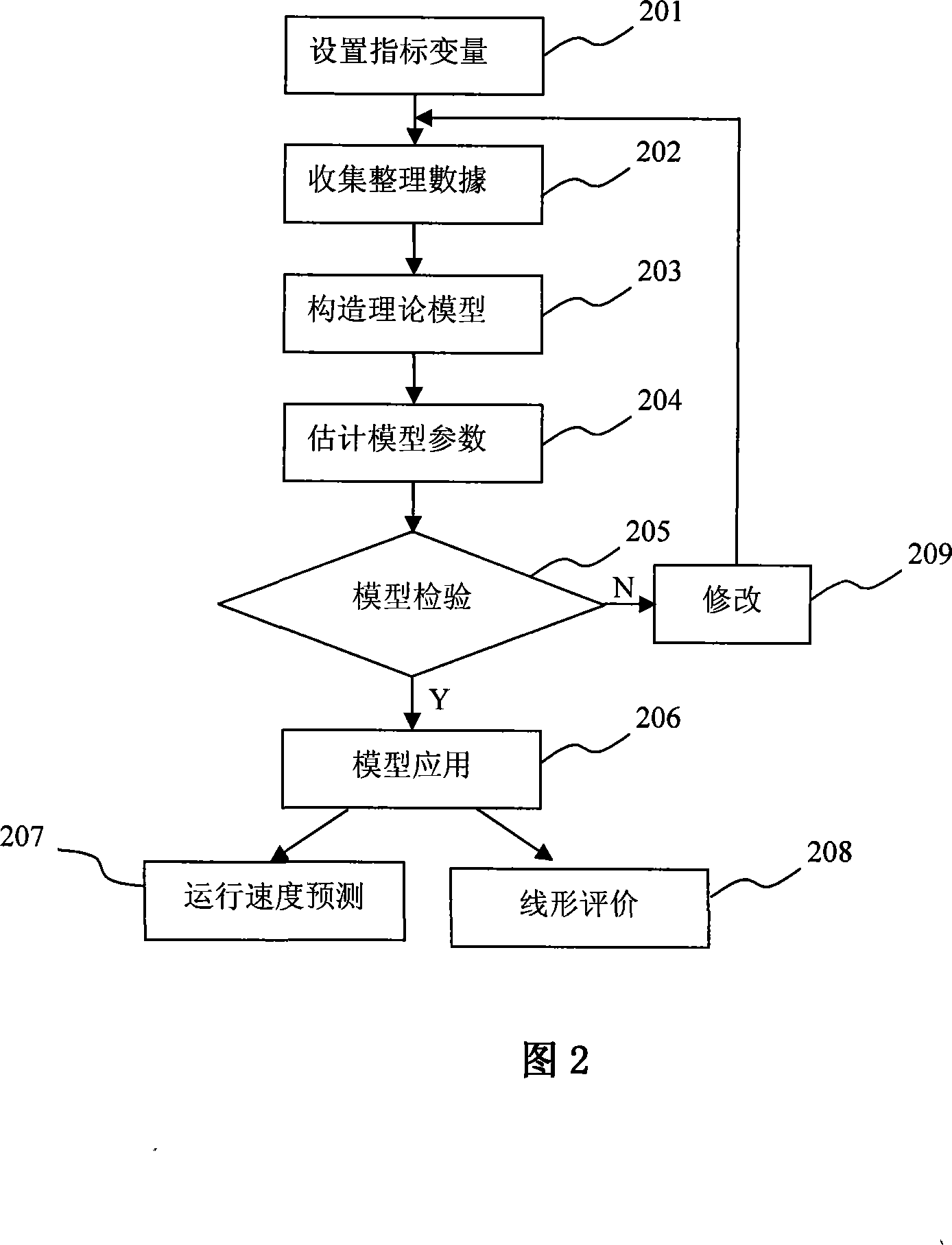

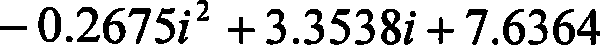

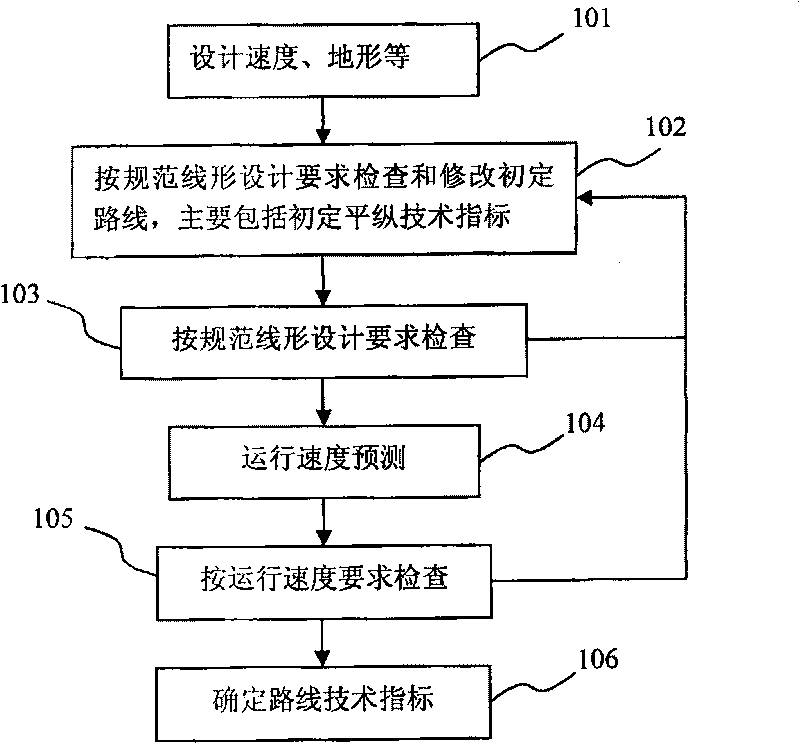

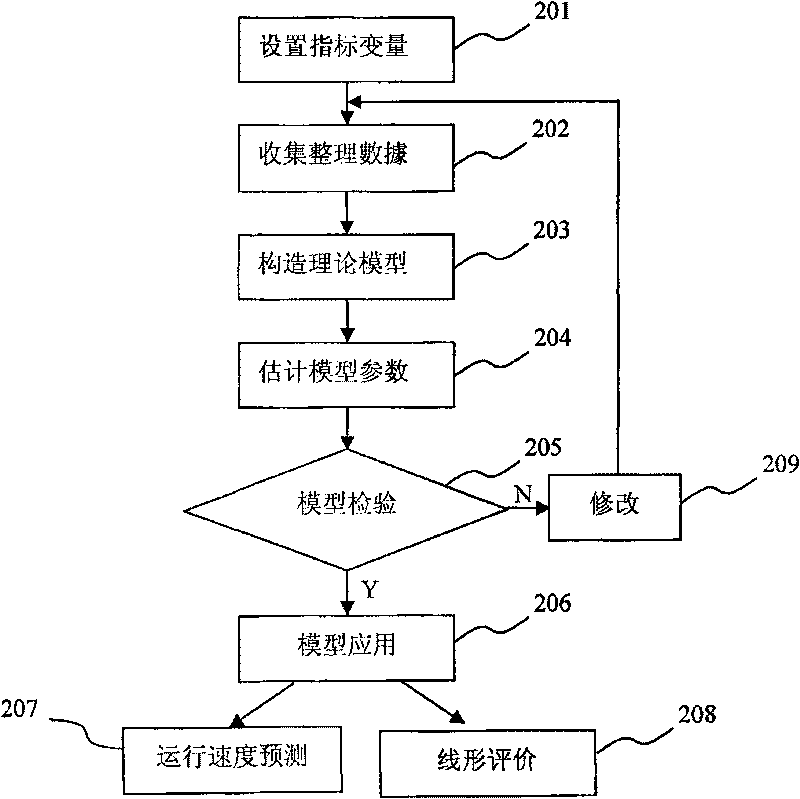

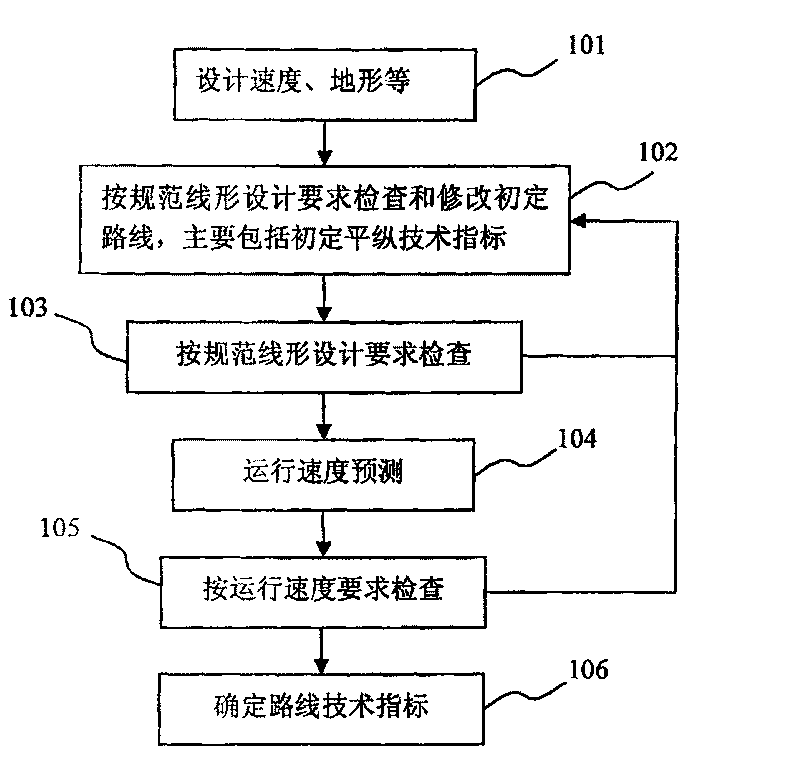

Highway geometric design method adopting speed of service forecast model

ActiveCN101109166ALow costImprove design qualityRoadwaysMultiple linear regression analysisQuality by Design

A linear design method for express way using a run-speed predicating model is provided, which sets up a run-speed predicating model by multiple linear regression analysis method, carries out linear design by taking the run-speed predicating model as the design parameters. The method comprises the following procedures: selecting the designed speed, determining preliminarily the indexes for the horizontal and longitudinal faces in conjunction with the landform conditions; checking and modifying the preliminarily determined route according to standard linear design; predicating the run speed; checking and modifying the preliminarily determined route according to the run speed; determining the technical indexes for the route. Comparing with prior technology, the invention efficiently guarantees the reasonable matching between the linear factors for express ways, such as plane and curve radius, longitudinal slope, upright curve radius, etc. with the designed speed, gets a balanced design that is continuous, consistent, reasonable and objective, and will not increase the project cost due to too high requirement from the indexes, and increase the quality of the linear design for express ways.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

