Balance hole plate

A technology of orifice plates and round through holes, applied in the field of flow control devices, can solve the problems of reduced measurement accuracy, consumption, increased equipment operating costs, and increased processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

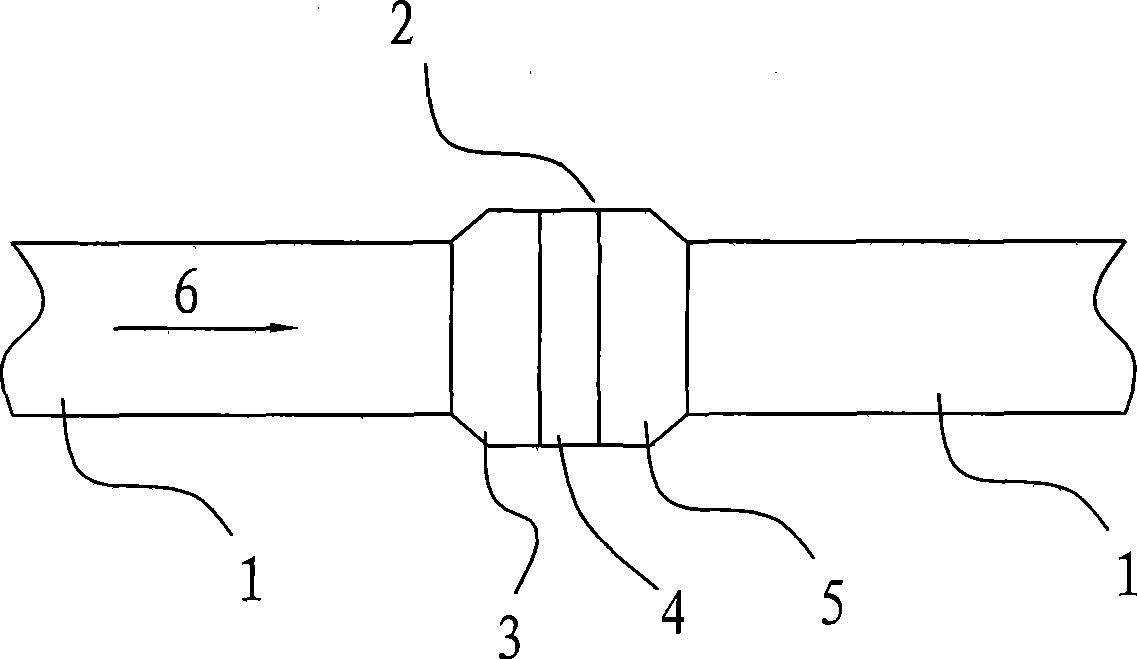

Method used

Image

Examples

no. 1 example

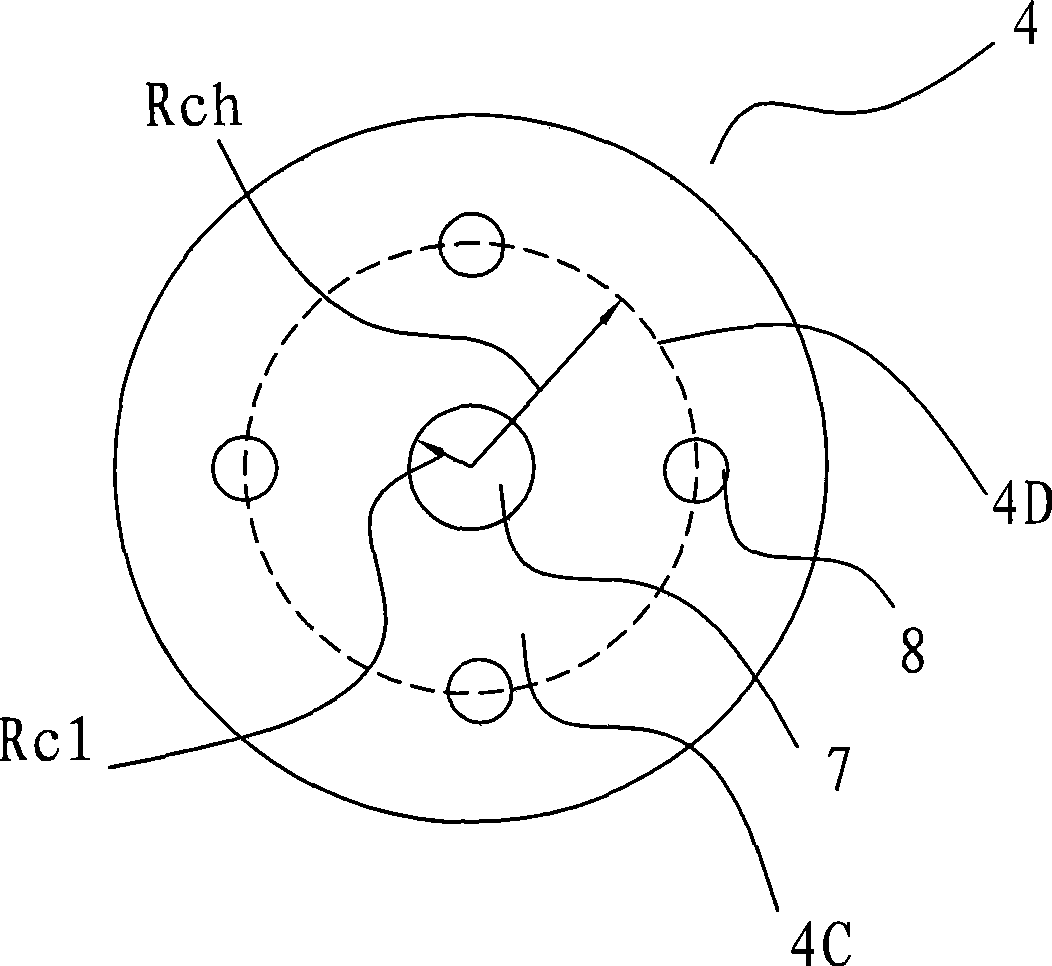

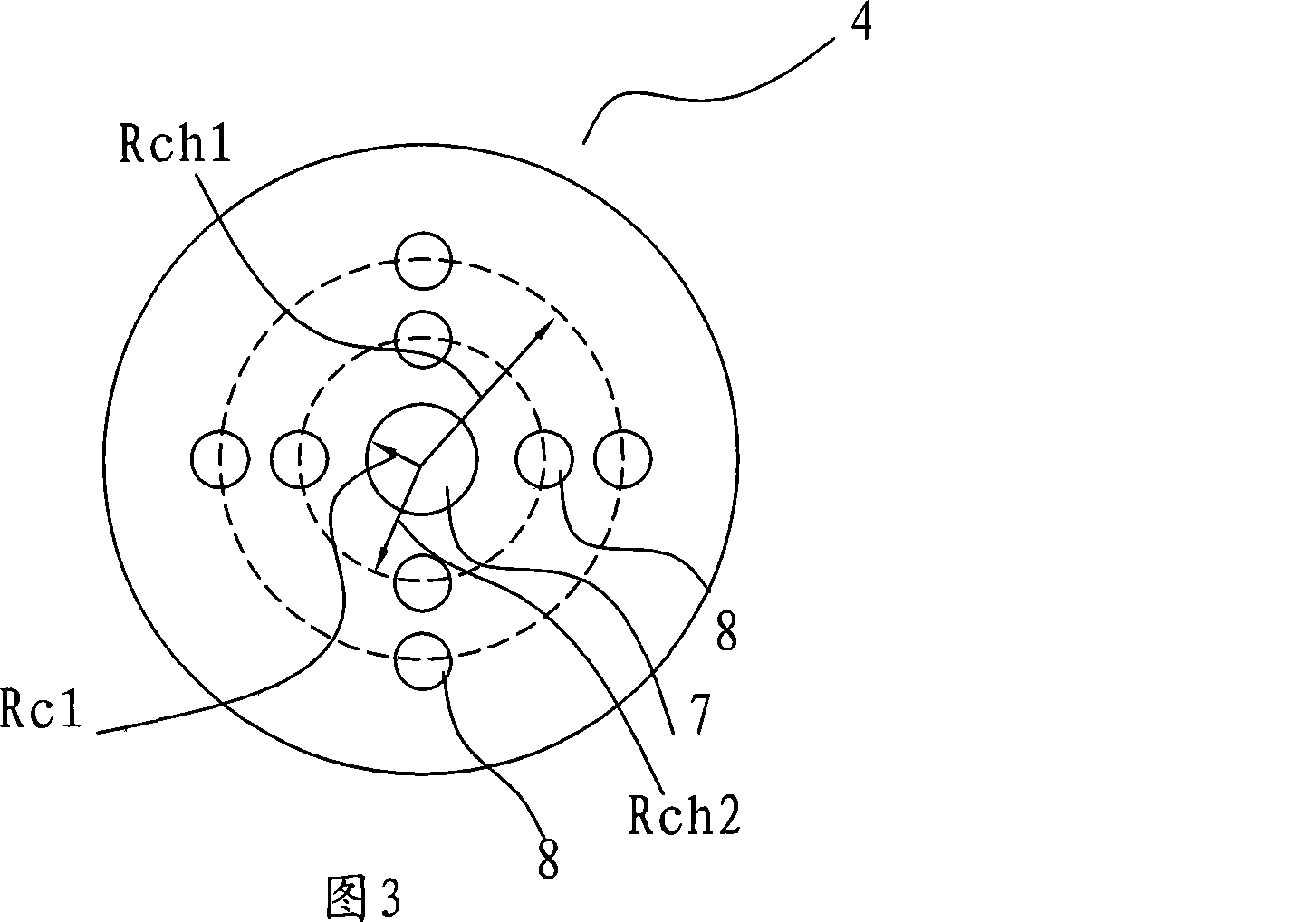

[0050] According to the first embodiment of the present invention, the distribution of the through holes (the central circular through hole 7 and the surrounding through holes 8) in the balanced flow area 4C on the orifice plate 4 satisfies the following basic relationship:

[0051] R c1 V c1 =R ch V ch (2)

[0052] in:

[0053] R c1 is the radius of the central circular through hole;

[0054] V c1 Be the flow velocity of the fluid in the pipeline at the center of the central circular through hole (that is, the center of the orifice plate);

[0055] R ch is the distance from the center of the board to the center of the surrounding vias;

[0056] V ch is the fluid velocity of the fluid in the pipe at the center of the surrounding through hole.

[0057] The formulas for the radial velocity of the fluid in the pipeline are:

[0058] V / V c1 =((1-R) / R w ) 1 / m (3)

[0059] in:

[0060] V c1 is the tube velocity of the fluid in the tube at the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com