Swinging type feeding mechanism

A feeding mechanism and swing-type technology, applied in the field of agricultural machinery, can solve problems such as easy accumulation and material blockage, achieve uniform and continuous feeding, prevent accumulation, and increase the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

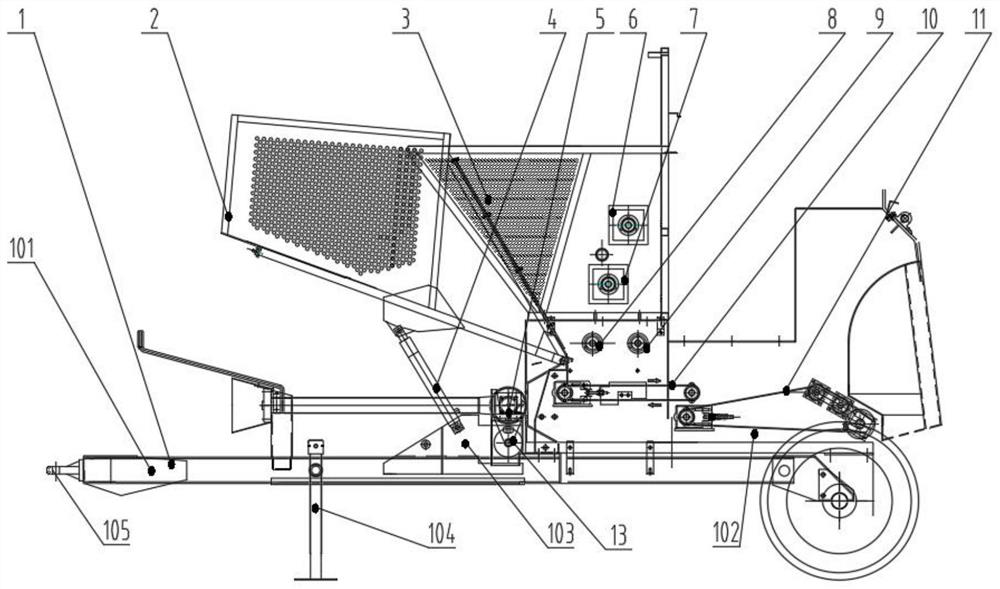

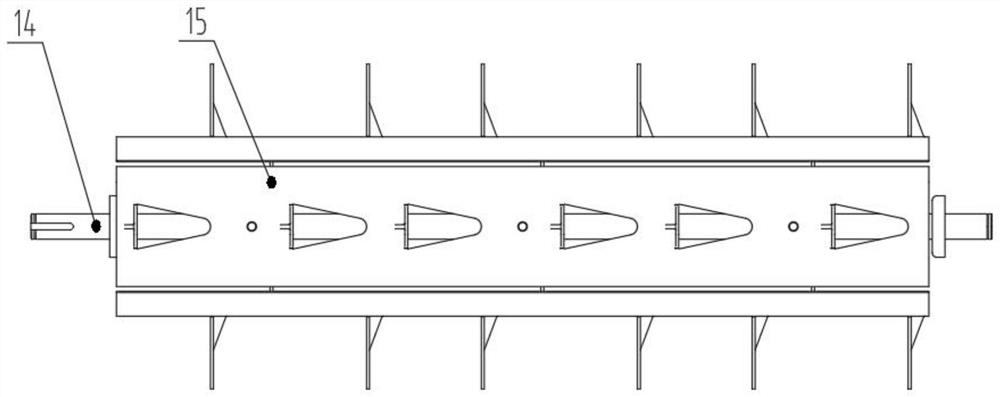

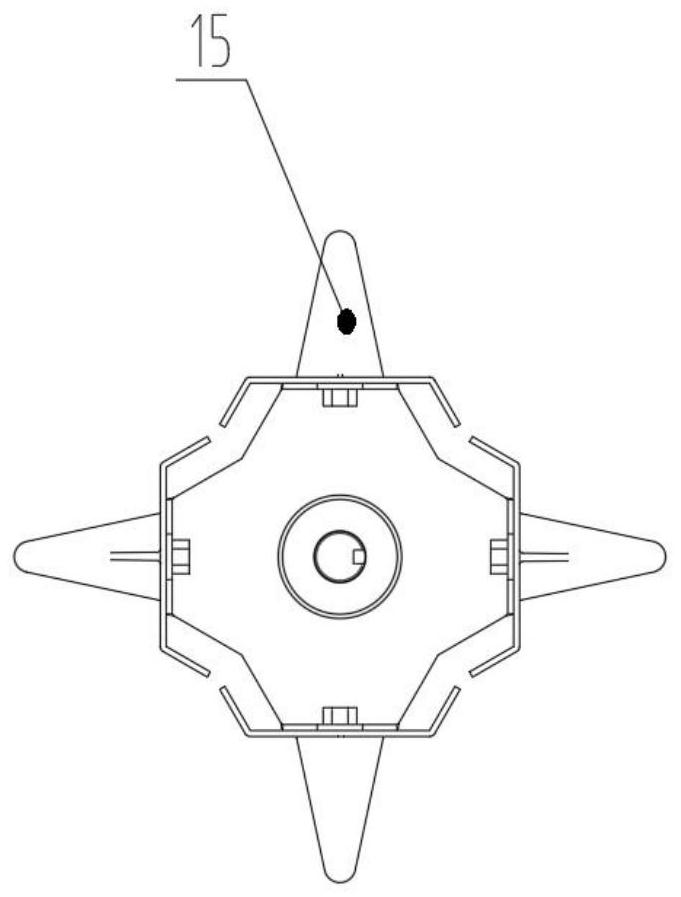

[0030] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, a kind of swing type feed mechanism of this embodiment, comprise frame 1, swing hopper 2, fixed hopper 3, hydraulic system 5, first material shifting roller 6, second material shifting roller 7, third The material shifting roller 8, the first-level transmission mechanism 10 and the second-level transmission mechanism 11, the frame 1 is fixedly connected with the fixed hopper 3, the swing hopper 2 is hingedly installed on the fixed hopper 3, and the first material removal roller 6 is installed inside the fixed hopper 3 With the second push roller 7, the third push roller 8 is installed inside the fixed hopper 3, the primary transmission mechanism 10 is positioned at the lower side of the fixed hopper 3, and the secondary transmission mechanism 11 is positioned at the right side of the primary transmission mechanism 10. The stage transmission mechanism 11 establishes a connection with t...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 1 Describe this embodiment, a kind of swing type feeding mechanism of this embodiment, frame 1 comprises bottom frame 101, stand 102 and auxiliary stand 103, the two sides of bottom frame 101 are fixedly connected with