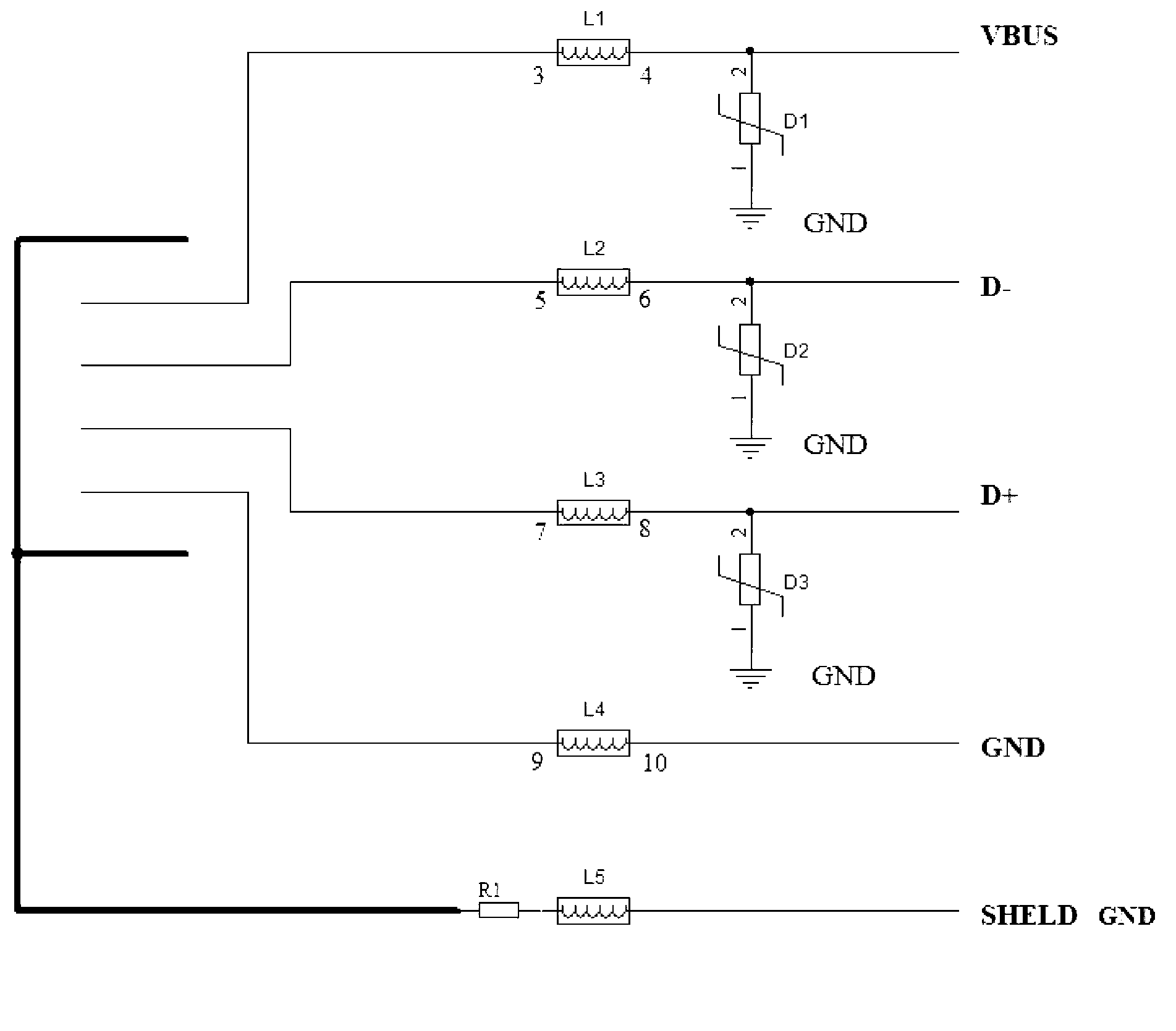

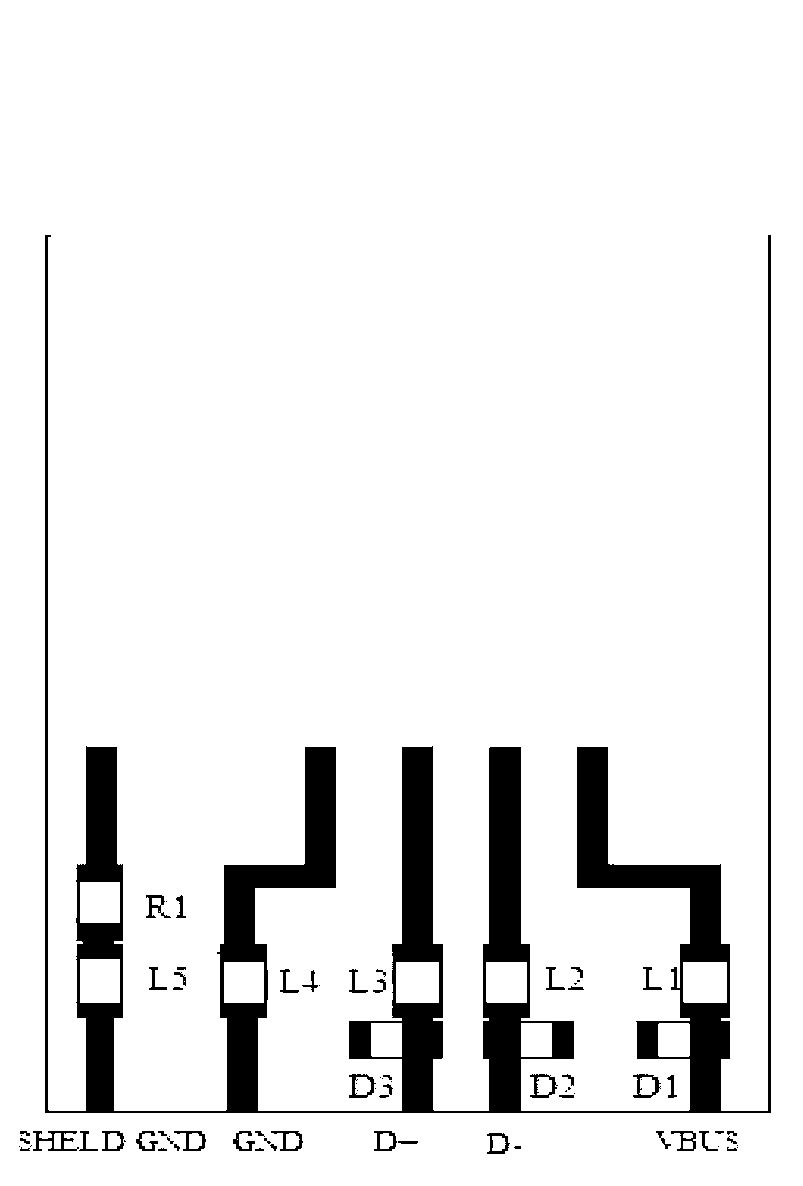

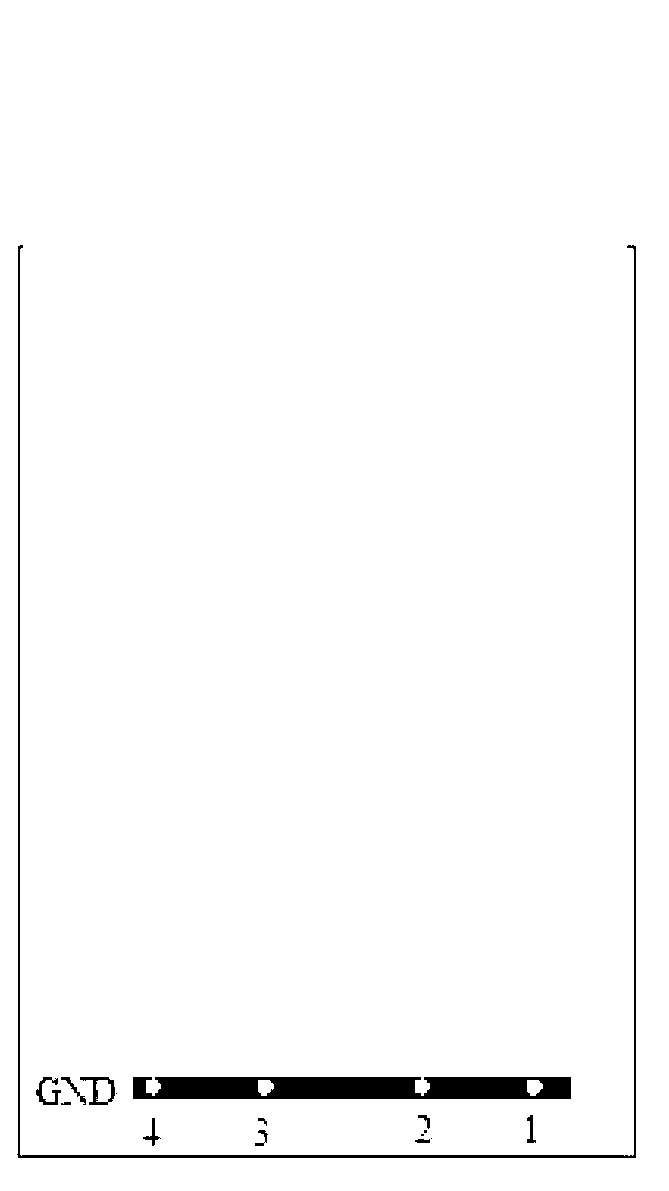

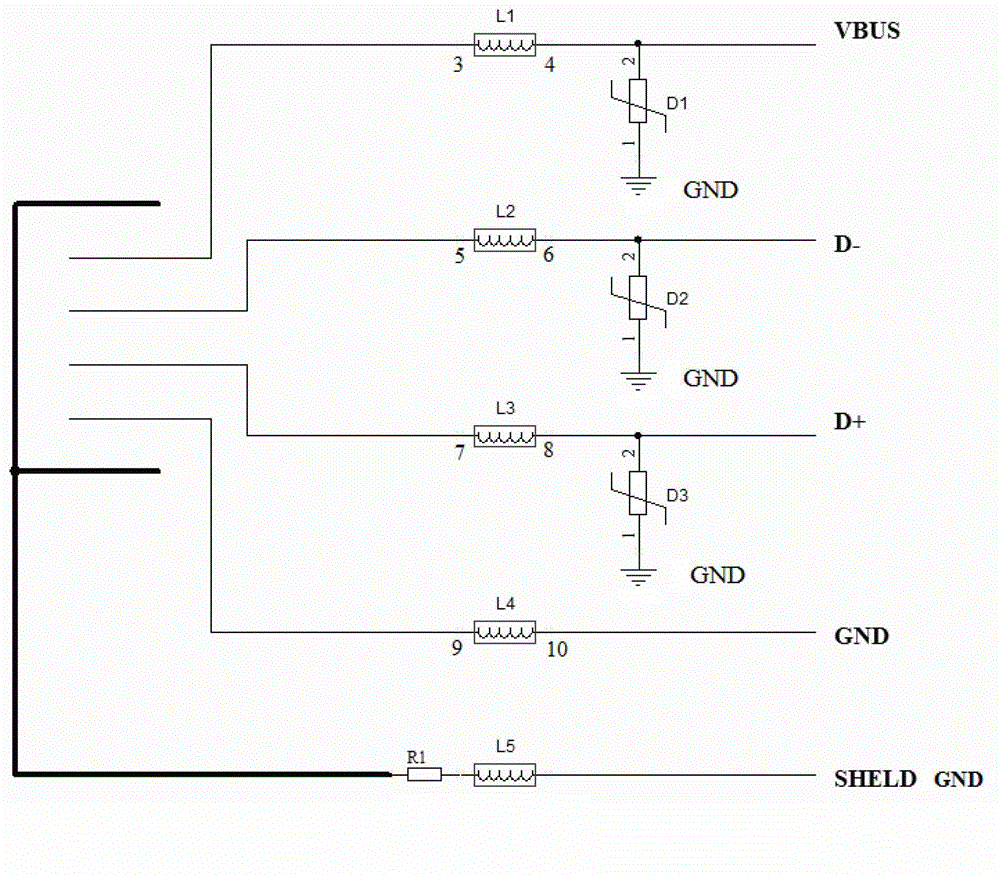

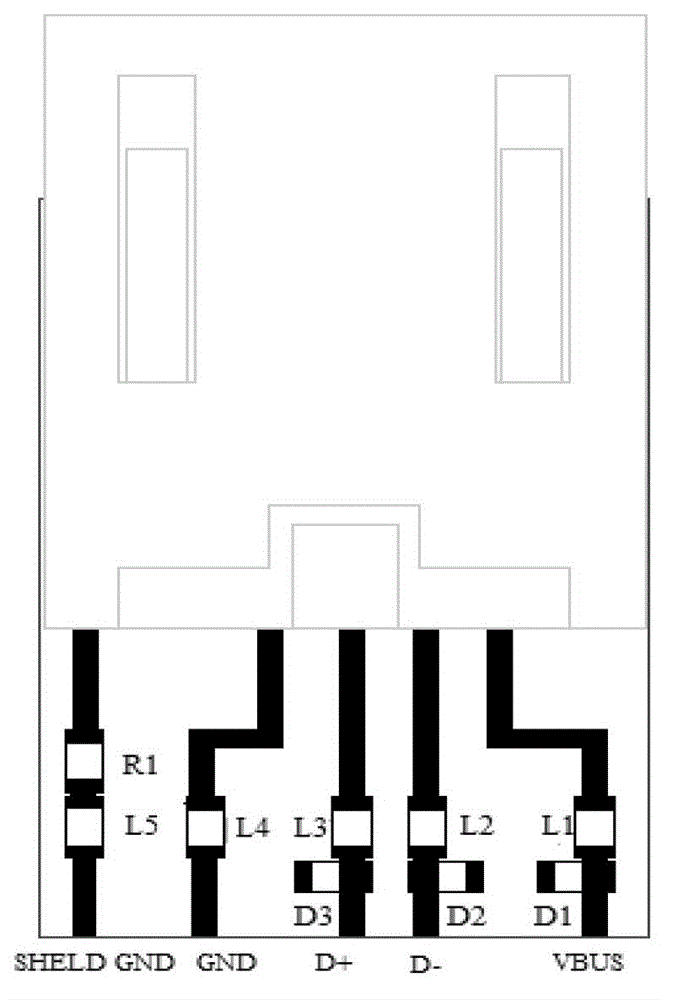

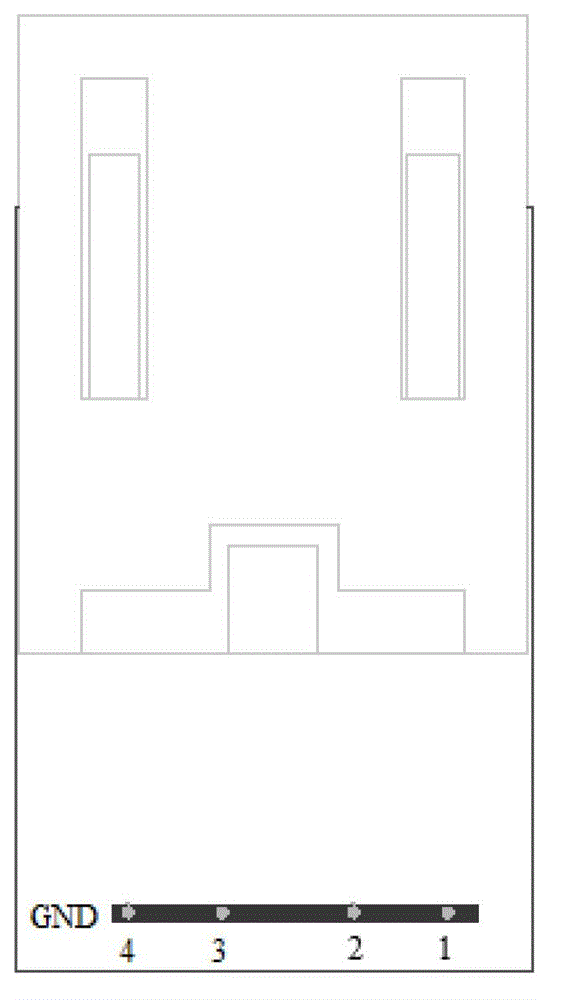

Universal serial bus (USB) connecting device and electronic product

ActiveCN103199393AConsistent EMIConsistent designCoupling device detailsEmergency protective arrangements for limiting excess voltage/currentElectromagnetic interferenceUSB

The invention discloses a universal serial bus (USB) connecting device and an electronic product. The USB connecting device comprises a printed circuit board. A static releasing protecting circuit which has the function of protecting static release is arranged on the printed circuit board. A static releasing circuit of the USB connecting device is not required to be designed time and again. The static releasing circuit of the USB connecting device can ensure uniformity of design. The static releasing circuit of the USB connecting device does not always need renewed debugging after being designed each time. Electromagnetic interference of the static releasing circuit of the USB connecting device is uniform after being designed each time.

Owner:GOERTEK INC

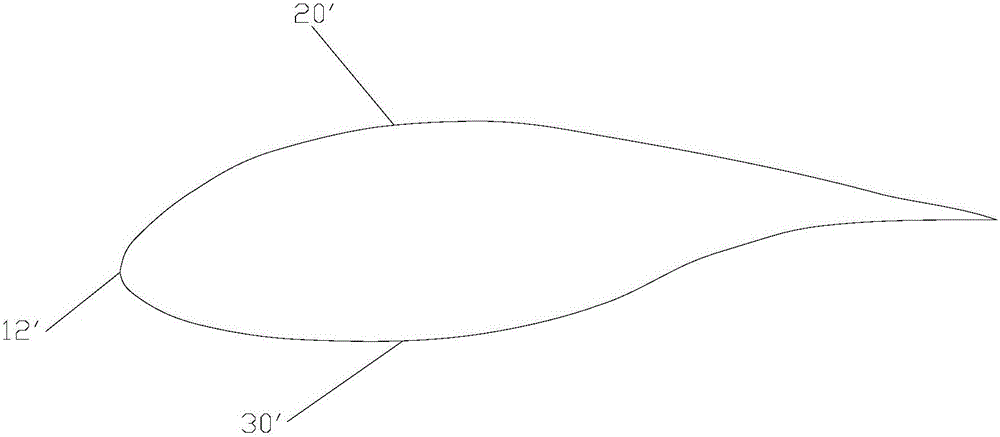

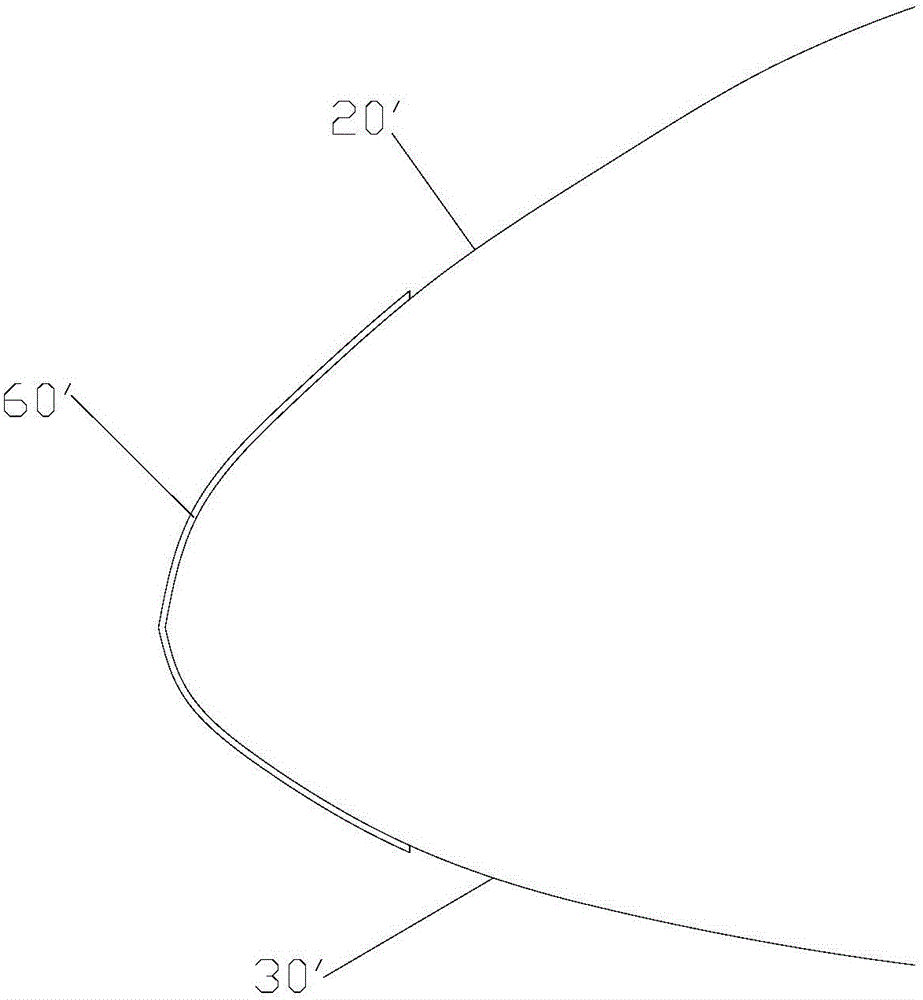

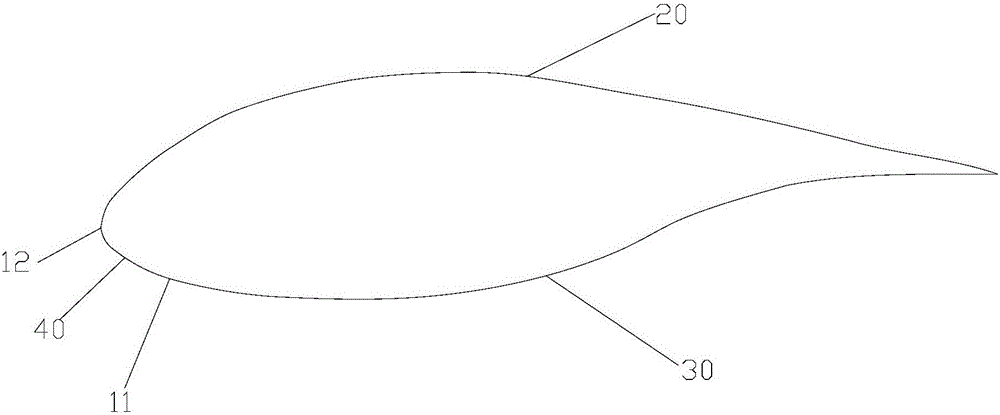

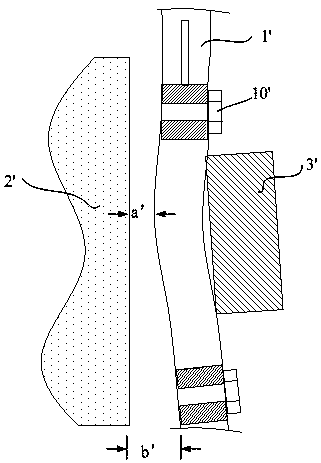

Blade, wind driven generator and blade manufacturing method

ActiveCN105089942ASolve the problem of reduced aerodynamic performanceImprove aerodynamic performanceFinal product manufactureMachines/enginesWind drivenSplit lines

The invention provides a blade, a wind driven generator and a blade manufacturing method. The blade has a first shell and a second shell, wherein the bonding place between the first shell and the second shell is a cutting line; and at least one part of the cutting line is positioned at one side of the front edge of the blade in the length direction of the blade. At least one part of the front edge of the blade is not cut to prevent the problem of weak pneumatic performance of the blade caused by machining errors.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Highway geometric design method adopting speed of service forecast model

ActiveCN101109166BLow costImprove design qualityRoadwaysMultiple linear regression analysisQuality by Design

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

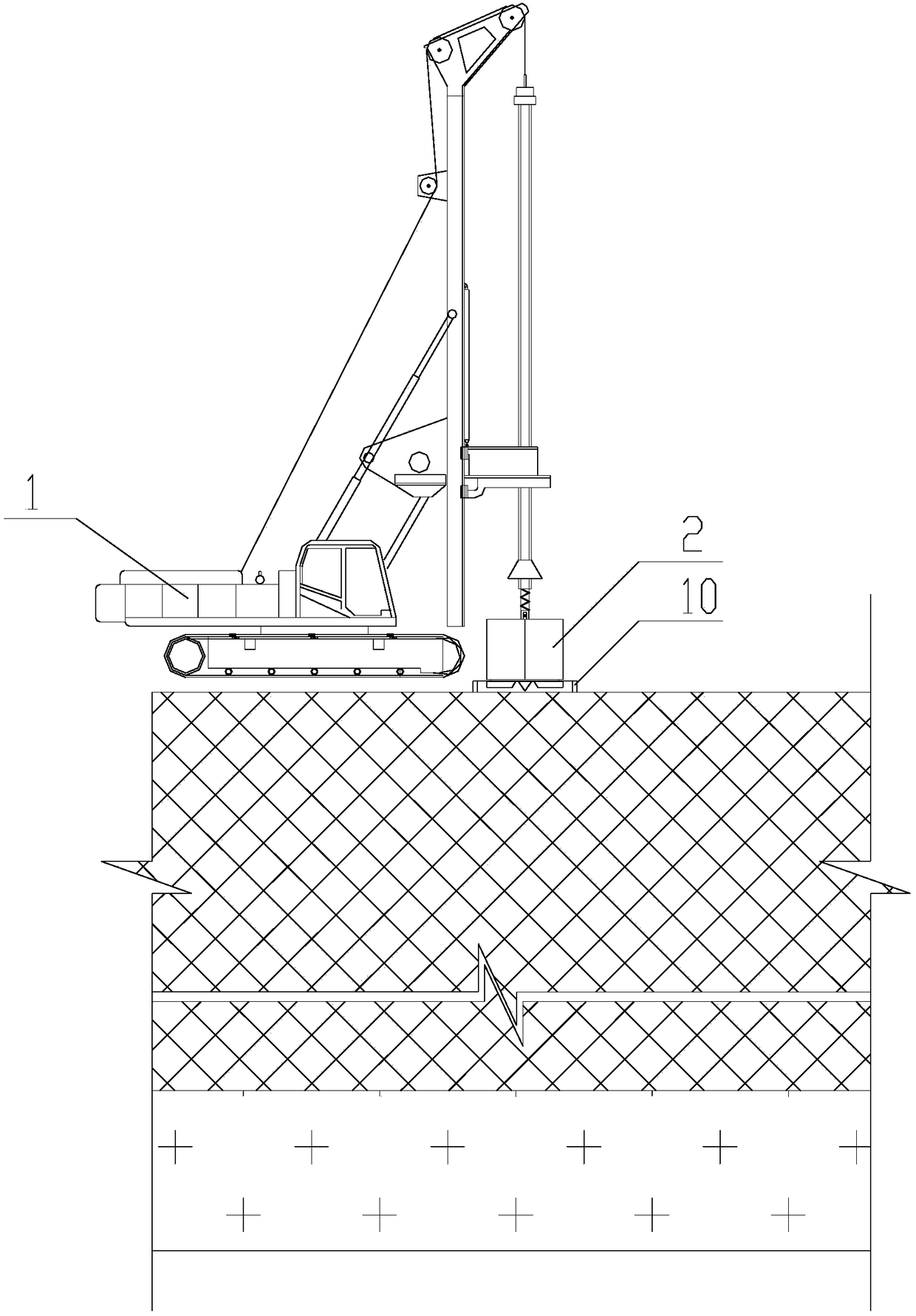

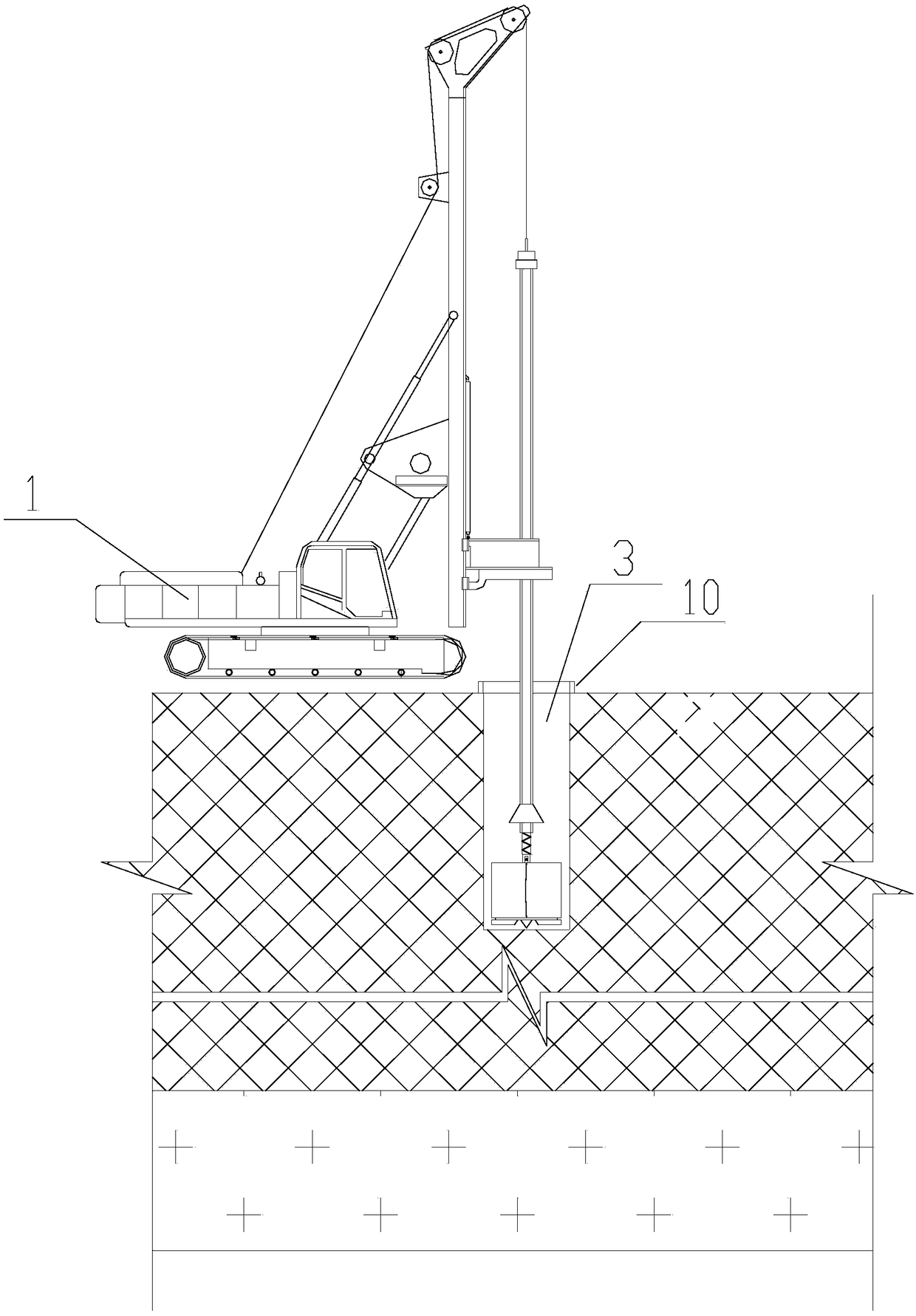

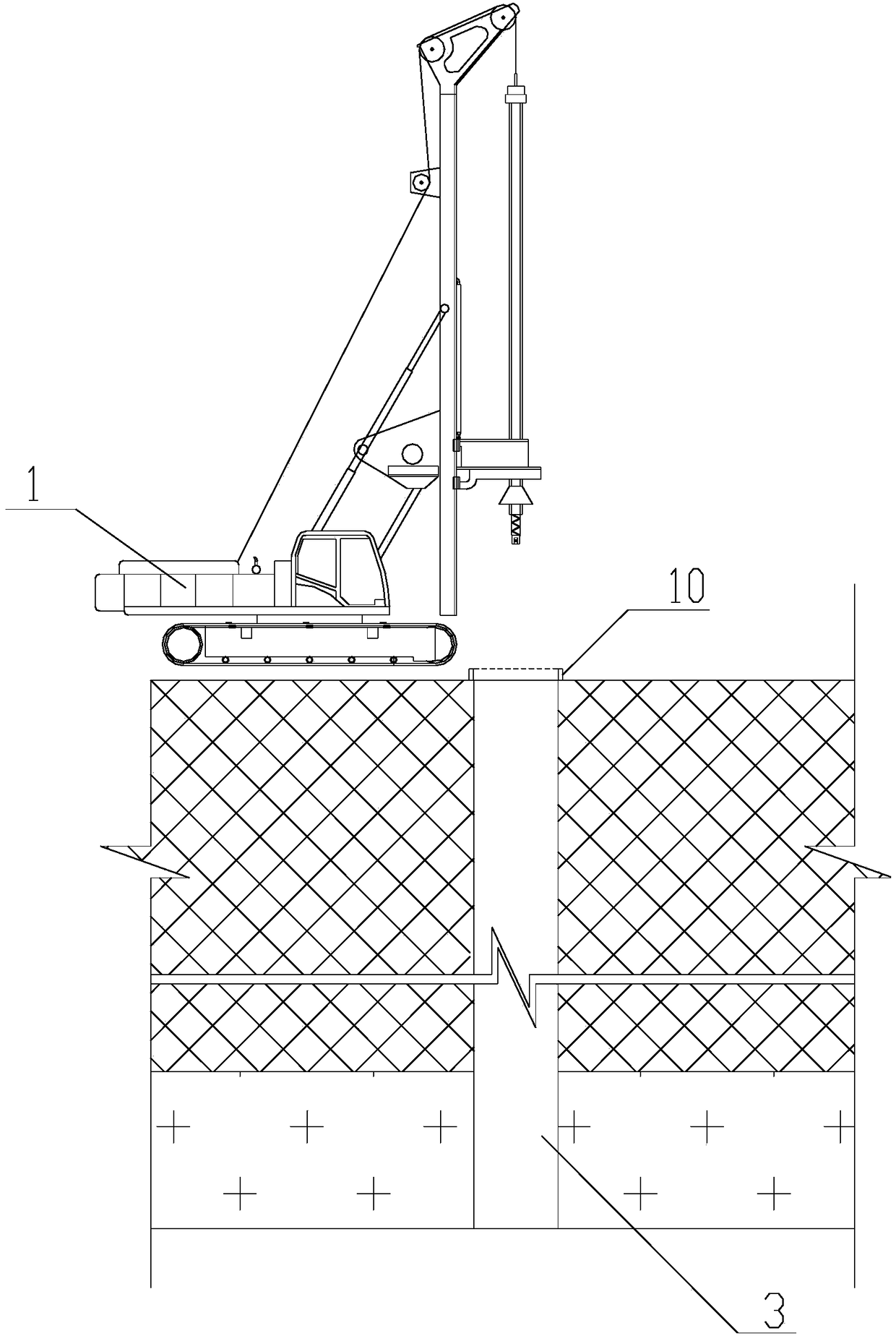

Excavation method of pile hole

ActiveCN108798508AGuarantee the construction qualityImprove construction progressDrilling machines and methodsDrill bitBuilding construction

The invention discloses an excavation method of a pile hole. The excavation method comprises the following steps that a drilling rig is in place, primary excavation is conducted through an ordinary drill bit, and a main body pile hole is obtained; the ordinary drill bit is replaced with an expanding drill bit, the bottom of the main body pile hole is primarily expanded through the expanding drillbit, and an expanded hole is obtained; the drilling rig is moved away, a crane is driven to the position beside the main body pile hole, and a protective cylinder is placed into the main body pile hole through the crane; a worker enters the bottom of the main body pile hole through the protective cylinder, and then a protective shed is constructed between the top of the expanded hole and the outerwall of the protective cylinder; the expanded hole is manually expanded to the size; and the protective shed is dismantled, the worker withdraws from the expanded hole, the crane hoists the protective cylinder out, and construction of the pile hole is completed. The excavation method combines the advantages of high mechanical hole forming speed with good manual hole forming quality, the construction progress is fast, manpower construction is reduced, and potential safety hazards brought by manual excavation are lowered. Consistency of the pile bottom expanding line type and design is guaranteed through manual bottom expanding, the construction quality of a cast-in-place pile is guaranteed, the construction quality is good, and construction is fast.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Double-end motive power luxury sleeper coach

The invention discloses a double-end motive power luxury sleeper coach which is composed of a 12 or 16-liter six-cylinder in-line arrangement turbocharging electronic fuel oil engine with an intercooler. The double-end motive power luxury sleeper coach is 19.5 to 28 meters in length, a main cab and an auxiliary cab of the two-connection double-end motive power luxury sleeper coach are uniform in design, and the double-end motive power luxury sleeper coach runs in forward pulling mode and backward pulling mode and can run in a single coach mode. The maximum load-bearing capacity of the double-power motive power luxury sleeper coach is 30 to 50 tons, 80 people can be loaded, a 12-liter engine and a 16-liter engine can provide 340x2 and 380x2 to 520x2 watts respectively, 9 types of front axle configuration are arranged on a chassis of the double-end motive power luxury sleeper coach, 11 different types of configuration including back shafts such as 4x2, 4x4, 6x2, 6x4, 8x2 and 8x4 and double rear axles are arranged on an axle structure, and a speed control system is configured with 6 manual and automatic gears and configured electrically.

