Reclosable pouring element

A part, closed state technology, applied in the direction of closure, rigid container, container, etc., can solve the problems of unsealed packaging, damage, disadvantage, etc., and achieve the effect of reduced structure height, good stackability, and consistent design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

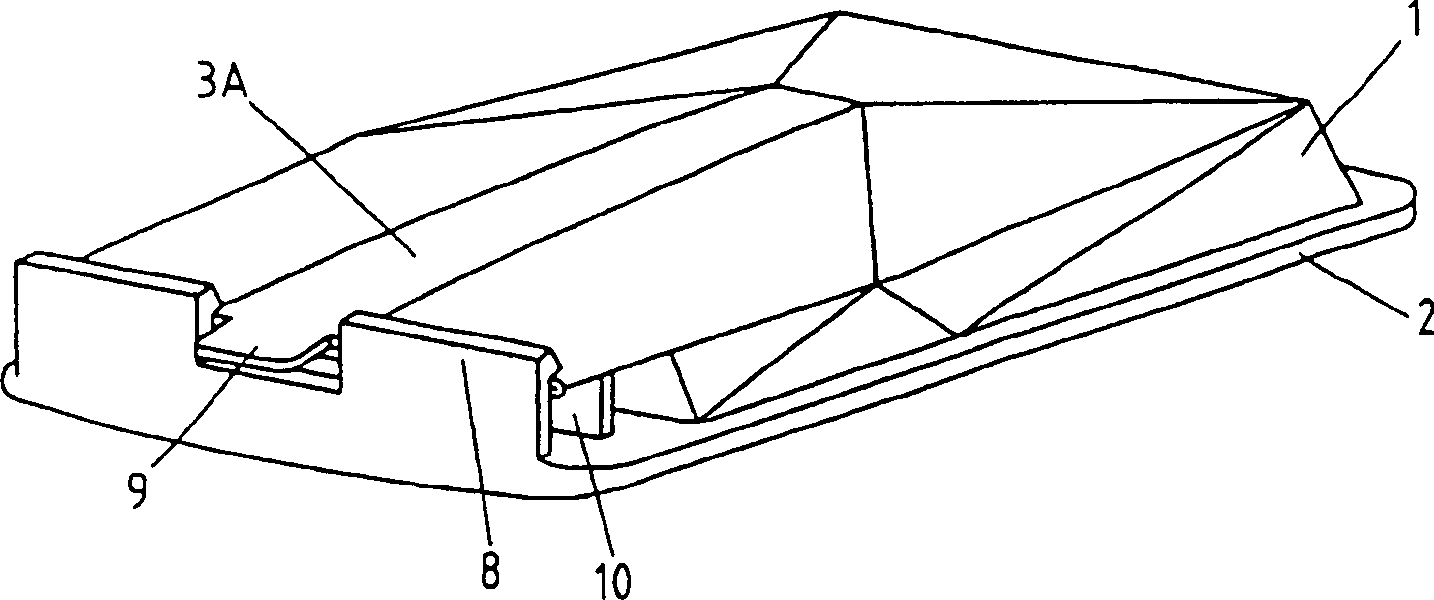

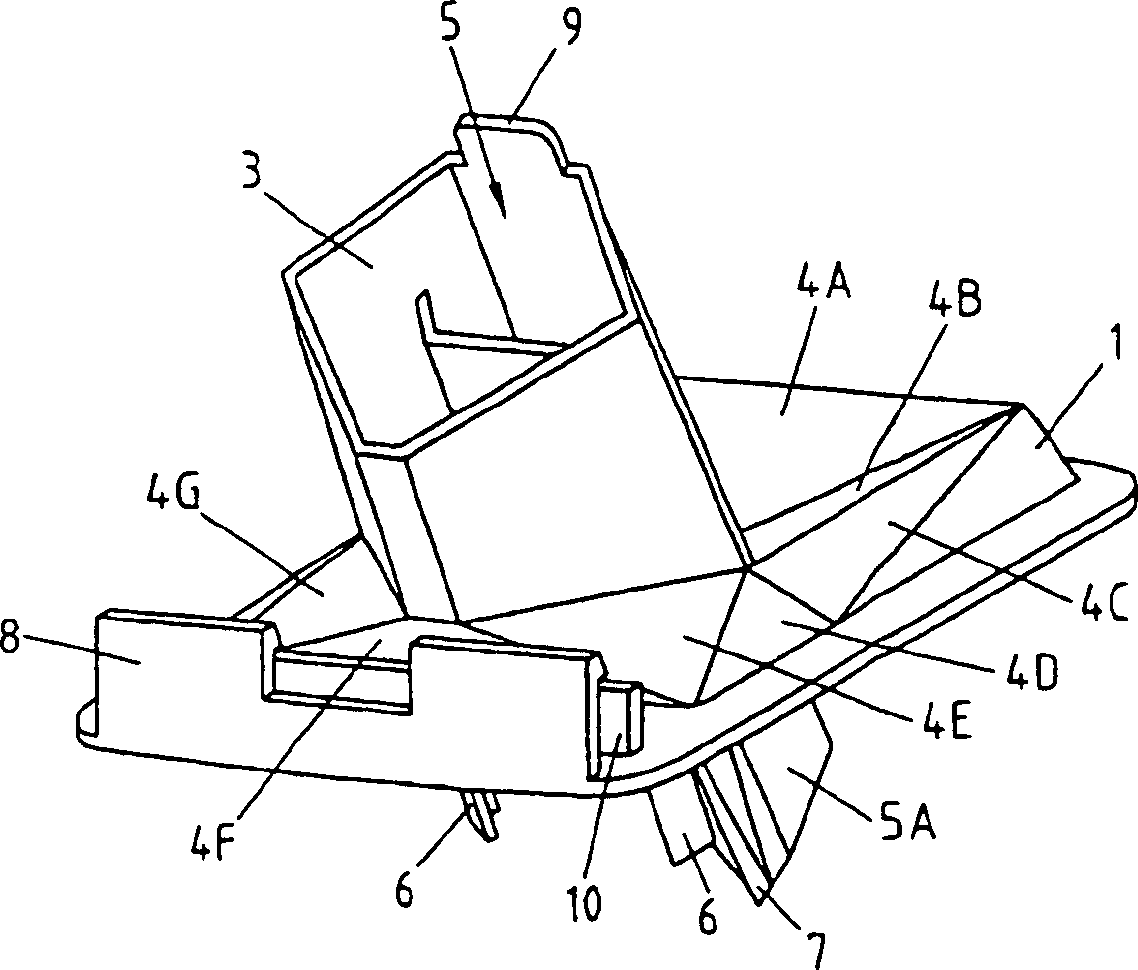

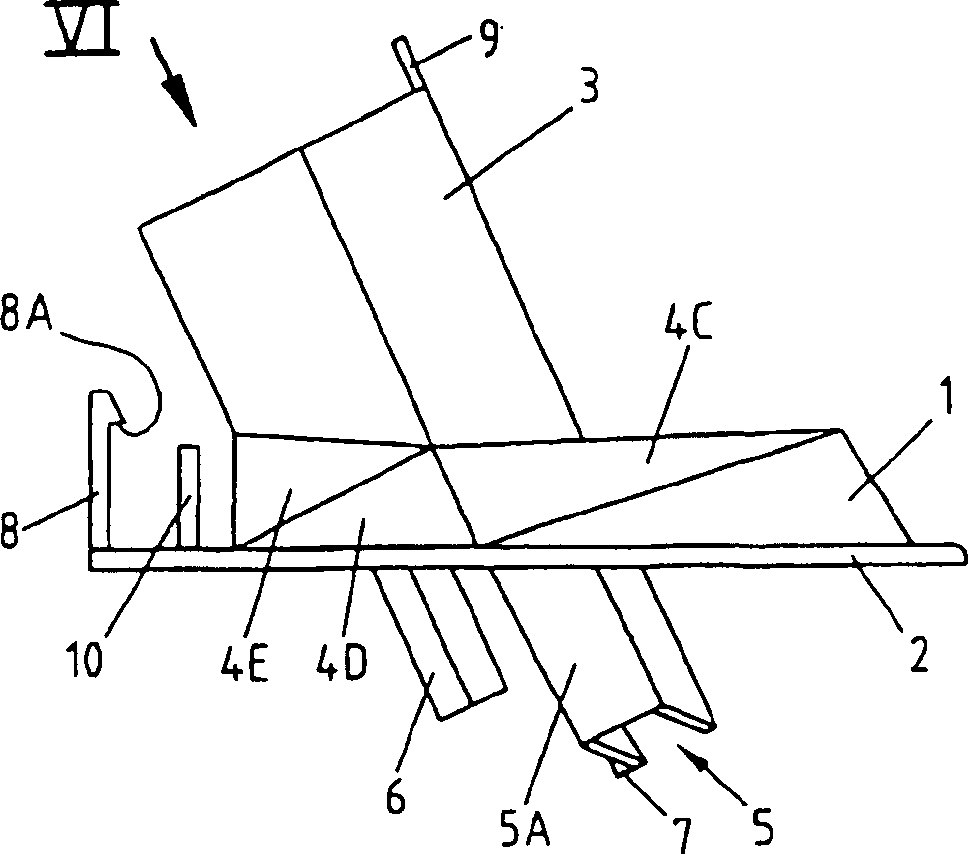

[0030] exist figure 1 shows a pouring member according to the invention in the closed position, and in particular in the form such as it is used in a packaging (not shown). It basically consists of a frame-shaped base 1 with a surrounding fitting flange 2 and a figure 2 The open position is required to fully see the 3 components of the pouring tube. exist figure 1 Only the folded flat upper side 3A of this pouring tube 3 can be seen in FIG. The pouring tube 3 is surrounded by a surrounding flexible film 4 which is in turn integrally connected with the base body 1 . In the illustrated and preferred embodiment in this respect, the membrane 4 has a plurality of quadrangular or triangular individual faces, wherein figure 2 Faces 4A to 4G can be seen in FIG. 4 and faces 4B to 4I can be seen in FIG. 4 .

[0031] For more clarity, in Figures 3 to 5 drawn in figure 2 Three different views of the poured part drawn in perspective, and in Figure 9 A longitudinal sectional vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com