Patents

Literature

42results about How to "Optimal balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

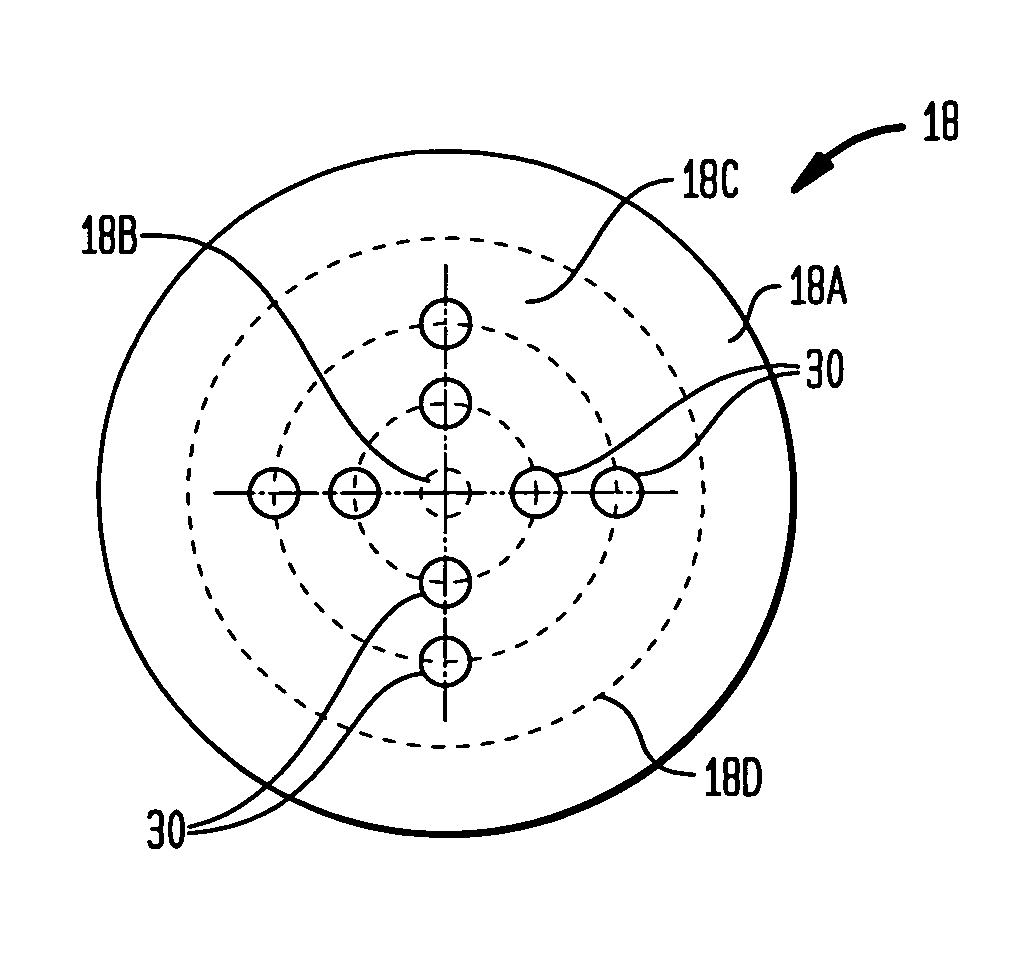

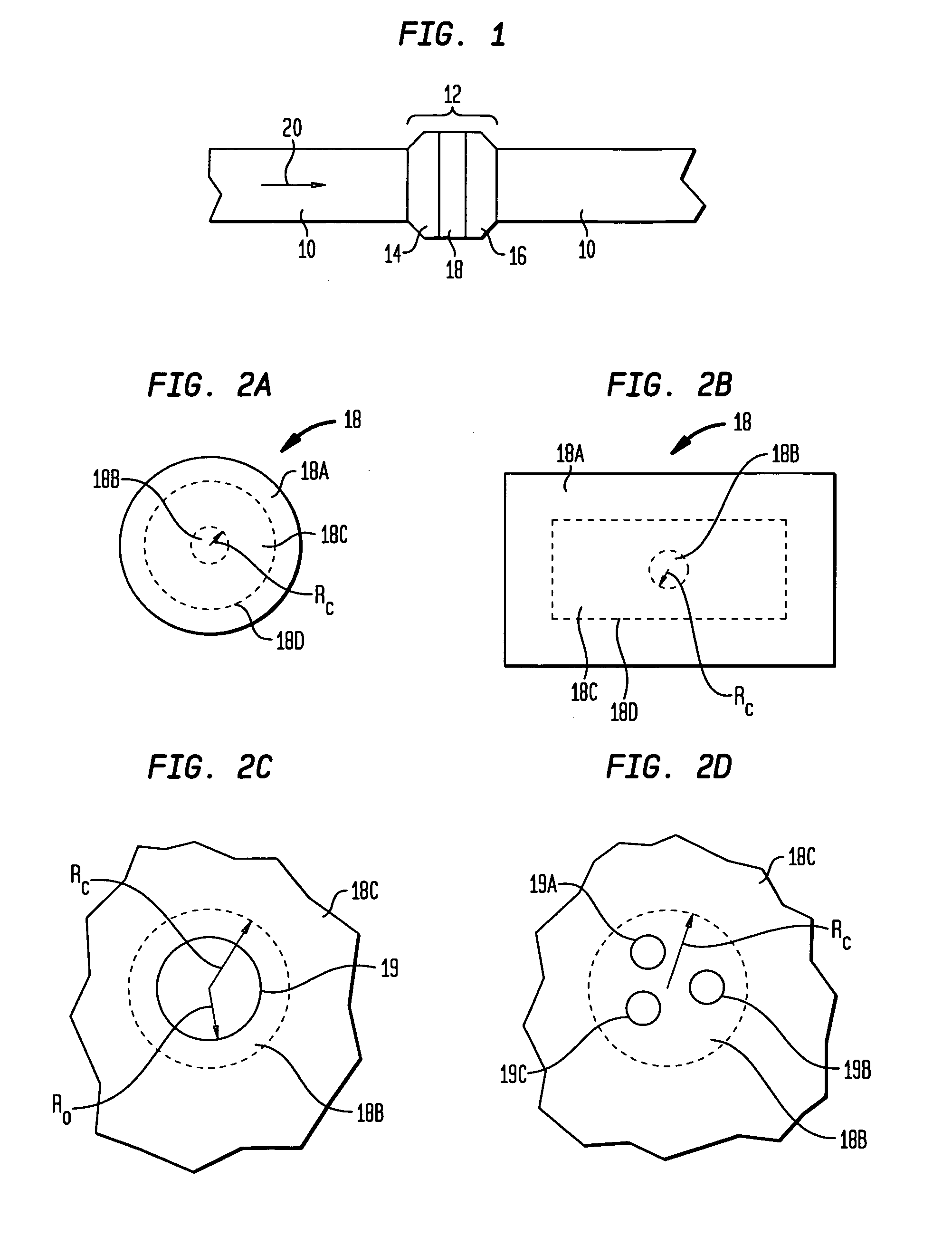

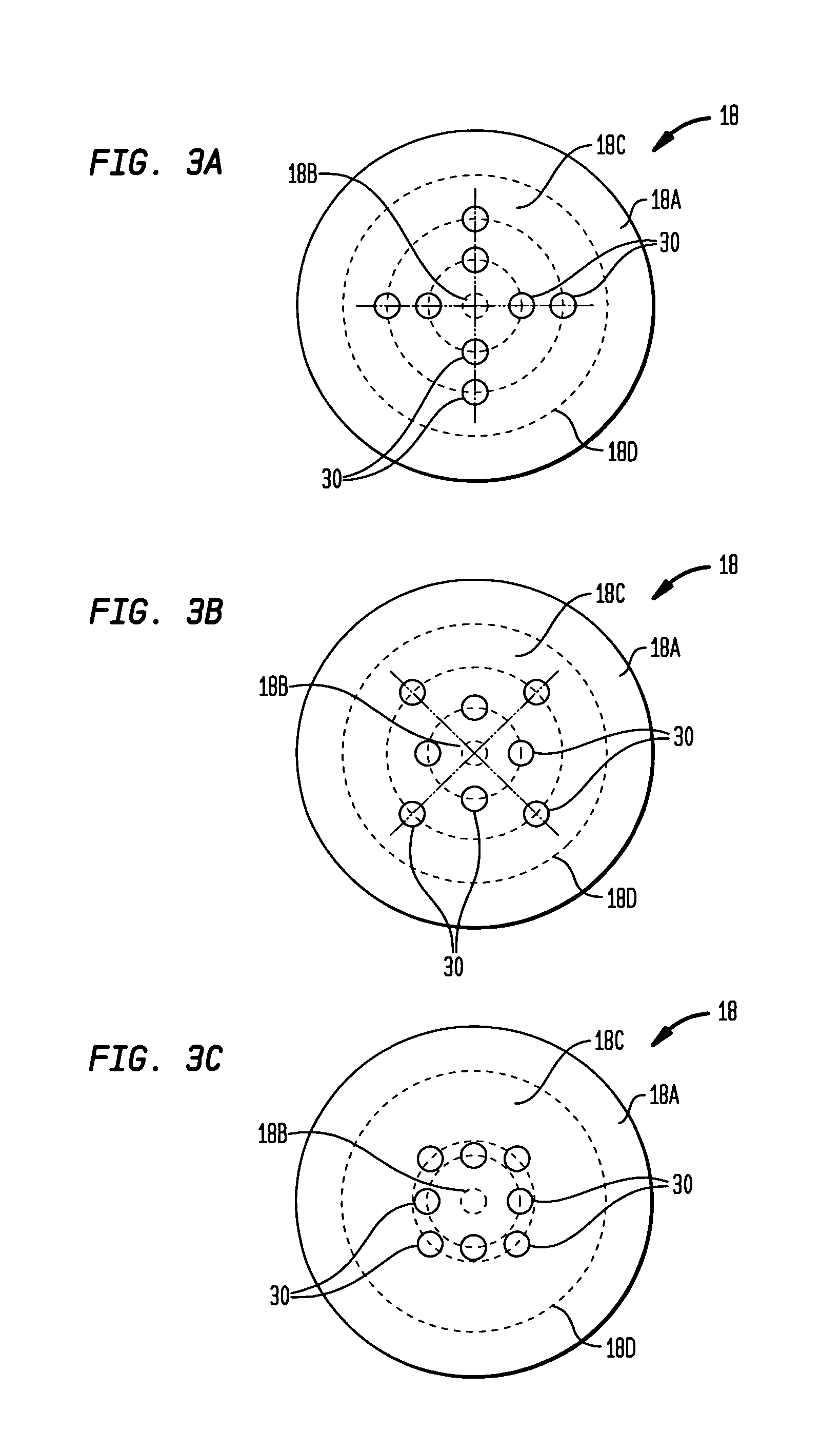

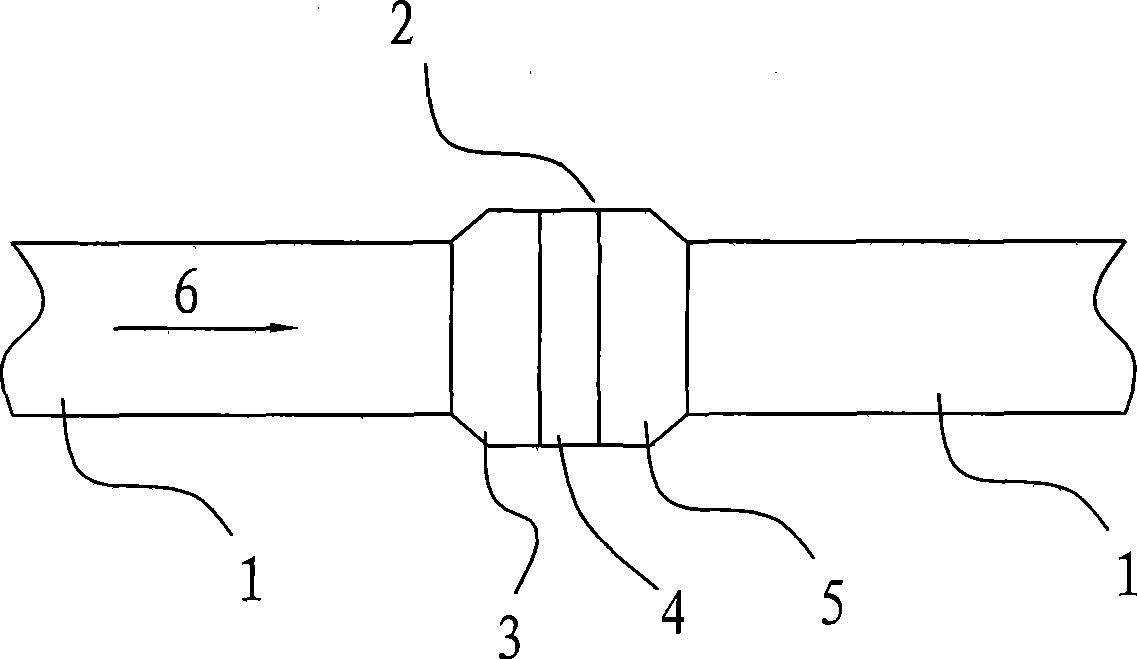

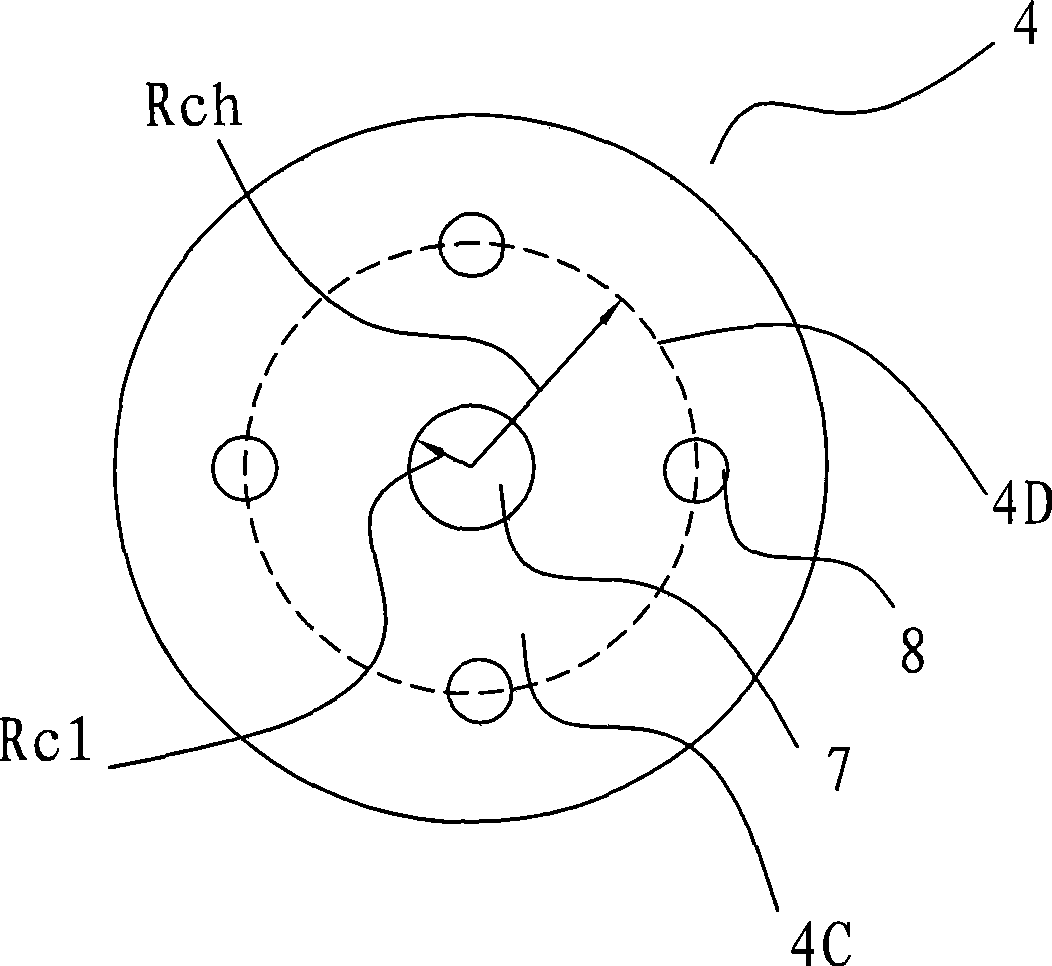

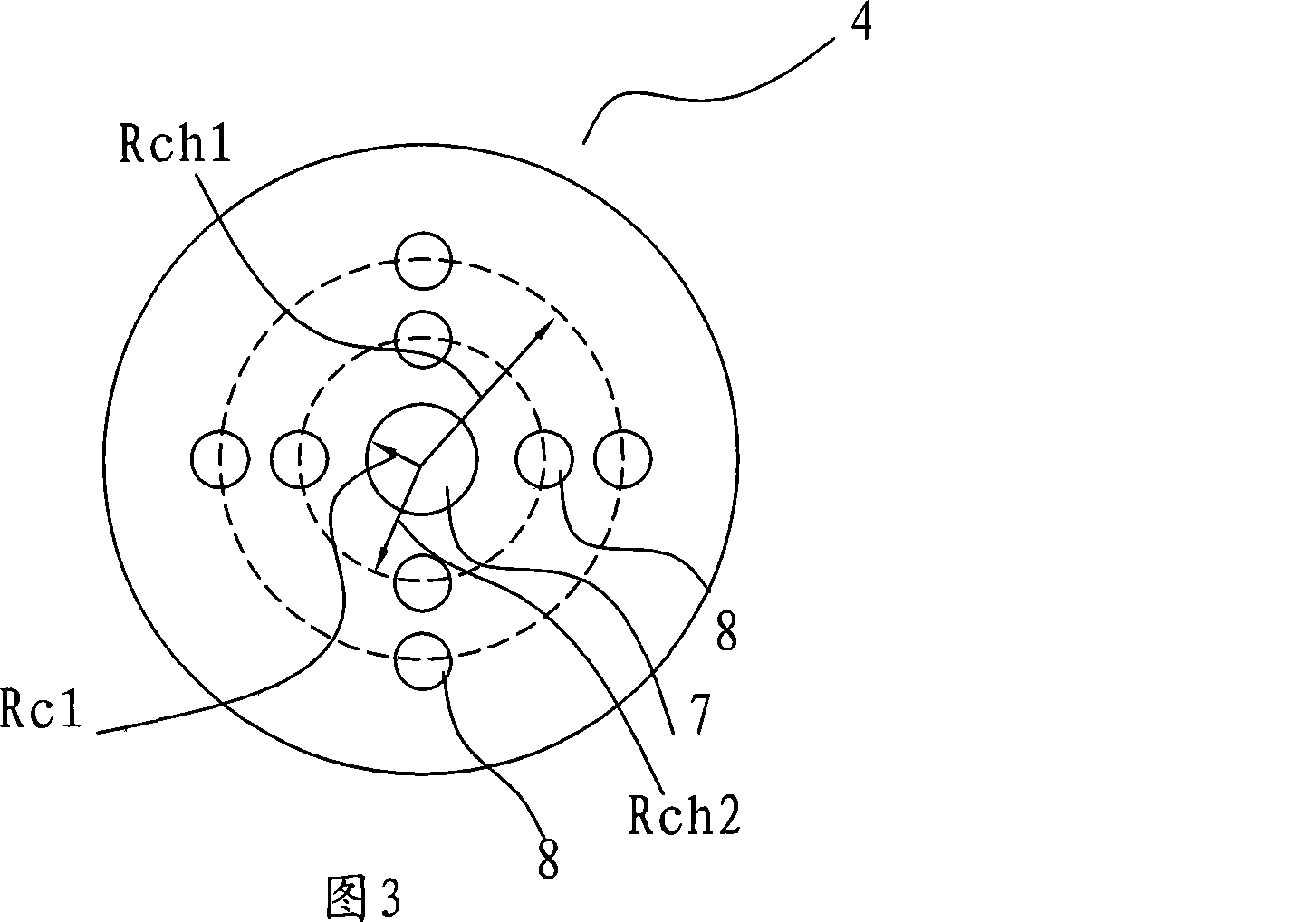

Balanced orifice plate

An orifice plate for use in a conduit through which fluid flows is defined by a central circular region having a radius R0 and a ring-shaped region surrounding the central circular region. The ring-shaped region has holes formed therethrough with those holes centered at each radius R thereof satisfying a relationshipAR=a / (XRVRb)whereAR is a sum of areas of those holes having centers at radius R,XR is a flow coefficient at radius R,VR is a velocity of the fluid that is to flow through the conduit at radius R,b is a constant selected to make at least one process variable (associated with the fluid that is to flow through the conduit) approximately equal at each radius R, anda is a constant that is equal to (XRARVRb) at each radius R.

Owner:NASA

Bio-protein feed prepared by adopting cellulose raw material and preparation method thereof

InactiveCN102232466ASimple preparation processShort fermentation cycleFood processingAnimal feeding stuffDecompositionRapeseed

The invention relates to a bio-protein feed prepared by adopting a cellulose raw material, and the bio-protein feed provided by the invention comprises an organic material and complex bacteria, wherein the weight of the complex bacteria is 1-10% of that of the organic material; and the organic material comprises the cellulose raw material, rapeseed meal and bran; the cellulose raw material is one or more of corn stalks, corn cobs, straw, manioc waste and fruit residue; and the complex bacteria comprises bacillus subtilis, microzyme, lactobacillus and cellulose decomposition bacteria, and the cellulose decomposition bacteria is one or more of trichoderma harzianum and white-rot fungi. In the bio-protein feed, the content of probiotics is more than 108cfu / g, the bio-protein feed contains a variety of prolease, cellulase, amylase and the like, the preparation process is simple, and the fermentation period is short. The invention further discloses a preparation method of the feed.

