Aqueous photocuring material and preparation process thereof

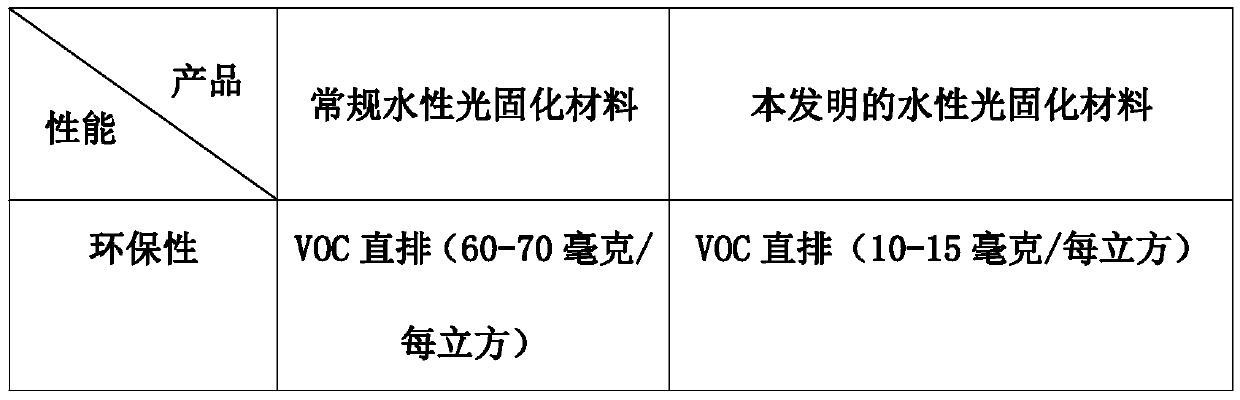

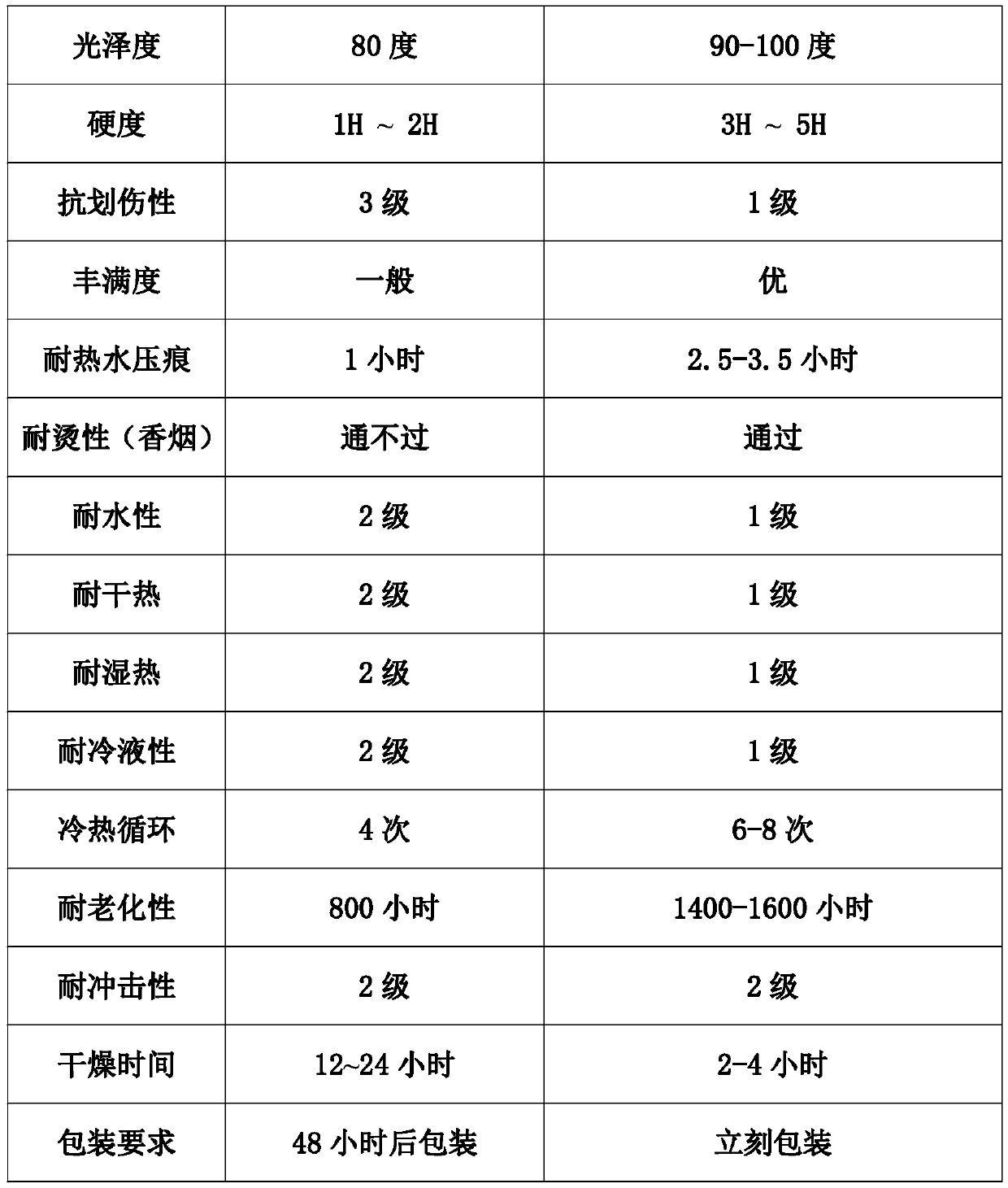

A light-curing material and preparation process technology, applied in the field of water-based light-curing material and its preparation process, can solve the problems of poor gloss, affect aesthetics, low hardness, etc., achieve good gloss and hardness, improve dispersion effect, high The effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1. The high-gloss water-based light-curing material includes the following components by weight: water-based polyurethane acrylate emulsion, 45-55 parts; water-based aliphatic polyurethane dispersion, 18-22 parts; anionic aliphatic polyurethane dispersion, 9-11 parts ; Emulsifier, 2.3-2.5 parts; Photoinitiator, 2.5-3.5 parts; Wetting agent, 0.8-1.3 parts; Leveling agent, 0.3-0.5 parts; Hand feeling agent, 0.3-0.5 parts; 0.3 parts; thickener, 0.3-0.4 parts; deionized water, 9-11 parts.

[0032] The water-based polyurethane acrylate emulsion includes water-based polyurethane acrylate and an emulsifier, and the ratio between the water-based polyurethane acrylate and the emulsifier is 115:10-120:8.

[0033] A preparation process of water-based light-curing material, comprising the following steps:

[0034] a, prepare water-based polyurethane acrylate emulsion, obtain A product;

[0035] b. Mix product A, water-based aliphatic polyurethane dispersion and anionic a...

Embodiment 2

[0057] Example 2. The water-based photocurable material comprises the following components by weight: water-based polyurethane acrylate emulsion, 50 parts; water-based aliphatic polyurethane dispersion, 20 parts; anionic aliphatic polyurethane dispersion, 10 parts; emulsifier, 2.4 parts; Initiator, 3 parts; Wetting agent, 1 part; Leveling agent, 0.4 parts; Hand feeling agent, 0.4 parts; Defoamer, 0.2 parts; Thickener, 0.4 parts; Deionized water, 10 parts.