Owner:付长发

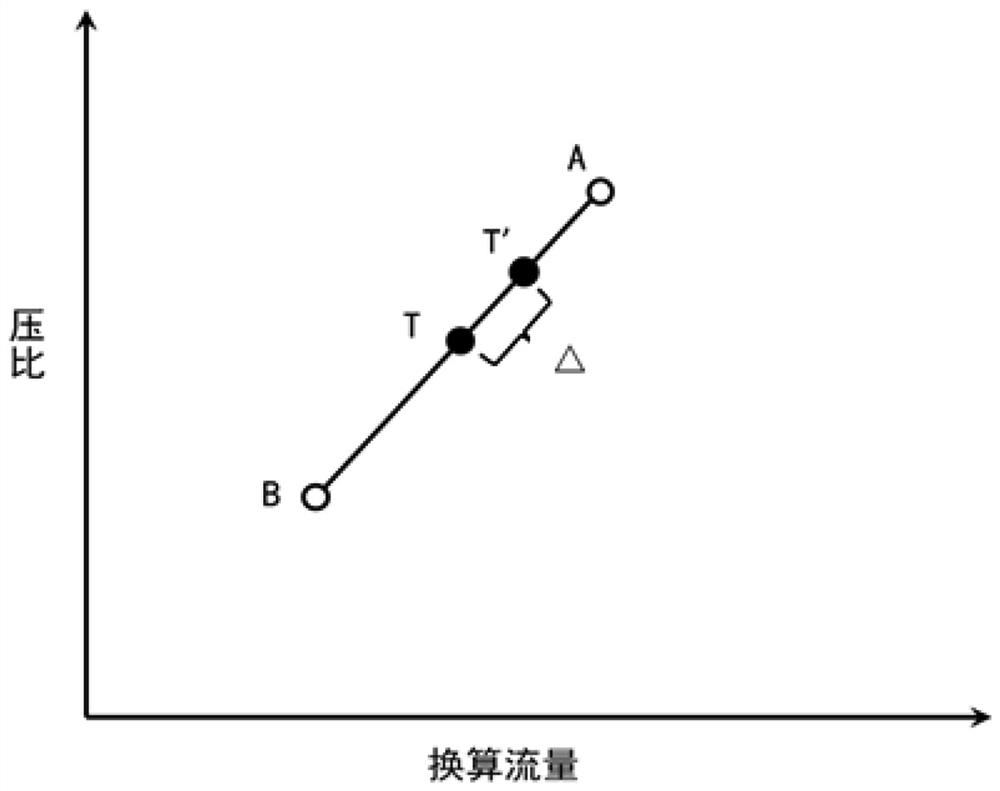

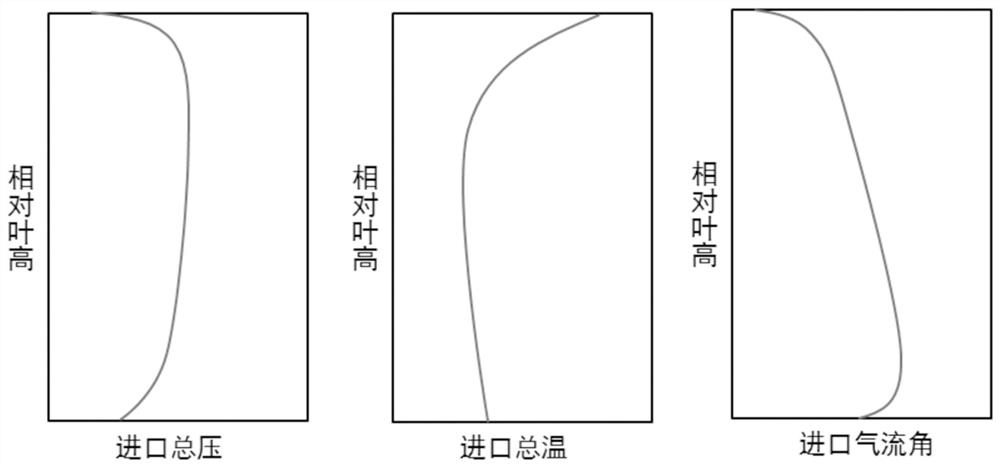

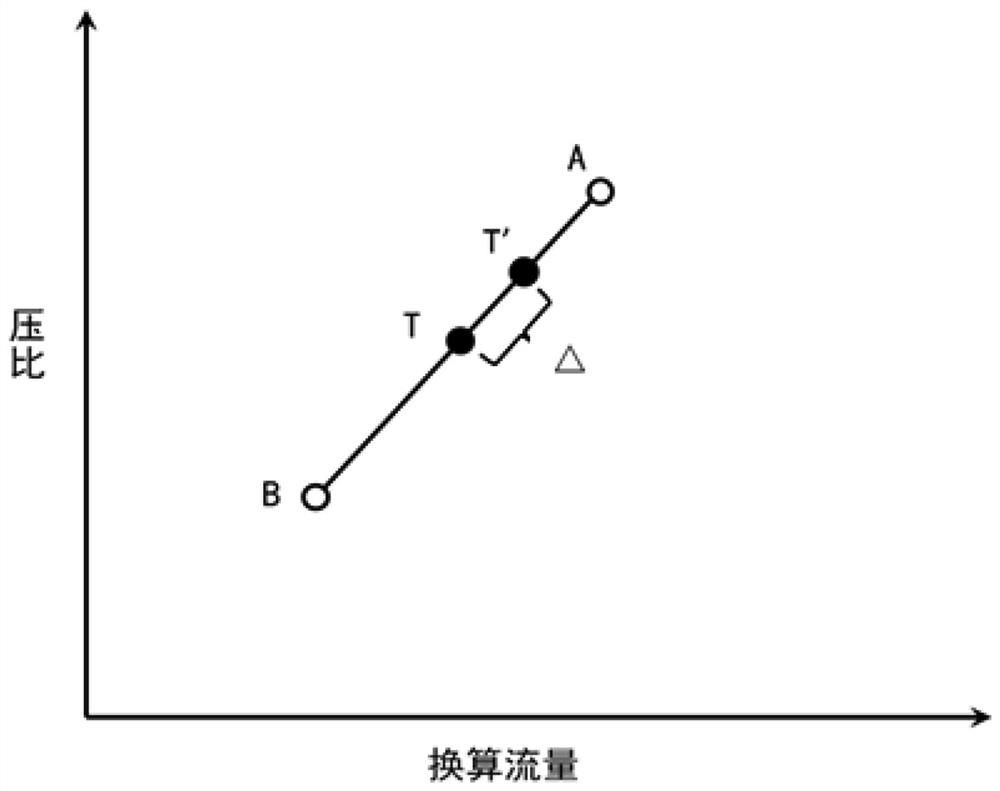

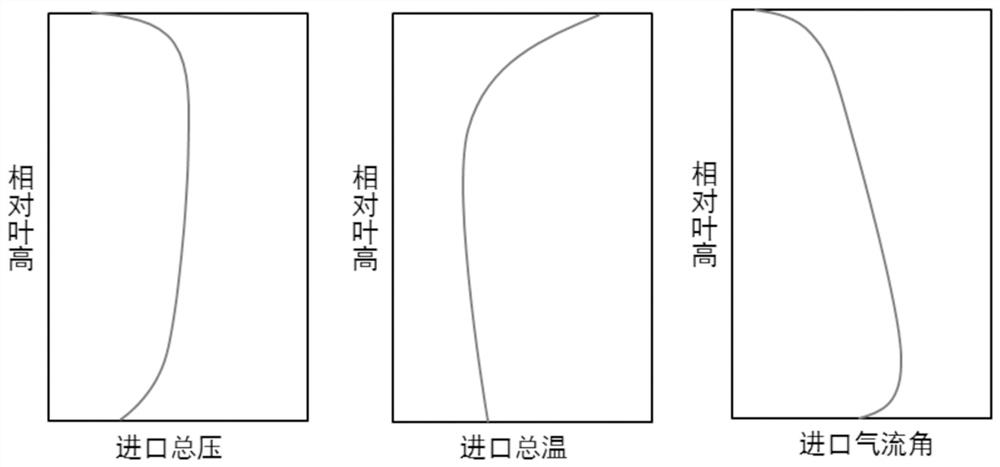

Multistage compressor aerodynamic matching design method

ActiveCN112711923AUnchanged aerodynamic layoutSingle-Stage Design SimplificationGeometric CADSustainable transportationGas compressorControl engineering

The invention relates to a multistage compressor aerodynamic matching design method, which is based on the principle of equal-outlet conversion flow and under the condition of keeping'constant isentropic efficiency ', an equal-outlet conversion flow line passing through a single-stage design working point is calculated and obtained; after a single-stage equal-outlet conversion flow line is obtained, a corrected single-stage design target is obtained along the equal-outlet conversion flow line through design system deviation correction, and then single-stage iterative design is carried out; when the three-dimensional design work of a certain specific level is specifically carried out, the two-dimensional total temperature, total pressure and airflow angle profile obtained in the design link S2 is used for the inlet condition of the level, so that the three-dimensional design result is consistent with the one-dimensional and two-dimensional design results, namely, all design links of the gas compressor are kept consistent. On the premise that the pneumatic layout design target of the whole compressor is met, single-stage design can be effectively stripped from multi-stage design work, pneumatic design of the single-stage compressor is completed on the premise that the whole pneumatic layout of the compressor is not affected, and therefore the design process of the compressor is optimized.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

Packaging box for toothbrush sales

The invention relates to the technical field of toothbrush packaging boxes, in particular to a packaging box for toothbrush sales. The packaging box comprises a paper board made of paper and a transparent plastic housing used for wrapping a toothbrush, wherein the paper board is bonded to the rear surface of the transparent plastic housing to form a seal cavity used for accommodating the toothbrush; the edge shape of the paper board is flush with that of the rear surface of the transparent plastic housing; a groove suitable for the passing of a finger is formed in the side, far away from the head of the toothbrush, of the transparent plastic housing; a pinching part pinched by the finger to tear the paper board apart is formed at a corresponding groove in the paper board. According to the packaging box, the uniformity of the whole packaging box can be kept and the paper board can be guaranteed to be smoothly torn off.

Owner:陆璟璇

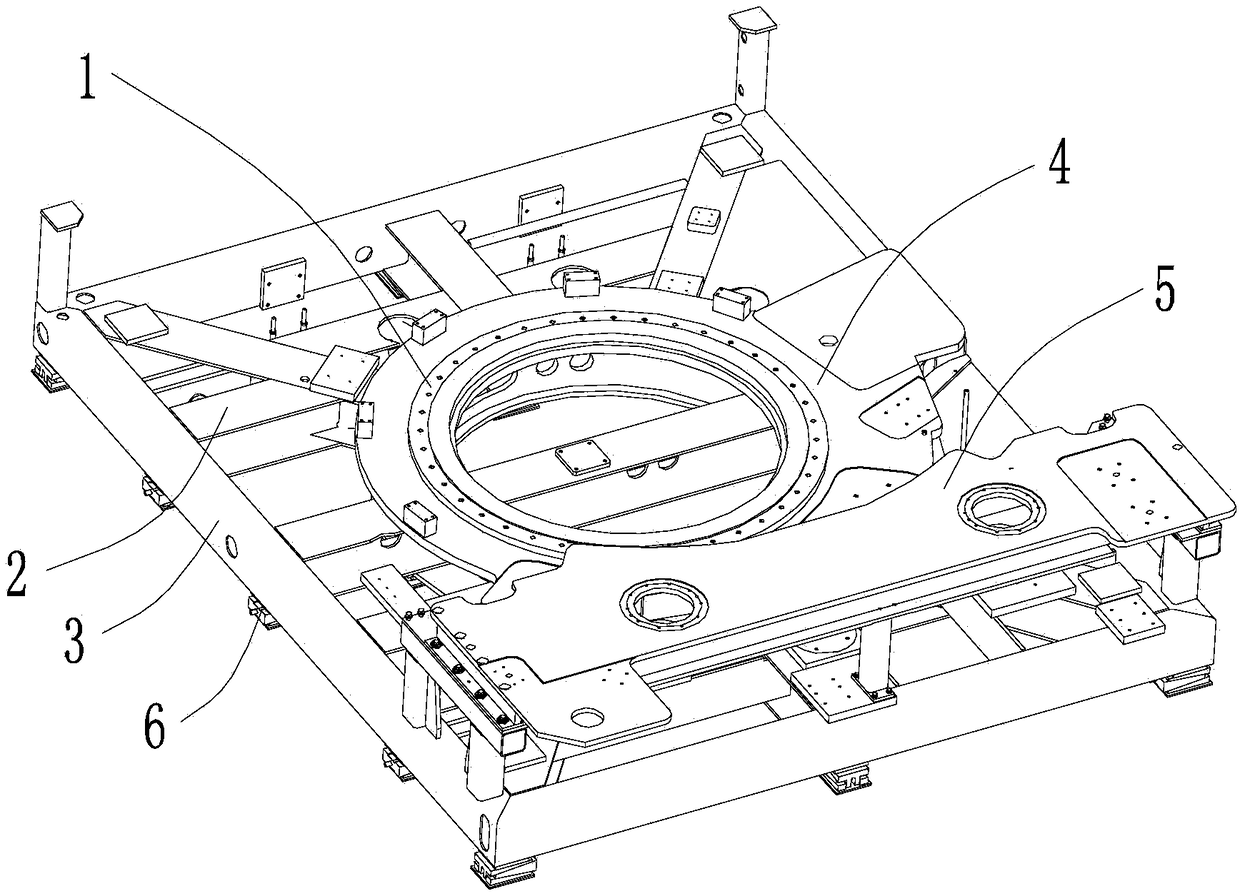

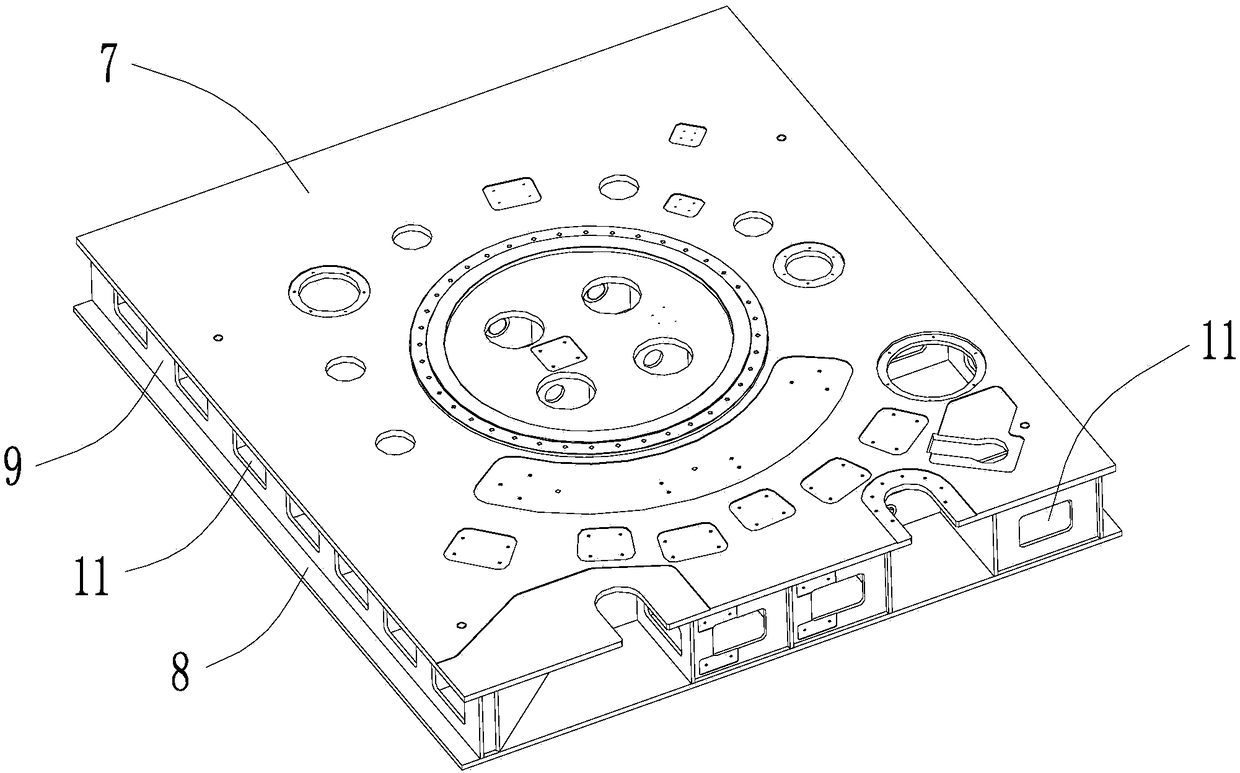

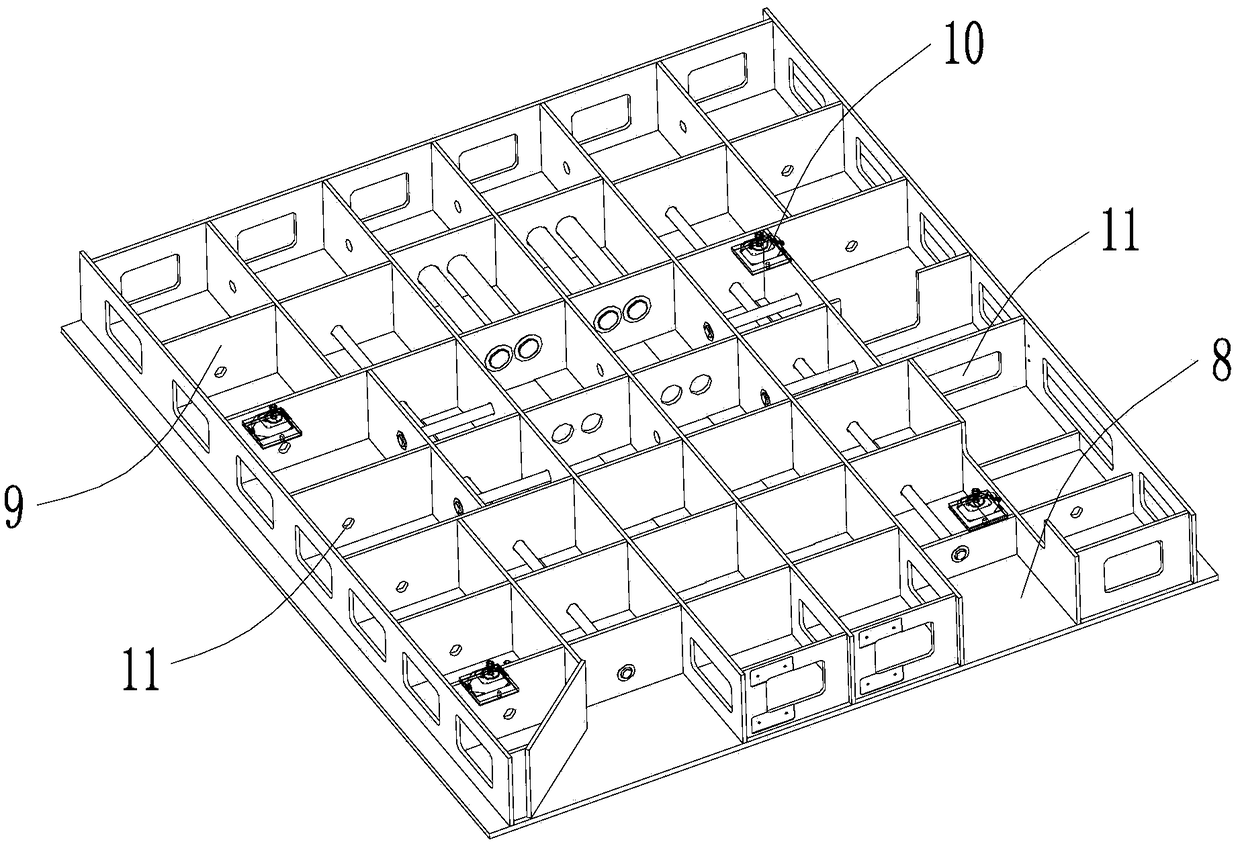

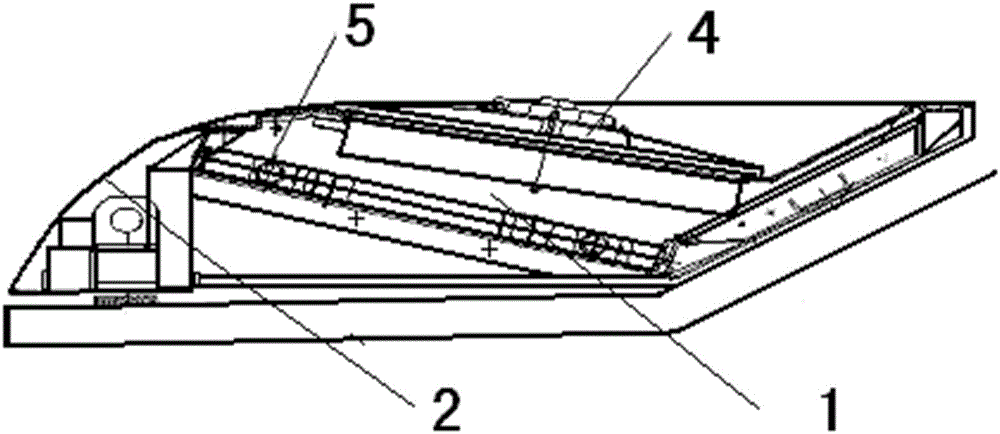

Bottle blowing machine installing rack

The invention discloses a bottle blowing machine installing rack used for installing main motion components of a bottle blowing machine. The installing rack comprises an upper panel, a lower panel, aplurality of middle rib plates and ground foot supports, wherein a plurality of installing faces are machined on the surface of the upper panel, the middle rib plates are connected between the upper panel and the lower panel, and the ground foot supports are arranged below the lower panel. A box-shaped laminated board structure is integrally formed by the upper panel, the lower panel and the middle rib plates. According to the bottle blowing machine installing rack, the specific rigidity of the rack is high, machining and installing datum planes are consistent, and the phenomena such as motioncomponent matching precision lowering, machine dynamic property worsening and even structure damage caused by deformation or other factors during installing and transporting can be prevented; meanwhile, according to the installing rack, the component machining number and machining faces are reduced, and the machining cost can be reduced; main components are directly arranged on the rack, design,technology and assembling datum is consistent, machining and assembling precision is high, the machine running speed is high, vibration and noise are low, and replacement and maintenance of formworksand other components are convenient.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