Owner:洋浦慷民高科生物有限公司

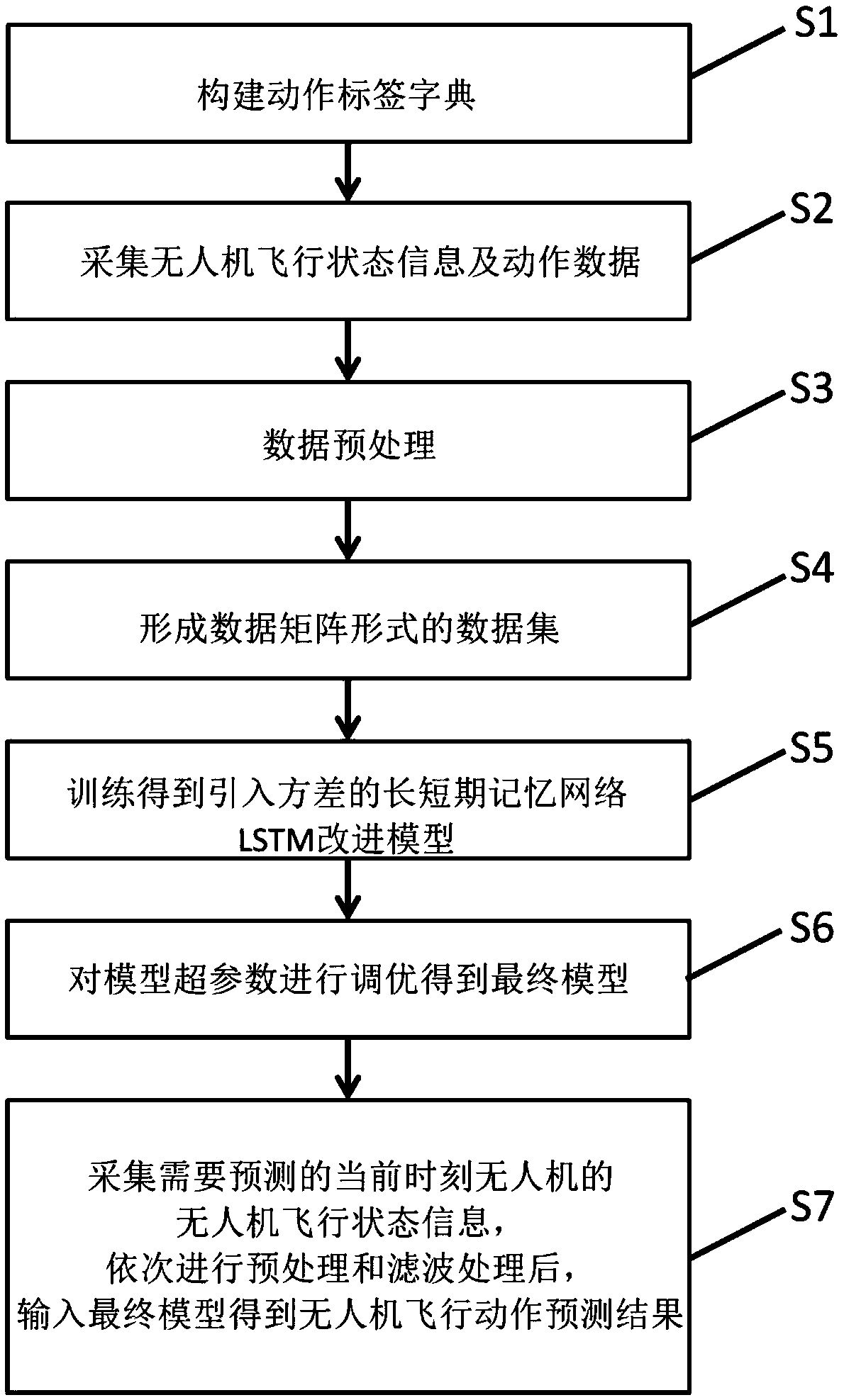

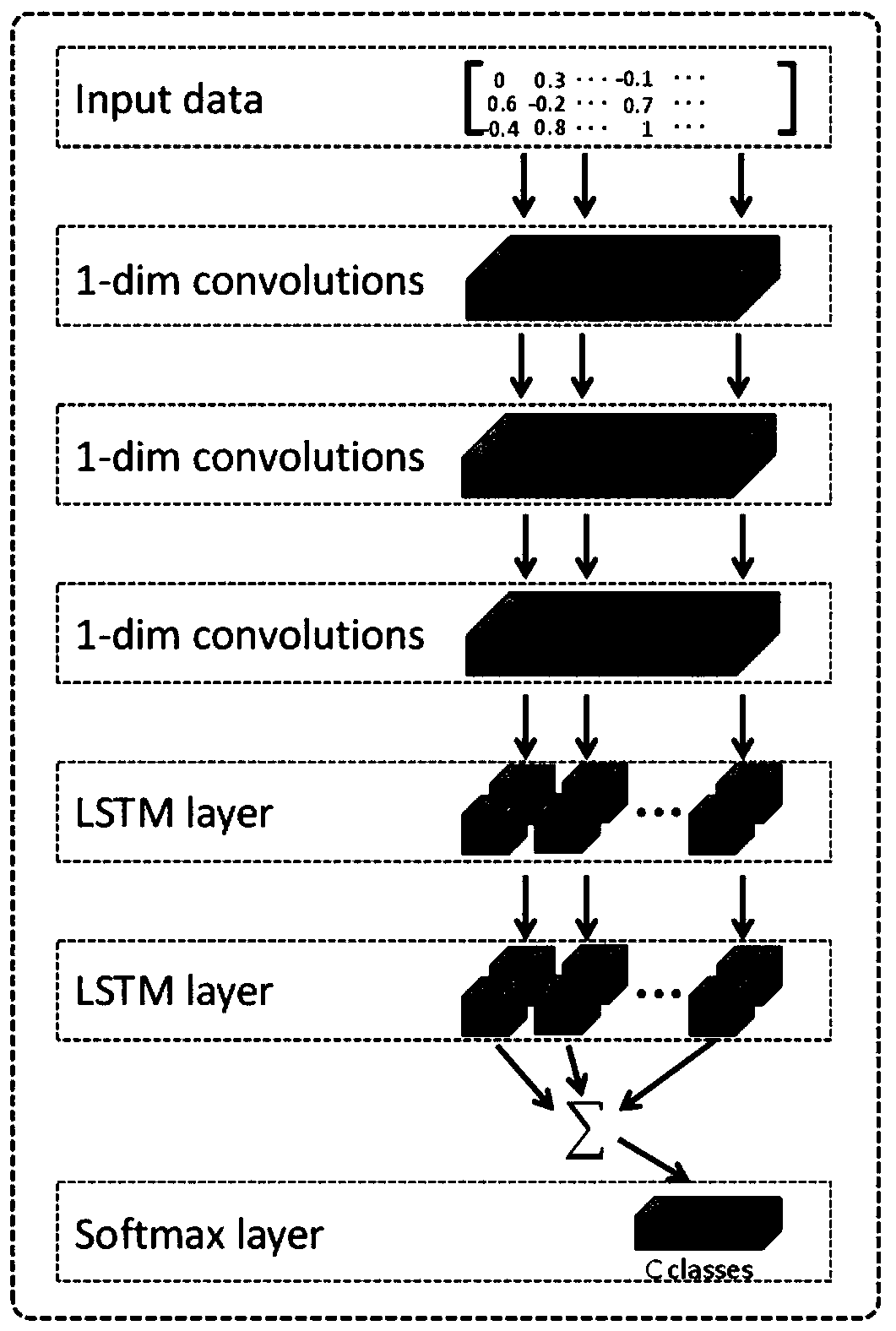

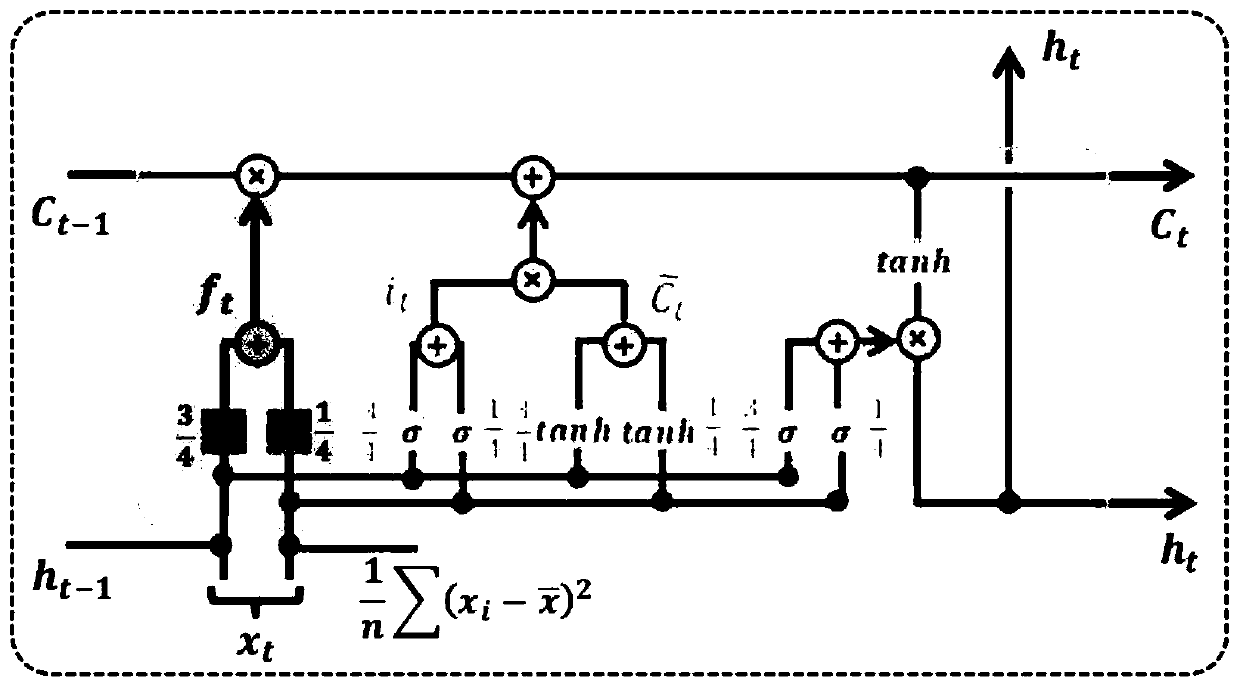

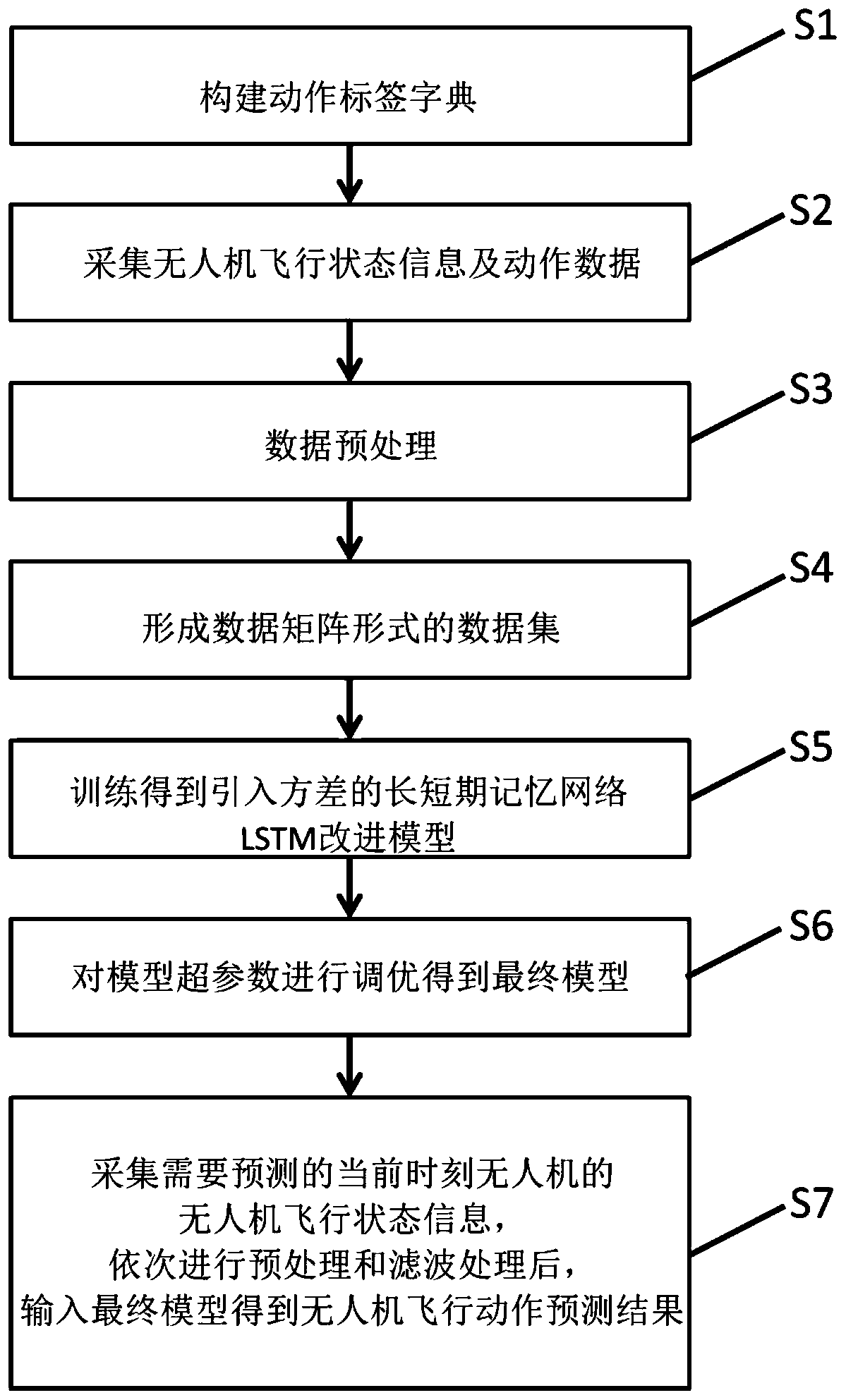

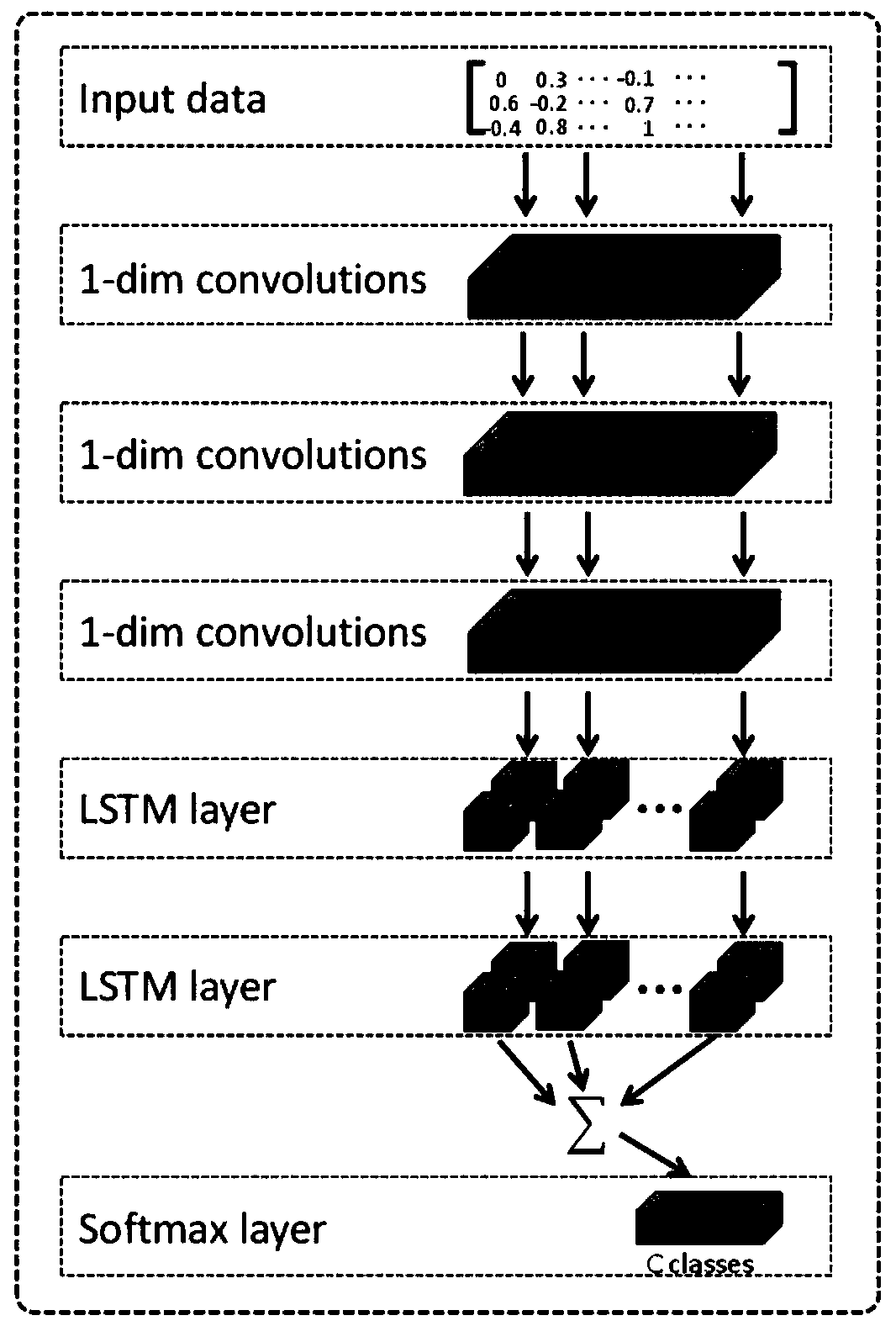

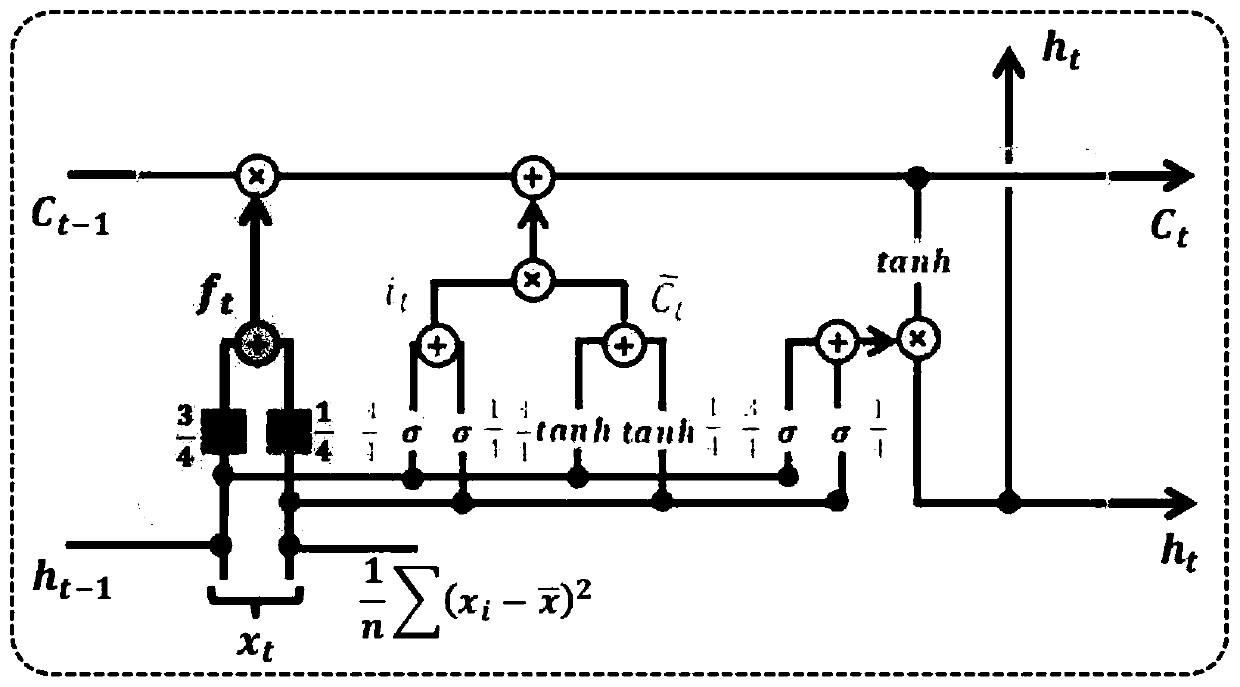

An unmanned aerial vehicle flight state prediction method and system based on LSTM

ActiveCN109034376AFind regular featuresStable outputNeural architecturesNeural learning methodsData predictionShort duration

The invention provides an unmanned aerial vehicle flight state prediction method and system based on LSTM. The method of the invention comprises the following steps: step 1, constructing an action label dictionary; 2, collecting flight state information and motion data of the unmanned aerial vehicle; 3, preprocessing the collected flight state information of each unmanned aerial vehicle; 4, forming a data set in the form of a data matrix; 5, randomly dividing the data set into 70 percent of the training set and 30 percent of the verification set; obtaining the improved LSTM model of a long-short-term memory network with variance by training. 6, tuning the super parameters of the model to obtain a final model by using a verification set; 7: collecting the UAV flight state information of theUAV at the current time which needs to be predicted, and inputting the information into the final model after preprocessing and filtering to obtain the UAV flight motion prediction result. The technical proposal of the invention solves the problem that the existing control model cannot predict the flight action according to the collected flight state data.

Owner:NORTHEASTERN UNIV

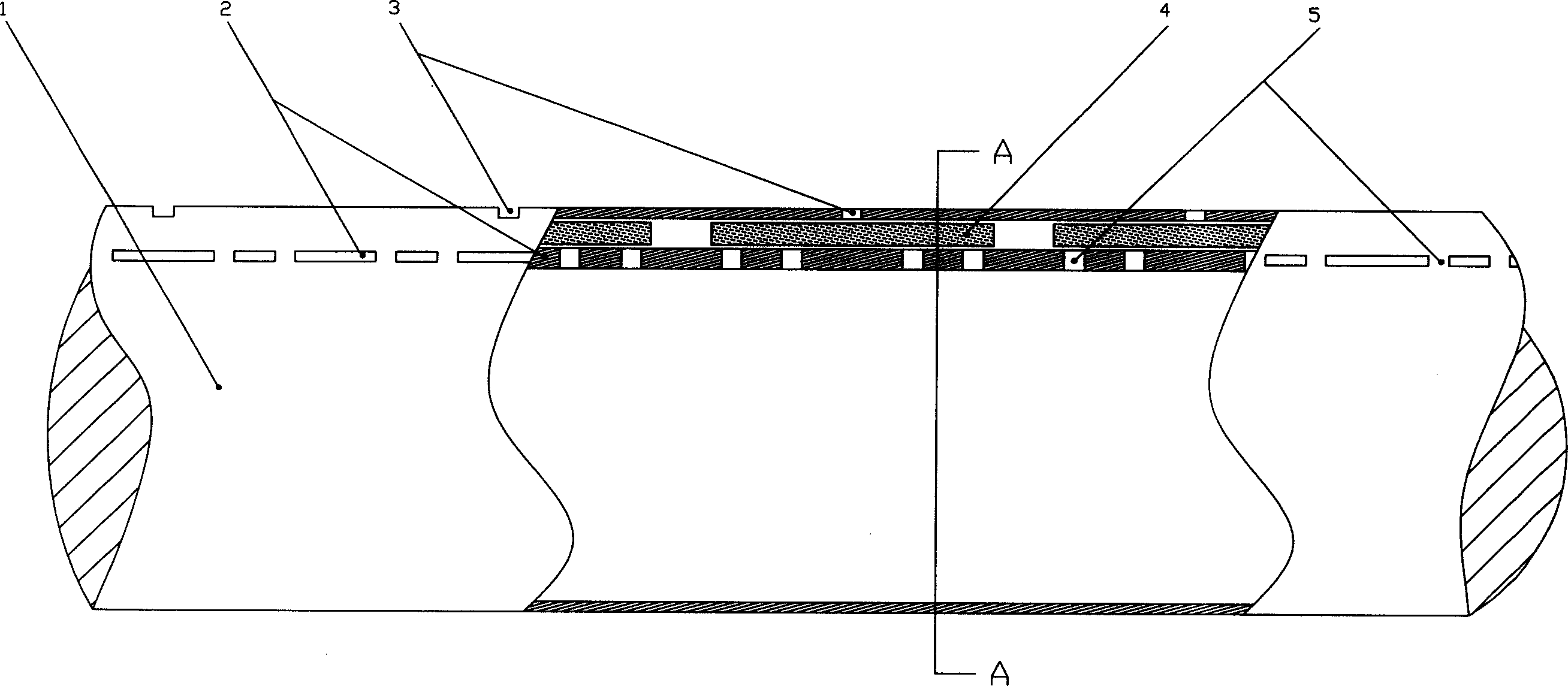

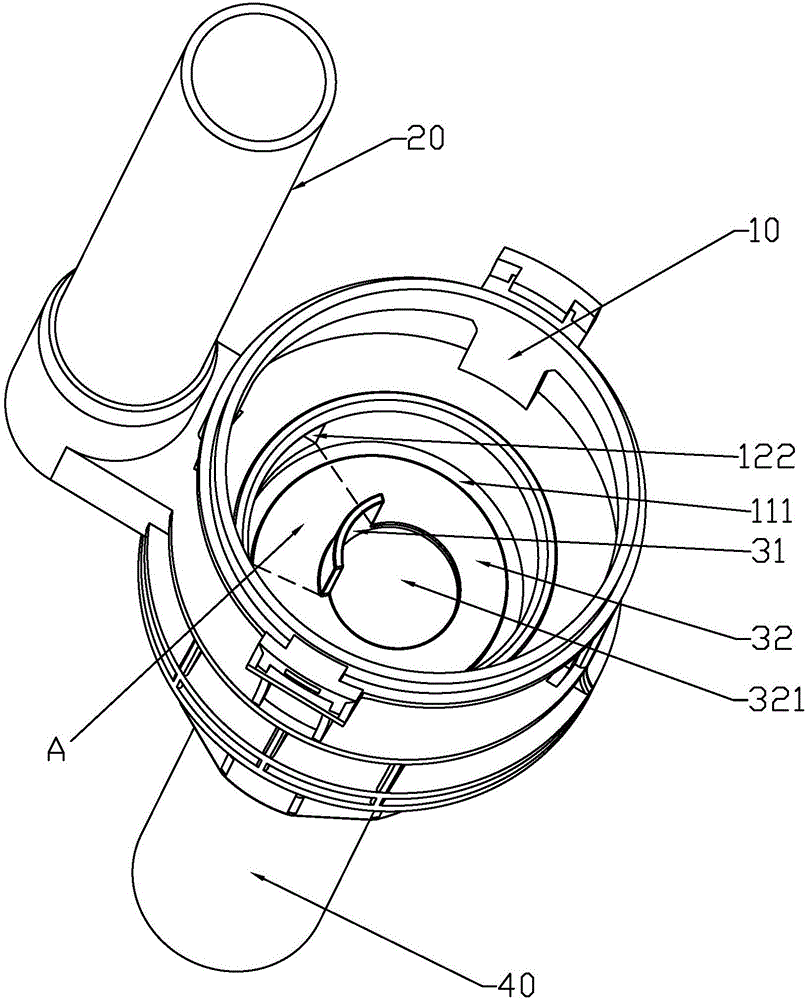

Balance hole plate

The invention discloses a balance porous plate, comprising a plate which is suitable for being arranged in pipelines, extending and passing through the cross-section of the pipelines; the plate is provided with a plurality of through holes which have the same Reynolds number of fluids which pass through each through hole. The porous plate leads a process variable related to the fluid passing through the porous plate to be balanced when spanning the surface of the porous plate or a plurality of process variables to be arranged at a best balance state when spanning the surface of the porous plate, namely, the Reynolds numbers of fluids which pass through the surface of the porous plate are equal, thus improving the measurement precision.

Owner:SHANGHAI KEYONTECHS CO LTD

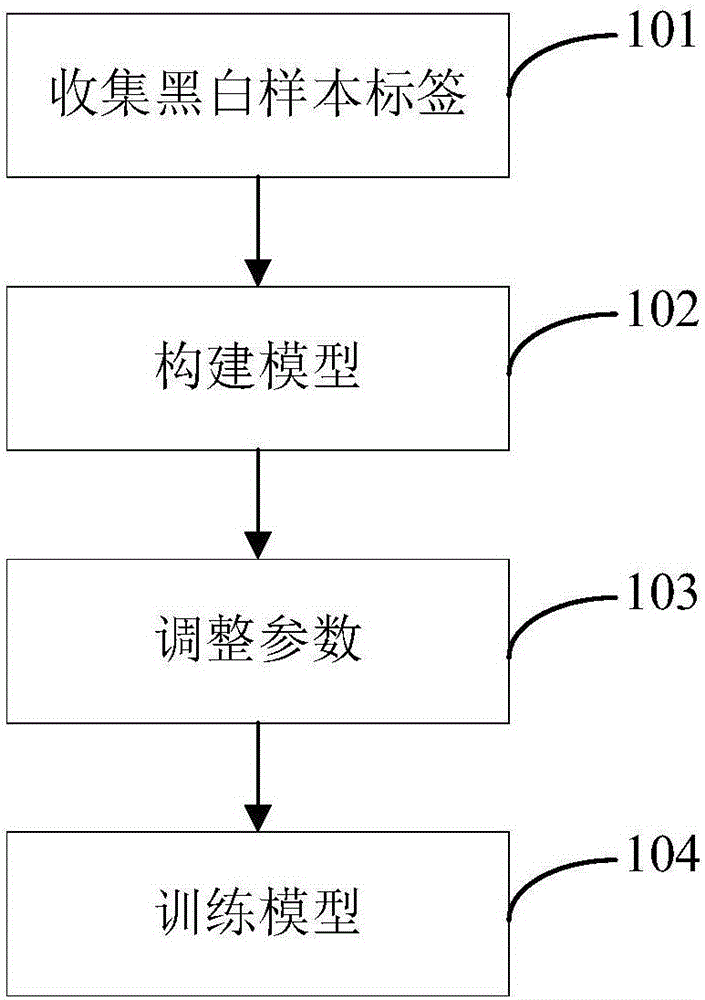

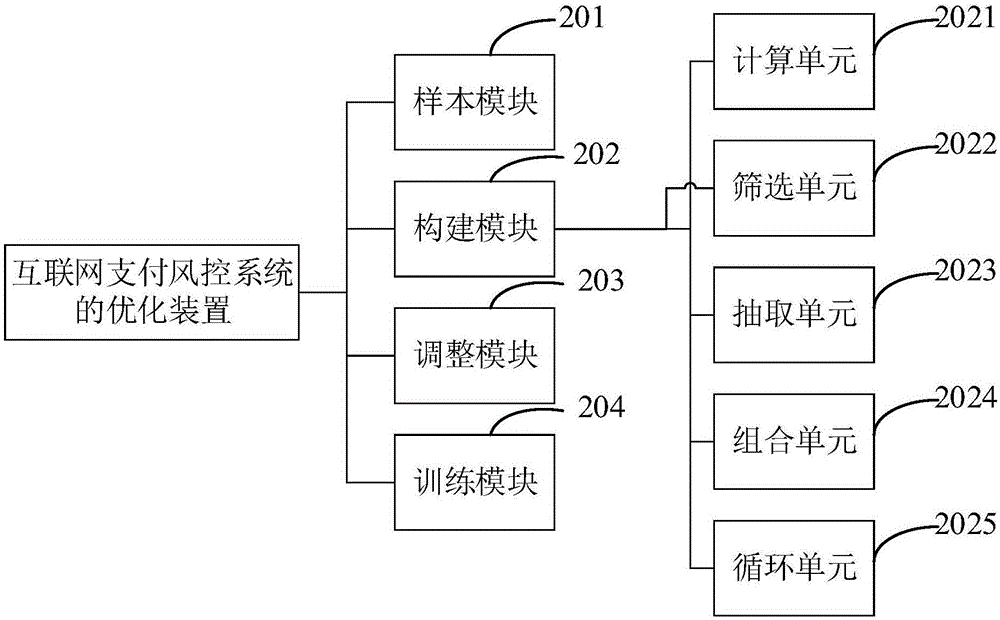

Optimizing method and apparatus for internet based payment risk control system

InactiveCN106600073AImprove operational efficiencyImprove payment securityForecastingProtocol authorisationRisk ControlPayment

The invention discloses an optimizing method and apparatus for internet based payment risk control system wherein the internet based payment risk control system comprises a risk control policy pool where the control policy pool is provided with a plurality of policies. The optimizing method comprises of obtaining an optimizing model through machine learning wherein the optimizing model is used to combine at least two policies to form a best policy combination whose balance state is better than the balance state of any single policy of the best policy combination and better than the balance state of the policy combination formed by any single policy with the rest policies in the risk control policy pool wherein the balance state of the policies / policy combination is measured by the harmonic mean of the accuracy to identify fraudulent orders and the coverage rate for covering the fraudulent orders by the policies / policy combination. The optimizing method and apparatus of the invention increase the operation efficiency of the existing policies and models of a traditional internet based payment risk control system, therefore, enabling the risk control policies and models to identify frauds more accurately and to cover more fraudulent orders.

