Offshore floating type draught fan and draught fan foundation thereof

A wind turbine foundation and floating technology, which is applied in the installation/support of wind turbine configuration, wind power generation, floating buildings, etc., can solve the problems of increasing project cost, large movement range, and increasing design difficulty, so as to improve impact resistance and Anti-fatigue performance, reduced heave and rotation, large seawater action area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

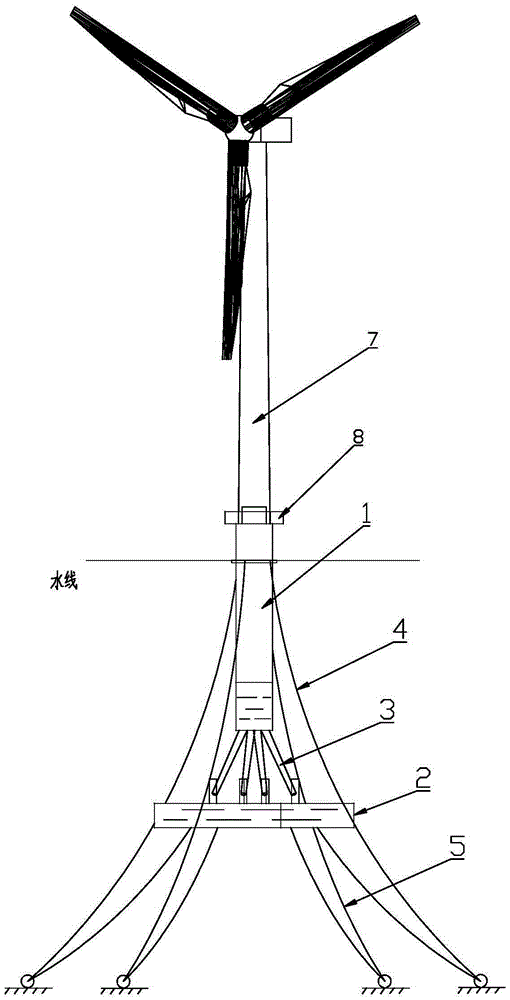

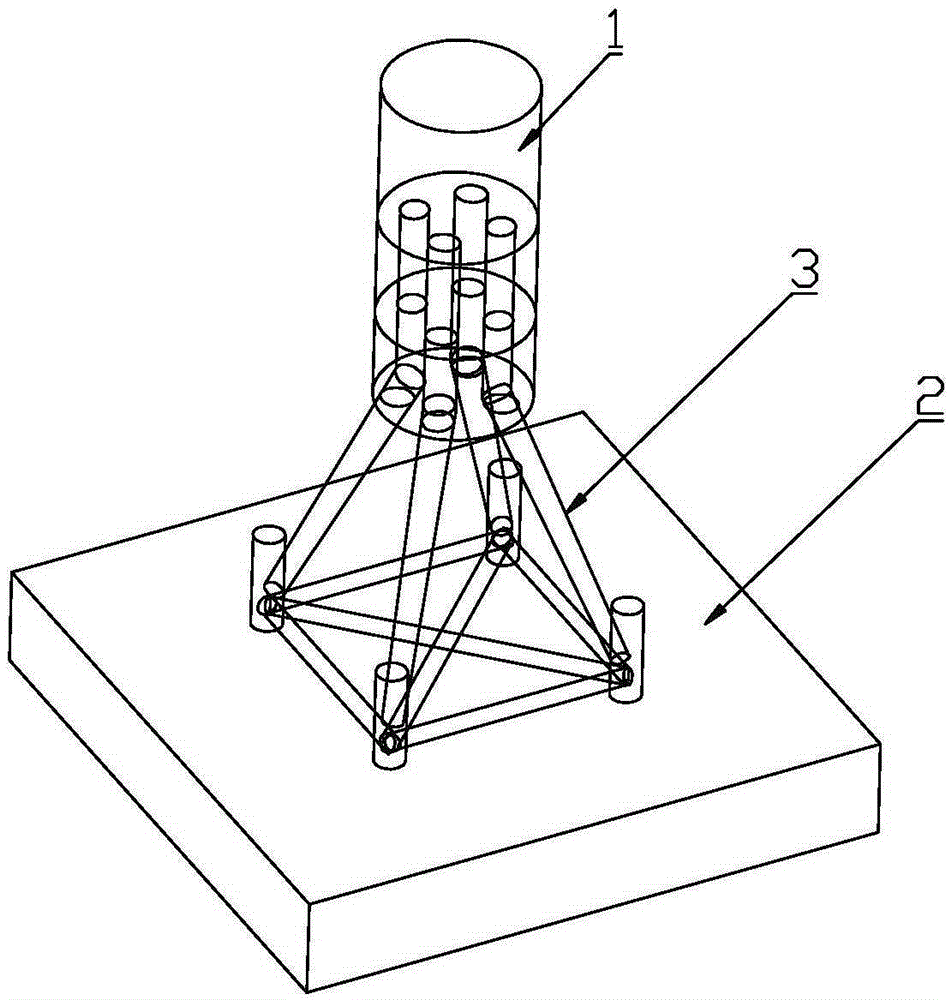

[0024] like figure 1 , 2 , 3 and 4, a offshore floating wind turbine foundation, including a buoy structure 1, a support structure, a ballast tank 2, an upper fixing device and a lower fixing device, the ballast tank 2 is located