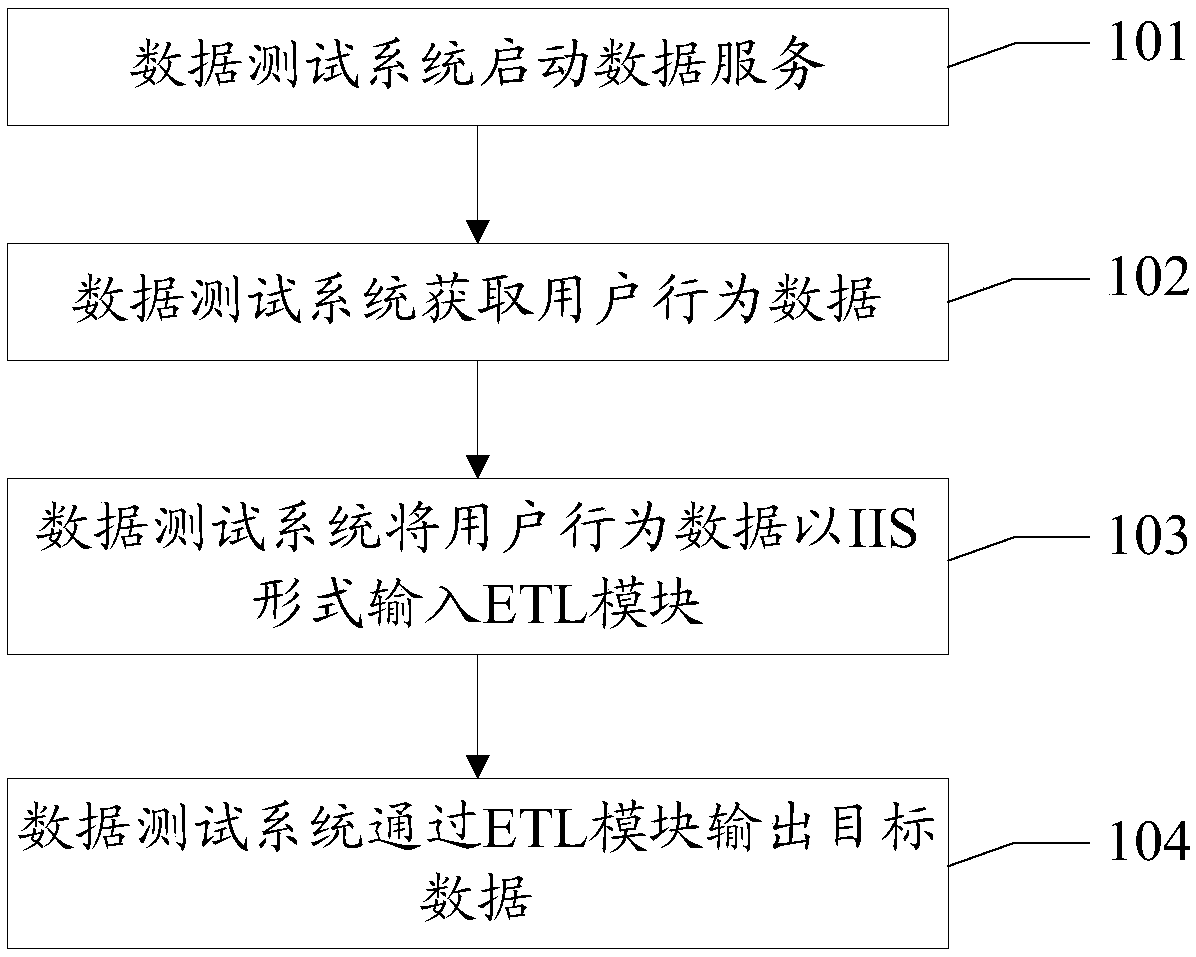

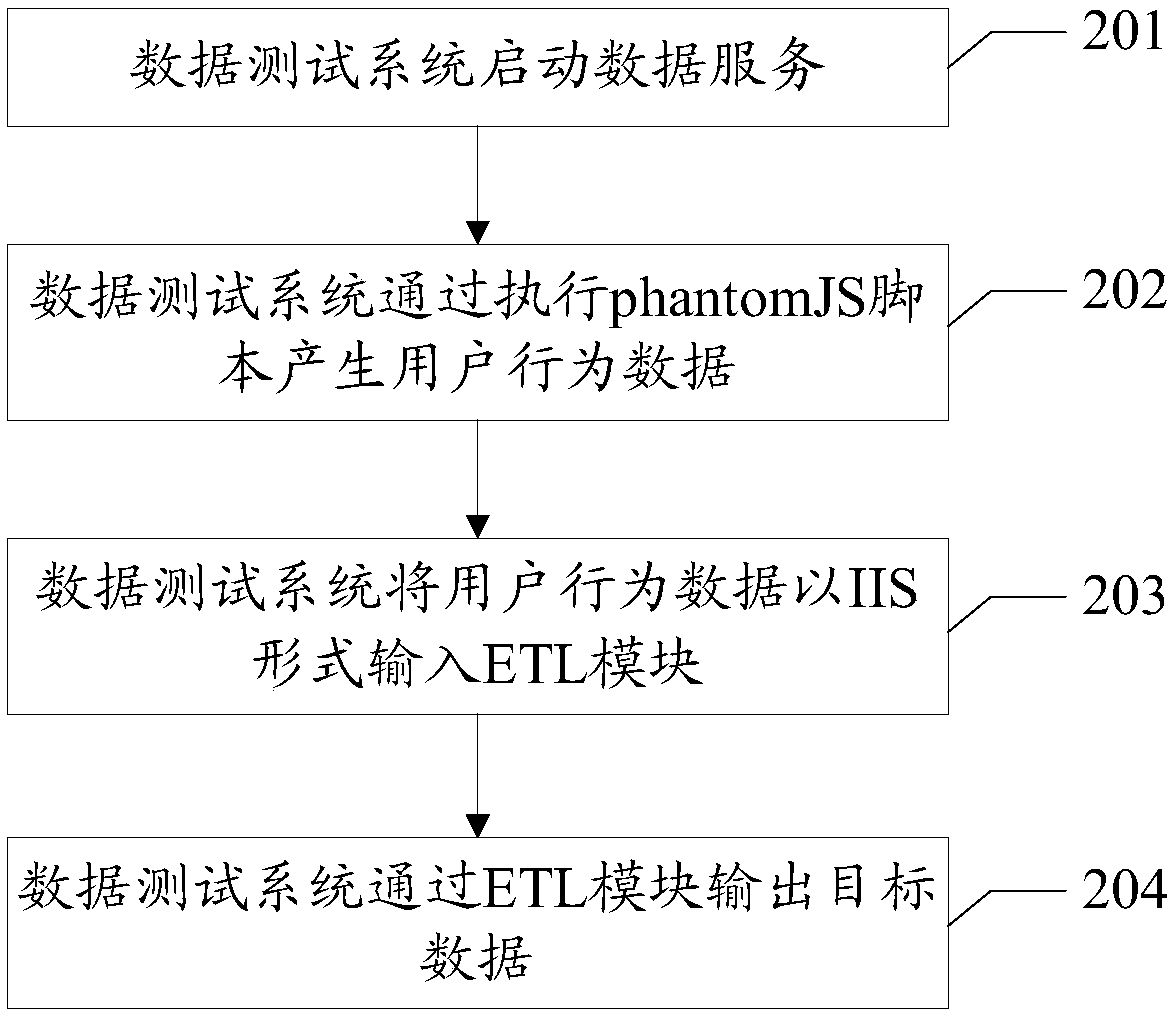

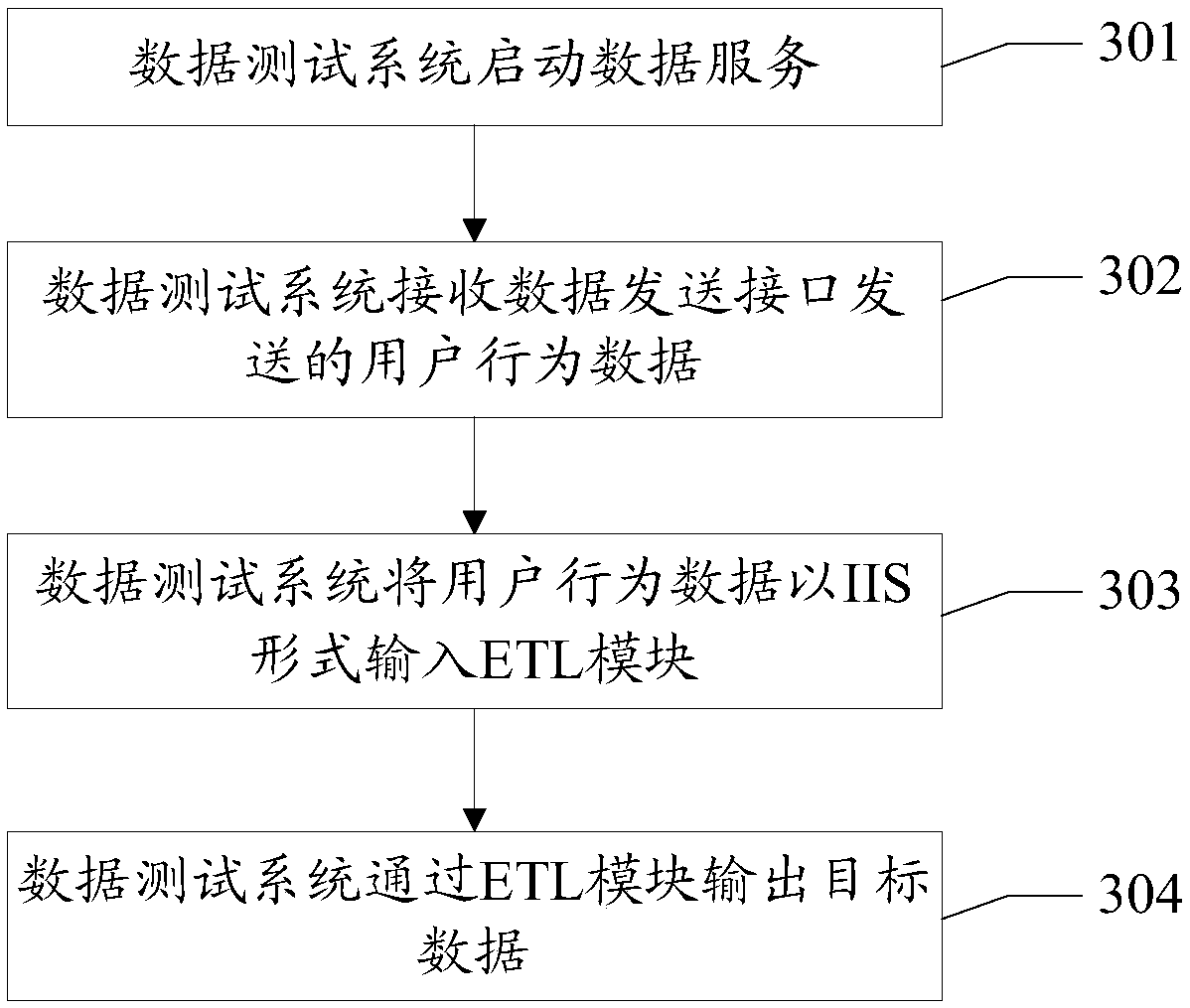

Data testing method and system

InactiveCN108153662AConsistent designVerify design for inconsistenciesSoftware testing/debuggingData mining

The embodiment of the invention discloses a data testing method and system for verifying whether the design of a testing module in the testing system is consistent or not. The method includes the steps that the data testing system starts data service, wherein the data service is used for allowing the data testing system to enter a data testing preparation state; the data testing system obtains user behavior data, wherein the user behavior data corresponds to a Tracker module, and the data testing system comprises the Tracker module; the data testing system inputs the user behavior data in theform of IIS in an ETL module, wherein the ETL module is used for processing the user behavior data, and the data testing system comprises the ETL module; the data testing system output target data through the ETL module.

Owner:BEIJING GRIDSUM TECH CO LTD

Novel supporting cushion block for steam generator

PendingCN108087857AReduce uncertaintyImprove measurement accuracySteam boilersSteam boilers componentsThermal stateEngineering

The invention discloses a novel supporting cushion block for a steam generator. The novel supporting cushion block is used for supporting the steam generator in a loop when a nuclear power unit is ina thermal state. The novel supporting cushion block is characterized in that the supporting cushion block is of a thin sheet structure, wherein fixing holes are formed in two ends of the supporting cushion block, a first surface of the supporting cushion block is in contact with a supporting body structure, and a certain gap is reserved between a second surface of the supporting cushion block anda side anchoring part; the supporting cushion block comprises a first section, a second section and a third section, wherein the first section and the second section are arranged at two ends of the supporting cushion block, the third section is arranged between the first section and the second section, and the thickness of the third section is smaller than the thickness of the first section and the thickness of the second section; and when the supporting cushion block is in the hot state, the third section is bent, and the maximum bending position does not exceed the planes of the first section and the second section towards the side anchoring part. By carrying out the novel supporting cushion block, the accuracy of the actual value and the measured value of the gap between the upper supporting cushion block and the side anchoring part of the steam generator can be improved, so that the secondary stress state of the loop during the thermal state of the unit is consistent with originaldesign, and therefore the reliability and the safety of the unit are improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