[0058] The water-based polyurethane acrylate emulsion includes water-based polyurethane acrylate and an emulsifier, and the ratio between the water-based polyurethane acrylate and the emulsifier is 116:9.

[0059] A preparation process of water-based light-curing material, comprising the following steps:

[0060] a, prepare water-based polyurethane acrylate emulsion, obtain A product;

[0061] b. Mix product A, water-based aliphatic polyurethane dispersion and anionic aliphatic polyurethane dispersion, and stir at a mediu...

Embodiment 3

[0081] Example 3. High-gloss water-based light-curing material, including the following components by weight: water-based polyurethane acrylate emulsion, 45 parts; water-based aliphatic polyurethane dispersion, 18 parts; anionic aliphatic polyurethane dispersion, 9 parts; emulsifier, 2.3 parts ; Photoinitiator, 2.5 parts; Wetting agent, 0.8 parts; Leveling agent, 0.3 parts; Hand feeling agent, 0.3 parts; Defoamer, 0.1 parts;

[0082] The water-based urethane acrylate emulsion includes water-based urethane acrylate and an emulsifier, and the ratio between the water-based urethane acrylate and the emulsifier is 115:10.

[0083] A preparation process of water-based light-curing material, comprising the following steps:

[0084] a, prepare water-based polyurethane acrylate emulsion, obtain A product;

[0085] b. Mix product A, water-based aliphatic polyurethane dispersion and anionic aliphatic polyurethane dispersion, and stir at a medium speed for 3 minutes to obtain product B;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com