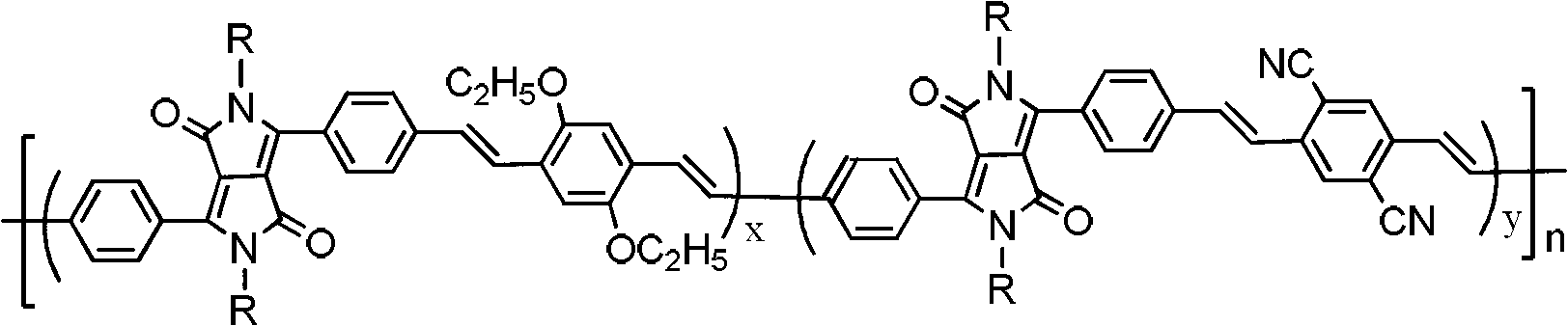

Dione pyrrolo-pyrrole copolymer red electroluminescent material and preparation method and application thereof

A technology of diketopyrrolopyrrole and copolymer electricity, applied in the field of electroluminescent materials, can solve the problems of low luminous efficiency of devices, low external quantum efficiency of PLED devices, concentration quenching, etc., and achieve good electron transport ability, excellent Effects of improving hole transport ability and electroluminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of 3,6-bis(4-benzaldehyde ethylene glycol acetal)pyrrolo[3,4-c]pyrrole-1,4-dione (compound 2 for short)

[0055] Sodium metal (1.472mg, 64mmol) and anhydrous ferric chloride (74mg, 0.455mmol) were added to 40ml of dry tert-amyl alcohol and reacted at 100°C for 1h until the sodium was completely dissolved. Add p-cyanobenzaldehyde ethylene glycol acetal (7g, 40mmol) in the reaction system, then slowly drop diisopropyl succinate (3.232g, 16mmol, be dissolved in 20ml tert-amyl alcohol in advance), the reaction system gradually Turn into a deep red viscous shape, pay attention to strengthen the stirring. After the dropwise addition, the constant temperature reaction was continued at 100°C for 24h, and a large amount of red solid was formed. After being cooled to room temperature, the reaction mixture was poured into a mixed solvent of 16ml glacial acetic acid and 200ml methanol, and the resulting mixture was filtered after standing still for several hours, and t...

Embodiment 2

[0057] Preparation of 2,5-dioctyl-3,6-bis(4-benzaldehyde ethylene glycol acetal)pyrrolo[3,4-c]pyrrole-1,4-dione (compound 3 for short)

[0058] Compound (2) (3.456g, 8mmol), potassium tert-butoxide (1.975g, 17.2mmol) was added to 80ml of dried N-methylpyrrolidone (NMP), stirred at 60°C for 1h, and then bromo n-octane (9.264g, 48mmol, pre-dissolved in 20ml NMP). React at constant temperature at 60°C for 24h, cool to room temperature, filter, add 50ml ethyl acetate to the filtrate, wash with water three times, and wash with anhydrous MgSO 4 After drying, filtering and rotary evaporation to remove the solvent, the crude product was separated by column chromatography (silica gel, ethyl acetate / petroleum ether 1:5). The resulting solid was recrystallized from dichloromethane / methanol to obtain 2.414 g of orange crystals (yield 46%). m.p.=130-131℃. 1 H NMR (400MHz, CDCl 3 ): δ7.81(d, 4H), 7.62(d, 4H), 5.87(s, 1H), 4.14-4.04(m, 8H), 3.70(t, 4H), 1.54(br, 4H), 1.21( br, 20H), 0.8...

Embodiment 3

[0060] Preparation of 2,5-dioctyl-3,6-di(4-benzaldehyde)pyrrolo[3,4-c]pyrrole-1,4-dione (referred to as compound 4)

[0061] Compound (3) (1.968g, 3mmol) was added to a mixed solvent of 30ml tetrahydrofuran and 15ml hydrochloric acid solution (2mol / l), and reacted at 60°C for 2h. Cool to room temperature, add 30ml ethyl acetate, wash with water three times, the organic layer is dried with anhydrous magnesium sulfate, filter, rotary evaporation removes solvent, the obtained crude product is recrystallized with dichloromethane / methanol to obtain 1.67g purple-black solid (yield 98 %). m.p.=128-130℃. 1 H NMR (400MHz, CDCl 3 ): δ10.08(s, 2H), 8.03-7.94(m, 8H), 3.74(t, 4H), 1.54(br, 4H), 1.18(br, 20H), 0.82(t, 6H).Anal. Calcd for C 36 h 44 N 2 o 4 :C,76.02;H,7.75;N,4.93.Found:C,76.10,H,7.85,N,4.97.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com