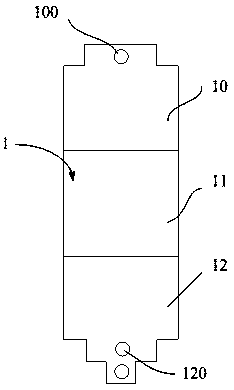

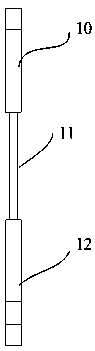

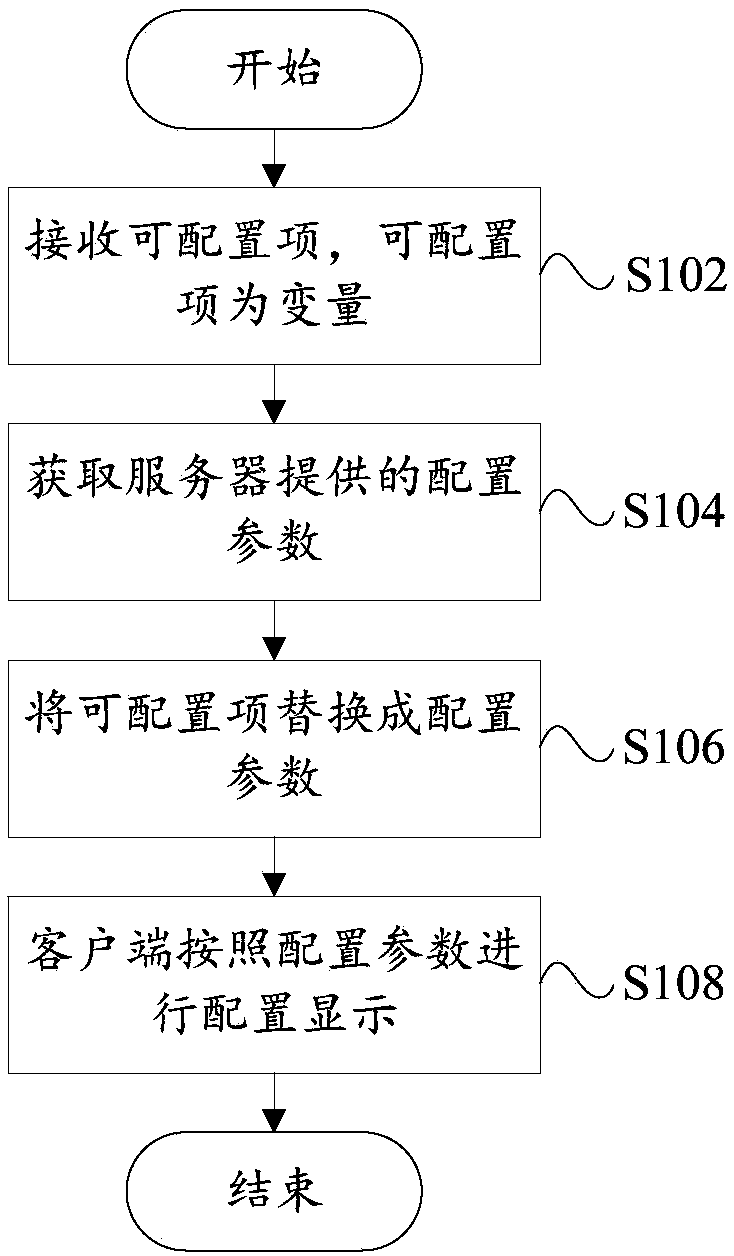

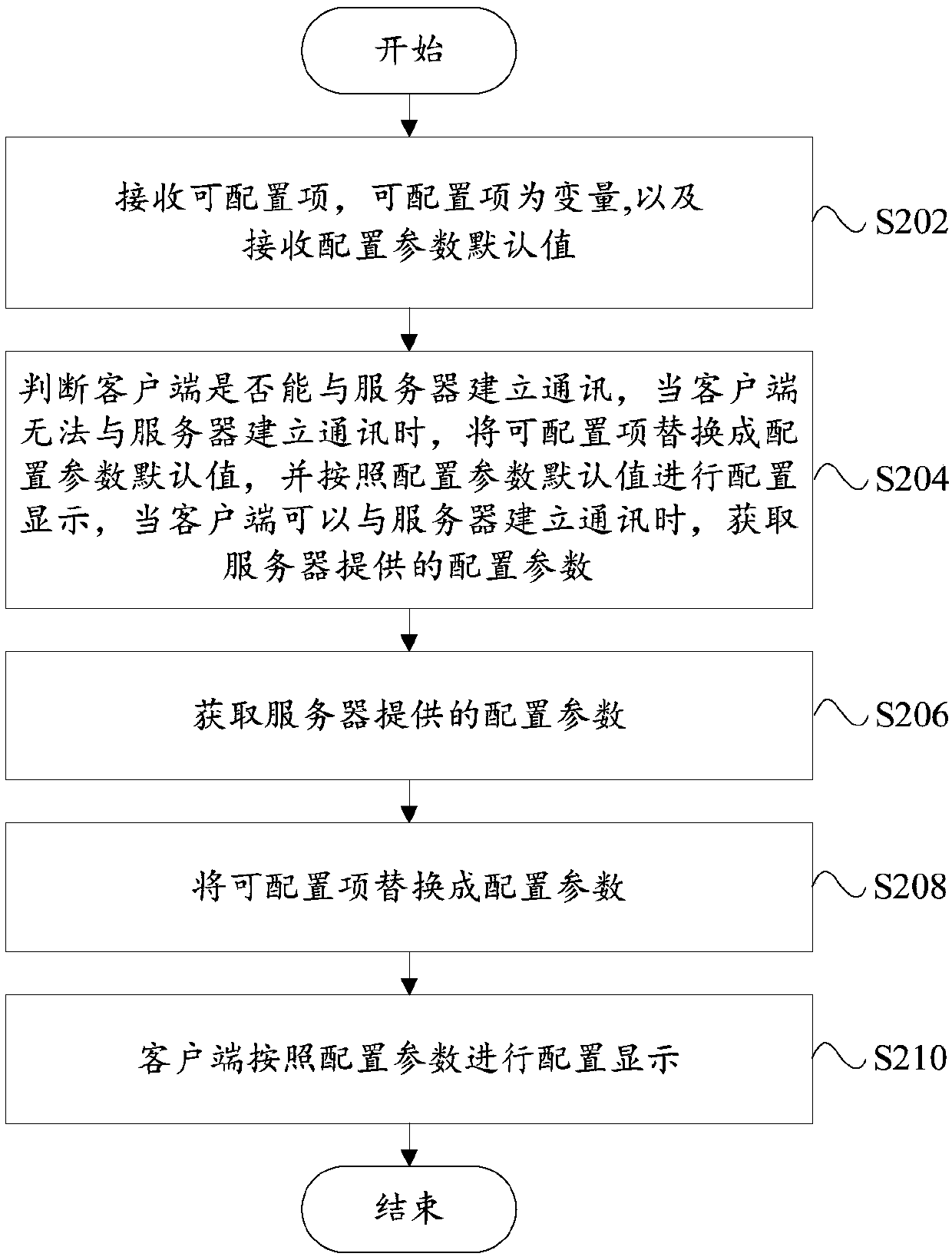

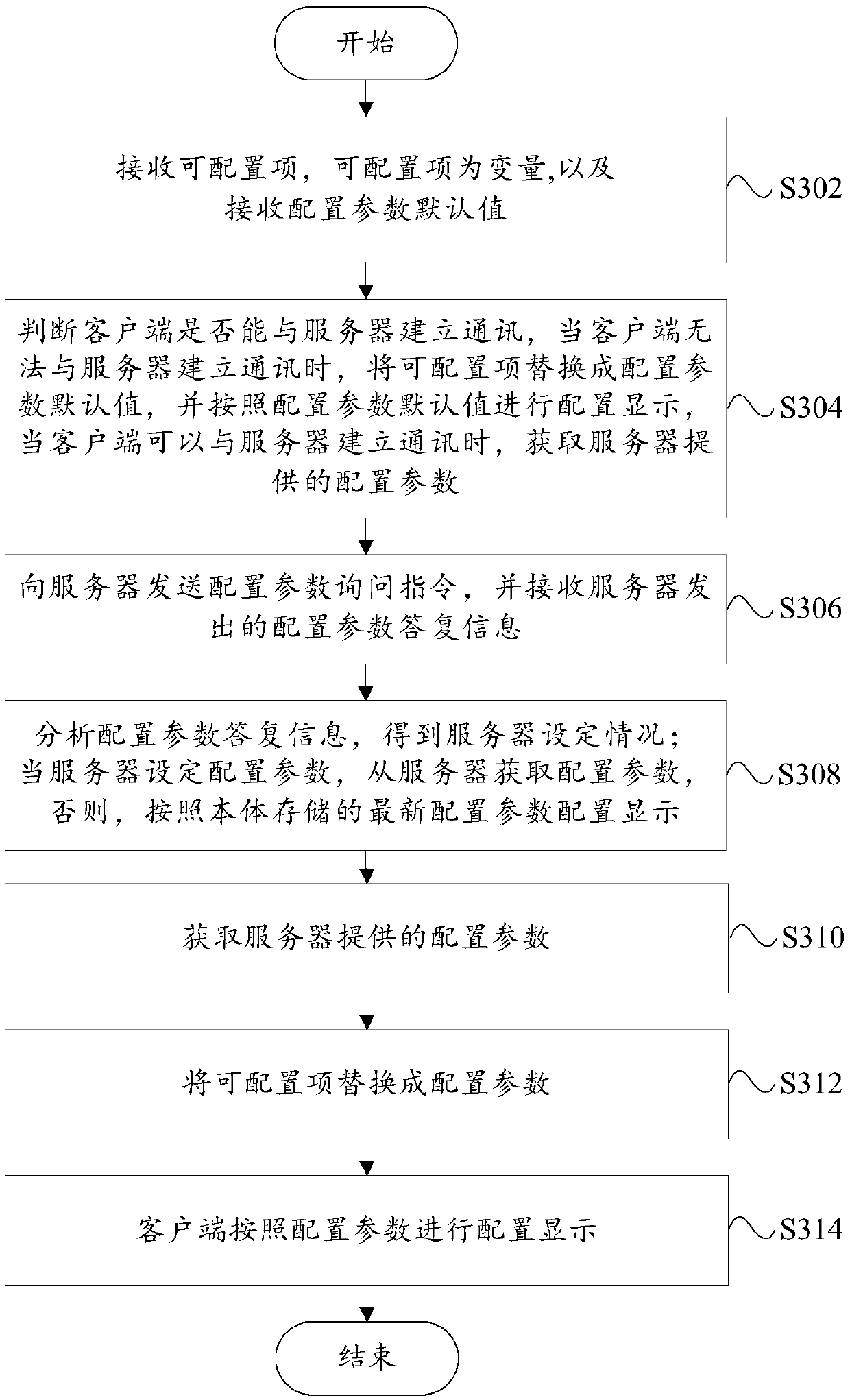

Pattern changing method and system, computer equipment and storage medium

InactiveCN110032408AConsistent designReduce unnecessary human expenditureProgram loading/initiatingExecution for user interfacesApplication softwareClient-side

The invention provides a pattern changing method and system, computer equipment and storage medium. The method comprises the following steps: receiving a configurable item, wherein the configurable item is a variable; obtaining configuration parameters provided by a server; replacing the configurable item with a configuration parameter; and enabling the client to perform configuration display according to the configuration parameters. Through the technical scheme, the design pattern of the client in the server can be kept consistent, and the distress that the client needs to be repeatedly developed and maintained in the current stage is avoided, so that the effect of dynamically changing the pattern of the application program of the client is achieved on the basis of reducing the meaningless manpower expenditure in repeated development.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Universal serial bus (USB) connecting device and electronic product

ActiveCN103199393BConsistent EMIConsistent designCoupling device detailsEmergency protective arrangements for limiting excess voltage/currentElectromagnetic interferenceUSB

The invention discloses a universal serial bus (USB) connecting device and an electronic product. The USB connecting device comprises a printed circuit board. A static releasing protecting circuit which has the function of protecting static release is arranged on the printed circuit board. A static releasing circuit of the USB connecting device is not required to be designed time and again. The static releasing circuit of the USB connecting device can ensure uniformity of design. The static releasing circuit of the USB connecting device does not always need renewed debugging after being designed each time. Electromagnetic interference of the static releasing circuit of the USB connecting device is uniform after being designed each time.

Owner:GOERTEK INC

Quick-beam change construction method for existing railway line of railroad

ActiveCN103410103BReduced impact on normal operationsNormal operation impact is minimizedBridge erection/assemblyBridge strengtheningEngineeringSunroof

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU

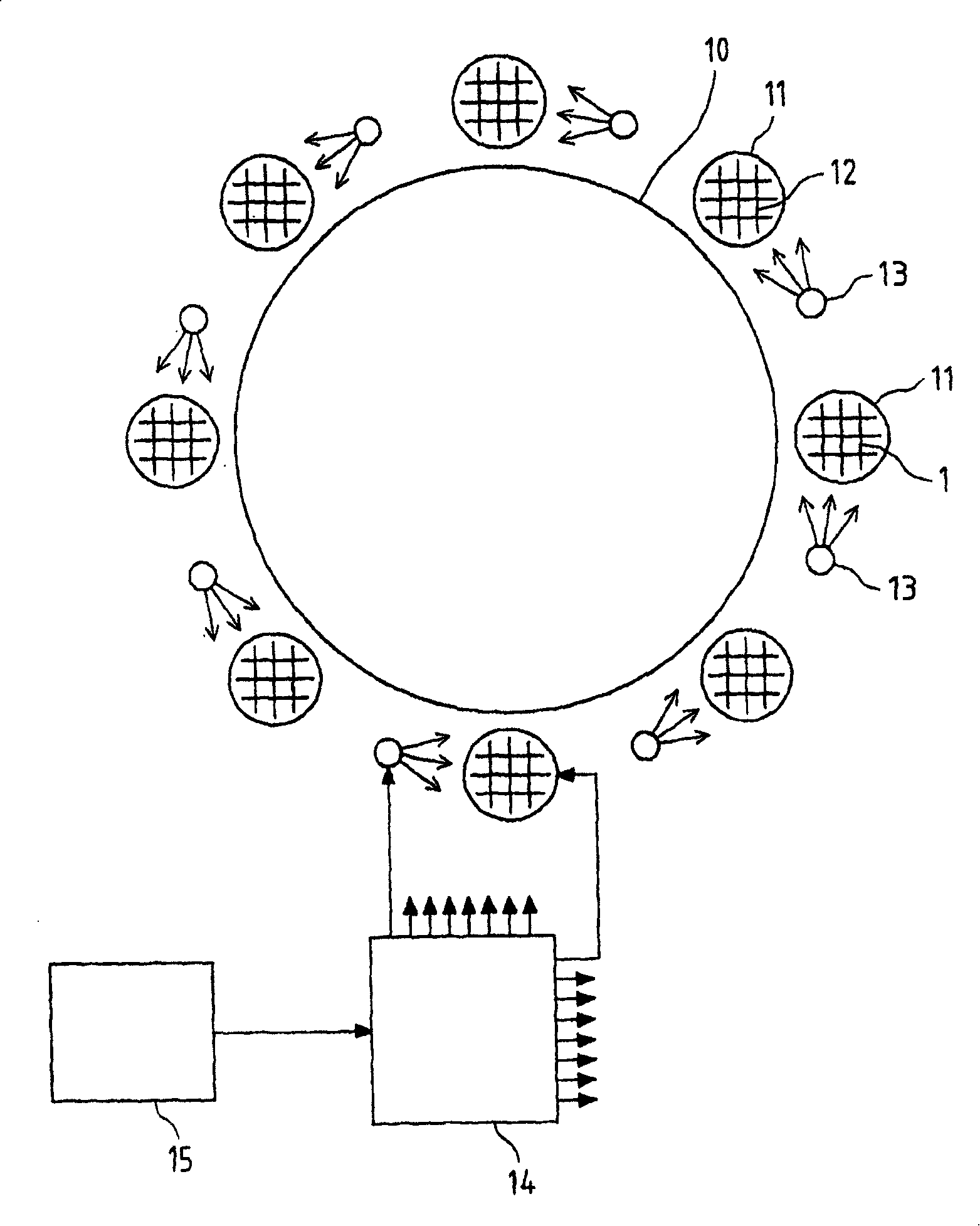

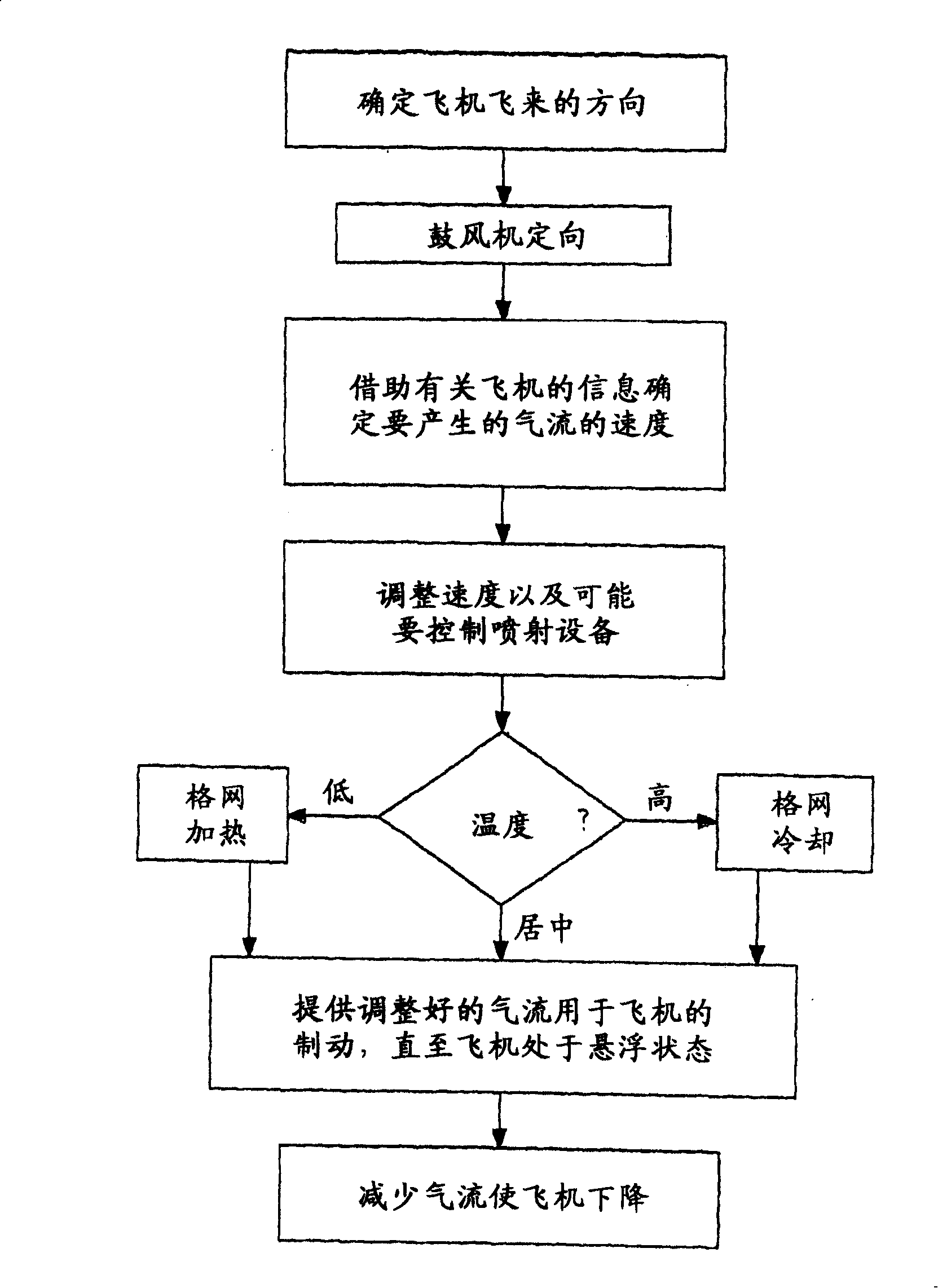

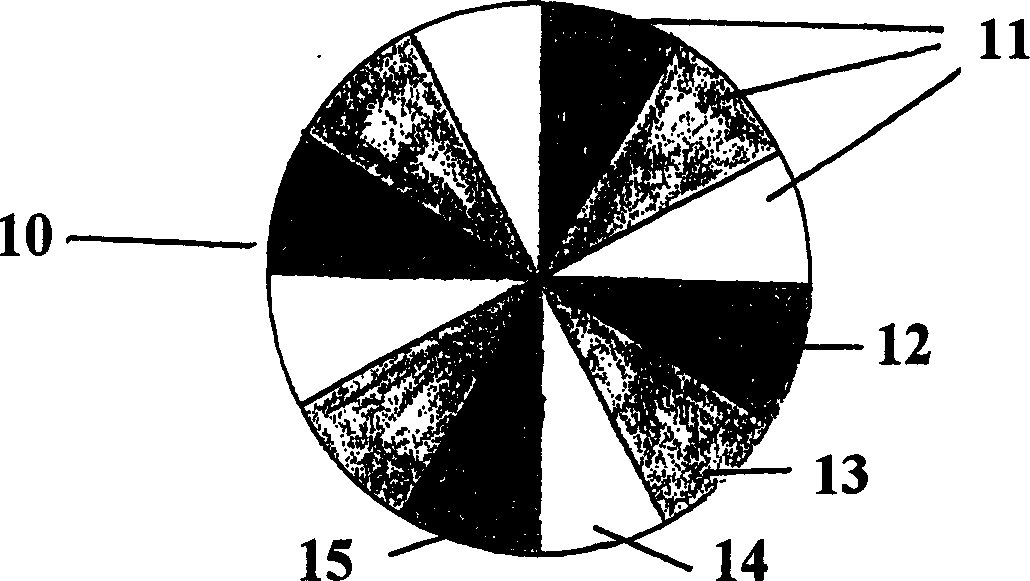

Method for supporting a propelled flying object during take-off and/or landing

InactiveCN100387488CUniversal and flexible useEasy to take offGround installationsFlight vehicleEngineering

The invention relates to a method for supporting a propelled flying object during take-off and / or landing. Support is given by means of a fluidic current, which is generated at a fixed point in relation to a take-off or landing surface (10) and which transfers energy to the flying object. The invention also relates to a device comprising a fluidic current generator (11) for producing said fluidic current.

Owner:克劳斯·沃尔特

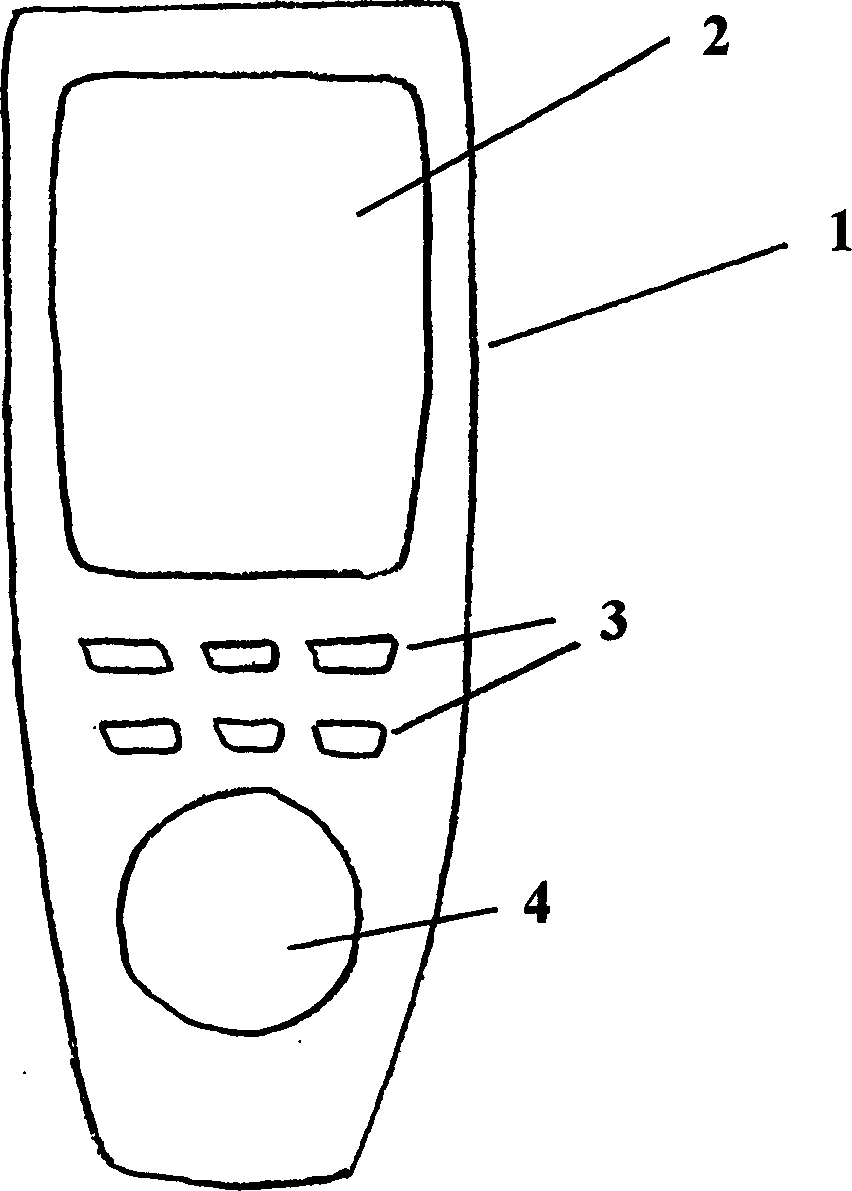

Encoding device

A motion encoder for use with a rotating key. The motion encoder allows the direction of rotation to be determined by providing elements having different characteristics for the transmission of a IR beam. These elements are arranged in a pattern that allows an IR beam impinging on the elements to trace a path detected as the rotating key turns. The beam being detected after changes in the reflected or transmitted beam indicating the direction of rotation of the beam.

Owner:NOKIA TECH OY

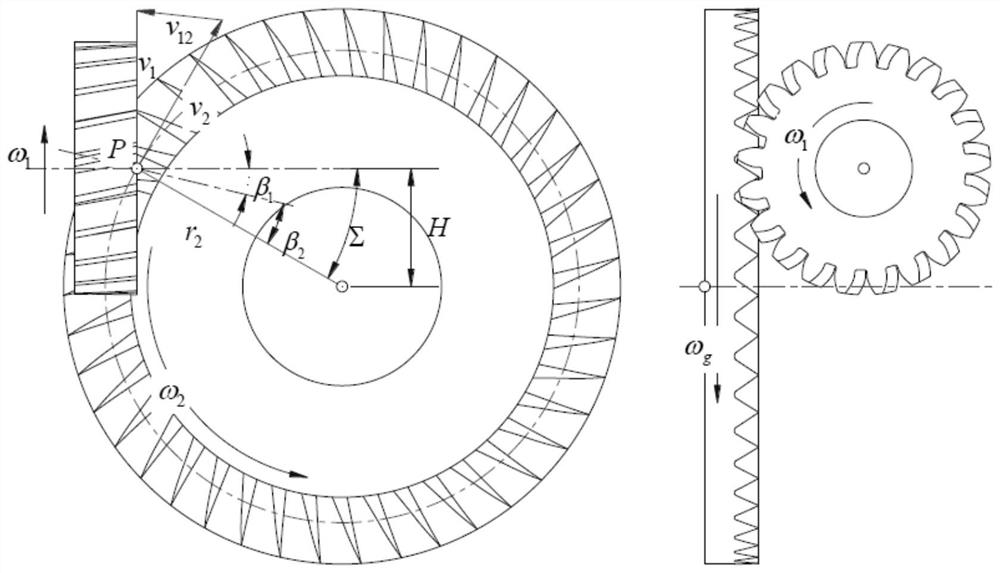

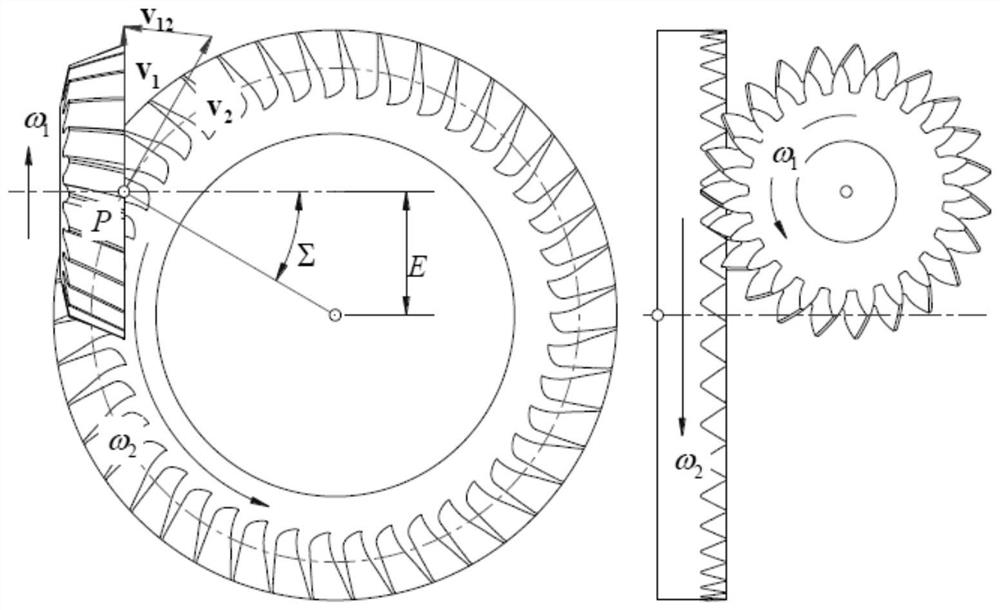

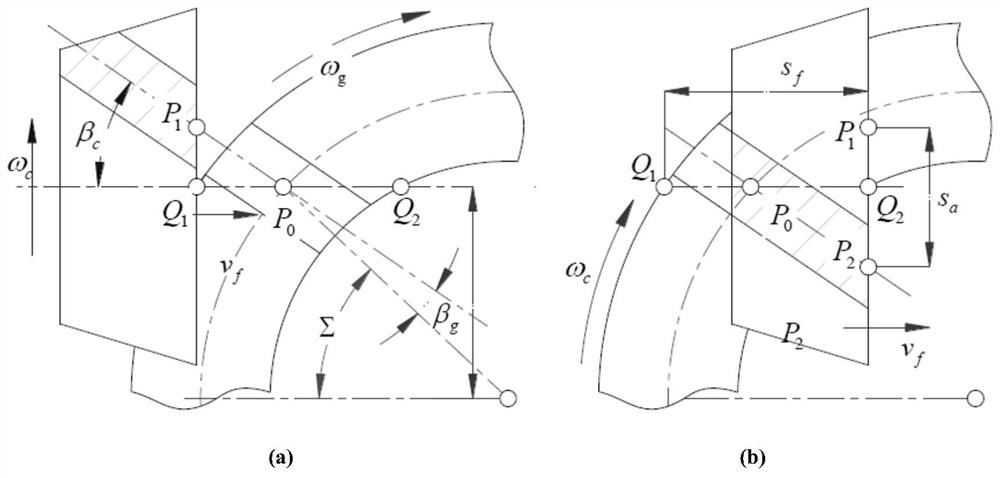

Face gear tooth scraping machining method

ActiveCN112719467AIncrease productivityImprove machining accuracyGear-cutting machinesGear teethGear wheelEngineering

The invention relates to a face gear tooth scraping machining method. A face gear is machined by adopting a method of using a cutter to cut a workpiece, the cutter and a workpiece are in spatial staggered axial surface worm transmission, namely the cutter and the workpiece form a spatial cylindrical surface worm pair, and therefore, tooth scraping machining of the face gear is realized. The face gear tooth scraping machining method inherits the technical advantages of tooth scraping of the cylindrical gear and possesses higher production efficiency and machining precision. According to the face gear tooth scraping machining method, enveloping of the tooth surface is achieved through the space surface worm transmission principle, and materials are removed by adjusting offset of the cutter and the workpiece in the machining process.

