Excavation method of pile hole

A pile hole and expansion hole technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of slow hole forming speed of single pile, large labor usage, leakage of construction personnel, etc., to reduce manpower Construction, construction progress is fast, and the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] The excavation method of pile hole of the present invention, comprises the following steps:

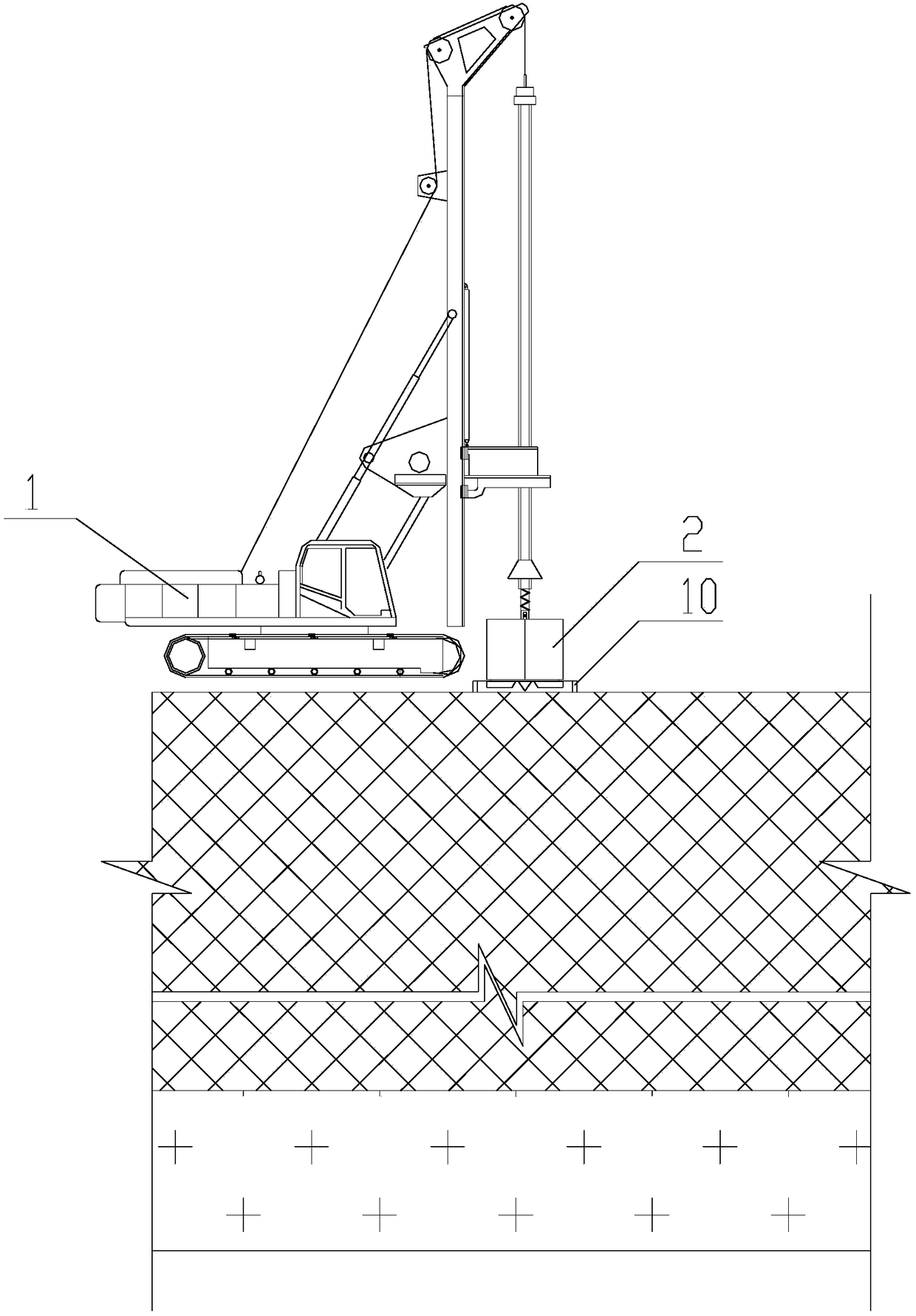

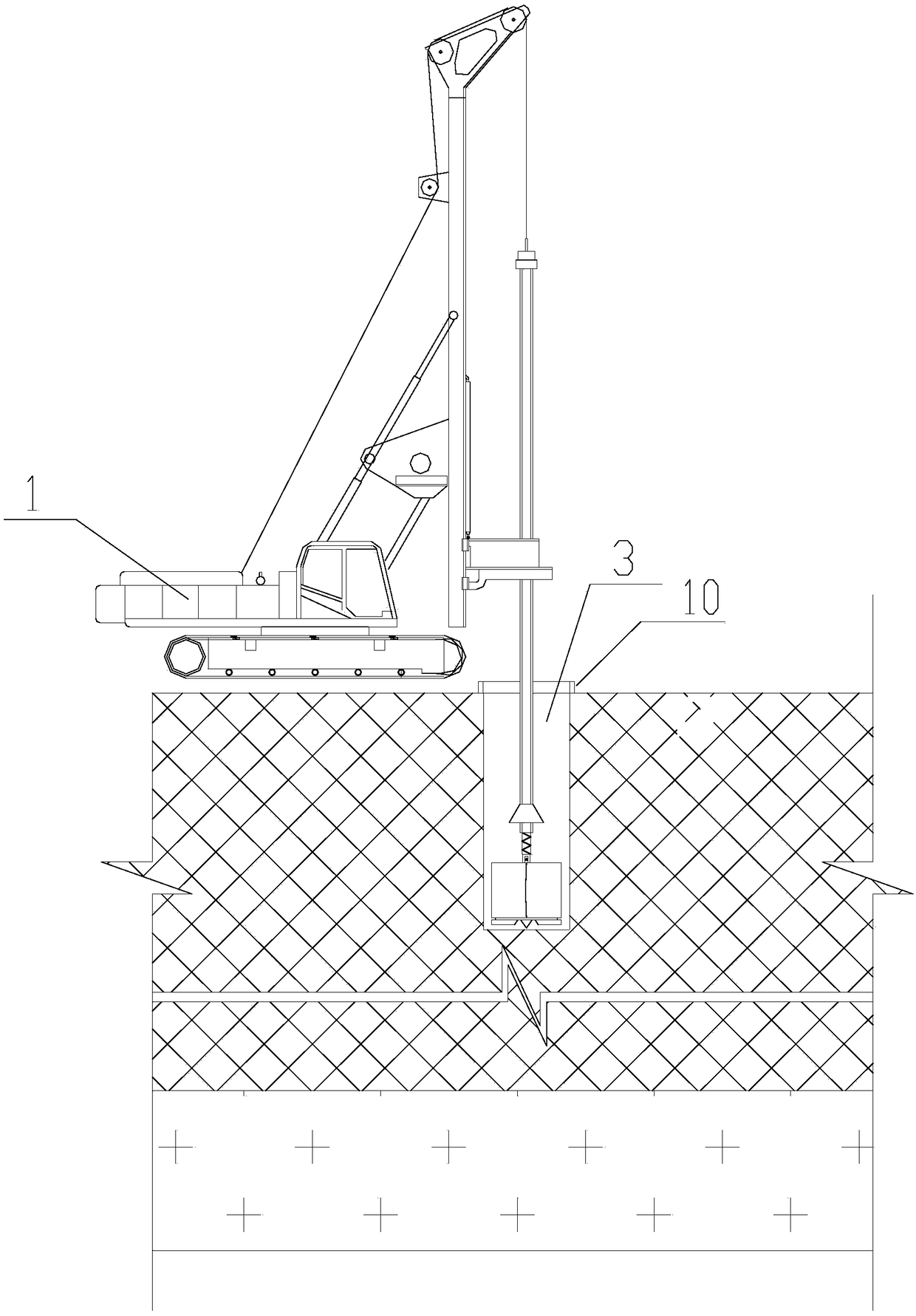

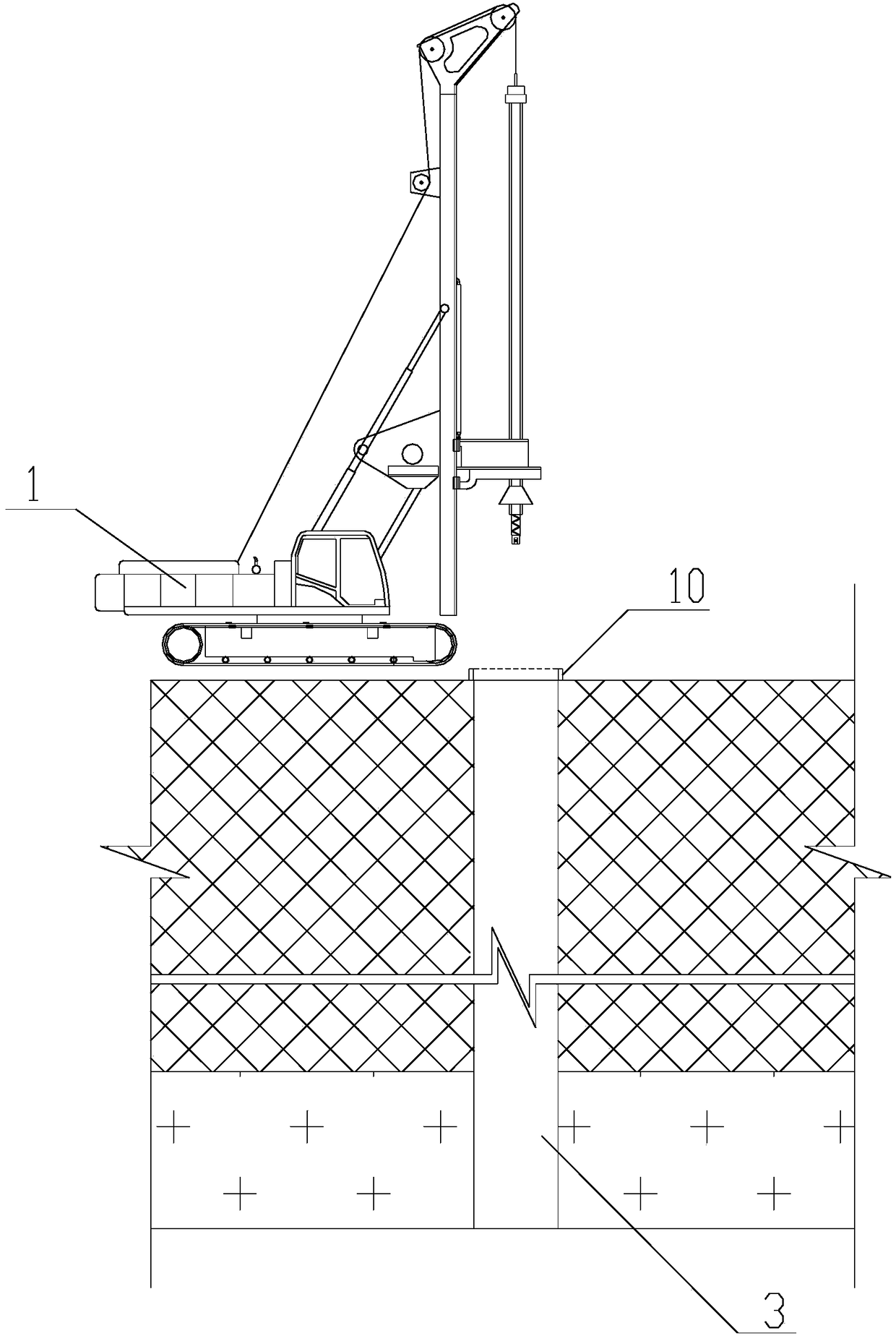

[0037] A. If figure 1 , figure 2 and image 3 As shown, first find out the excavation position of the pile hole, then drive the drilling machine 1 to a suitable position, install the ordinary drill bit 2 after the drilling machine is in place, the ordinary drill bit 2 refers to the conventional drill bit for drilling straight holes downward, and the ordinary drill bit 2 is used. Carry out an excavation to obtain the main pile hole 3, the depth of the main pile hole 3 is less than 250mm to 350mm of the total design depth of the pile hole, and leave a suitable margin for manual excavation to ensure the accuracy of the hole. The depth of the main pile hole 3 dug is less than 300mm of the total design depth of the pile hole. The diameter of the main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com