Owner:CTRIP TRAVEL NETWORK TECH SHANGHAI0

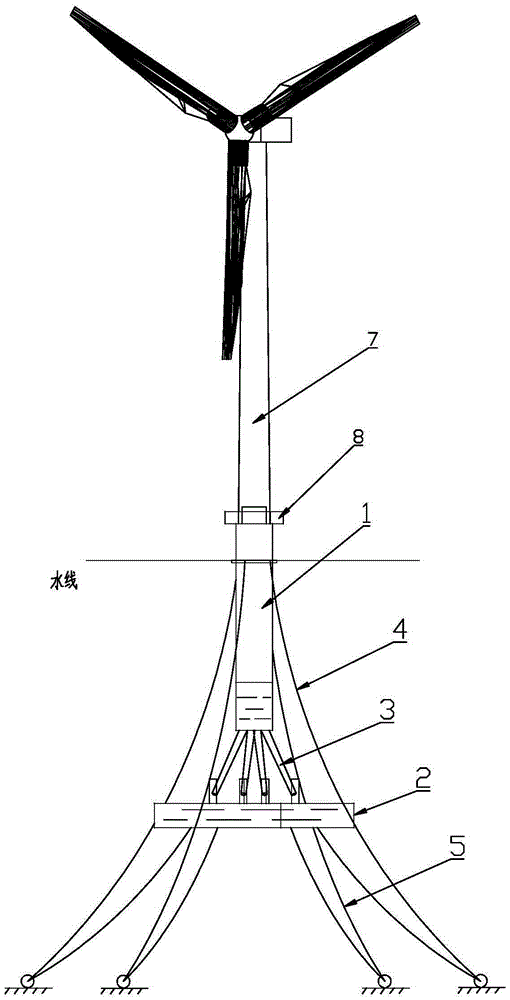

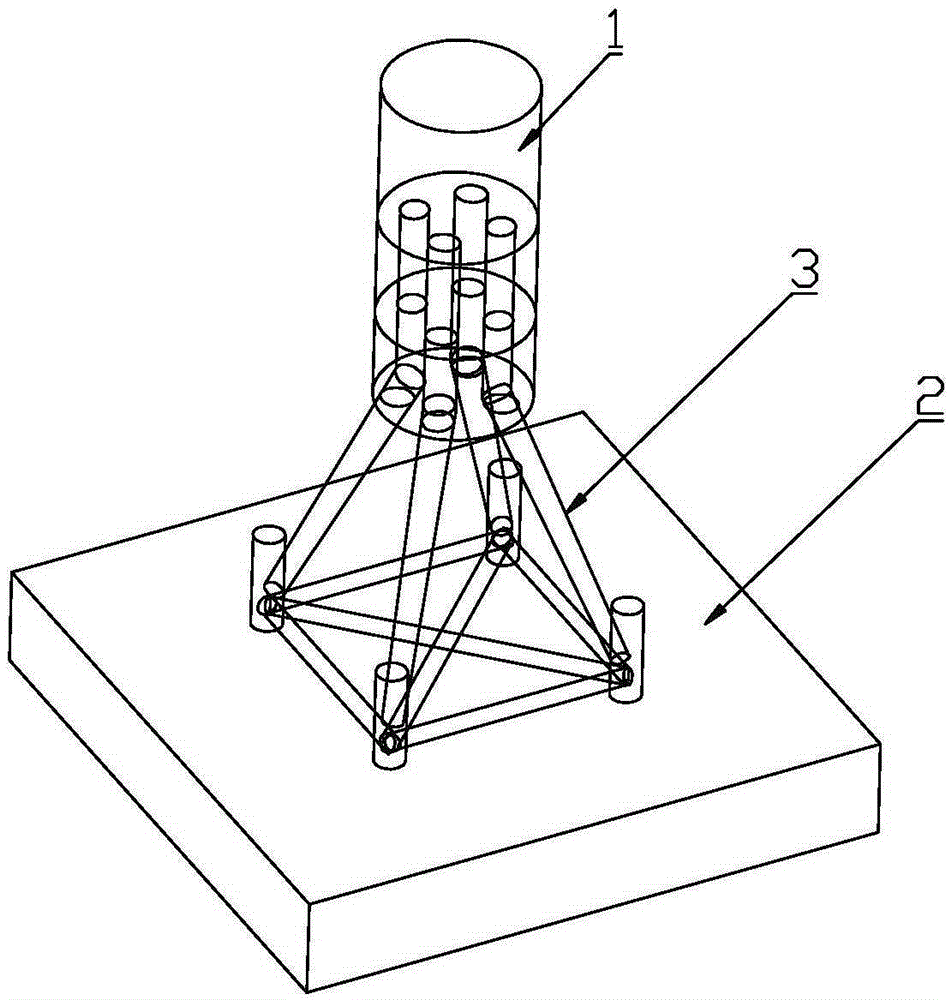

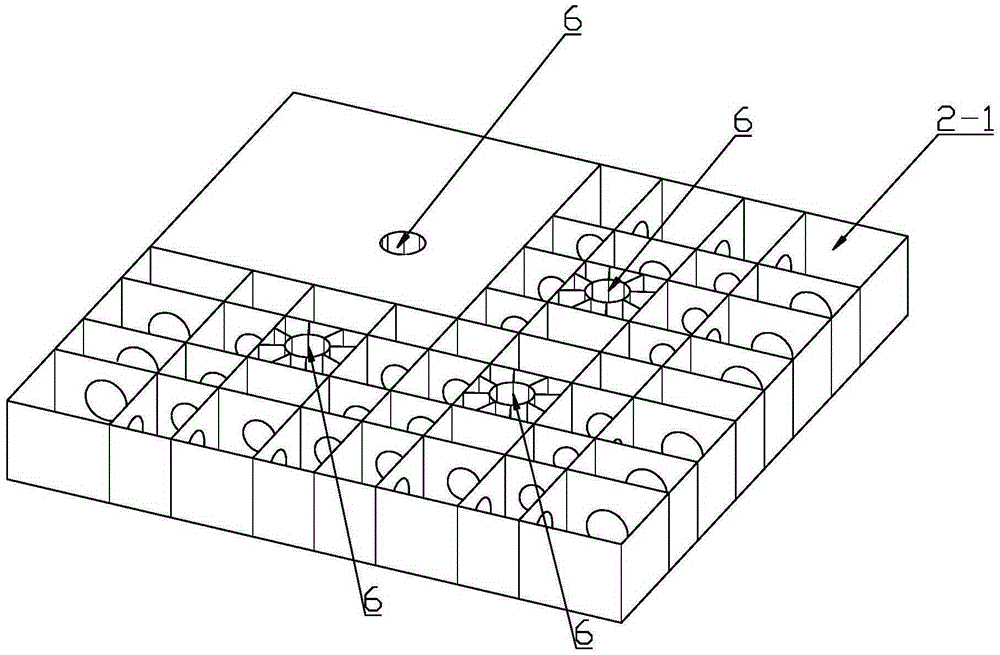

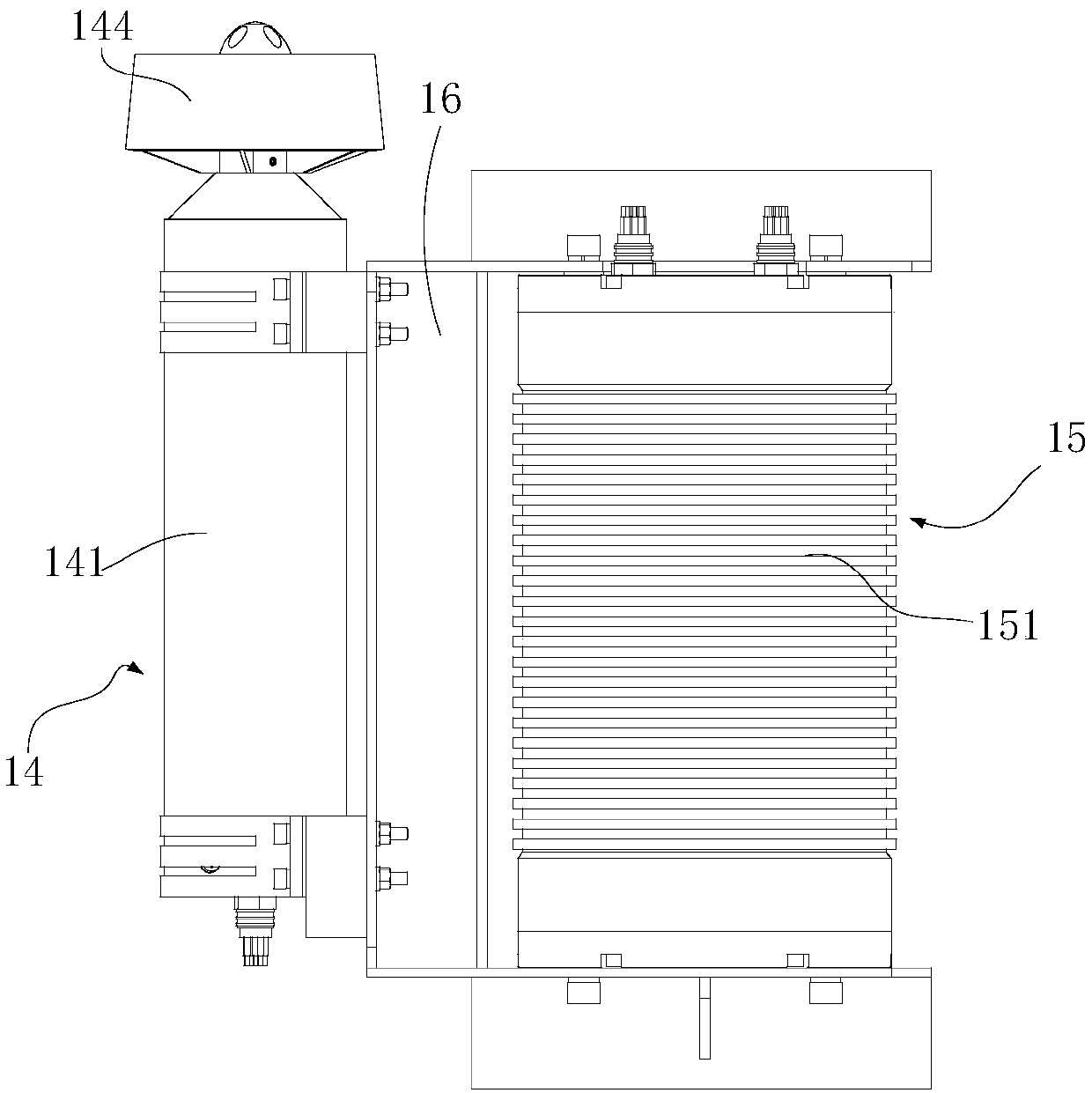

Offshore floating type draught fan and draught fan foundation thereof

InactiveCN105402091AOptimal balanceLimit horizontal movementWind motor supports/mountsWind energy generationOcean bottomEngineering

The invention relates to an offshore floating type draught fan and a draught fan foundation thereof. The draught fan foundation comprises a floating barrel structure, a support structure, a ballast tank, an upper-layer fixing device and a lower-layer fixing device. The ballast tank is located below the floating barrel structure. The floating barrel structure and the ballast tank are connected through the support structure. The ballast tank is of a flat box structure, and the outer contour of the ballast tank is larger than that of the floating barrel structure. The upper-layer fixing device comprises a plurality of upper-layer cables, the upper-layer cables are evenly distributed around the floating barrel structure, the upper ends of the upper-layer cables and the floating barrel structure are fixed, and the lower ends of the upper-layer cables and the seabed are fixed. The lower-layer fixing device comprises a plurality of lower-layer cables, the lower-layer cables are evenly distributed around the ballast tank, the upper ends of the lower-layer cables and the ballast tank are fixed, and the lower ends of the lower-layer cables and the seabed are fixed. The offshore floating type draught fan and the draught fan foundation thereof have the beneficial effects of being simple in structure, good in stability, not likely to be damaged, high in adaptability to water depth and especially suitable for sea areas with large water depth.

Owner:NEW UNITED GROUP

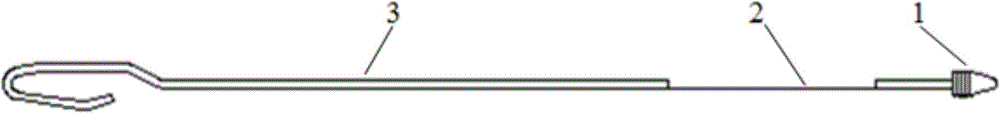

Natural bionic watering device

InactiveCN1729753AOptimal balanceRealize the purpose of water supply on demandWatering devicesCultivating equipmentsEngineeringWater saving irrigation

The invention relates to the natural and bionic irrigating, belonging to the water industry field, especially relating to a bionic irrigating machine which can provide water in accordance with the plant growing need for the whole day in the agricultural saving-water irrigation. The invention breaks the traditional intermittent rotation irrigation idea, making use of the physiological characteristic of the crop, the mechanism of the blood supply by the human capillary vessel to the cell and the principle of capillary absorbent, when the crop needs little water, the water entering to soil through line 4 is little; when the crop needs much water, the water entering into soil through line 4 is much, which on the whole reaches a optimum equilibrium state.

Owner:范世峰 +1

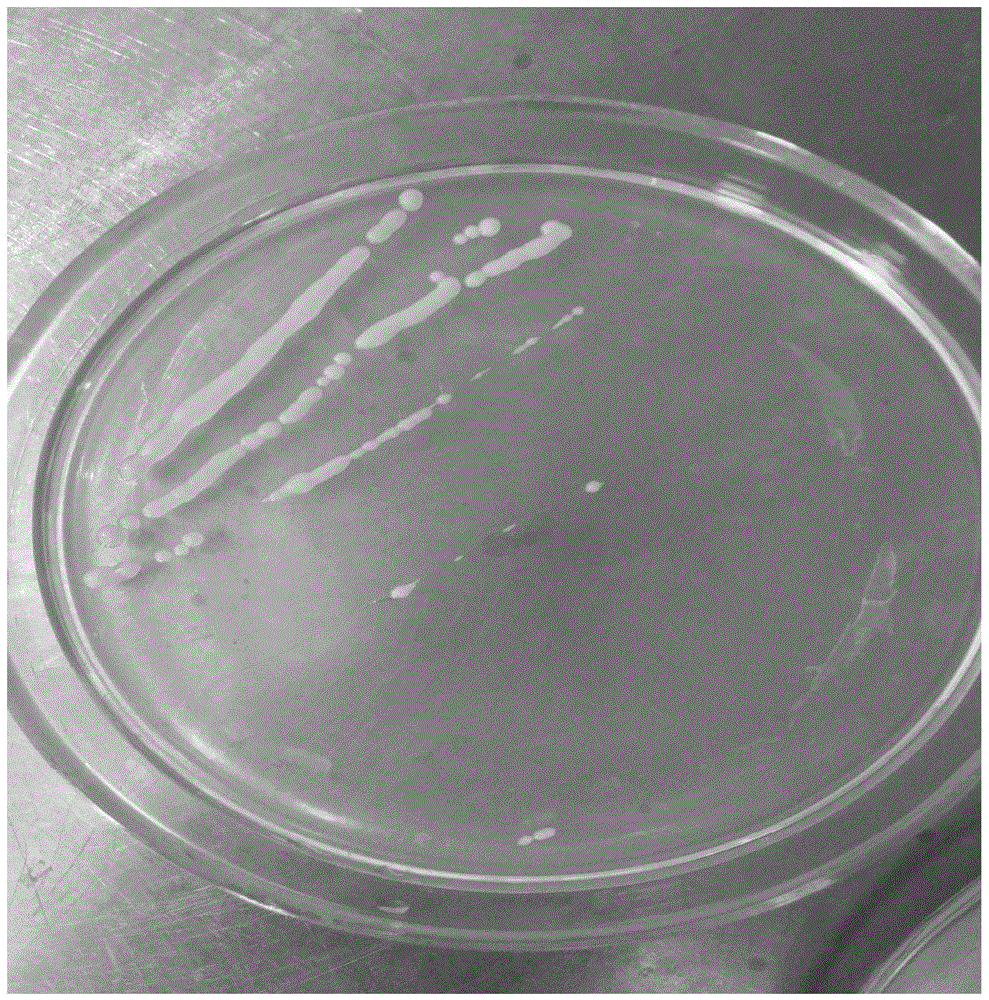

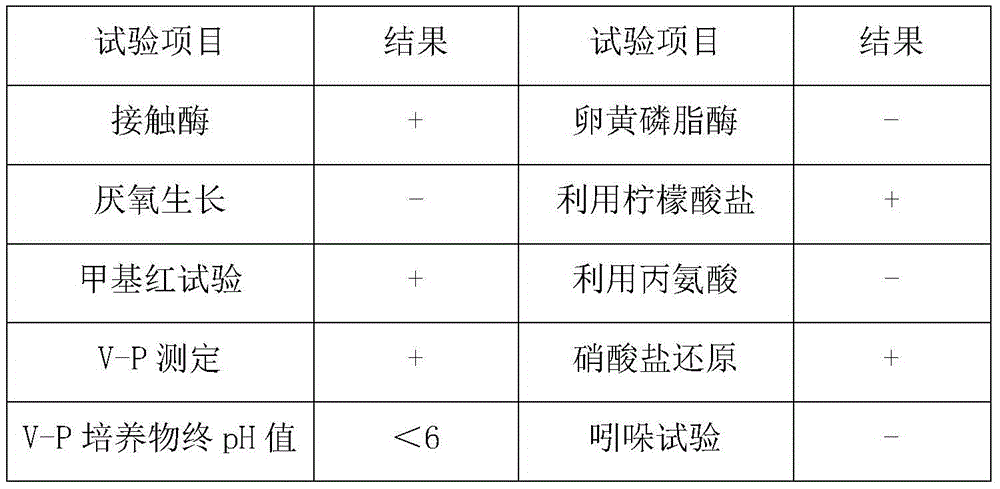

Bacillus subtilis, fermentation method, powder and application

ActiveCN105602865APromote growthImprove stress resistancePlant growth regulatorsBiocideMicroecosystemKosteletzkya virginica

The invention discloses bacillus subtilis, a fermentation method, powder and application. The bacillus subtilis is bacillus subtilis Gv-1, the depository authority is the China Center for Type Culture Collection, the depository address is Wuhan University, Wuhan of China, the depository number is CCTCC NO: M2015766, and the depository date is December 21, 2015. According to the invention, Kosteletzkya virginica earthnut endophyt is separated from a Kosteletzkya virginica earthnut for the first time, and purification, 16S rDNA sequencing and morphological and physiological characteristic analysis are performed, so that isolated and cultured stra Gv-1 is identified as bacillus subtilis. According to the invention, bacillus subtilis powder is prepared through bacillus subtilis fermentation liquor and is added into pig feed, and results show that the pig feed with the bacillus subtilis powder added can sufficiently realize the effect of the bacillus subtilis Gv-1, promote the production performance of piglets and digestive absorption for protein, Ca and P by the piglets, improve the intestinal microorganism flora of the piglets, and ensure that the intestinal microorganism flora is in an optimum equilibrium state.

Owner:河南广安生物科技股份有限公司 +2

Multifunctional biology corn feedstuff

ActiveCN101449741ASimple preparation processShort fermentation cycleFood processingAnimal feeding stuffBiotechnologyOxygen

A multifunctional biologic corn chop is prepared according to the following technical process: (1) throwing materials in turn into an organic biochemistry fermenting machine for even mixing, modulating 50-60% water; (2) setting temperature as 70 DEG C, performing aerobic fermentation for 8-10 hours; (3) terminating the reaction when material water is lower than or equal to 10%; (4) weighing and packaging after materials are discharged and sieved. The inventive multifunctional biologic corn chop replaces 30-60% foodstuff materials of corns in livestock complete feed; content of probiotic is larger than 10<7> cfu / g, containing a plurality of proleases, lipase and amylase and the like, preparing technical is simple and fermenting period is short.