Owner:WUHAN UNIV OF TECH

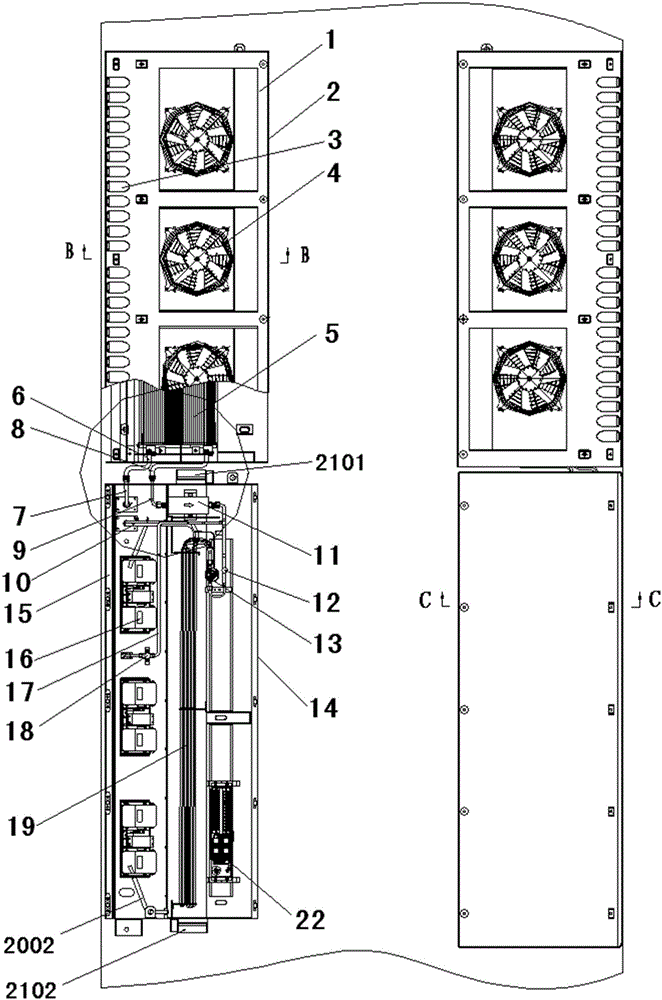

Sunken overhead passenger car air conditioner

ActiveCN103496309BLower the altitudeIncreased Design FreedomAir-treating devicesVehicle heating/cooling devicesWhole bodyFresh air

The invention discloses a sunken type top-set air-conditioner of a passenger car. The sunken type top-set air-conditioner is of a split type double-system structure. A cooling system of two condensers, two evaporators, two expansion valves and two liquid supply pipes which all working under a compressor is adopted. The cooling system is designed to be two laterally-symmetric and mutually-independent cooling structures. The two cooling structures are arranged on concave positions, on the two sides below a car ceiling cover, of car body luggage brackets in a sucken type. Highest positions of the cooling structures are not higher than the middle part of the car ceiling cover. The radian of a top cover of each cooling structure is a part transiting from a car ceiling to a side wall of a car body. The structure of the edge of each cooling structure is almost uniform with a large plane of one car body side wall. After installation, the appearance of the cooling structures, the top of the car body of the passenger car, side walls of the car body of the passenger car form a unified whole body. The sunken type top-set air-conditioner of the passenger car is reduced in weight, is provided with a fresh air inlet on the condition that the height of the car body is not increased, and is convenient to maintain, favorable to coordinated development of an air-conditioner structure and a whole shape of the passenger car, and capable of exploring a new conception for the development of air-conditioners of passenger cars.

Owner:SONGZ AUTOMOBILE AIR CONDITIONING

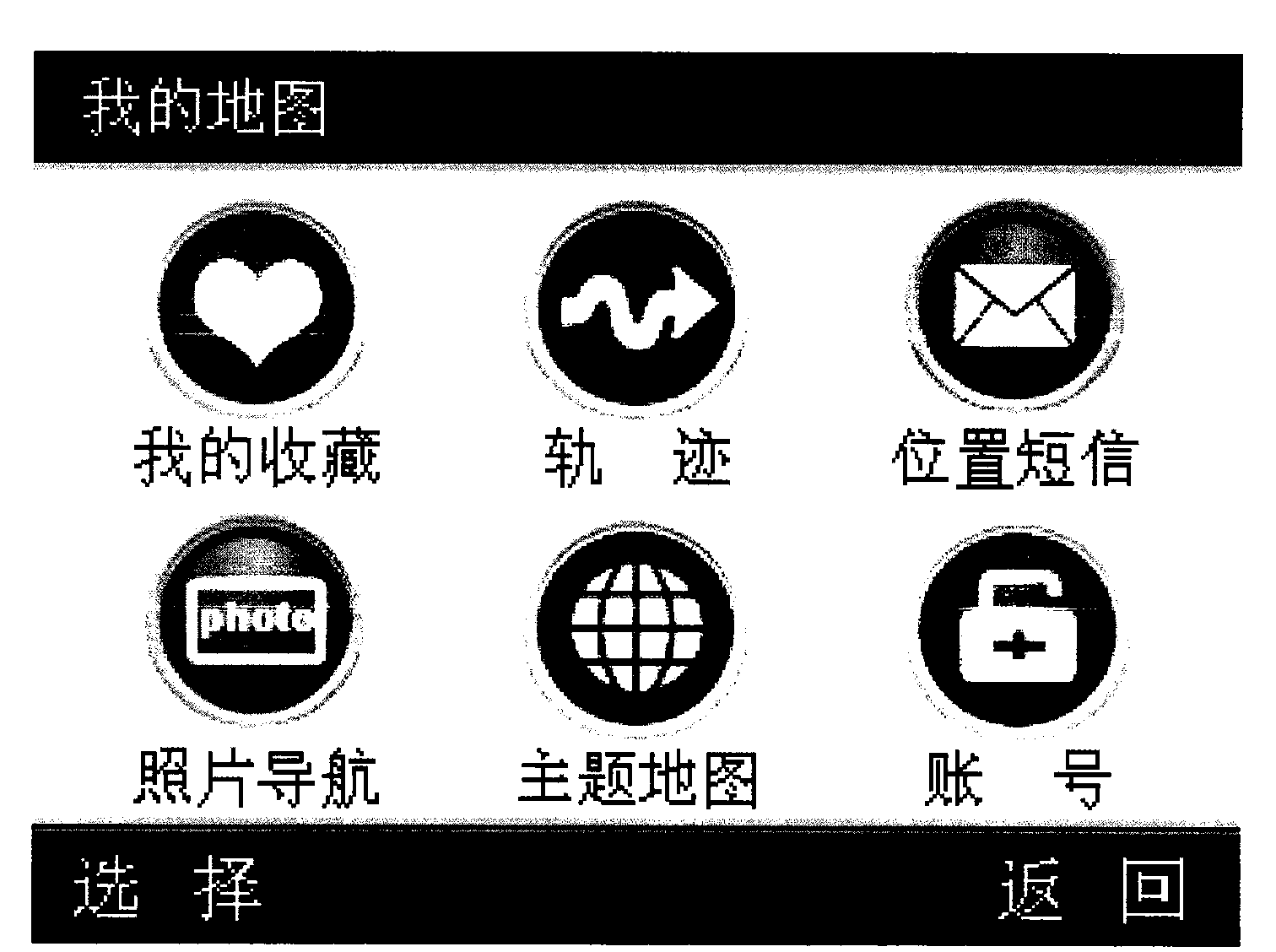

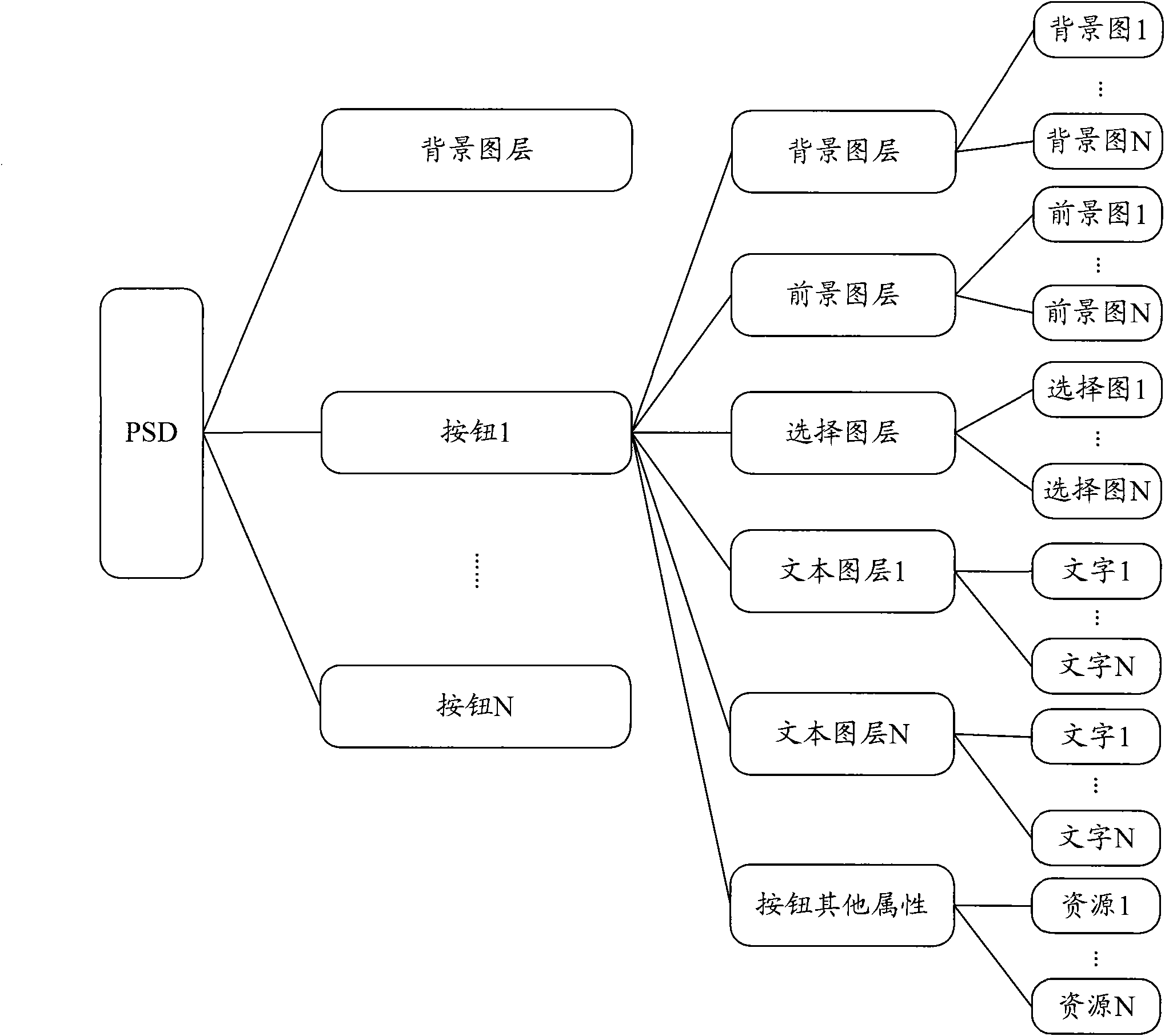

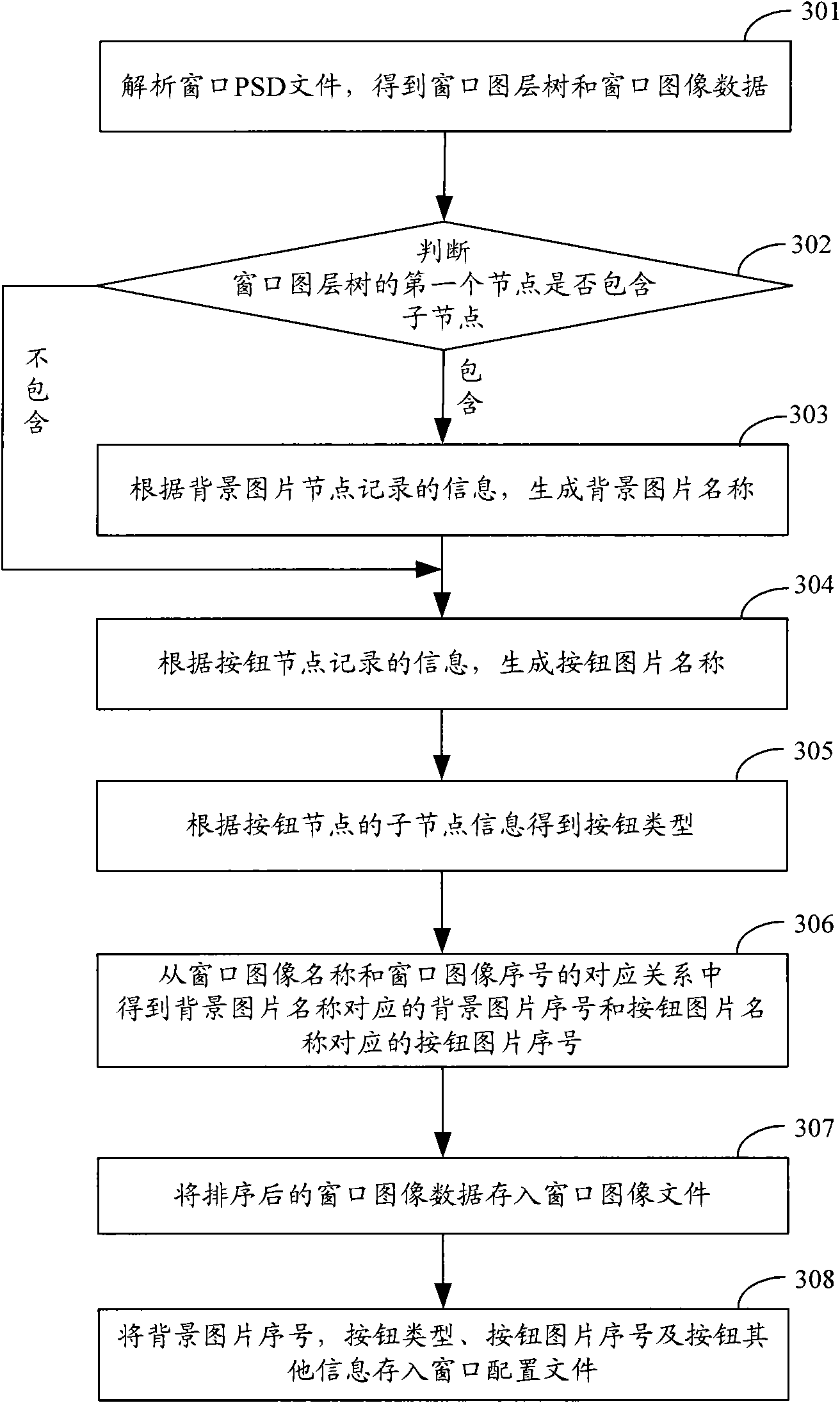

Method and device for generating window resource file

InactiveCN102117205BImprove production efficiencyConsistent designSpecific program execution arrangementsImaging dataResource file

The invention provides a method and a device for generating a window resource file. In the method provided by the invention, a window map layer tree and window image data are acquired by resolving a window photoshop document (PSD) file; and because the map layer structure of the window map layer tree is ordered, the window resource file can be automatically generated according to the window map layer tree and the window image data. Further, the invention also provides the device for implementing the method. By adopting the method and the device for generating the window resource file, the window resource file can be automatically generated without manual participation; compared with the prior art, the generation efficiency of the window resource file is improved; and in the absence of manual participation in the process of generating the window resource file, the window resource file contains all information in the PSD file, so that complete consistency of a window obtained through the window resource file and an original window designed by an artist is ensured.

Owner:ALIBABA (CHINA) CO LTD

Method for measuring peak sunshine hours

InactiveCN101718880BConsistent designRadiation data consistentSunshine duration recordersICT adaptationSolar cellSunshine duration

The invention discloses a method for measuring peak sunshine hours, which comprises the following steps: (1) using calibrated standard solar cells to divide each day into N time periods with a duration of t and measuring instantaneous radiation intensity S of each time period, wherein the daily radiation quantity can be calculated according to an equation that Q is equal to N,S and t and the corresponding daily peak sunshine hours can be calculated according to an equation that Hp is equal to NST / 1,000; (2) obtaining daily average peak sunshine hours of each month and yearly average peak sunshine hours by using an averaging method; and (3) storing and exporting the data on the daily peak sunshine hours, monthly average peak sunshine hours and yearly average peak sunshine hours. The methodcan directly obtain peak sunshine hours and make photovoltaic system design more visual and convenient.