below the buoy structure 1, and the buoy structure 1 It is connected with the ballast tank 2 through a bracket structure, which increases the length of the entire wind turbine foundation, moves the center of gravity of the structure down, and increases the moment of inertia of the wind turbine tower and the foundation structure and the moment of the reverse couple.

[0025] The buoy structure 1 is a single buoy structure.

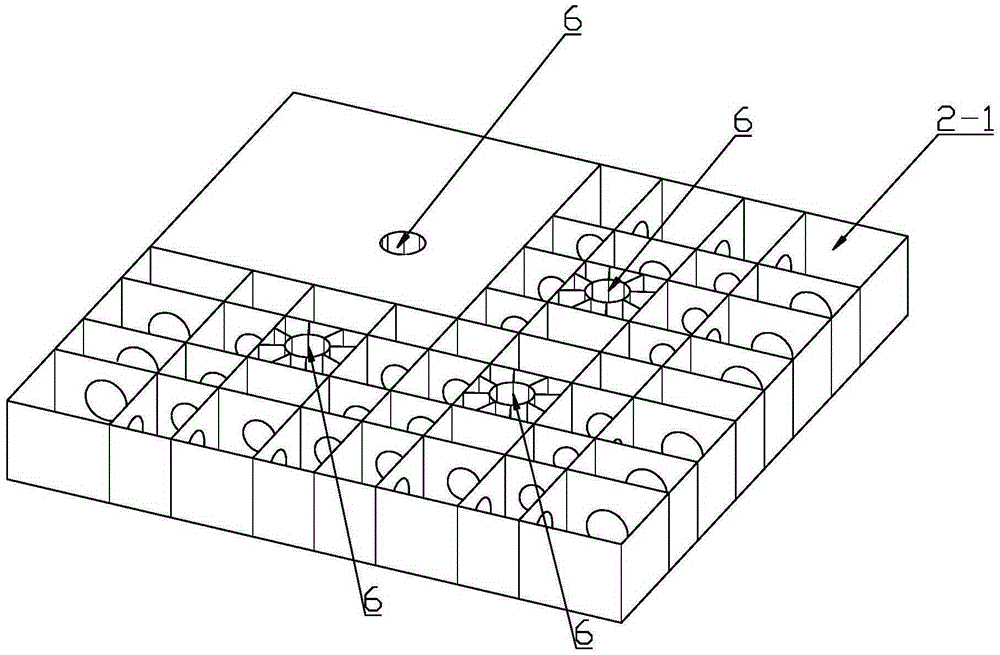

[0026] The ballast tank 2 is a flat box structure, the outer contour of the ballast tank 2 is larger than the outer contour of the buoy structure 1, and the interior of the ballast tank 2 is divided into a plurality of independent cabins 2-1, and the independent cabin 2-1 passes through the ballast tank The water volume adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com