stand 102 and auxiliary stand respectively symmetrically. The stand 103, the auxiliary stand 103 and the stand 102 are respectively arranged on the left and right sides of the fixed hopper 3, and the secondary transmission mechanism 11 is connected with the stand 102, and the material on the fixed hopper 3 is driven by its own gravity, the first shifting roller 6 and the second feeding roller 7 to convey to the working direction, the first feeding roller 6 and the second feeding roller 7 ensure that the material enters the next process with an appropriate delivery amount, and at the same time prevent material accumulation, arching and blockage.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 Describe this embodiment, a kind of oscillating feed mechanism of this embodiment, also comprise the 4th material transfer roller 9, the 4th material transfer roller 9 is connected with fixed hopper 3, the 4th material transfer roller 9 and the 3rd material transfer roller 8 are arranged on the same level, the primary transmission mechanism 10 is horizontally located on the lower side of the fourth material roller 9 and the third material roller 8, the hydraulic motor 13 is connected with the fourth material roller 9 and drives the fourth material roller 9, The primary conveying mechanism 10 is made up of the first master pulley, the first slave pulley and the first conveyor belt, the first master pulley and the first slave pulley are installed on the fixed hopper 3 by the rotating shaft, the first master pulley and the second A slave pulley is connected through the first conveyor belt, the hydraulic motor 13 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com