Owner:CSI CELLS CO LTD +6

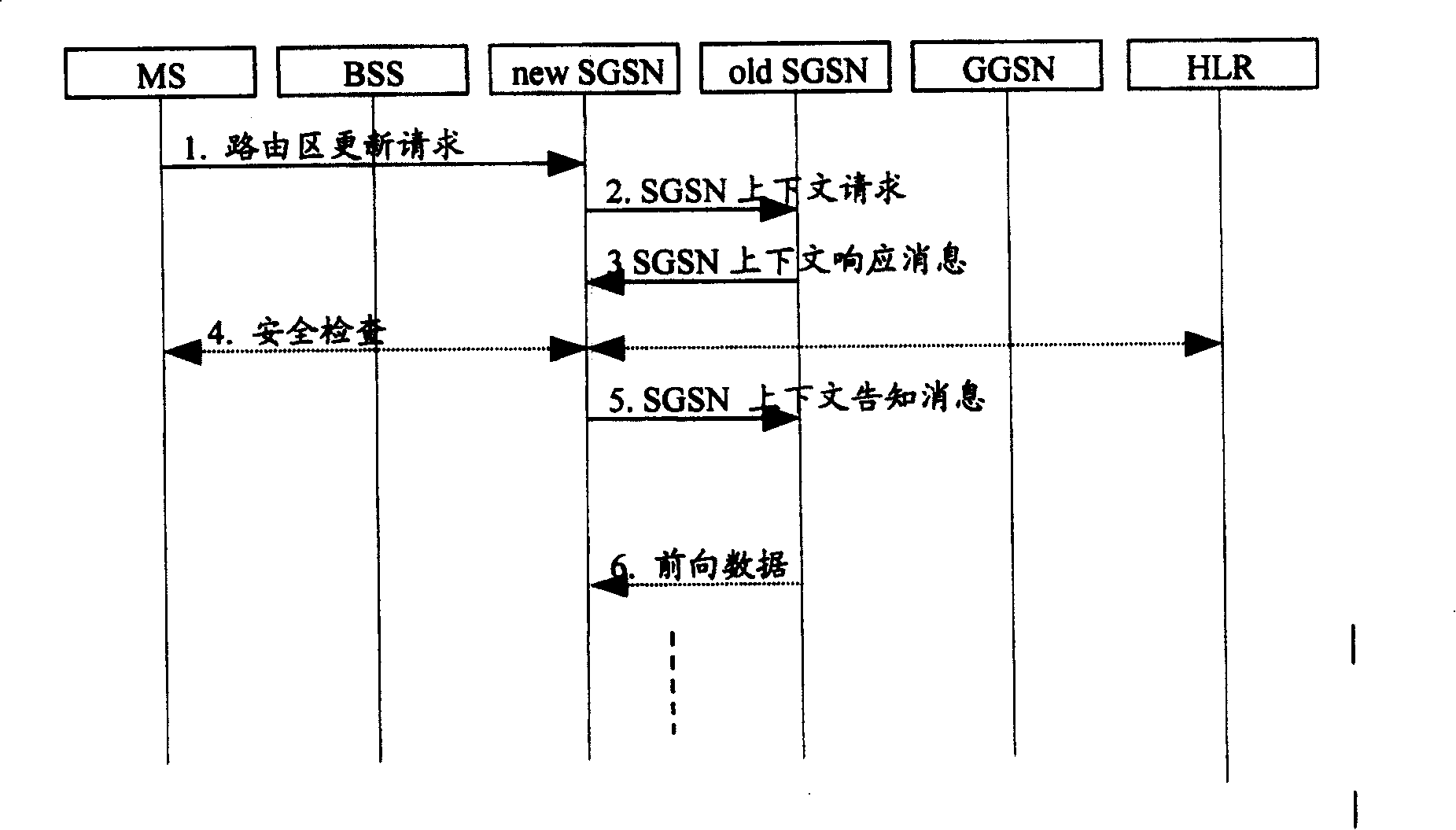

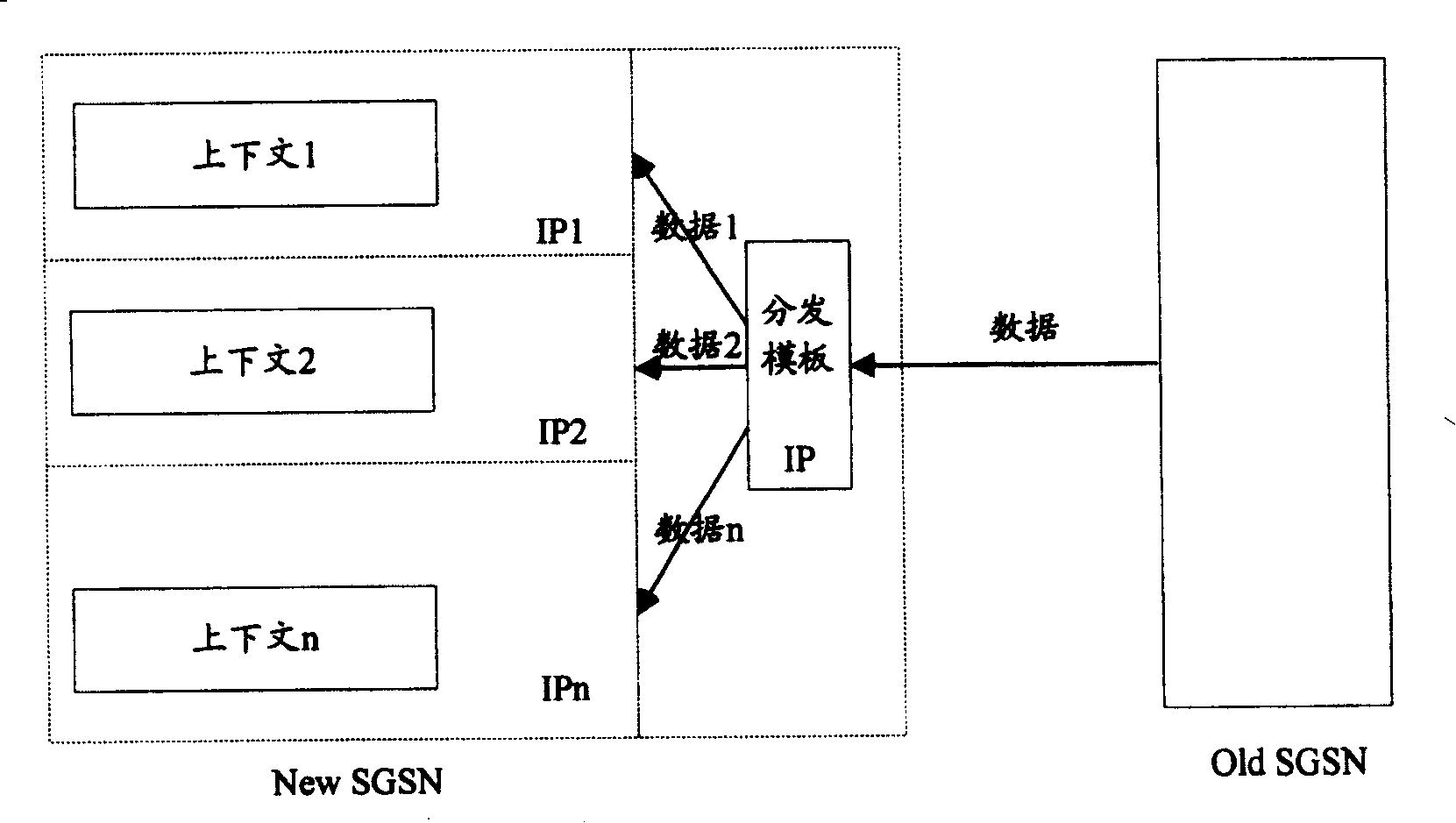

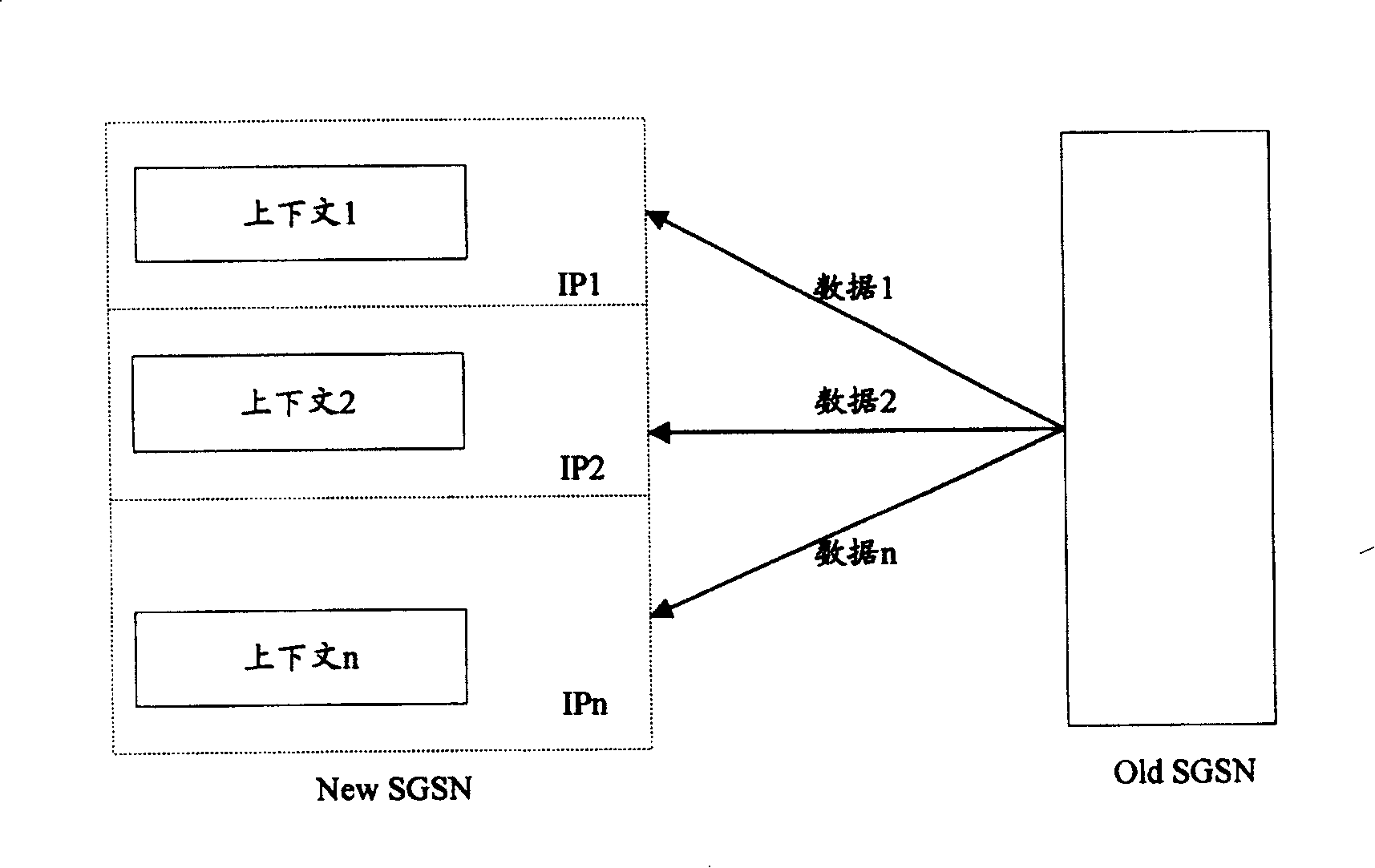

Data transmission method when routing area updates

InactiveCN100411385CFlexible transmissionSimple designConnection managementData switching by path configurationIp addressData transmission

The invention discloses data transmission method when the route region is refreshed. The method comprises following steps: MS requires the new SGSN of new route region to attain the PDP context from the old SGSN of old route region when the route region is refreshed in SGSN; the new SGSN arranges the tunnel to each PDP context after receiving the PDP context from old SGSN and arranges the IP address of relative PDP context to each tunnel, then, sending the relation between distributed tunnels and IP addresses to the old SGSN; the old SGSN transmits the data of each PDP context to the new SGSN via relative tunnel. The inventive method solves the problem that old SGSN can only transmit the data to unique address in present technique, so the new SGSN should relates to distribution modules for distributing data. The invention can make the transmission of user's data more flexible when the route region of SGSN is refreshed, simplify the design of system and shorten the refresh time of route region.

Owner:HUAWEI TECH CO LTD

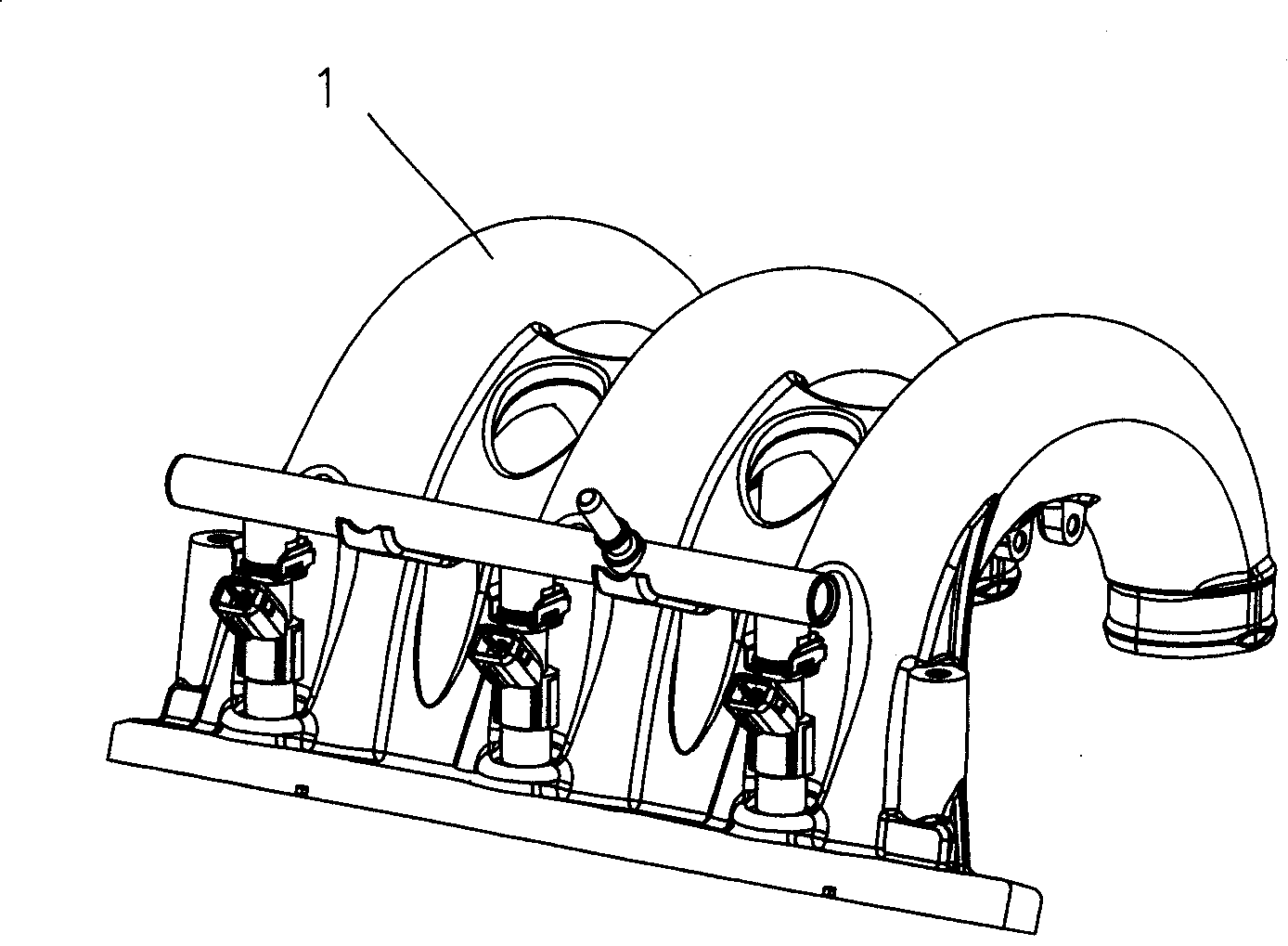

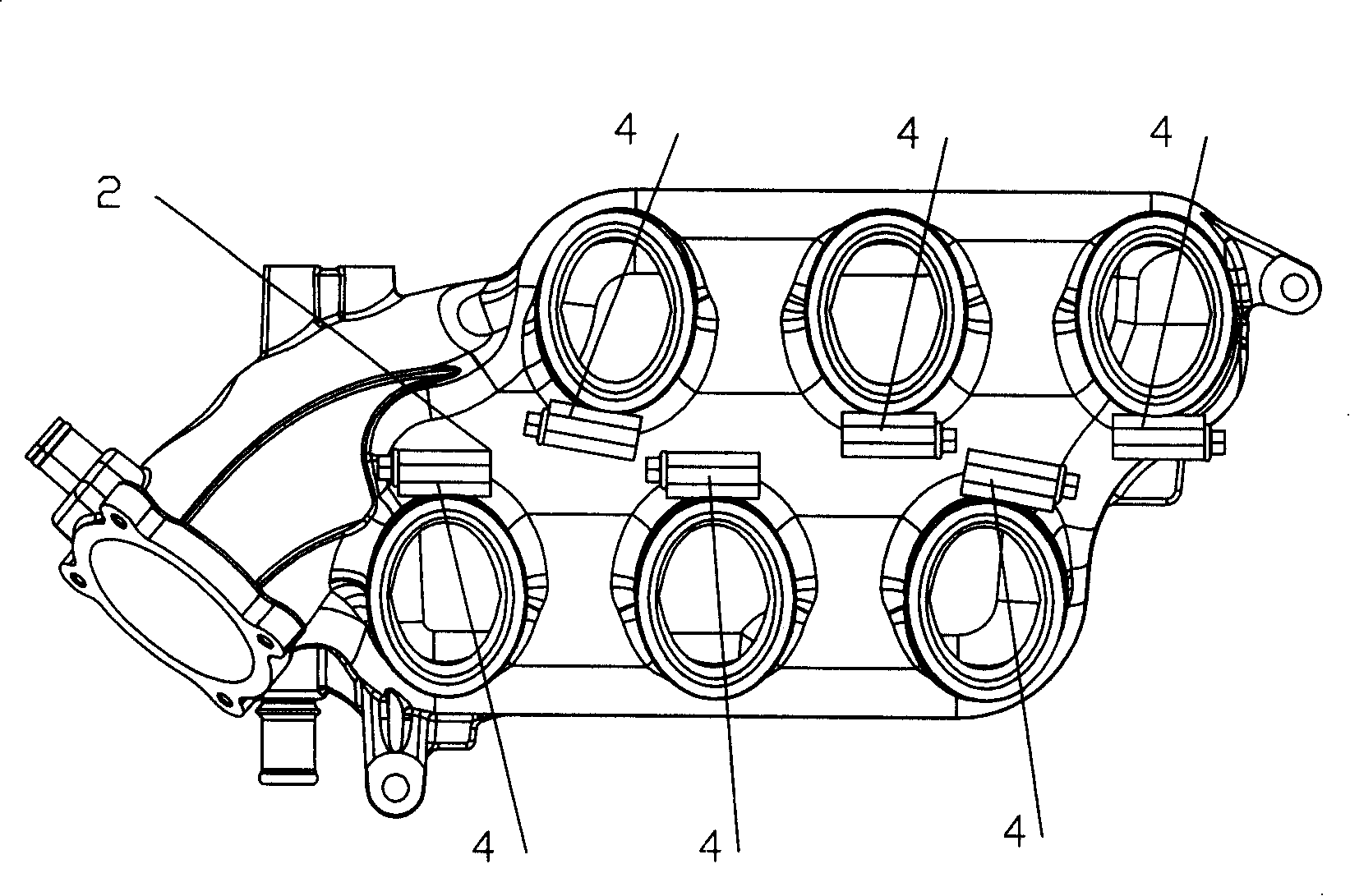

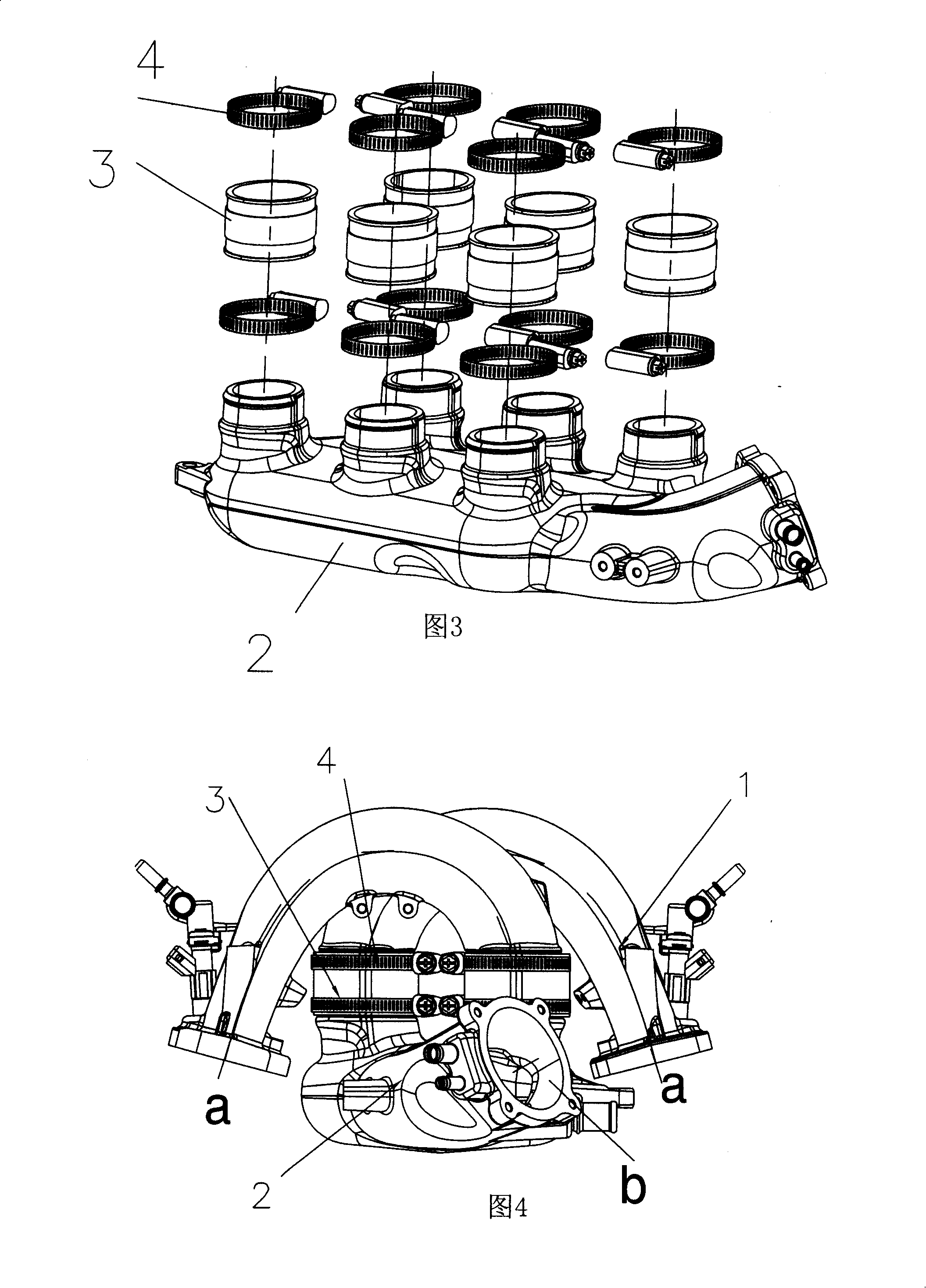

Engine intake manifold

InactiveCN101210525ACompact layoutConsistent designCombustion-air/fuel-air treatmentMachines/enginesCylinder headEngineering

Disclosed is an intake manifold for an engine. The intake manifold is arranged and connected between two cylinder heads of a V-shaped engine; the lower part of the intake manifold is designed as a pressure-regulating cavity which is provided with an intake; the upper parts of two intake manifolds intersect and connect with the lower part of the intake manifold via connecting hoses and clamps. In order to ensure the strength of a manifold branch on the upper part of the intake manifold, connecting ribs are arranged among manifold branches. Since the upper part of the intake manifold only adopts a cross structure, the intake manifold is arranged between two cylinder heads of the V-shaped engine, and the upper parts of the two intake manifolds intersect and connect with the lower part of the intake manifold via the connecting hoses and the clamps, so that arrangement is compact and space is fully utilized; lengths between the intake manifolds and gas passages of cylinders are designed as identical, structure is simple, casting process is convenient, and gas intake of each cylinder of the engine is uniform.