Owner:BEIJING GOLDENWAY BIO TECH

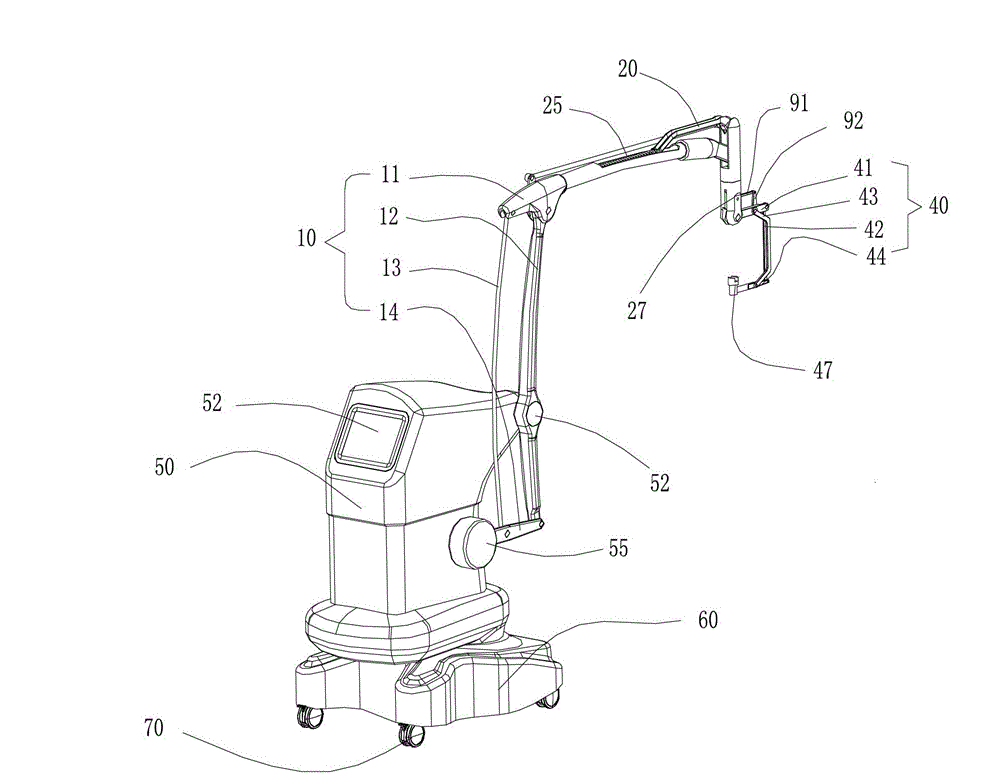

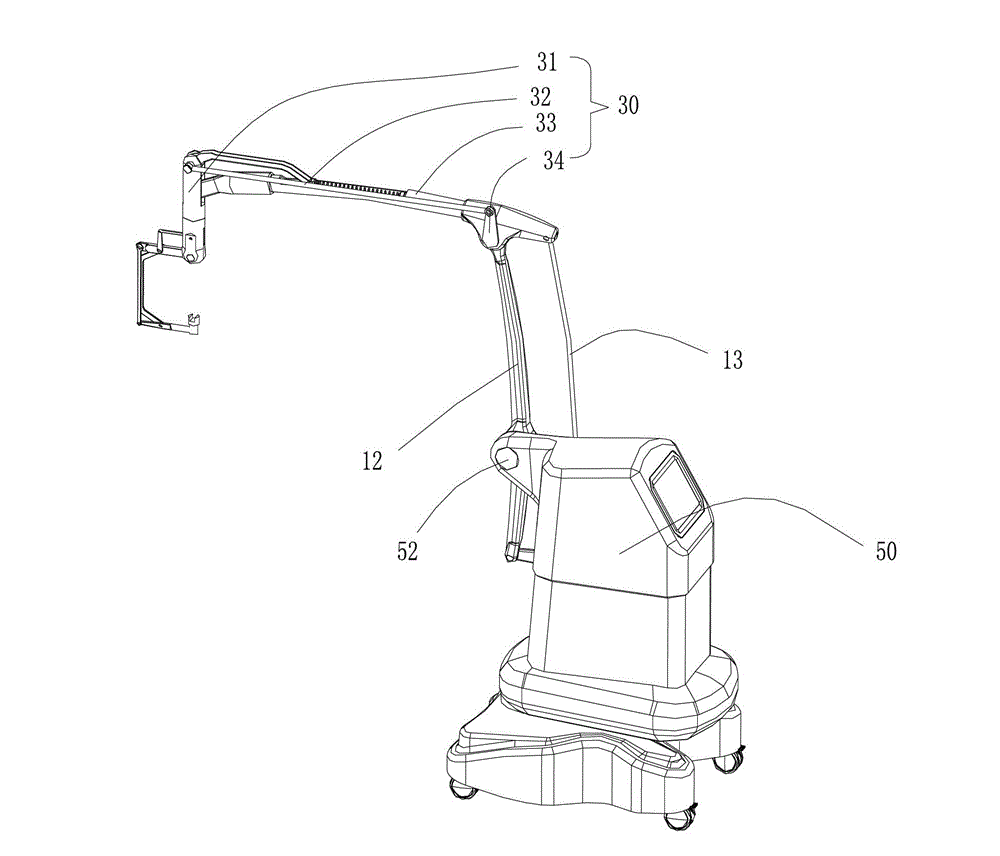

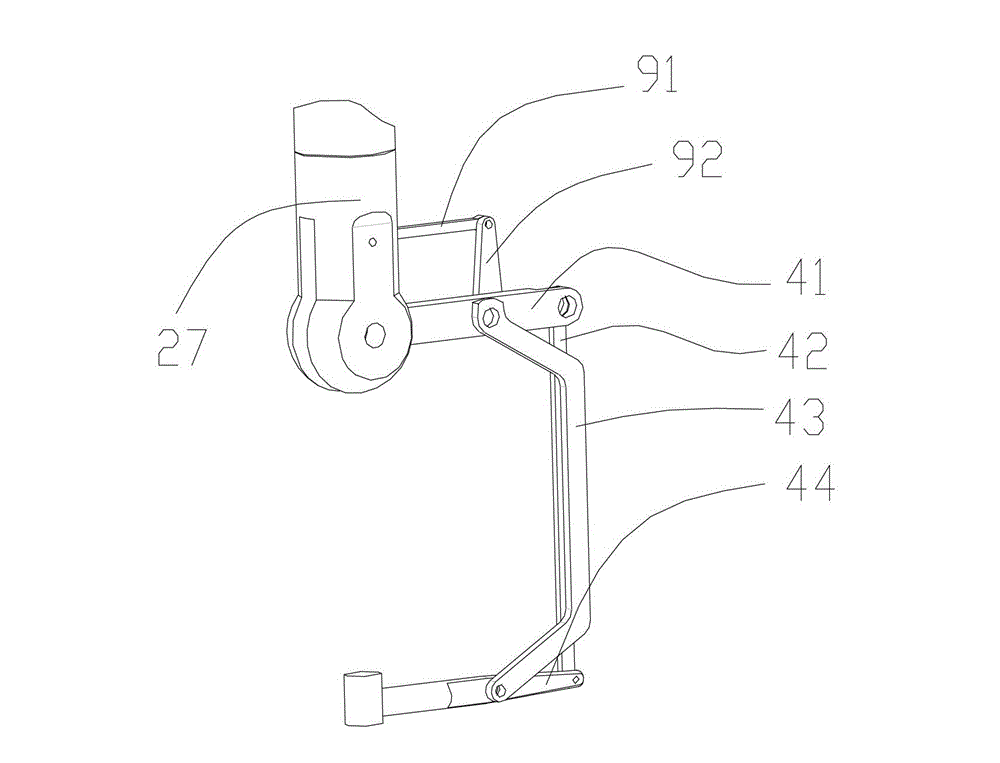

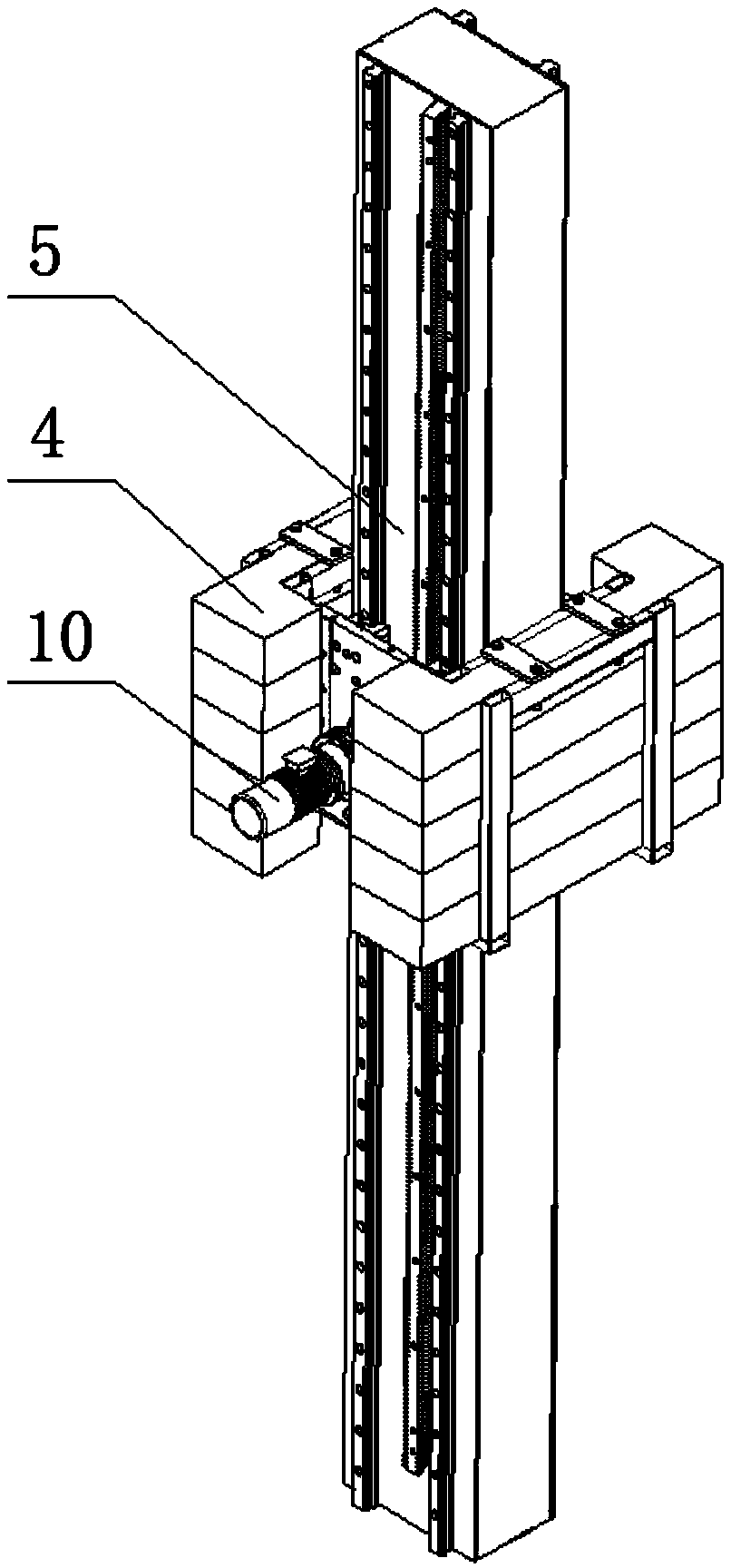

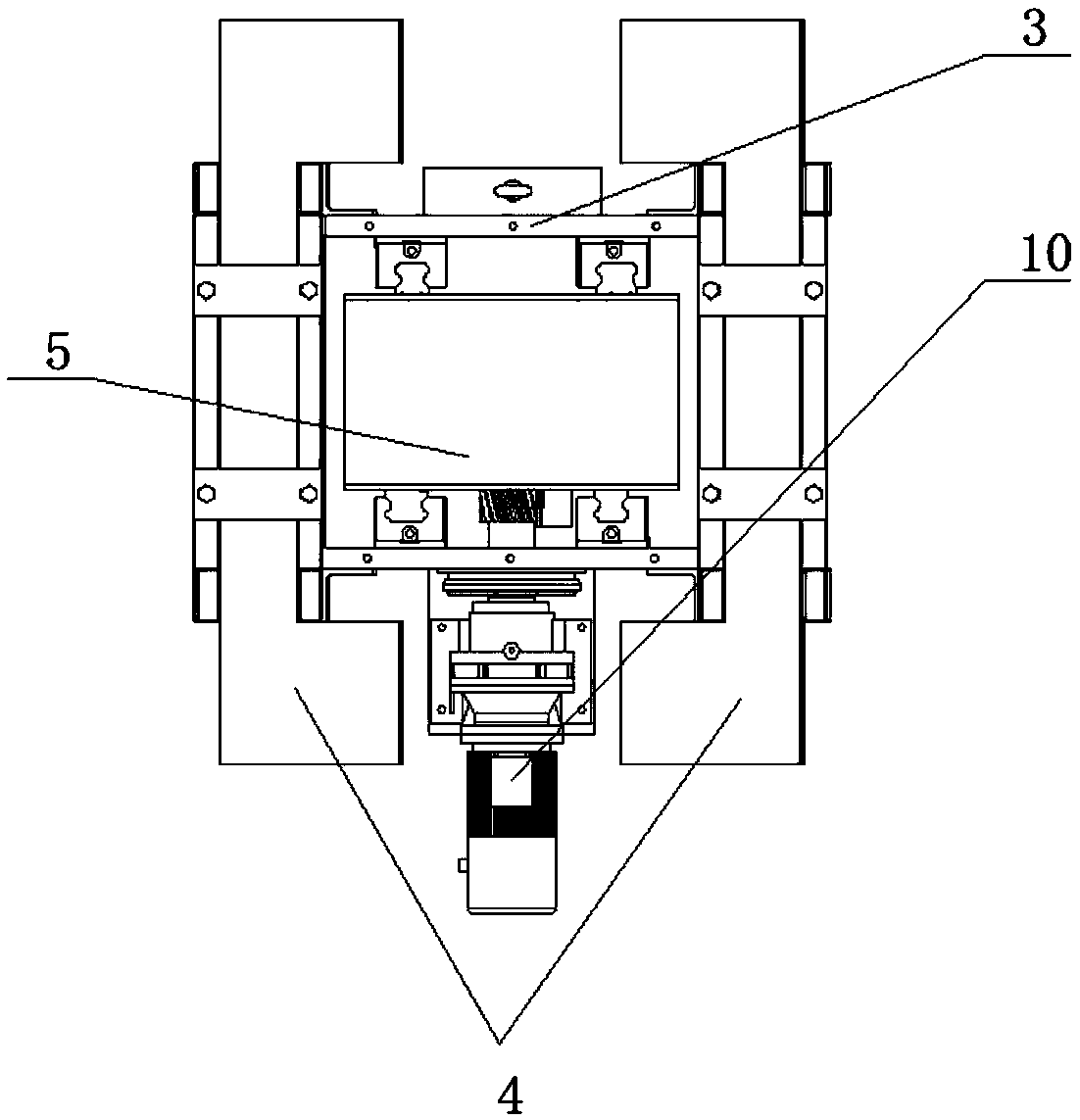

Operating microscope rack

ActiveCN102940532ASimple structureReduce swingDiagnosticsSurgical microscopesEngineeringOperating microscope

An operating microscope rack comprises a first parallel four-connection rod, a second parallel four-connection rod, a third parallel four-connection rod, a rack cabinet, a first connection rod, a second connection rod and a central rod, wherein the first parallel four-connection rod, the second parallel four-connection rod and the third parallel four-connection rod respectively comprise an upper connection rod, a lower connection rod, a left connection rod and a right connection rod, the upper connection rod is parallel to the lower connection rod, the left connection rod is parallel to the right connection rod, and a fourth parallel four-connection rod is formed by the first connection rod, the second connection rod, the central rod and the upper connection rod of the third parallel four-connection rod. The operating microscope rack is simple in structure, small in swing amplitude, free of collision on doctors or other objects, favorable for keeping a sterile operation environment, flexible in use, good in balance and particularly suitable to middle-to-high-grade operating microscopes, and multi-angle multi-region adjustment of the microscopes can be achieved.

Owner:深圳市益心达医学新技术有限公司

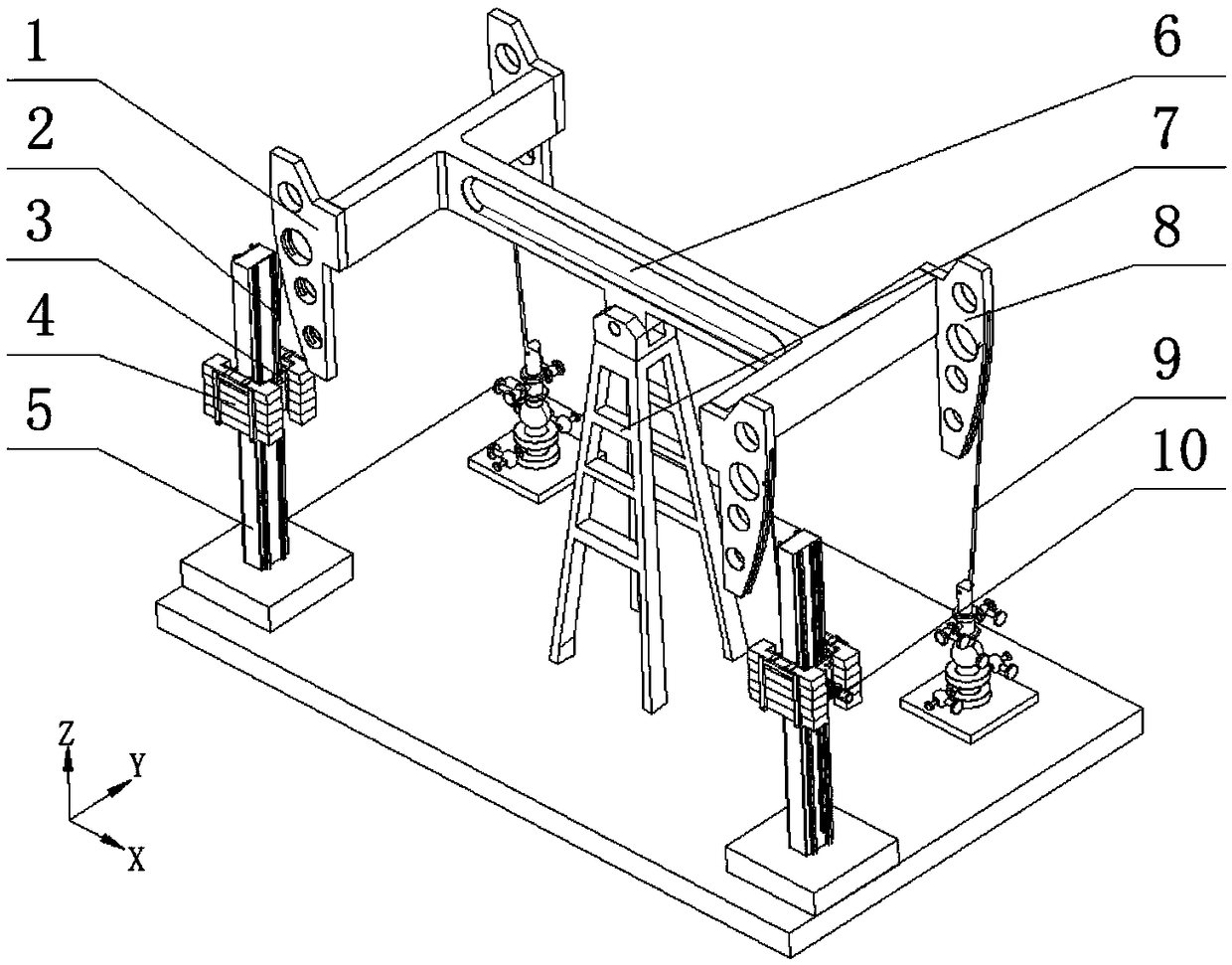

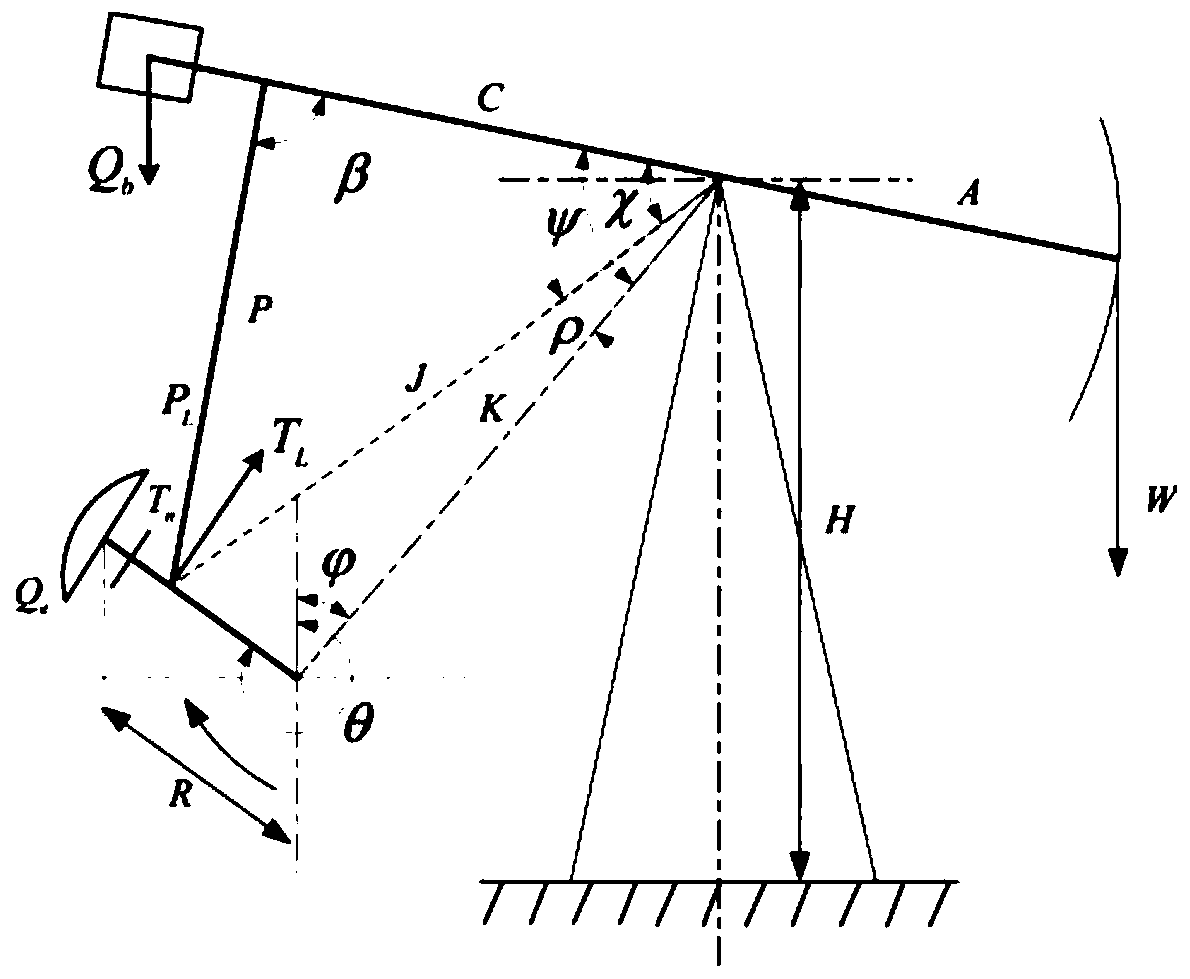

Dual-sucking energy-saving beam-pumping unit

PendingCN109339747AOptimal balanceImprove energy savingConstructionsFluid removalSystem structureMoving speed

The invention discloses a dual-sucking energy-saving beam-pumping unit. The dual-sucking energy-saving beam-pumping unit comprises sucker rods, driving horseheads, loading horseheads, a beam, a beam frame, driving wires and driving systems. The two ends of the beam is symmetric and all comprise one driving horseheads and one loading horseheads, the driving horseheads are connected with the corresponding driving systems through the driving wires, the loading horseheads are connected with the corresponding sucker rods, the structures of the driving systems on the two sides are the same, and thedriving systems all comprise driving units, traction units and counter weight units.When the left side driving unit moves downward, the left side traction unit draws the left side driving horsehead tomove downward, the left side loading horsehead and the left side sucker rod move downward, the right side loading horsehead draws the right sidesucker rod to move upward under the action of driving force of the left side driving system, and meanwhile, the right side driving unit moves upward initiatively, and the moving speed is higher than the downward moving speed of the left side driving unit,a right side counter weight fails to work, and back and forth. The dual-sucking energy-saving beam-pumping unit is driven by a gear and a gear rack, the counter weight can be adjusted correspondinglyaccording to actual working conditions of two wells, the balancing property is good, and the energy-saving effect is significant.

Owner:杭州中油智井装备科技有限公司

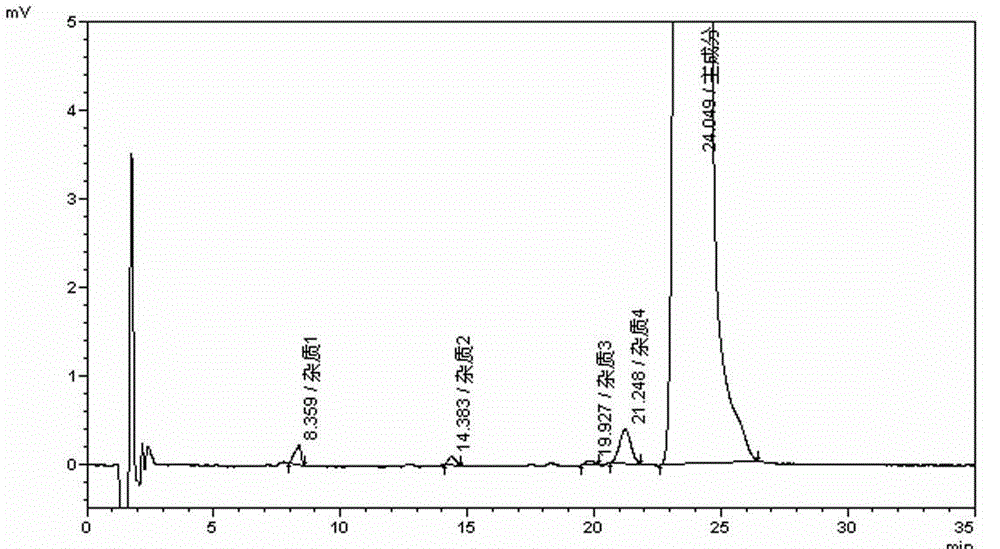

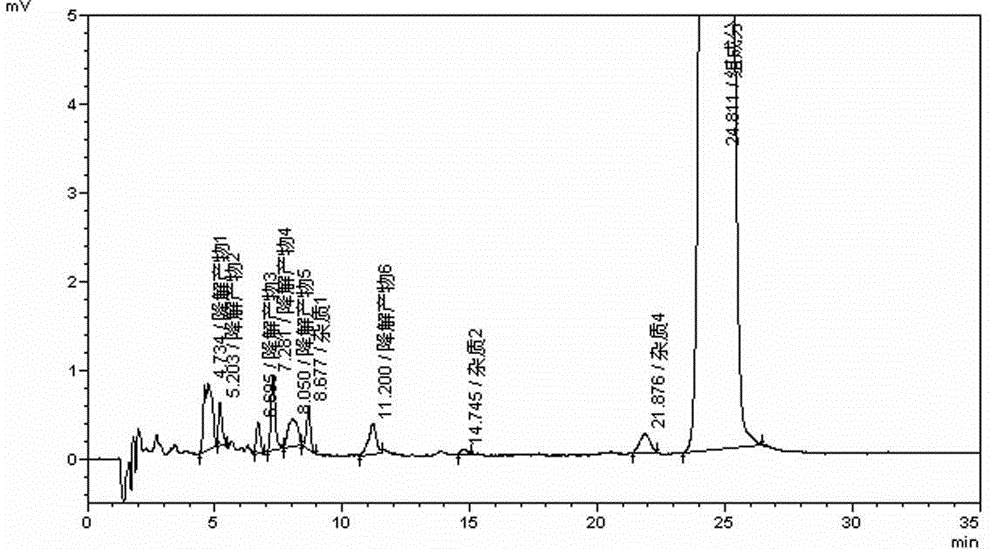

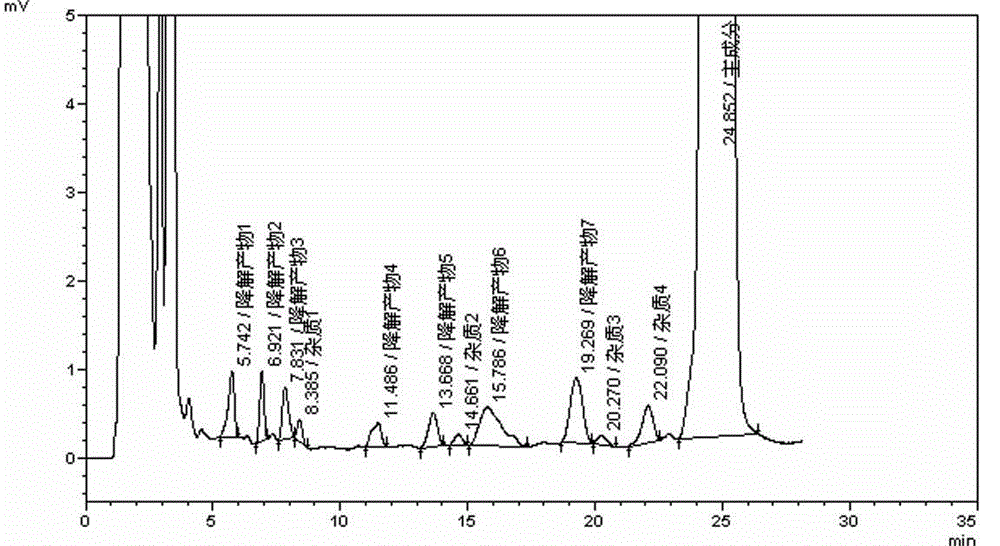

Desloratadine syrup preparation and preparation method thereof

InactiveCN104784110AOptimal balanceSolve the pink problemOrganic active ingredientsAntipyreticDesloratadineToxicity

A desloratadine syrup preparation mainly comprises desloratadine, sucrose, a pH adjusting agent, a stabilizer, and a flavoring or antiseptic, wherein desloratadine exists in a hydrochloride form. The pH value of the syrup preparation is 4.0-7.0. The desloratadine syrup preparation has the advantages of fast effectiveness, strong effect, no toxicity to the heart, less drug interaction, and no food taboo.

Owner:ZHEJIANG KAIRUN PHARMA

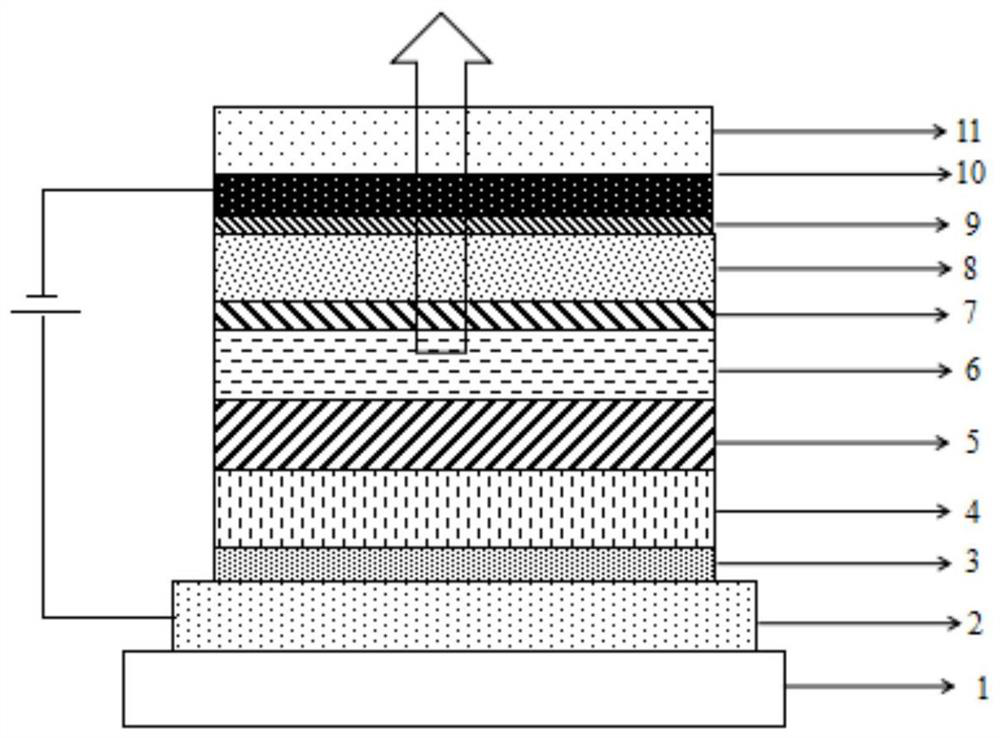

Arylamine organic compound and organic electroluminescent device containing same

ActiveCN113402399AStereo-asymmetricGuaranteed stabilityOrganic chemistrySolid-state devicesSemiconductor materialsOrganic electroluminescence

The invention relates to the technical field of semiconductor materials, and particularly discloses an arylamine organic compound and an organic electroluminescent device containing the compound. The structure of the compound is shown as a general formula (I). The arylamine organic compound provided by the invention has excellent hole transport capability and stability. When the arylamine organic compound is used for forming a hole transport material of the organic electroluminescent device, the performance of the device can be improved, for example, the efficiency of the device is improved, the driving voltage is reduced, and the service life is prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