Owner:CHERY AUTOMOBILE CO LTD

Design Method of Pneumatic Matching for Multistage Compressor

ActiveCN112711923BUnchanged aerodynamic layoutSingle-Stage Design SimplificationGeometric CADSustainable transportation3d designControl engineering

A multi-stage compressor aerodynamic matching design method, which is based on the principle of equivalent outlet conversion flow rate and under the condition of keeping "isentropic efficiency unchanged", calculates and obtains the equivalent outlet conversion flow line passing through the single-stage design working point; After the equal-outlet conversion flow line of the stage, through the deviation correction of the design system, along the equal-outlet conversion flow line, the revised single-stage design target is obtained, and then the single-stage iterative design is carried out; when carrying out the 3D design work of a specific stage, the The two-dimensional total temperature, total pressure, and air flow angle profiles obtained in the S2 design process are used for the stage inlet conditions, so that the three-dimensional design is consistent with the one-dimensional and two-dimensional design results, that is, the design links of the compressor are consistent. The present invention can effectively separate the single-stage design from the multi-stage design work on the premise of meeting the aerodynamic layout design target of the whole compressor, and complete the aerodynamic design of the single-stage compressor without affecting the overall aerodynamic layout of the compressor , thus optimizing the compressor design process.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

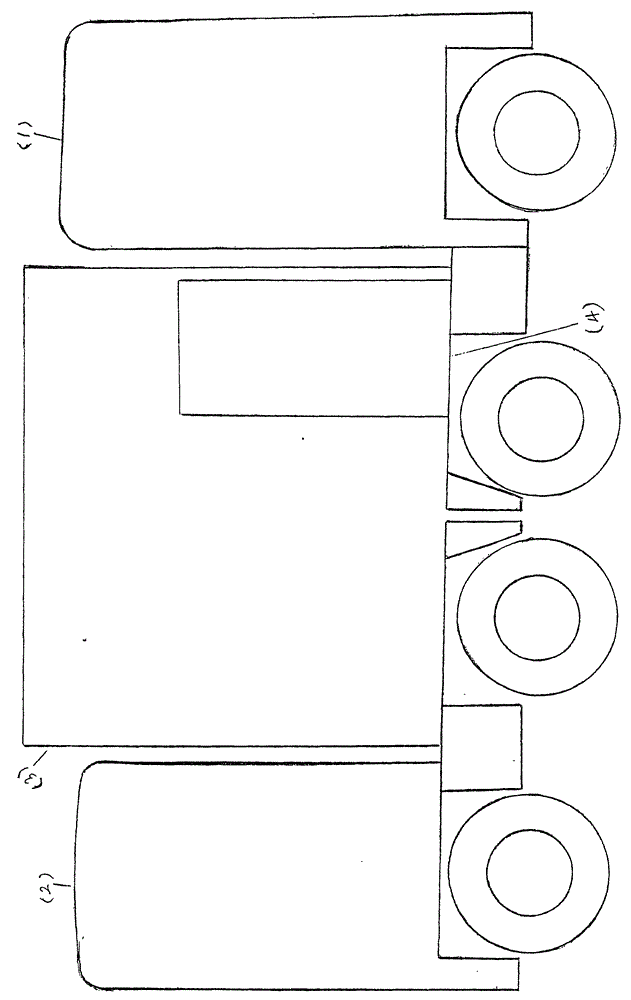

Double-end motive power heavy truck

The invention discloses a double-end motive power heavy truck which is composed of a 12 or 16-liter six-cylinder in-line arrangement turbocharging electronic fuel oil engine with an intercooler. The double-end motive power heavy truck is 19.5 to 28 meters in length, a main cab and an auxiliary cab of the two-connection double-end motive power heavy truck are uniform in design, and the double-end motive power heavy truck runs in forward pulling mode and backward pulling mode and can run in a single truck mode. The maximum load-bearing capacity of the double-power motive power heavy truck is 150 to 300 tons, a 12-liter engine and a 16-liter engine can provide 340x2 and 380x2 to 520x2 watts respectively, 9 types of front axle configuration are arranged on a chassis of the double-end motive power heavy truck, 11 different types of configuration including back shafts such as 4x2, 4x4, 6x2, 6x4, 8x2 and 8x4 and double rear axles are arranged on an axle structure, and a speed control system is configured with 6 manual and automatic gears and configured electrically. A truck suspension system includes three choices including an air suspension system, a parabola leaf-shaped suspension structure and a hinged truck frame suspension structure.

Owner:付长发

Intelligent skirt style and pattern design system

InactiveCN101482897BReduce the need for technical expertiseSmart addSpecial data processing applicationsEngineeringProfessional skills

The invention relates to an intelligent skirt style and pattern design system. The system obtains and describes skirt styles and pattern knowledge through the rule-based and case-based reasoning technology, establishes a skirt design rule base and a skirt design case base which integrate expertise and professional skills, breaks through the bottleneck of knowledge obtaining and description of theproduction expert system, and realizes to rapidly design a skirt style drawing, intelligently identify the style drawing and automatically and intelligently generate a corresponding templet. The invention provides two design modes according to the characteristics of the styles, and expands the applied range of the system. The reconstruction and reusing function can enrich the CAD system, effectively simplify the operation, improve the design efficiency, realize to reuse technology and experience of the enterprises, makes the designers liberate from simple and repeated work, and reflects the superiority of combining the dress and the artificial intelligence technology.

Owner:DONGHUA UNIV

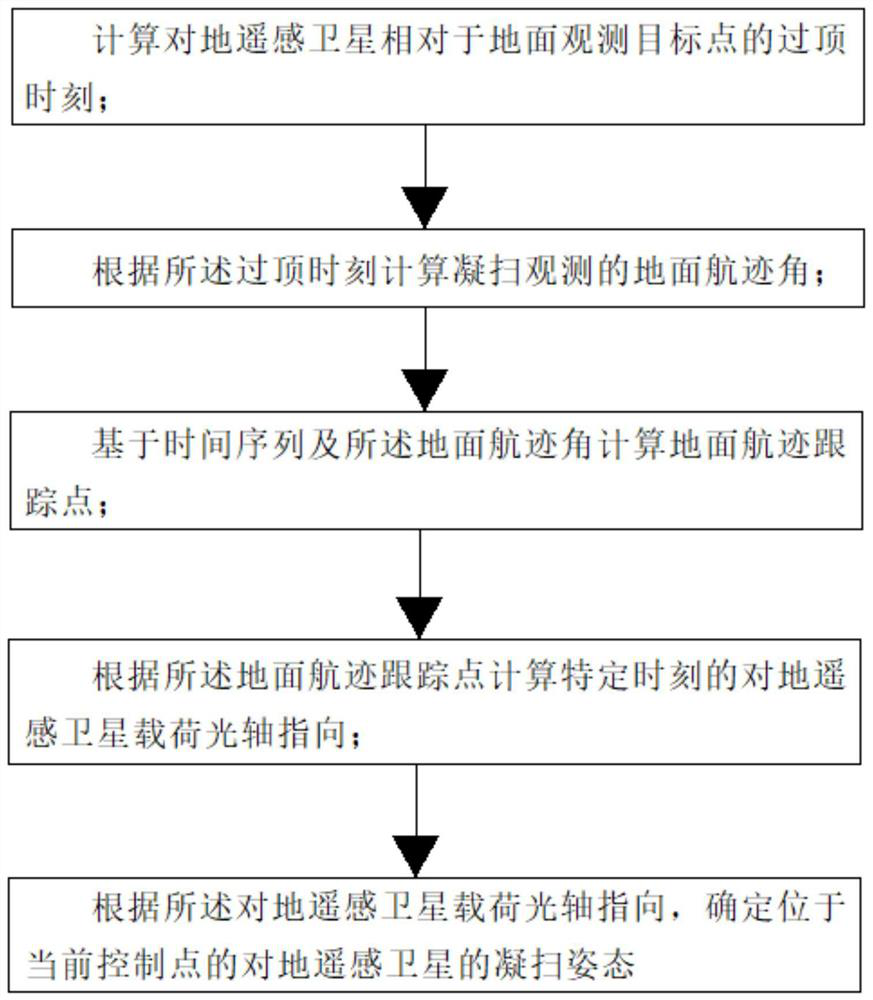

Method and system for controlling attitude of ground remote sensing satellite during sweeping and sweeping

ActiveCN112722329BImprove pointing accuracyRealize high-precision distortion-free gaze sweep observation controlMaterial analysis by optical meansSatellite radio beaconingAttitude controlOptical axis

The present invention provides a method and system for controlling the freezing and sweeping attitude of a remote sensing satellite on the ground. Calculate the ground track angle of the condensation sweep observation at the time of passing the top; calculate the ground track tracking point based on the time series and the ground track angle; ; According to the direction of the optical axis of the earth remote sensing satellite load, determine the freezing and sweep attitude of the earth remote sensing satellite located at the current control point.

Owner:上海中科辰新卫星技术有限公司

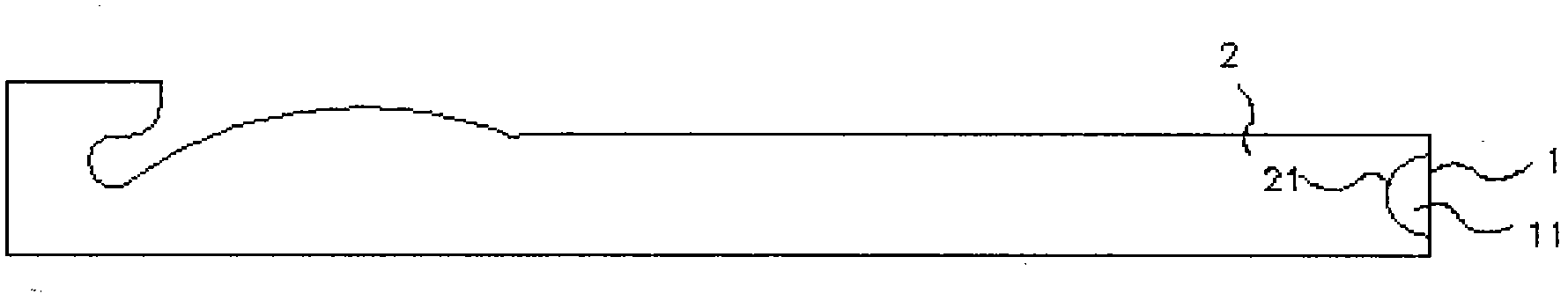

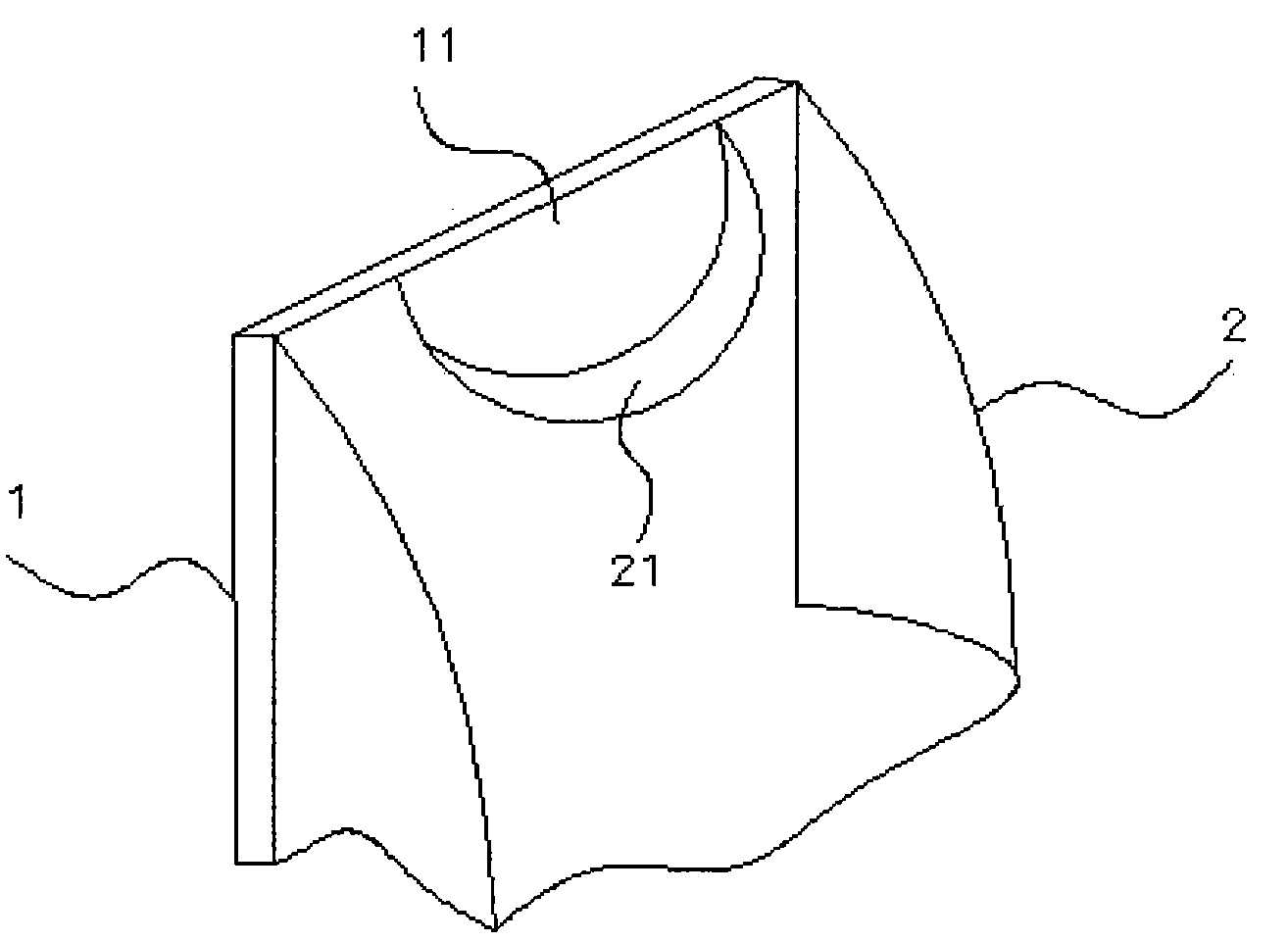

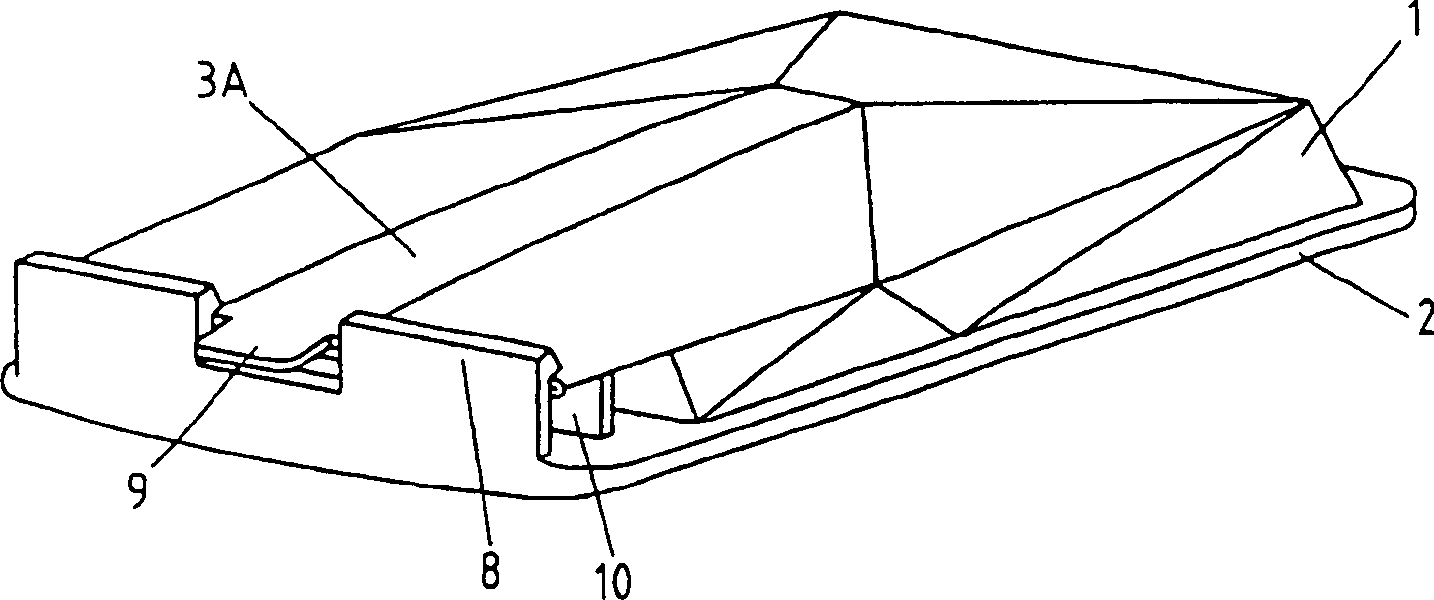

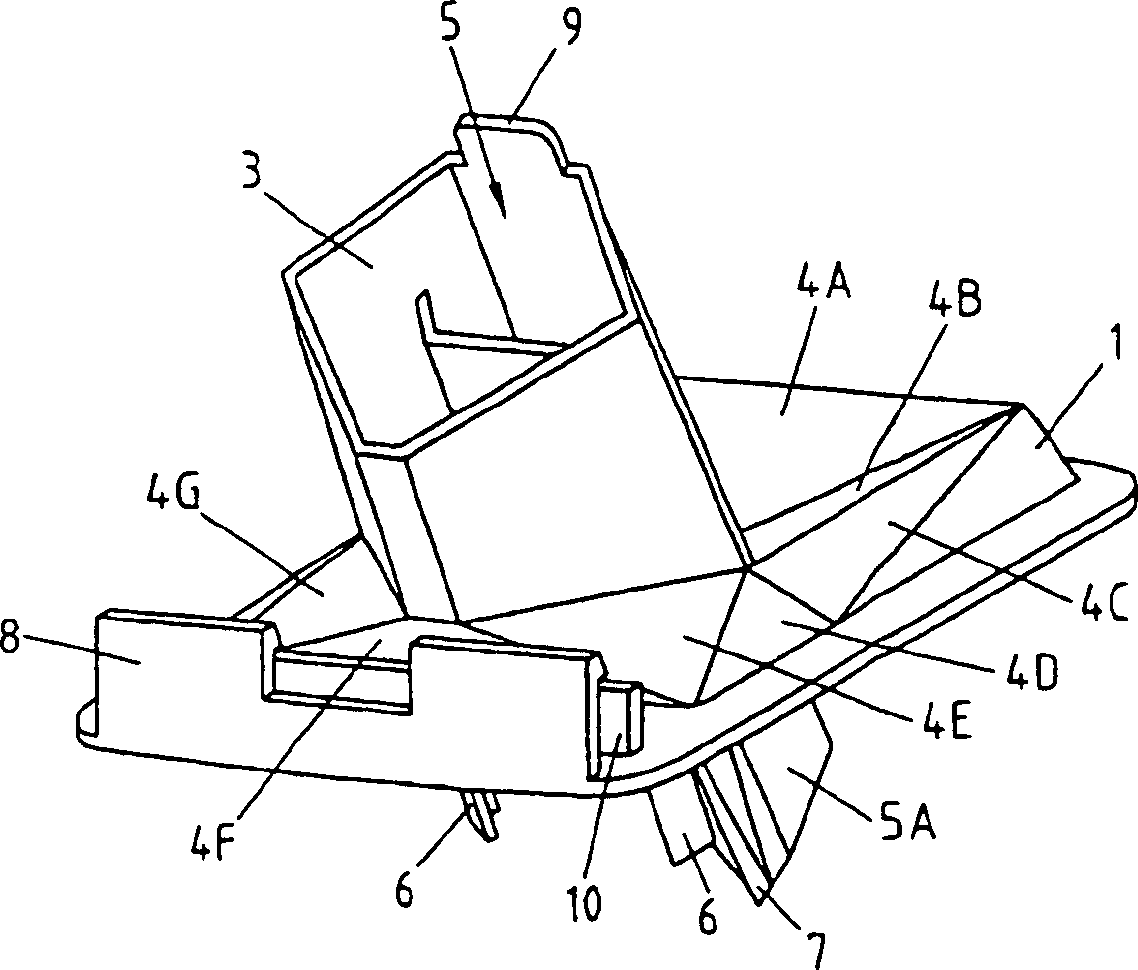

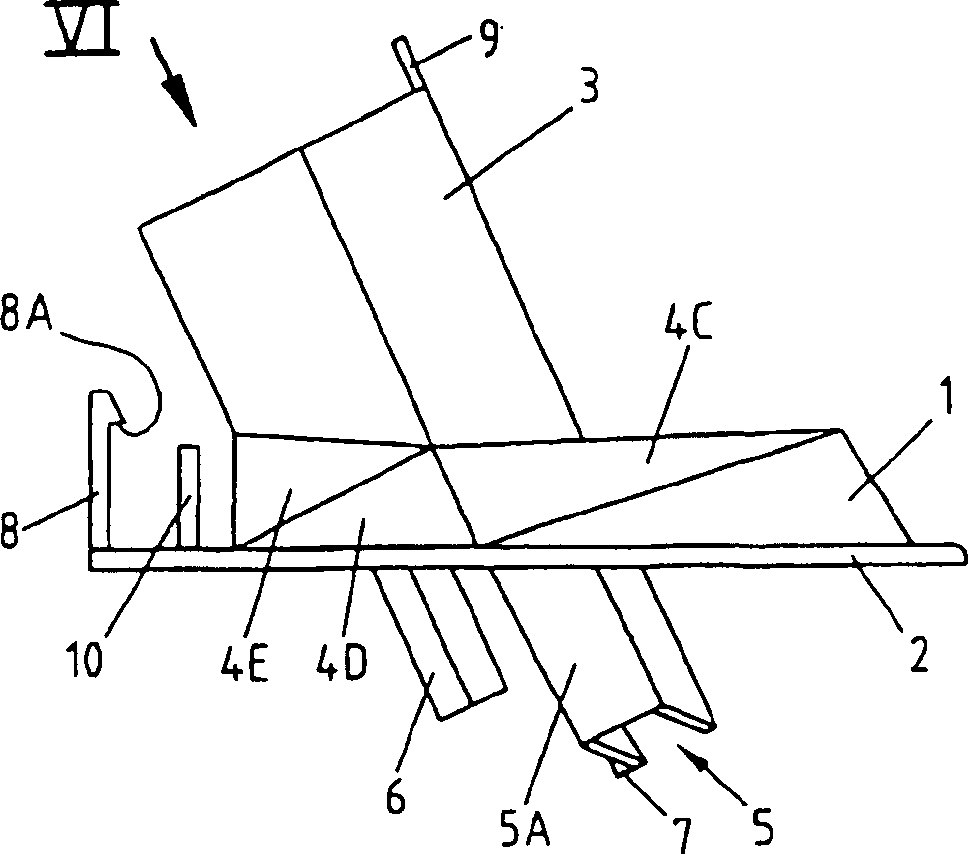

Reclosable pouring element

InactiveCN1278908CReduce the height of the structureImprove sealingClosure capsDischarging meansCardboardThin membrane

Illustrated and described is a reclosable pouring element for application to a multi-layer composite package, especially rectangular cardboard / plastic composite package, with a base body ( 1 ) and a pouring tube ( 3 ) joined flexibly to the base body in one piece, which at the same time is constructed as an opening element for piercing the package wall of the package in a zone of weakening provided therefor, and a package provided therefor. In order to achieve that a reliably opening and reclosing pouring element is obtainable with a small overall height, which is as user-friendly as possible for the consumer in every respect, it is provided that the pouring tube ( 3 ) is joined to the base body ( 1 ) by a circumferential flexible membrane ( 4 ) and is folded flat in the closed state so that the folded-flat pouring tube ( 3 ) is clamped between a clamping edge ( 8 ) and a clamping cross-piece ( 10 ) of the base body ( 1 ) in a sealing fashion.

Owner:SIG ALLCAP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com