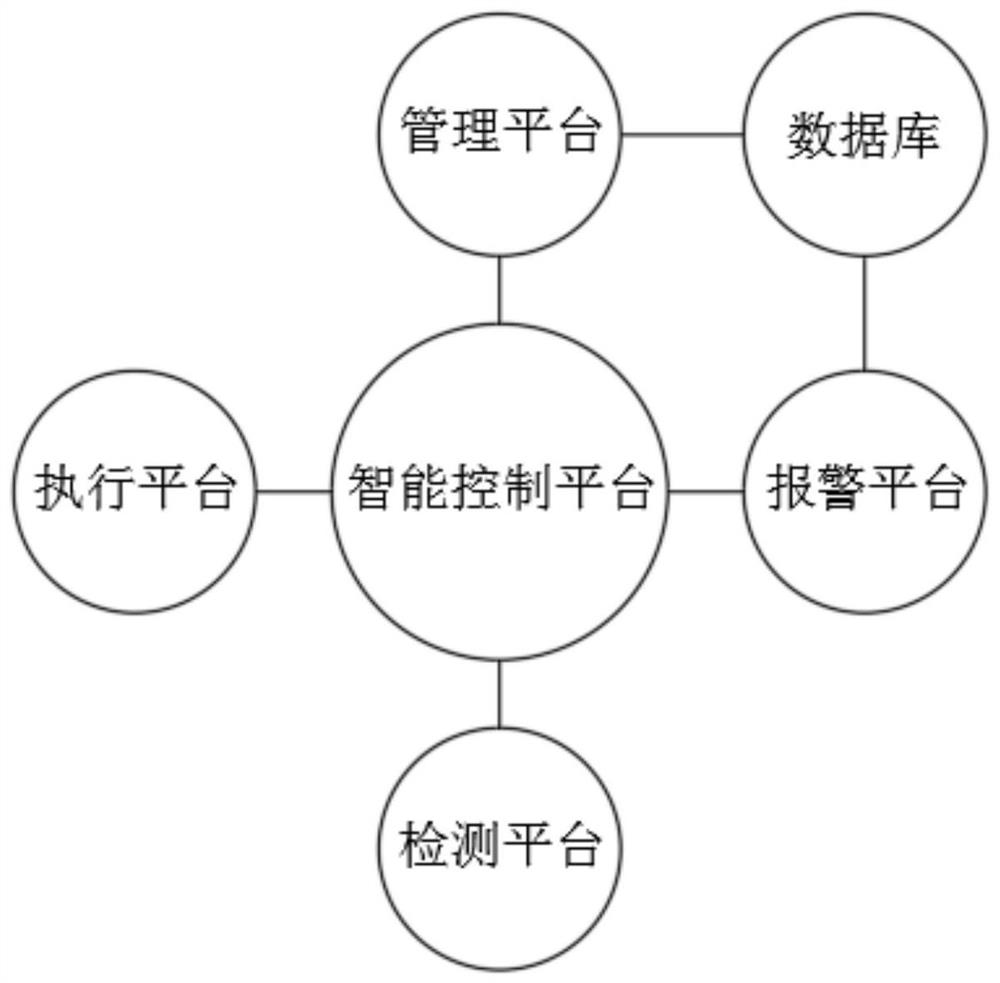

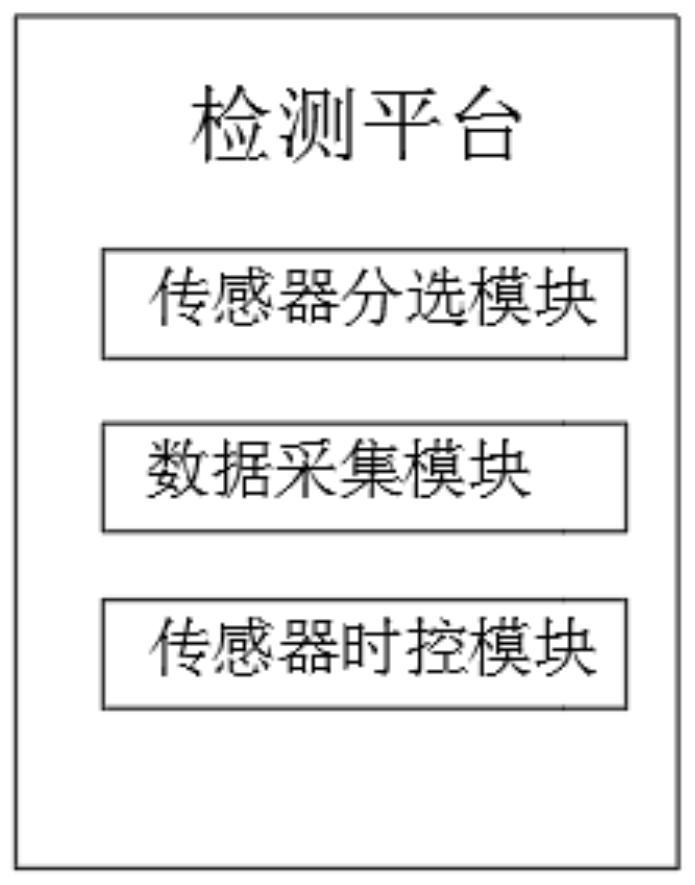

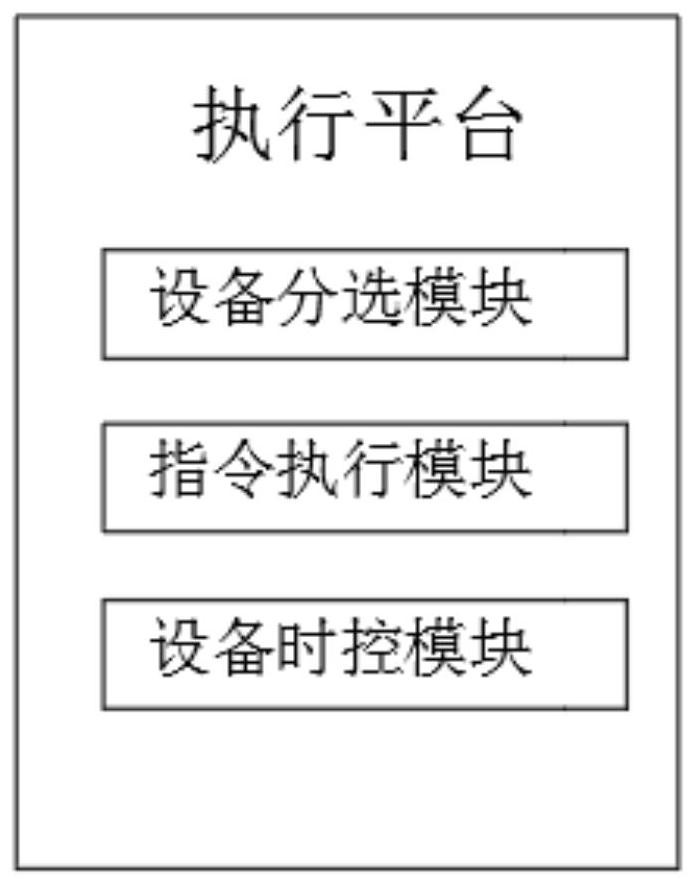

Indoor toilet environment intelligent control system

PendingCN111830876AAchieve real-time dynamic balance effectOptimal balanceProgramme controlMeasurement devicesComputer scienceEnvironmental data

The invention discloses anindoor toilet environment intelligent control system, which comprises a detection platform, an intelligent control platform, an execution platform, an alarm platform and a management platform, wherein the detection platform is various environmental data sensing detection equipment distributed in an indoor toilet; the execution platform is various environment data regulation and control equipmentdistributed in an indoor toilet; the intelligent control platform is used for carrying out self-checking processing on the collected environment data of the indoor toilet; thealarm platform is used for triggering to generate an alarm signal; and the management platform is used for receiving, querying and managing the environment data of the indoor toilet. According to theindoor toilet environment intelligent control system, a double self-checking mode is utilized, abnormal environment data existing in an indoor toilet can be comprehensively and accurately analyzed anddetected, the real-time dynamic balance effect of the indoor toilet environment is achieved through regulation and control operation of dynamic balance, and the indoor toilet environment is ensured to be in the optimal balance state.

Owner:白兴龙

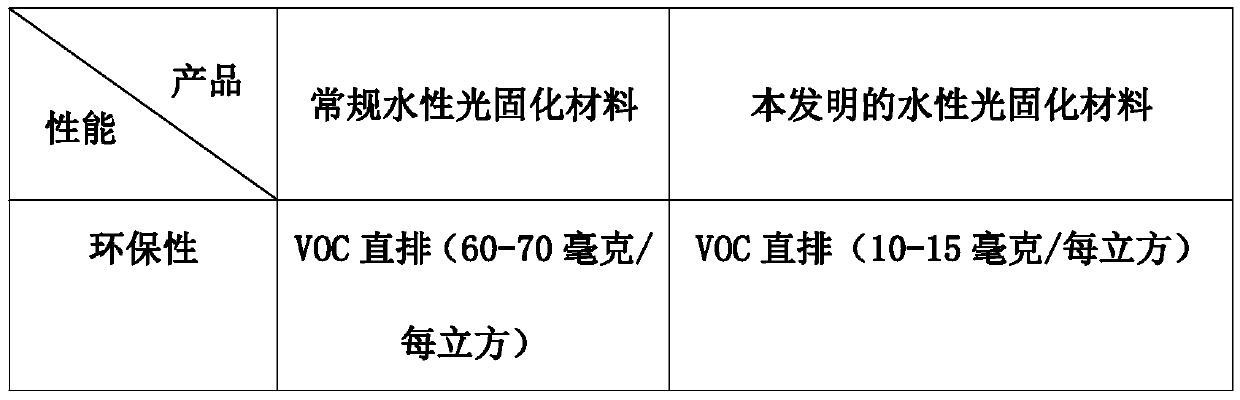

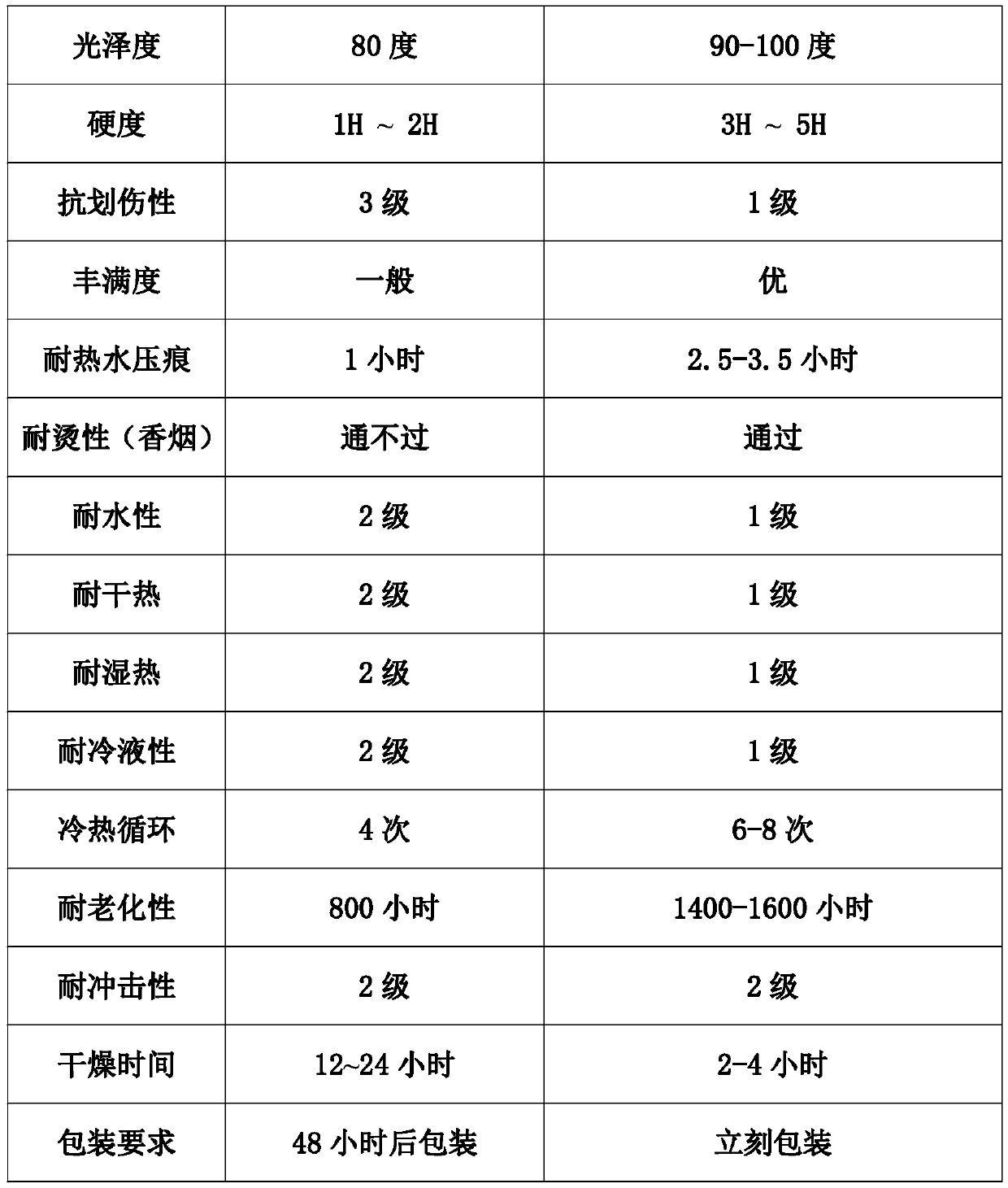

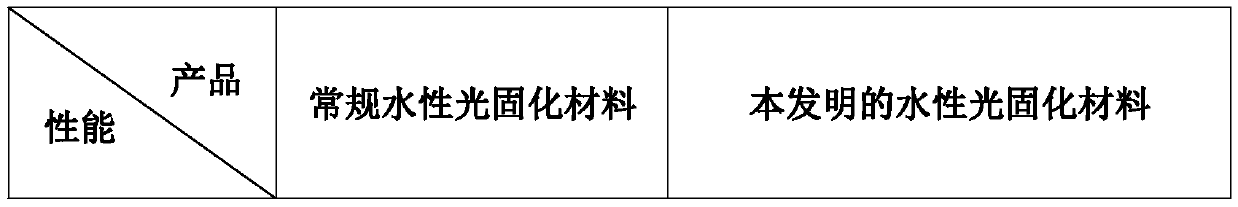

Aqueous photocuring material and preparation process thereof

The invention discloses an aqueous photocuring material and a preparation process thereof. The aqueous photocuring material is prepared from the following components in parts by weight: 45-55 parts ofa waterborne polyurethane acrylate emulsion, 18-22 parts of an aqueous aliphatic polyurethane dispersoid, 9-11 parts of an anionic polyurethane acrylate emulsion, 2.3-2.5 parts of an emulsifier, 2.5-3.5 parts of a photoinitiator, 0.8-1.3 parts of a wetting agent, 0.3-0.5 part of a flatting agent, 0.3-0.5 part of a feeling agent, 0.1-0.3 part of a defoamer, 0.3-0.4 part of a thickener and 9-11 parts of deionized water. The components are mixed and dispersed in proportions to obtain the aqueous photocuring material. The aqueous photocuring material has the characteristic of improving the glossiness and hardness of a cured film effectively.

Owner:HUZHOU JIFU NEW MATERIALS SCI & TECH CO LTD

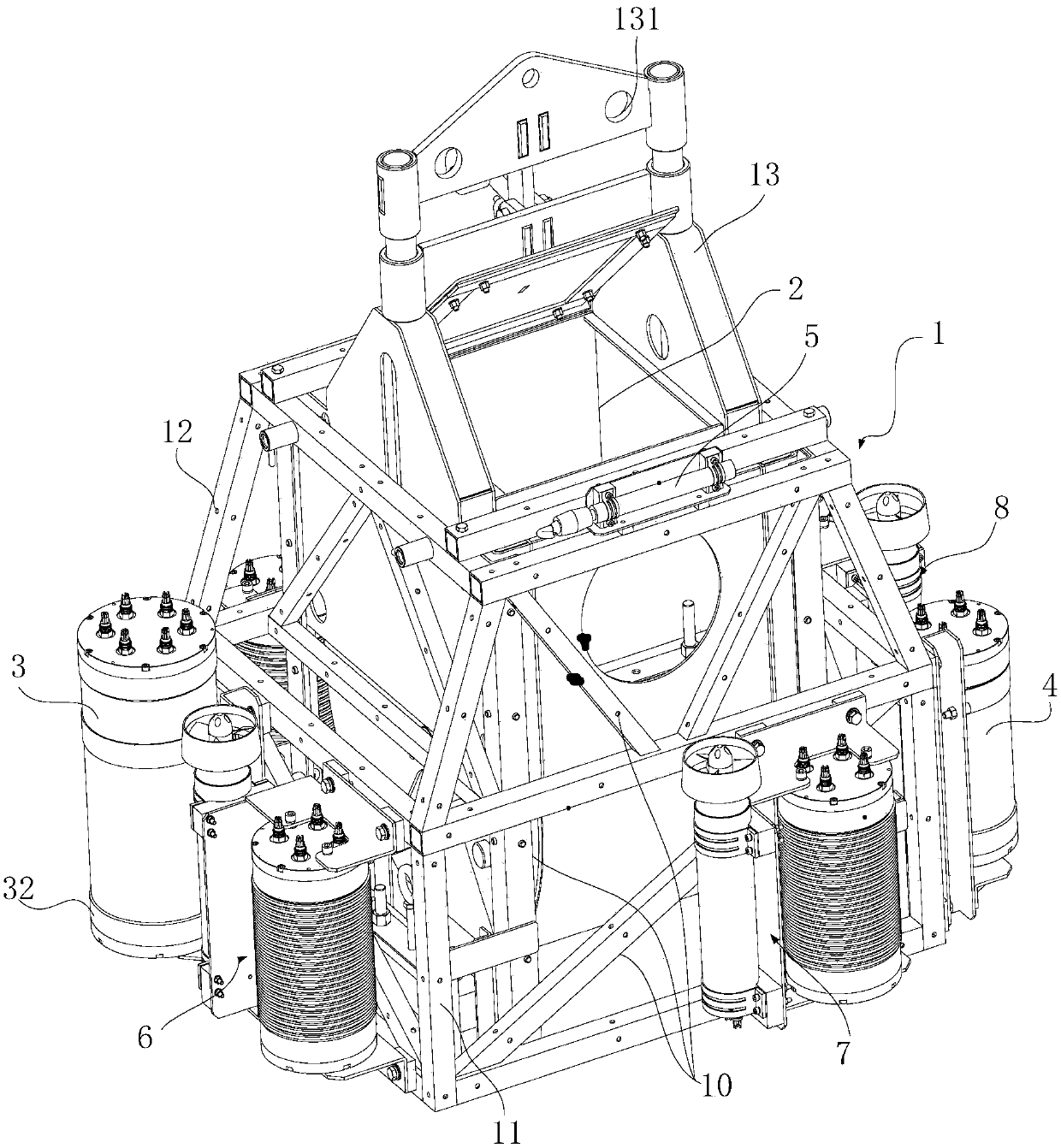

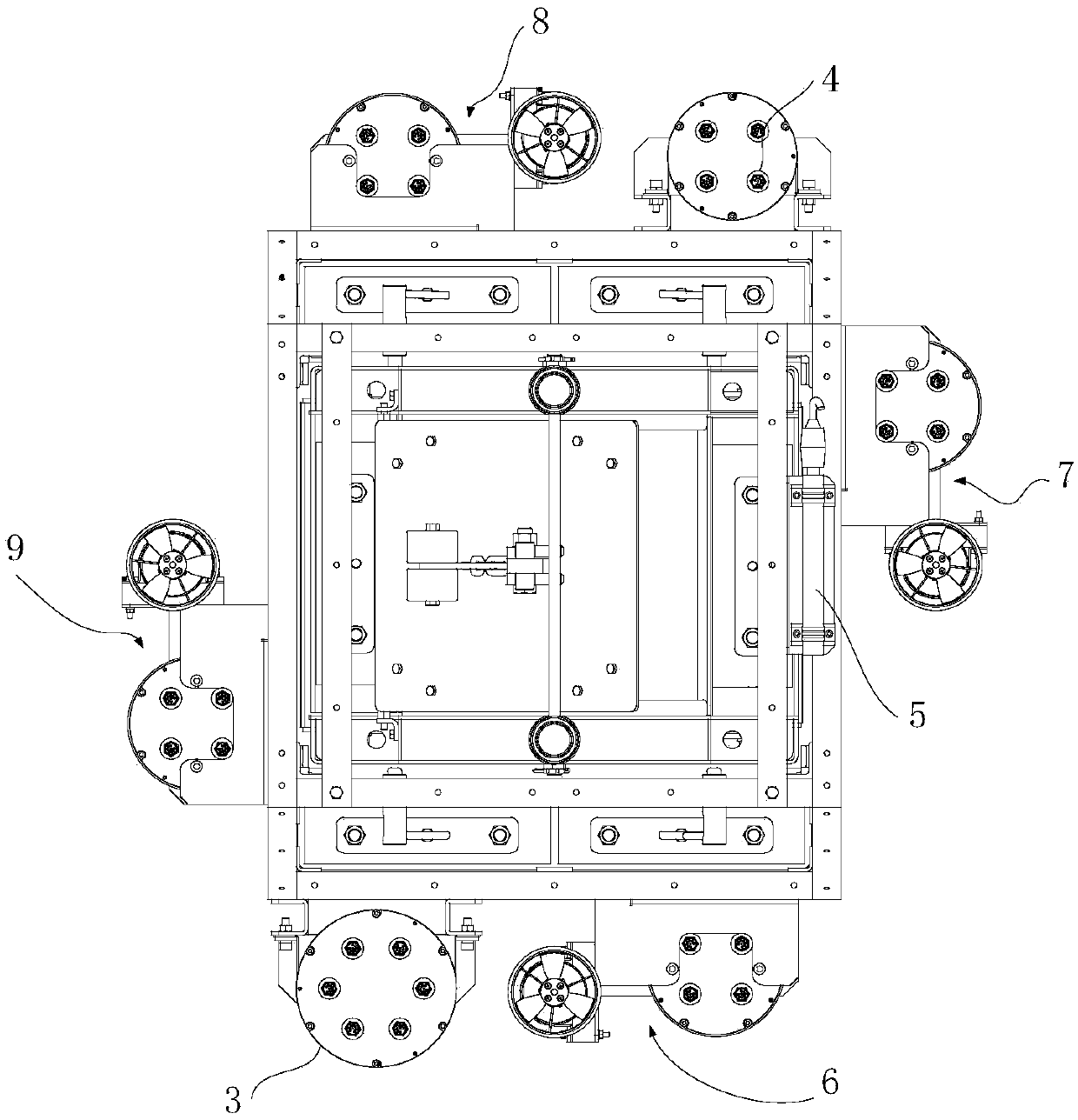

Deep sea autonomous attitude adjustment sampling system and attitude adjusting method thereof

ActiveCN109540575ASimplify the attitude adjustment processImprove attitude adjustment efficiencyWaterborne vesselsWithdrawing sample devicesPropellerControl mode

The invention discloses a deep sea autonomous attitude adjustment sampling system and an autonomous attitude adjusting method thereof. The sampling system comprises a sample assembling rack, a sampler, a battery chamber assembly, an MCU master control assembly, a propeller assembly and a clinometer. The clinometer and the propeller assembly are electrically connected with the MCU master control assembly. The propeller assembly comprises four sets of propellers. The four sets of propellers are correspondingly arranged at periphery of the sample assembling rack and are orthogonally arranged in atwo-to-two facing manner. Furthermore high integral structure design stability is realized. In sampling system attitude adjustment, self-learning is realized based on a balance algorithm. Action of the propeller is realized in a torque control mode. Simple and quick controlling is realized. The propellers are used for keeping an accurate seabed landing attitude of the sampling system, thereby realizing autonomous attitude adjustment of the system in a dropping process. Furthermore various actions are executed through setting one cycle. The sequence of the actions is determined according to the action sequence score. The deep sea autonomous attitude adjustment sampling system and the autonomous attitude adjusting method thereof have advantages of ensuring high speed in reaching an optimalbalance state in attitude adjustment and effectively improving efficiency in acquiring deep sea seabed surface-layer deposit.

Owner:QINGDAO INST OF MARINE GEOLOGY

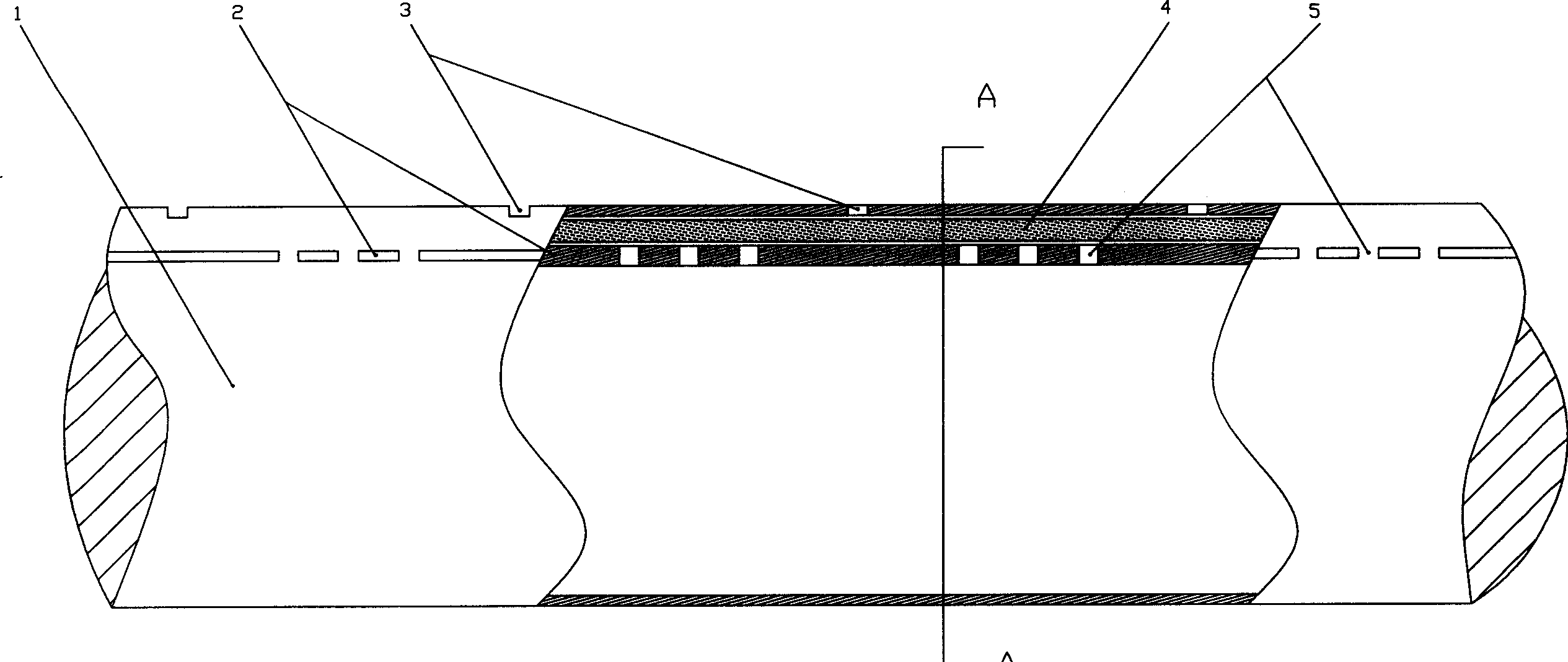

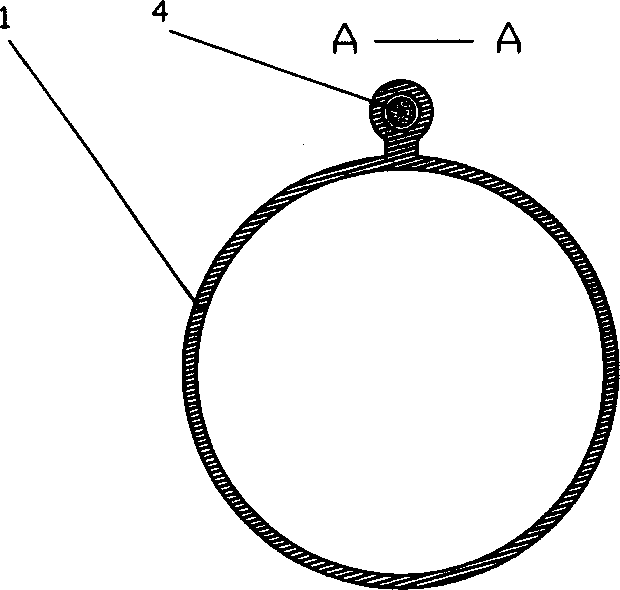

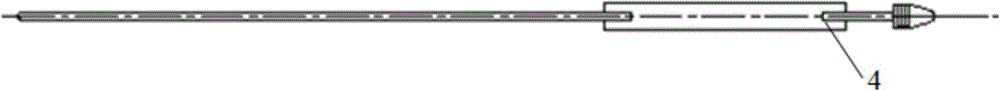

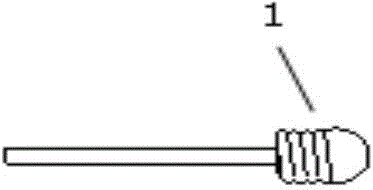

Electrode molybdenum sheet assembly for ultrahigh-voltage point light source and forming method thereof

InactiveCN104785925AEvenly distributedAvoid oversolderingLaser beam welding apparatusElectrical resistance and conductanceWave shape

The invention relates to an electrode molybdenum sheet assembly for an ultrahigh-voltage point light source and a forming method thereof. The electrode molybdenum sheet assembly is composed of a sealing-in molybdenum sheet, a transmitting electrode and an outgoing line, wherein the transmitting electrode and the outgoing line are welded to the two ends of the sealing-in molybdenum sheet. The sealing-in molybdenum piece is of an arc structure or a peak-shaped structure, the transmitting electrode is composed of a single core rod or a core rod and a spring connected to the front end of the core rod in a sleeving mode. The outgoing line is a molybdenum rod outgoing line, the tail of the outgoing line is of a diamond or hook-shaped structure, and the middle of the outgoing line is of a straight-rod-shaped or wave-shaped structure. One end of the sealing-in molybdenum sheet is provided with a laser electric welding spot connected with the transmitting electrode in a welding mode. Multi-point laser welding is conducted through a laser outgoing head, the transmitting electrode is connected to one end of the sealing-in molybdenum sheet in a welding mode, and the outgoing line is connected to the sealing-in molybdenum sheet in a welding mode and coaxially arranged with the transmitting electrode through the other end of the sealing-in molybdenum sheet in a resistance spot welding mode. Compared with the prior art, the welding quality and consistency are ensured, the bearing strength of the molybdenum sheet is improved and accurately controlled, straightness in the packaging process can also be improved, and accurate positioning is achieved.

Owner:上海亚尔精密零件制造有限公司

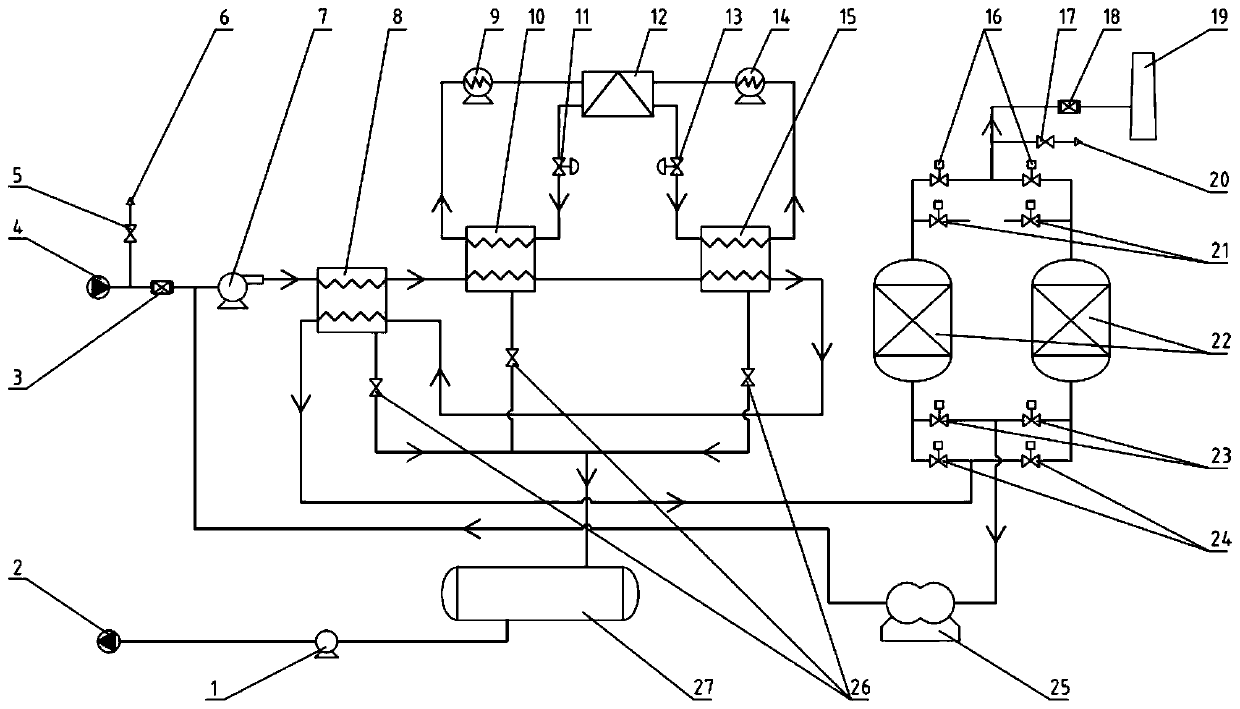

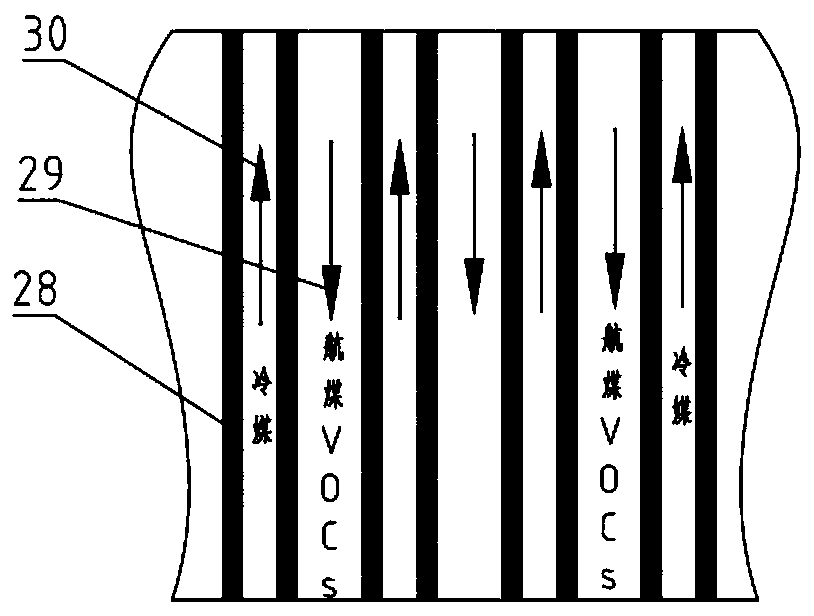

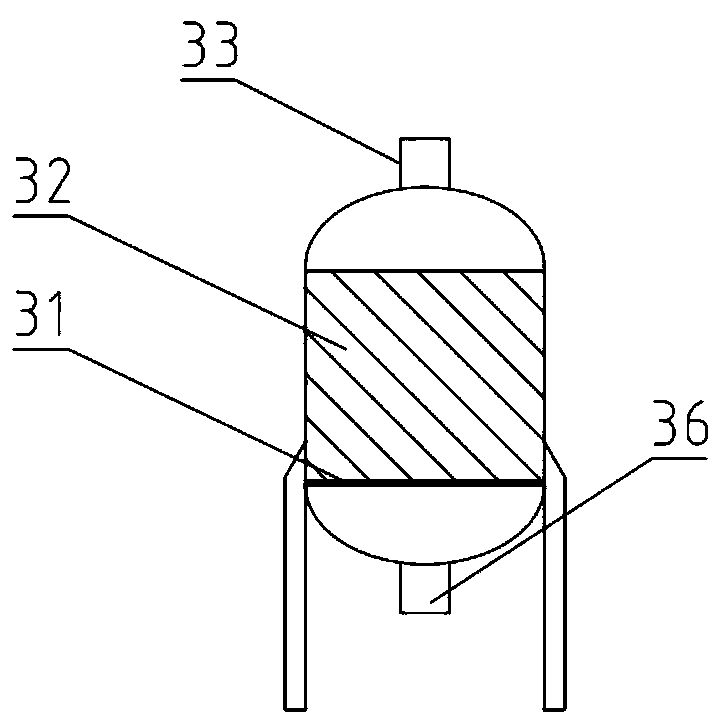

Treatment device and treatment method of aviation kerosene VOCs (volatile organic compounds)

PendingCN109999601AImprove icingFull heat exchangeGas treatmentDispersed particle separationThree levelActivated carbon

The invention discloses a treatment device and a treatment method of aviation kerosene VOCs (volatile organic compounds). VOCs gas is treated with a three-level condensation and adsorption manner. According to the scheme, the flowing smoothness of a condenser is improved through optimization of the condenser, and long-time and stable operation of condensation equipment is effectively guaranteed; besides, the last uncondensed gas in three-level condensation is taken as a cold medium of a precooler for use, and energy consumption is effectively saved; besides, special activated carbon in an adsorption system is only arranged at the straight cylindrical section of an adsorption tank, the diameter-length ratio of the special activated carbon is controlled in the range of 0.6-0.8, adsorption and desorption can reach the best balance state, waste gas can be uniformly and sufficiently adsorbed, and rapid desorption of the activated carbon can be realized. The treatment device provided by thescheme is reasonable in design, has the advantages of long and stable operation of equipment, environmental protection, energy saving, small floor area and high return on investment of equipment and can realize the good purification effect on the VOCs gas in cooperation with the treatment method.

Owner:湖北楚天蓝环保设备工程有限公司

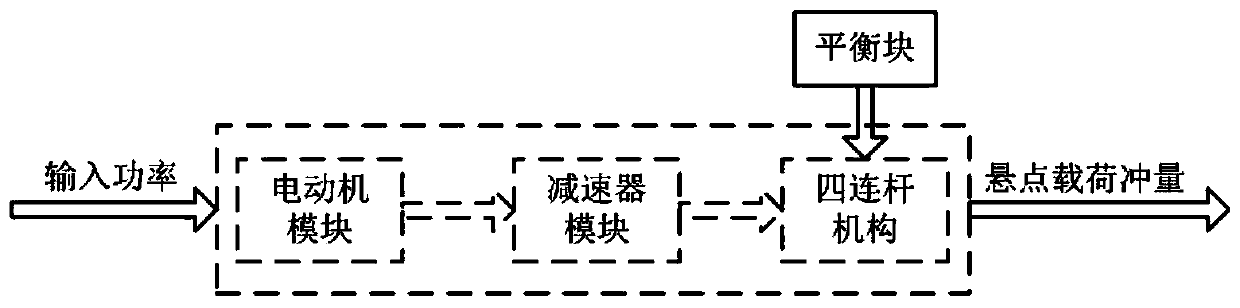

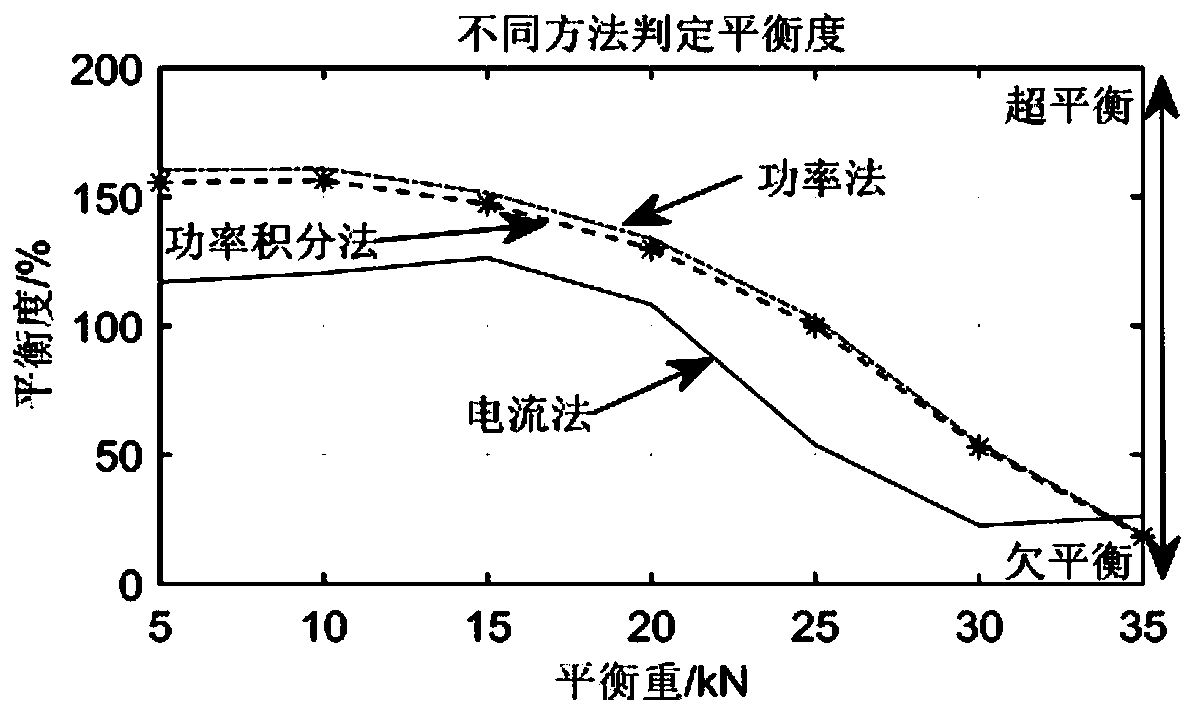

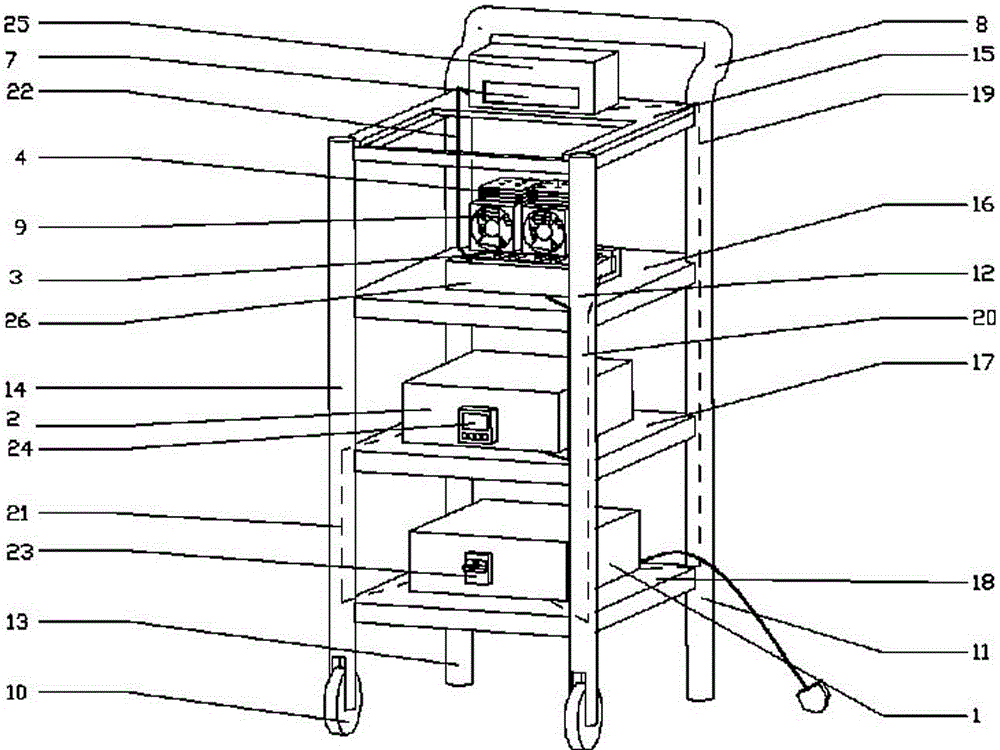

Iterative approximation follow-up leveling control method and device for beam-pumping unit

ActiveCN110895396AOptimal balanceImprove work efficiencyProgramme controlConstructionsControl engineeringUnit system

The invention provides an iterative approximation follow-up leveling control method for a beam-pumping unit, and the method comprises the steps: firstly analyzing the movement rule and energy circulation mechanism of a pumping unit system, and building an incidence relation mathematic model between the change of an input electric power integral value of a motor and the balance degree of the pumping unit; secondly, collecting real-time operation electrical parameters of the beam-pumping unit, and calculating the power integral ratio of unit stroke or multi-stroke up-stroke and down-stroke to detect the balance degree of a pumping unit system on line; and finally, according to the calculated balance degree, judging the balance state of the oil pumping unit operation system, and adopting a servo method to control a motor to drive a lead screw to adjust the position of the balance box body to change the balance torque so as to adjust the optimal balance state of the oil pumping unit. Compared with the prior art, the iterative approximation follow-up leveling control method and the iterative approximation follow-up leveling control device for the beam-pumping unit have the advantages that the working efficiency and the production safety coefficient of balance adjustment of the pumping unit are improved, the energy saving rate can reach 3 percent, and the engineering applicability ishigh.

Owner:XIAN HIRATE NET ELECTRIC EQUIP CO LTD

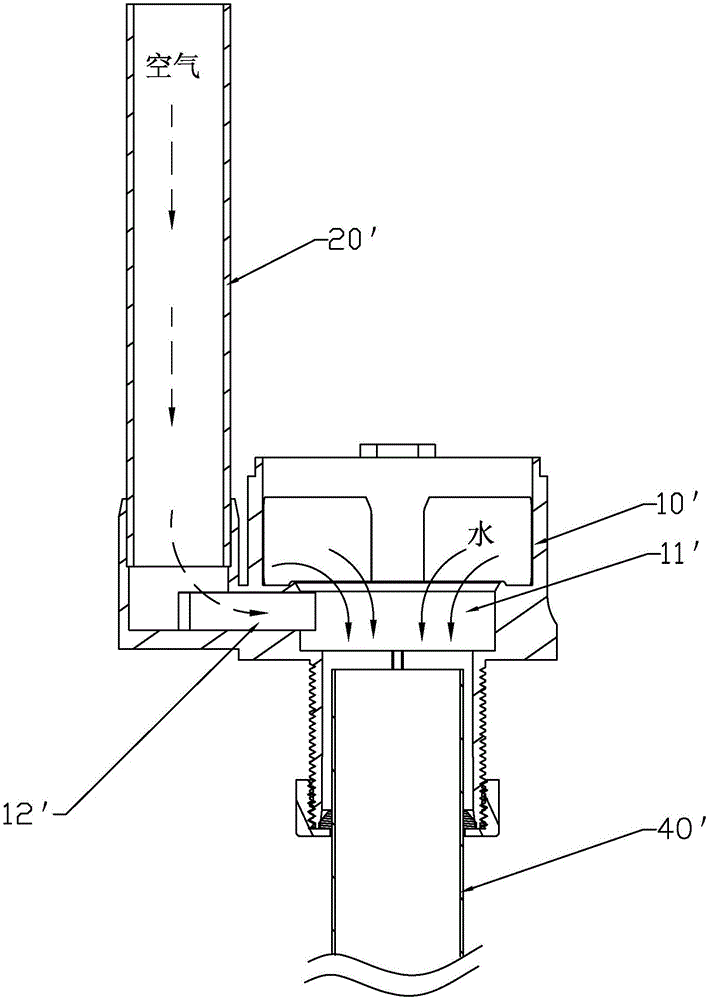

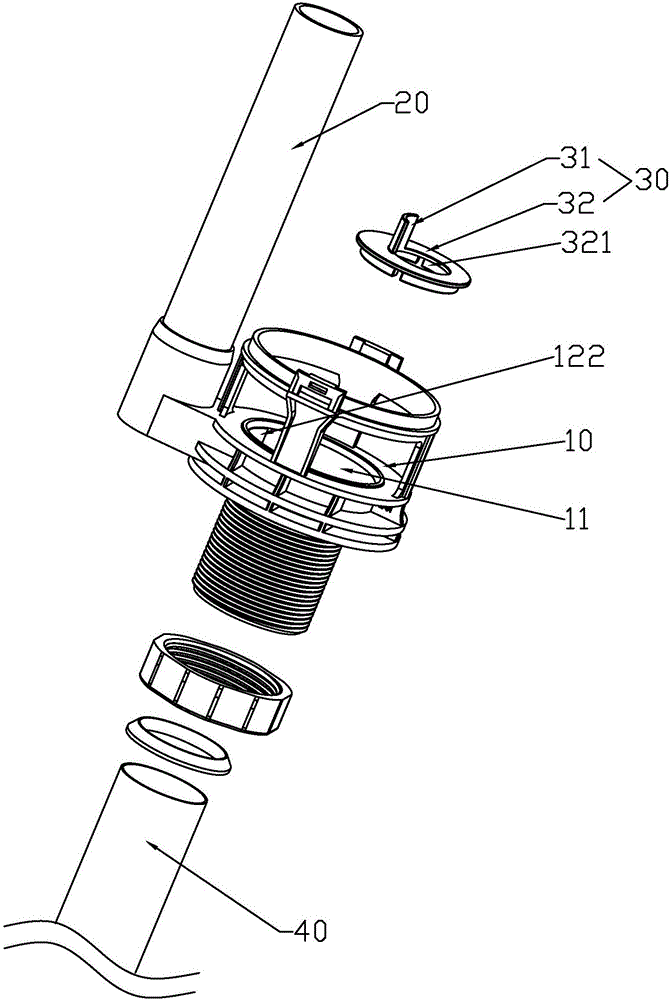

Drainage valve noise reduction structure with overflow pipe

PendingCN106759750ASolve the noise problemSimple structureFlushing devicesLavatory sanitoryContinuous noiseWater block

The invention discloses a drainage valve noise reduction structure with an overflow pipe. The drainage valve noise reduction structure comprises a base of a drainage valve and the overflow pipe, a drainage channel and an overflow channel are arranged in the base, the inlet of the overflow channel is communicated with the overflow pipe, the outlet of the overflow channel is communicated with the drainage channel, the overflow pipe is communicated with the drainage channel through the overflow channel in the base, a water blocking part is arranged in the drainage channel, and the water blocking part brings in part of water flow and blocks the same in the overflow channel when water is drained from the drainage channel to enable water seal to form in the outlet of the overflow channel. By the arrangement that the water blocking part is arranged in the drainage channel and brings in part of the water flow and blocks the same in the overflow channel when the water is drained from the drainage channel to enable the water seal to form in the outlet of the overflow channel, so that the problem that outside air is fed in the drainage channel of the drainage valve from the overflow pipe to produce continuous noise is effectively avoided; the drainage valve noise reduction structure is simple in structure, ingenuous in concept and obvious in noise reduction effect.

Owner:XIAMEN R&T PLUMBING TECH

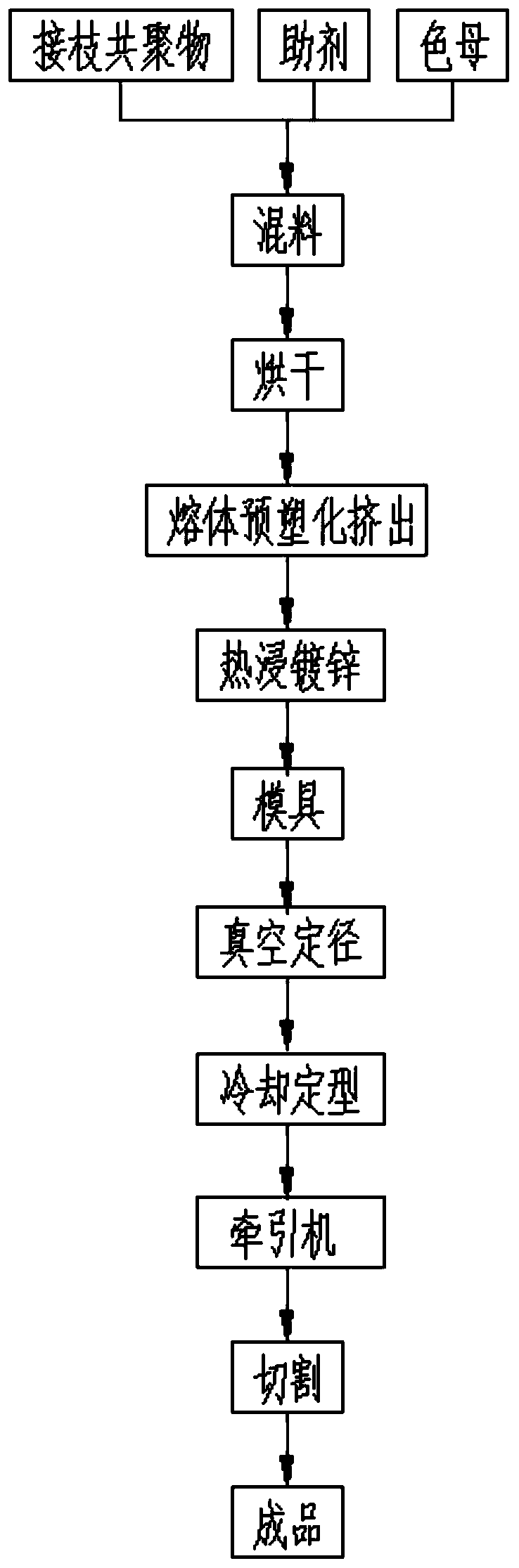

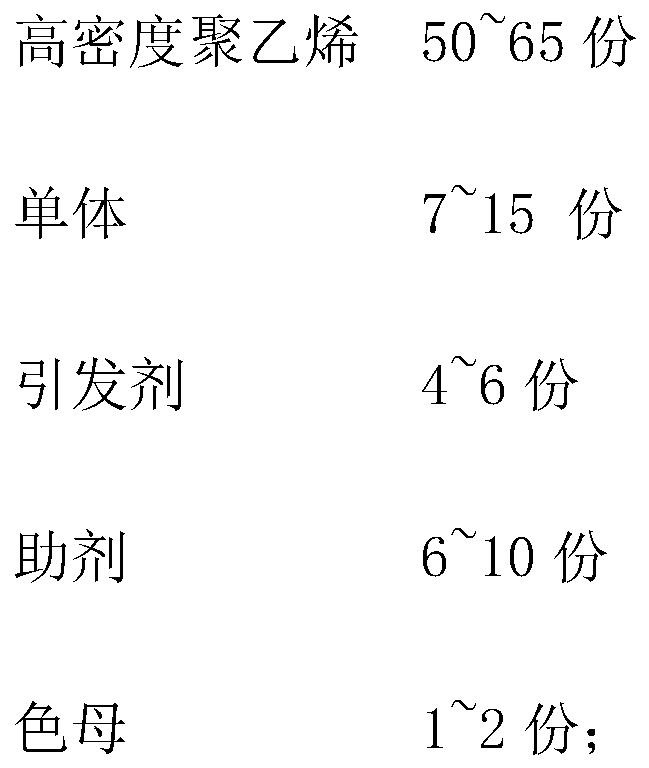

Pressure-resistant and tensile PE pipe and production method thereof

InactiveCN110591271AGuaranteed wear resistanceGuaranteed processing effectHot-dipping/immersion processesMethacrylateAntioxidant

The invention relates to a pressure-resistant and tensile PE pipe and a production method thereof. A medium-molecular weight high-density polyethylene is used as a polymer matrix, direct swelling graft copolymerization with a small molecule or a mixed monomer under the action of an initiator is carried out, the monomer is one or more of ethyl methacrylate, 4-isopropylphenylacetic acid, isopropyl methacrylate, and 1,4-diacetoxybutane, an auxiliary agent comprises one or more of an antioxidant, a light stabilizer, and a variable valence metal ion inhibitor, and a single-phase stable radical is formed. The PE pipe is extruded from a machine head by pre-plasticization compression, pipe demoulding pre-shaping is promoted by hot-dip galvanizing, vacuum sizing and cooling shaping are performed, and then traction cutting is performed, wear resistance and machining performance of the PE pipe are ensured, pressure-resistant and tensile properties are improved, environmental stress cracking is avoided, and the PE pipe is suitable of various drainage and pollution discharge, mining and gas pipelines.

Owner:扬中市长龙管业有限公司

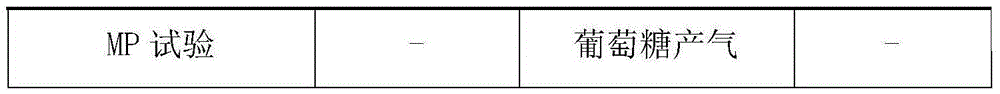

Biological protein feed made from cellulose raw material and preparation method thereof

InactiveCN108783013ASimple preparation processShort fermentation cycleFood processingAnimal feeding stuffRice strawChemistry

Disclosed is biological protein feed made from a cellulose raw material. The feed is composed of an organic material and compound bacteria. The weight of the compound bacteria is 1-10% of the weight of the organic material. The organic material is composed of the cellulose raw material, rapeseed meal and bran. The cellulose raw material is one or more of corn straw, corn cob, rice straw, cassava residue and fruit residue. The compound bacteria is composed of bacillus subtilis, yeast, lactic acid bacteria, and cellulose decomposing bacteria. The cellulose decomposing bacteria are one or more oftrichoderma and white rot fungi. In the biological protein feed, the content of probiotics is greater than 108 cfu / g, and a plurality of proteases, cellulases and amylases are contained. The preparation process is simple and the fermentation period is short. The invention also discloses a preparation method of the feed.

Owner:曾铮

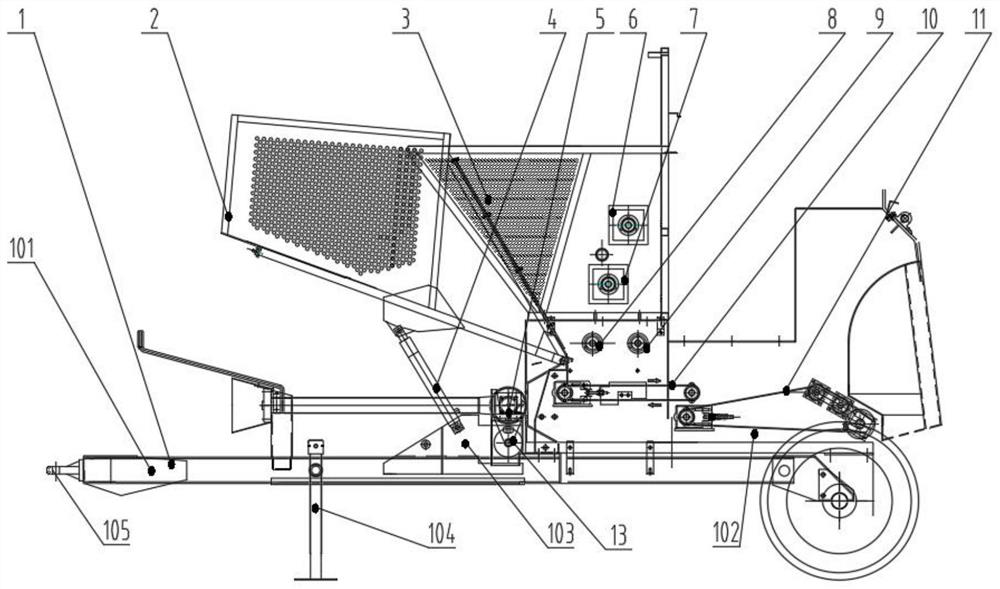

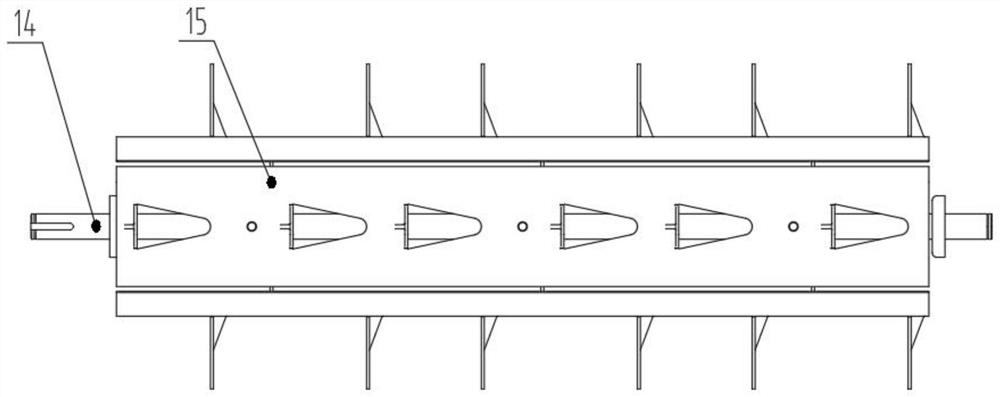

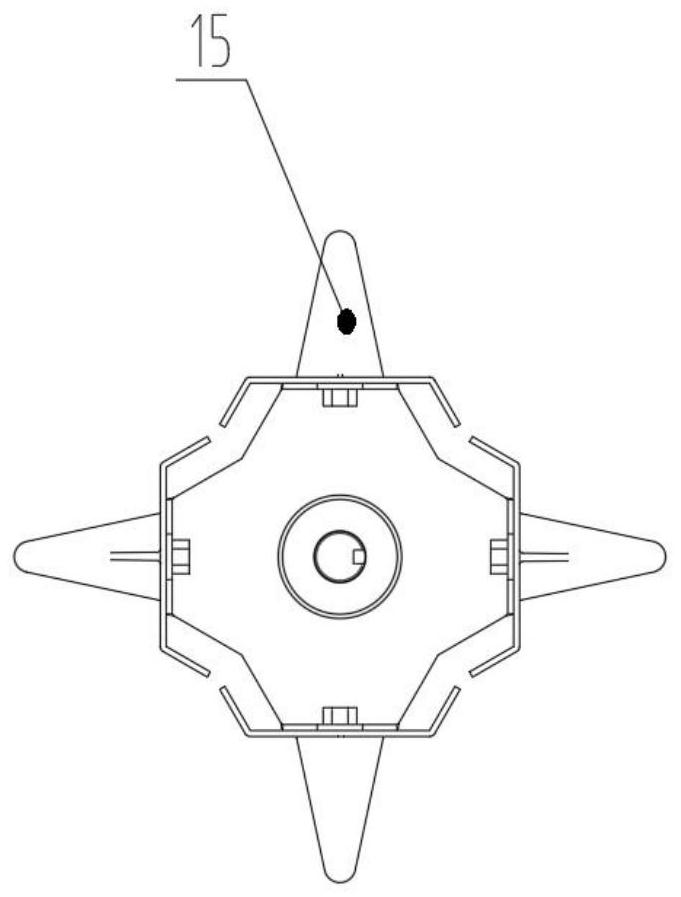

Swinging type feeding mechanism

PendingCN111642252AAvoid accumulationPrevent archingBalingAgricultural scienceAgricultural engineering

The invention relates to a swinging type feeding mechanism, and belongs to the technical field of agricultural machinery. The swinging type feeding mechanism comprises a stander, a swinging hopper, afixed hopper, a hydraulic system, a first material-poking roll, a second material-poking roll, a third material-poking roll, a first-stage conveying mechanism and a second-stage conveying mechanism, wherein the stander is fixedly connected with the fixed hopper, the swinging hopper is hinged on the fixed hopper, the first material-poking roll and the second material-poking roll are mounted in thefixed hopper, the third material-poking roll is mounted in the fixed hopper, the first-stage conveying mechanism is located on the lower side of the fixed hopper, and the second-stage conveying mechanism is located on the right side of the first-stage conveying mechanism and is connected with the stander. The invention aims at solving the problems that corn silage materials with relatively high moisture content are extremely easy to pile up in a bundling machine and then are blocked in the prior art.

Owner:HEILONGJIANG PROV AGRI MACHINERY ENG SCI INST +1

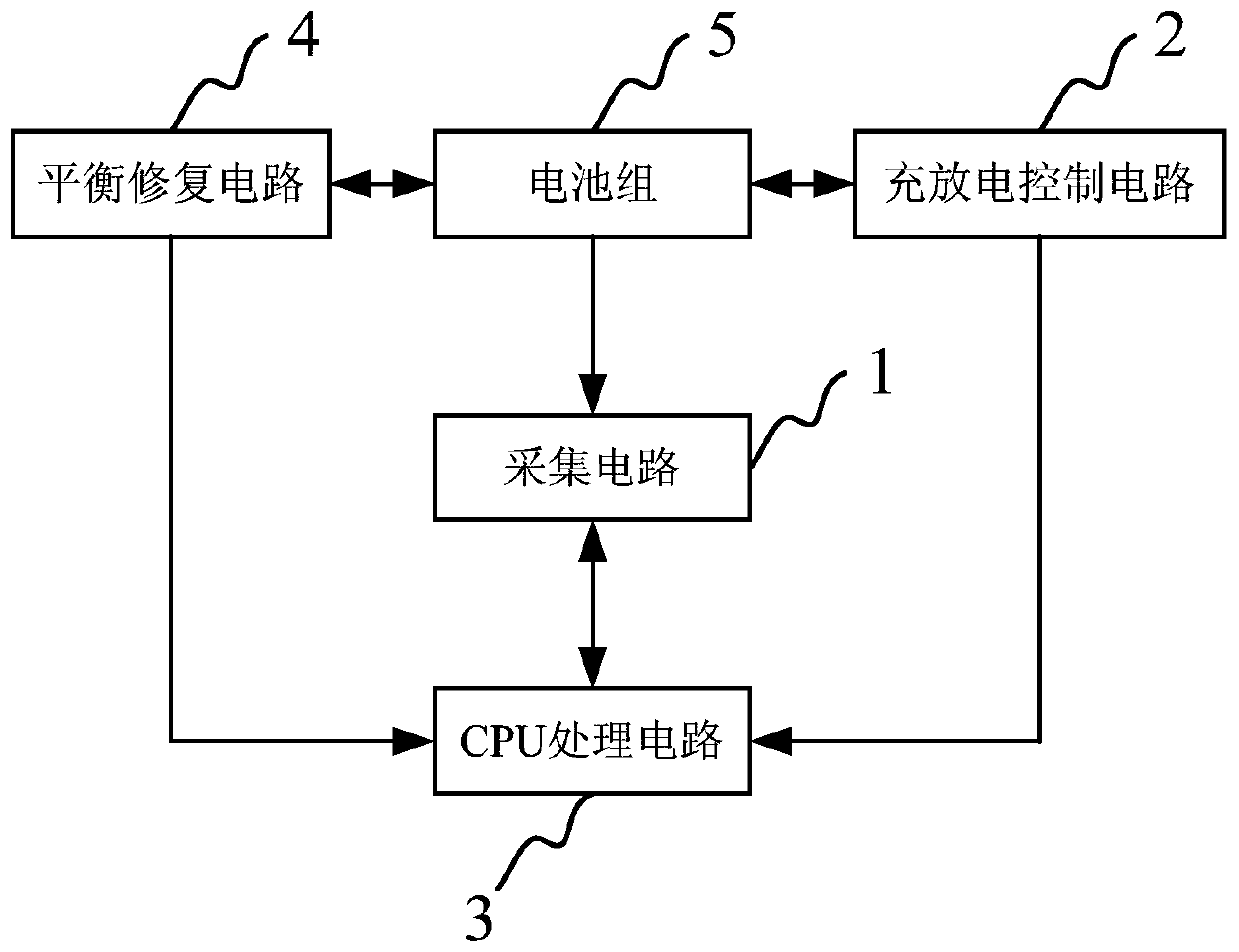

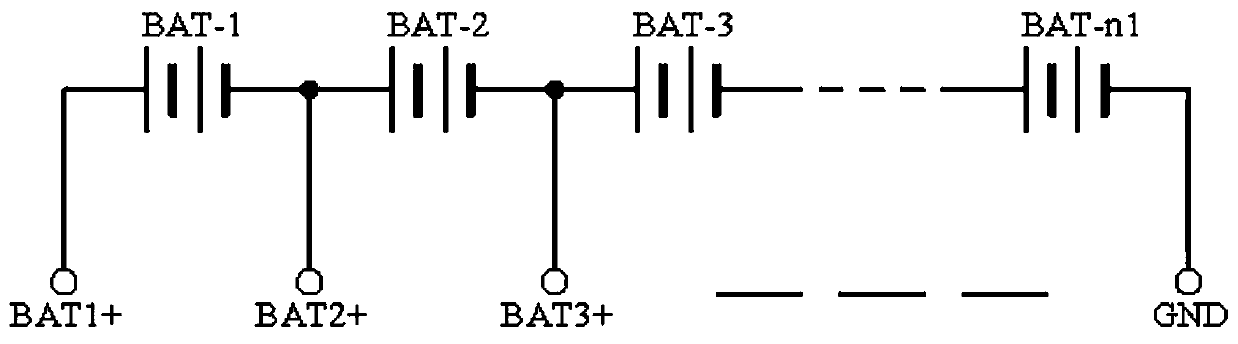

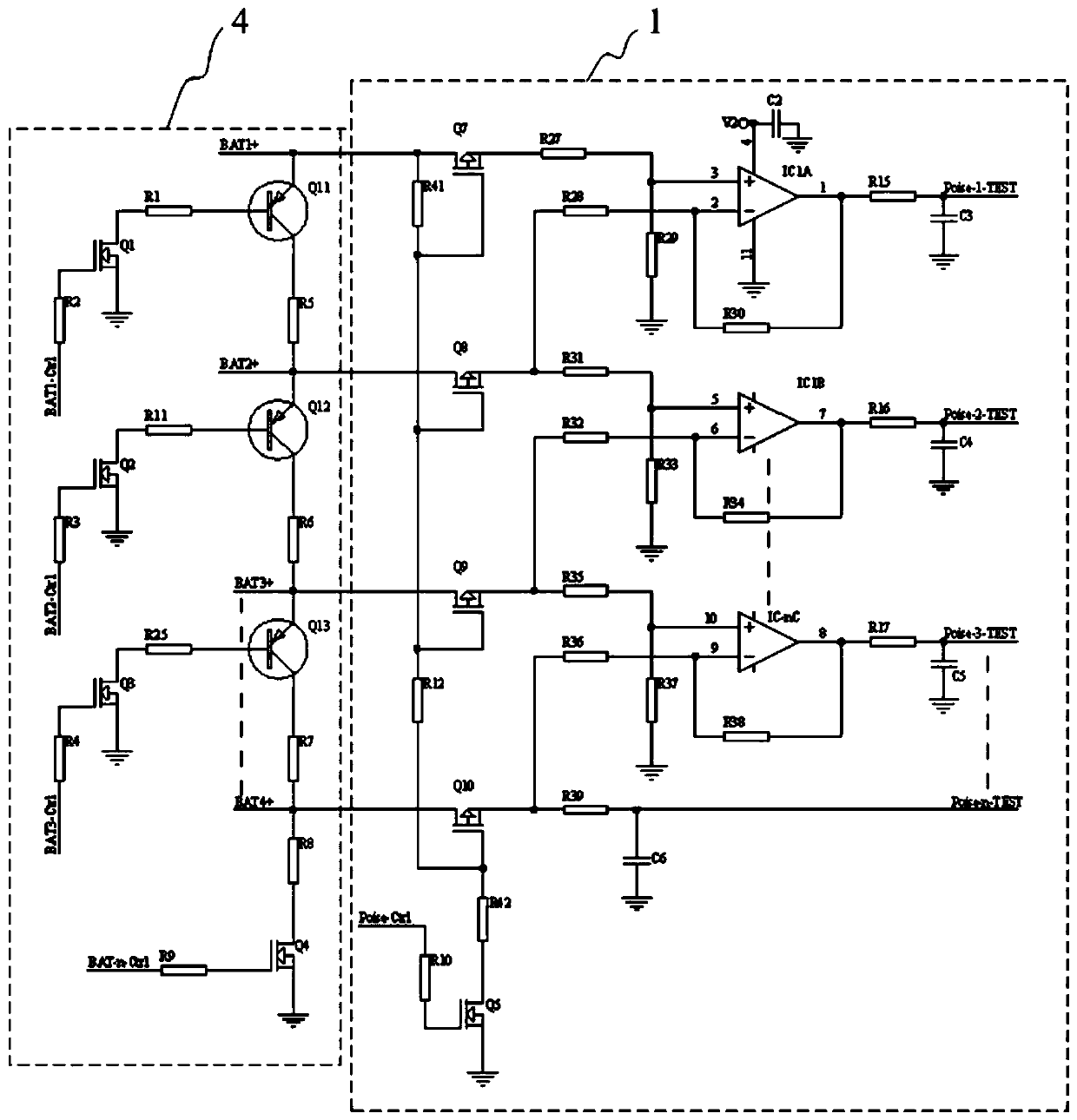

Battery Pack Balance Restoration Management System

ActiveCN106558899BReduce imbalanceOptimal balanceCharge equalisation circuitSafety/protection battery circuitsManagement systemBattery pack

Owner:SHANGHAI POWER STATION

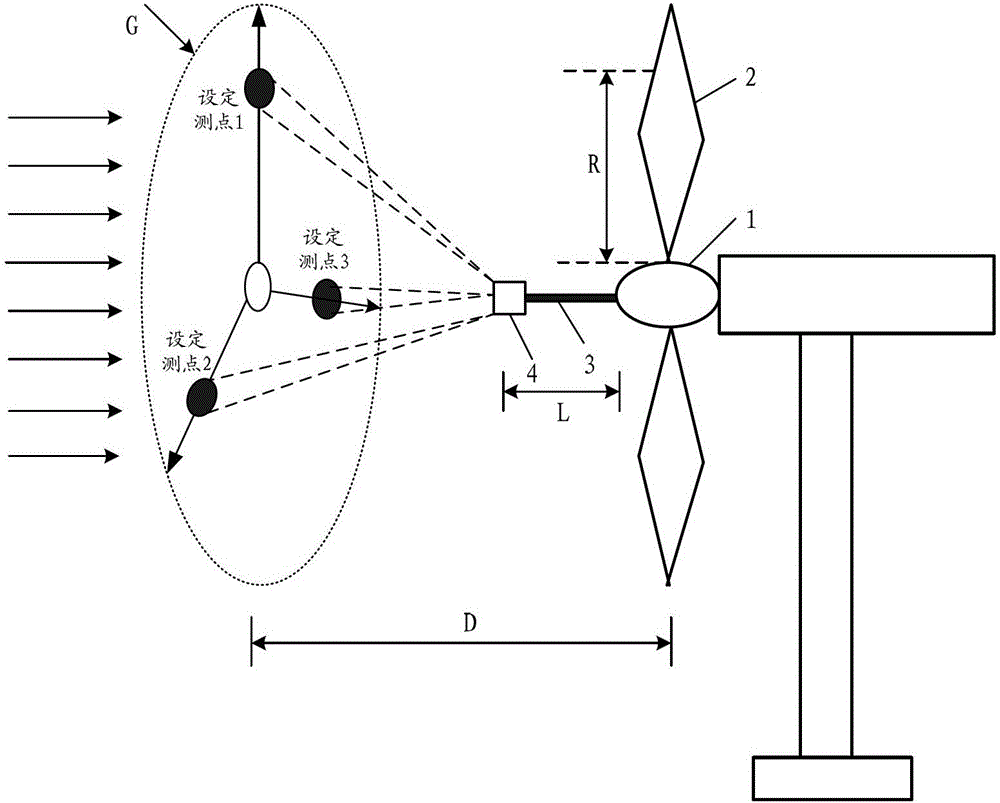

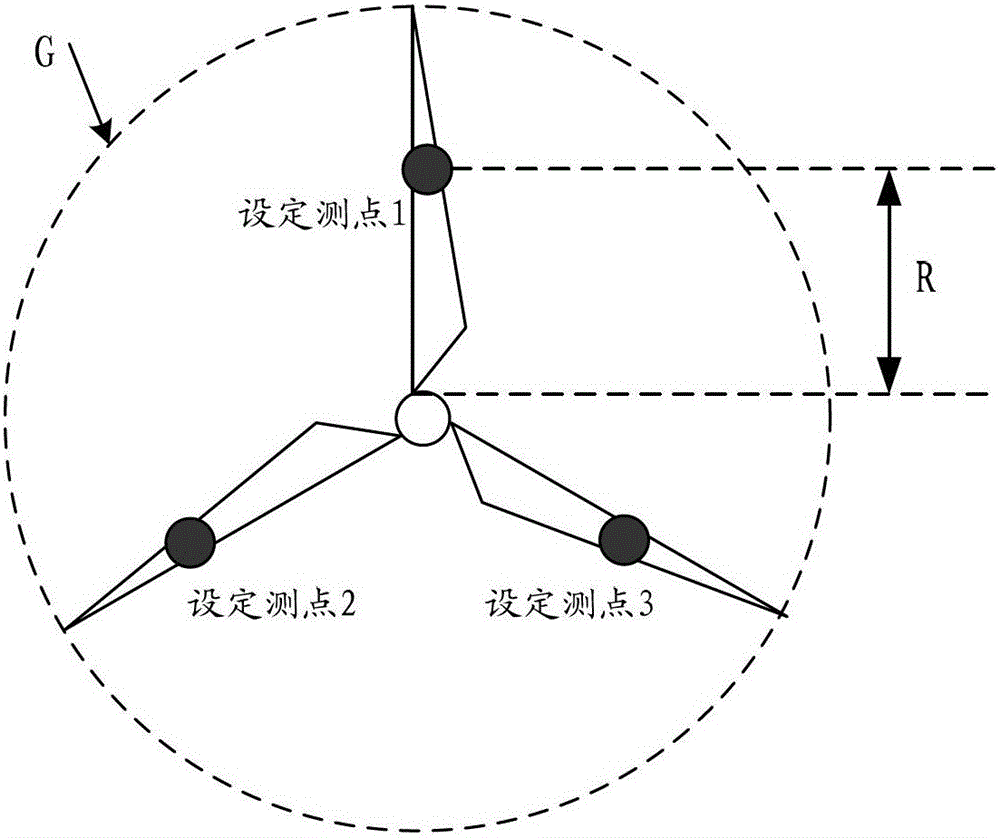

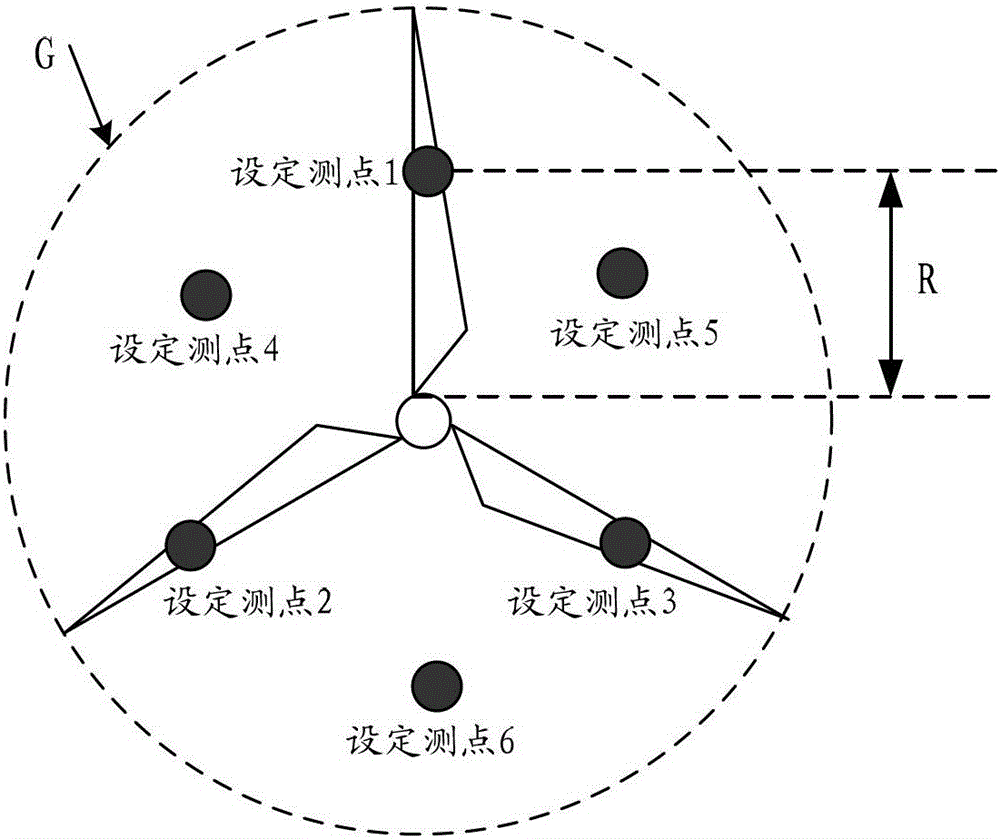

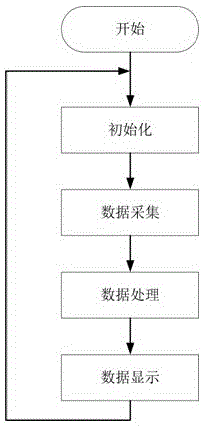

An input signal acquisition device and method for an independent pitch control system

ActiveCN102777321BNo interferenceOptimal balanceWind motor controlMachines/enginesFrequency stabilizationEngineering

The invention discloses an input signal acquisition device of an independent variable-pitch control system. The input signal acquisition device comprises a sensor bracket which is connected with a cross rod in front of a wheel hub, and a sensor bracket which has a first distance from the wheel hub. Axial direction of the sensor bracket and the cross rod is coaxial with the rotation axial direction of the wheel hub, the sensor bracket is synchronously rotated with the cross rod in a running process of an impeller, at least a receiving-transmitting device is installed in the sensor bracket, and the at least one receiving-transmitting device and a host machine installed in a cabin of a fan together constitute a laser Doppler radar wind measurement system. The receiving-transmitting device is used for transmitting a bundle of narrow band laser pulses with stable frequency and controlling the laser pulses to point to a set measure point area in an inflow area in a set slope angle so as to obtain Doppler frequency shift data so that the host machine can calculate the average wind speed in the set measure point area according to the Doppler frequency shift data. The invention also discloses an input signal acquisition method of the independent variable-pitch control system.

Owner:SINOVEL WIND GRP

A mobile semiconductor thermoelectric generator

ActiveCN103986372BEasy transferReduce thermal contact resistanceGenerators/motorsQuantum dotEngineering

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

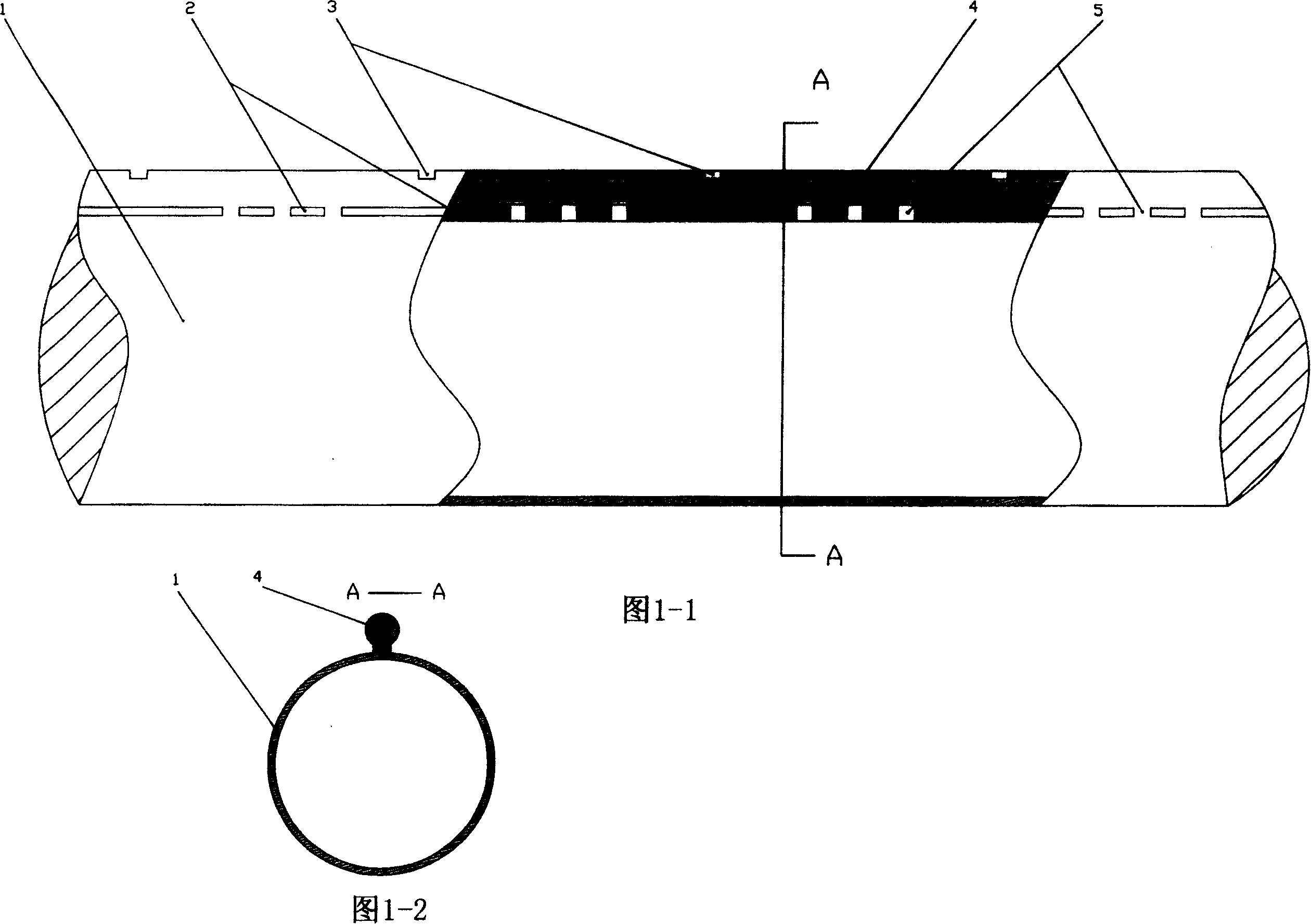

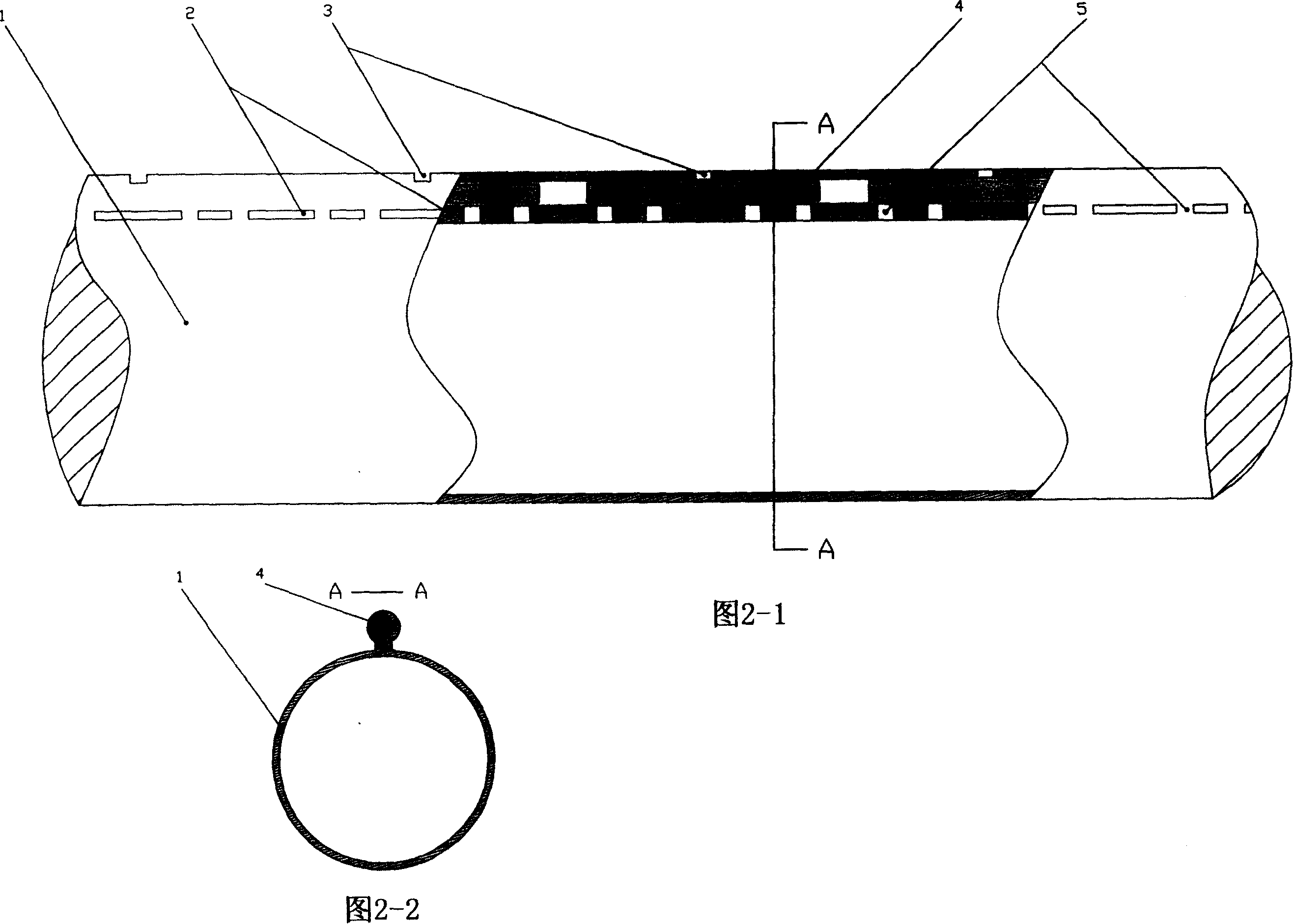

Micro fluidic continuous irrigation pipe

InactiveCN100374007COptimal balanceRealize the purpose of water supply on demandWatering devicesCultivating equipmentsEngineeringWater saving irrigation

The invention relates to the natural and bionic irrigating, belonging to the water industry field, especially relating to a bionic irrigating machine which can provide water in accordance with the plant growing need for the whole day in the agricultural saving-water irrigation. The invention breaks the traditional intermittent rotation irrigation idea, making use of the physiological characteristic of the crop, the mechanism of the blood supply by the human capillary vessel to the cell and the principle of capillary absorbent, when the crop needs little water, the water entering to soil through line 4 is little; when the crop needs much water, the water entering into soil through line 4 is much, which on the whole reaches a optimum equilibrium state.

Owner:范世峰 +1

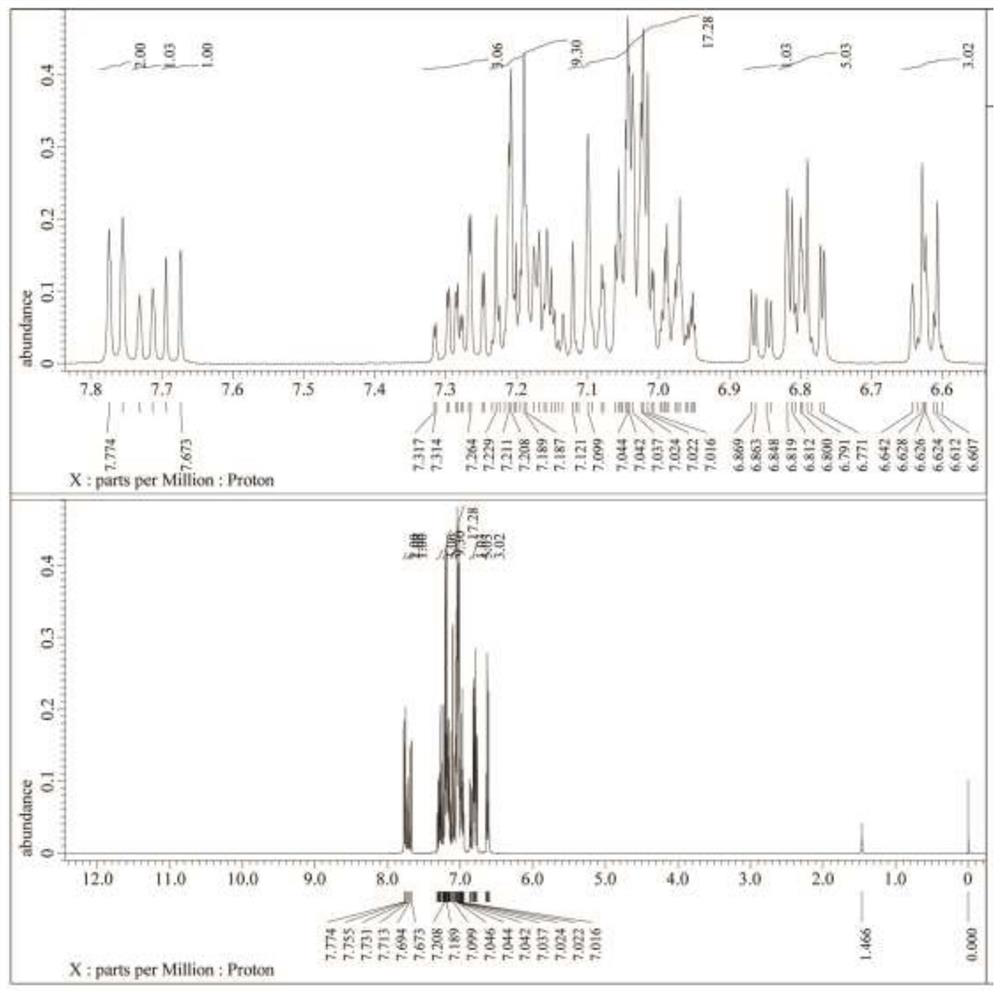

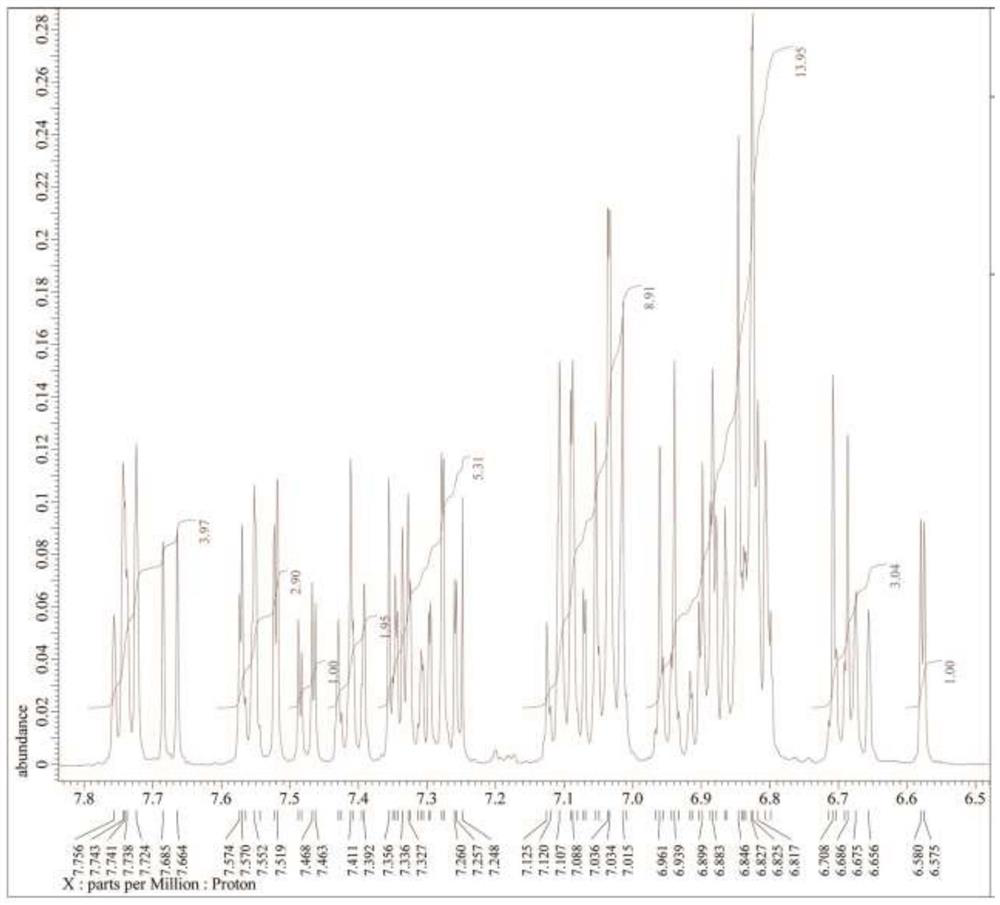

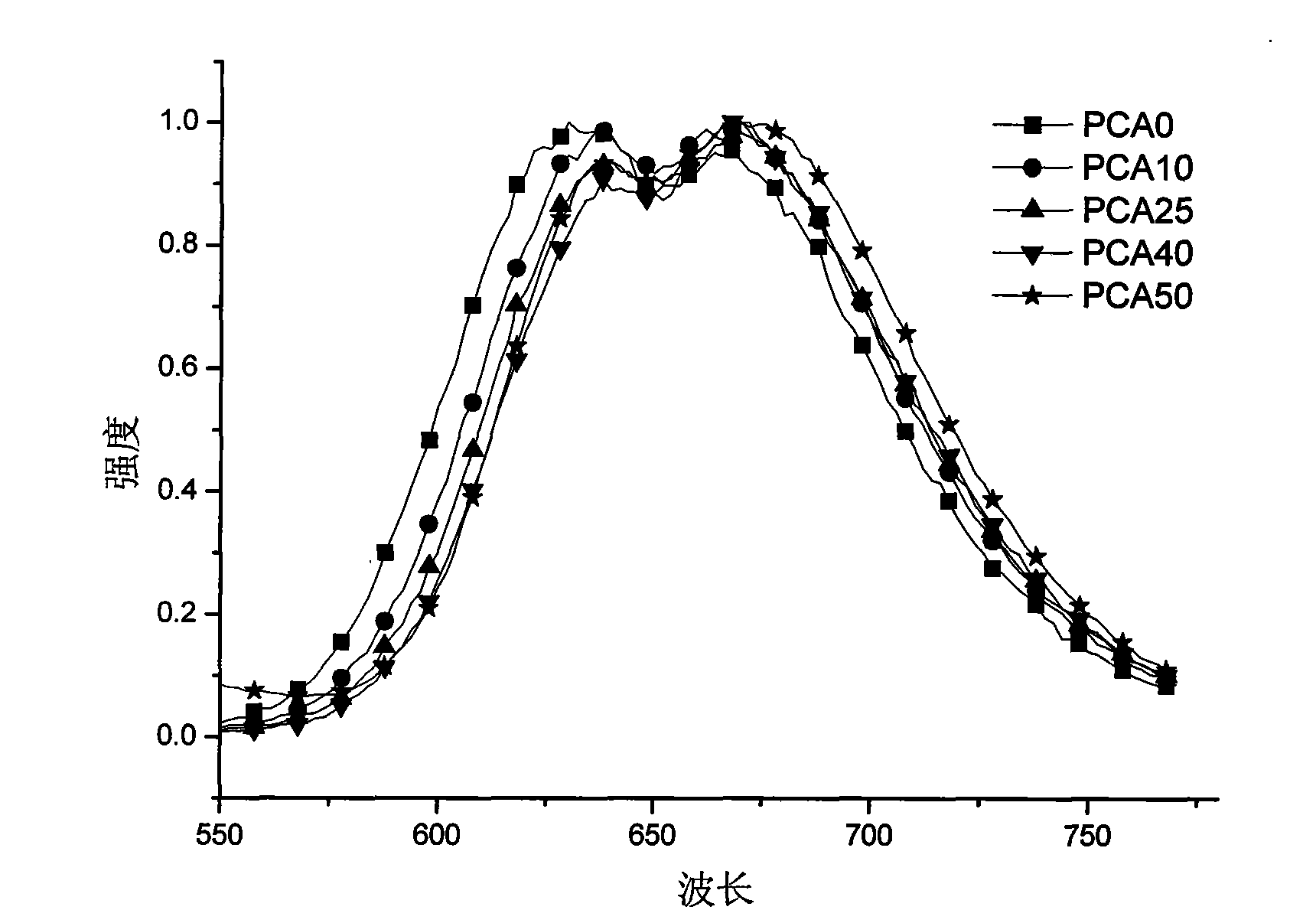

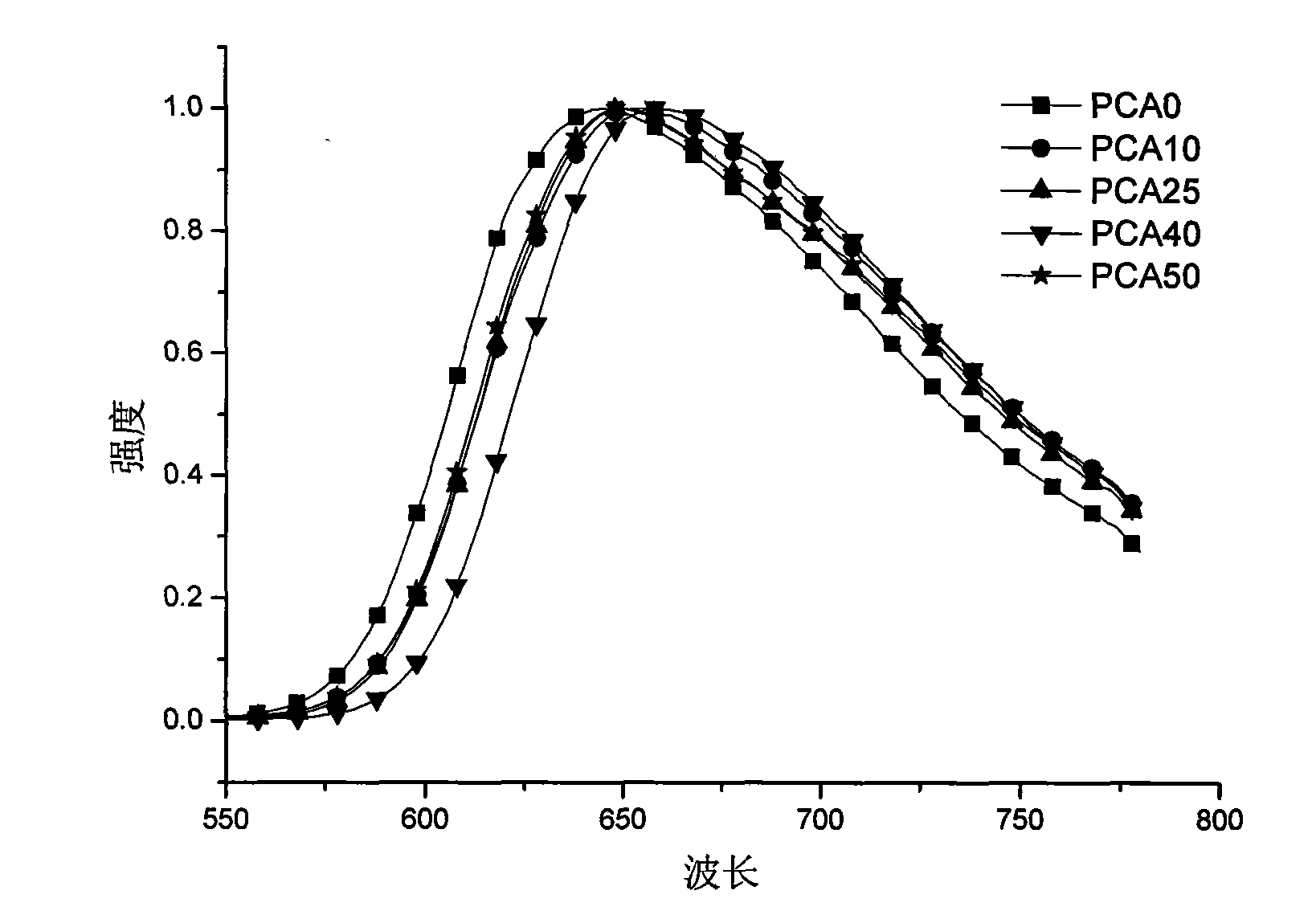

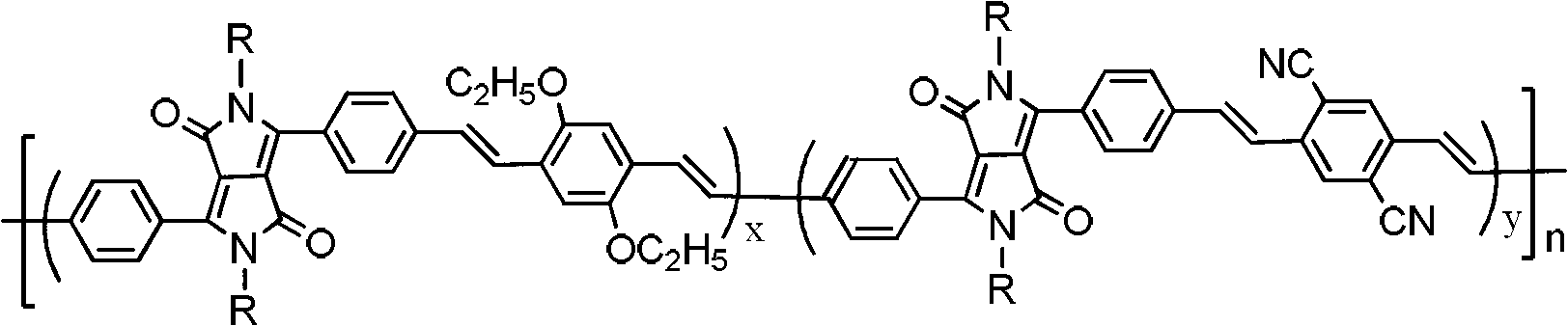

Dione pyrrolo-pyrrole copolymer red electroluminescent material and preparation method and application thereof

InactiveCN101580709BGood hole transport propertiesGood electron transport propertiesSolid-state devicesLuminescent compositionsSolubilityOrganic film

The invention discloses a dione pyrrolo-pyrrole copolymer red electroluminescent material and a preparation method and application thereof. The method introduces dione pyrrolo-pyrrole (DPP), hydroquinone ether and para-dicyano-benzene constitutional units into a main polymer chain to prepare a series of copolymer electroluminescent materials (PCA). A copolymer of the invention has excellent hole and electronic transporting properties at the same time and can be applied to preparing polymer red electroluminescent devices (PLED). The DDP copolymer prepared by the method serving as the red electroluminescent material not only has good solubility and can be easily prepared into high-quality organic films through spin coating, but also has the advantages of high luminous efficiency, high brightness, good current carrier mobility, good color purity, emission of pure saturated red light, low device driving voltage, good stability and the like.

Owner:SOUTH CHINA UNIV OF TECH

A method and system for predicting flight status of unmanned aerial vehicles based on LSTM

ActiveCN109034376BFind regular featuresStable outputNeural architecturesNeural learning methodsData setState prediction

The present invention provides an LSTM-based UAV flight state prediction method and system. The method of the present invention includes: Step 1: Constructing an action tag dictionary; Step 2: Collecting UAV flight status information and action data; Step 3: Preprocessing the collected UAV flight status information; Step 4: Form a data set in the form of a data matrix; Step 5: Randomly divide 70% of the data group in the data set as the training set and 30% as the verification set; train to obtain the long short-term memory network LSTM improvement model that introduces variance; Step 6: Use the verification set , optimize the model hyperparameters to obtain the final model; Step 7: Collect the UAV flight status information of the UAV at the current moment that needs to be predicted, perform preprocessing and filtering in sequence, and then input the final model to obtain the UAV flight action prediction. result. The technical solution of the present invention solves the problem that the existing control model cannot predict flight actions based on the collected flight status data.

Owner:NORTHEASTERN UNIV LIAONING

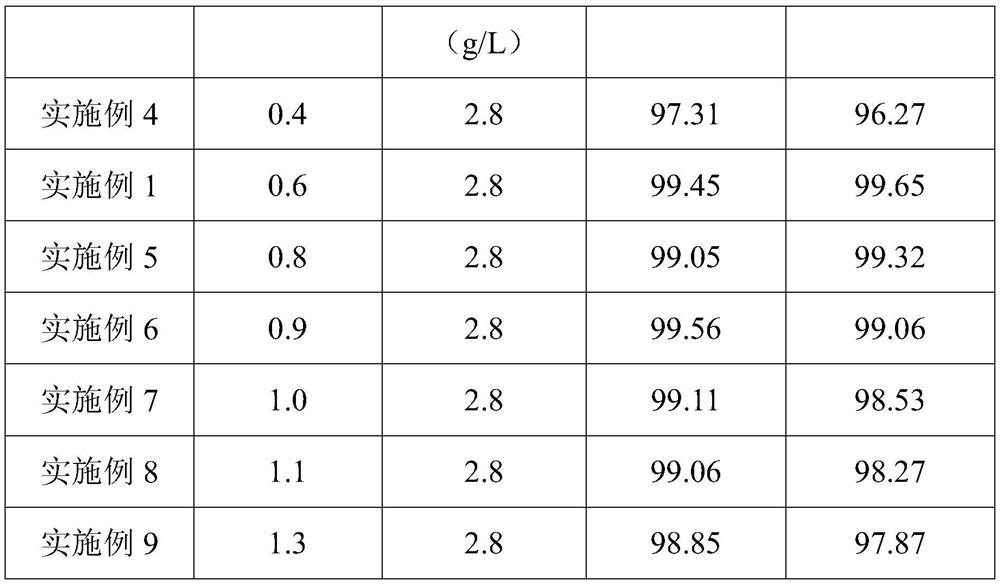

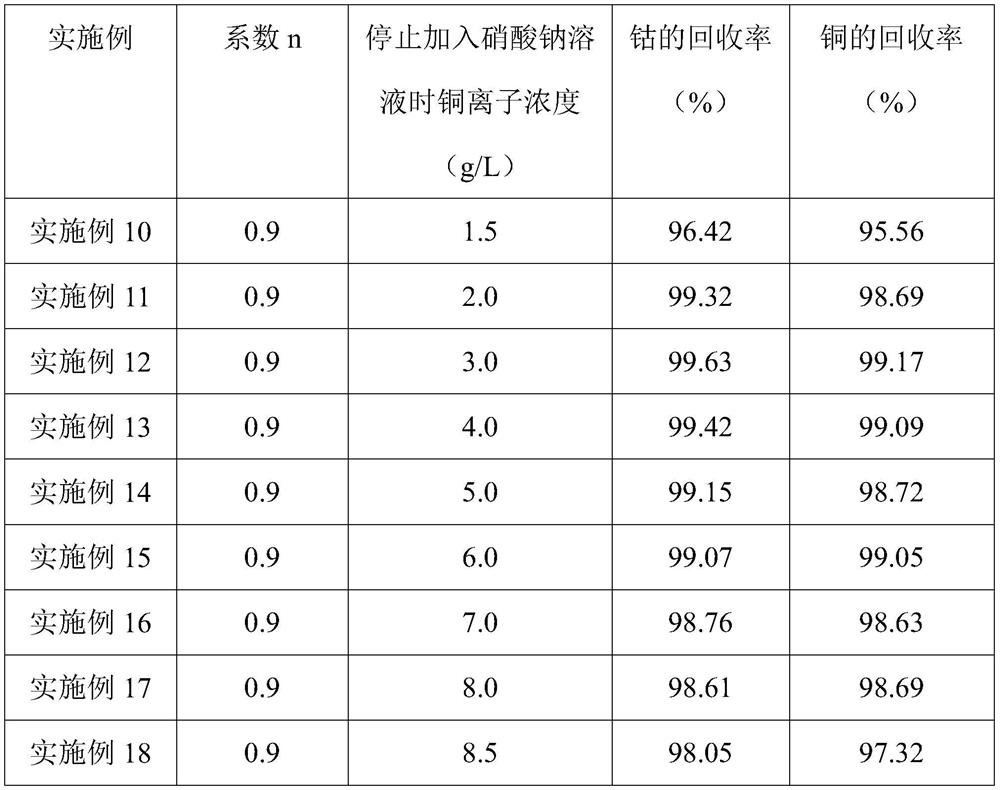

A method for separating and recovering cobalt, copper and iron in white metal

ActiveCN111057846BOptimal balanceMild responseProcess efficiency improvementIron powderPhysical chemistry

The invention provides a method for separating and recovering cobalt, copper and iron in white metal, comprising the following steps: step 1, mixing white metal powder with water, stirring and slurrying to obtain a slurry mixture; step 2, adding to step 1 In the obtained slurry mixture, after adding concentrated sulfuric acid while stirring, the first solution is obtained; step 3, at a temperature of 70°C to 85°C, adding sodium nitrate solution to the first solution obtained in step 2 while stirring, When Cu in solution 2+ When the ion content is 2g / L~8g / L, stop adding the sodium nitrate solution to obtain the second solution. Step 4, adding iron powder to the second solution obtained in step 3, reacting, and filtering to obtain simple copper and a third solution, the third solution is a mixed solution containing cobalt and iron. Then, iron powder is used to replace copper with copper, so that copper, cobalt and iron are separated, and then further recovery of cobalt and iron is carried out. The method has mild reaction, stability, safety, easy control, high leaching rate and easy realization of large-scale production.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com