A method for separating and recovering cobalt, copper and iron in white metal

A technology for separation and recovery of white alloy, applied in the field of separation and recovery of cobalt, iron, and copper in white alloy, can solve the problems of low leaching rate, difficult to control, violent reaction, etc., and achieve easy, easy to control, and high leaching rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

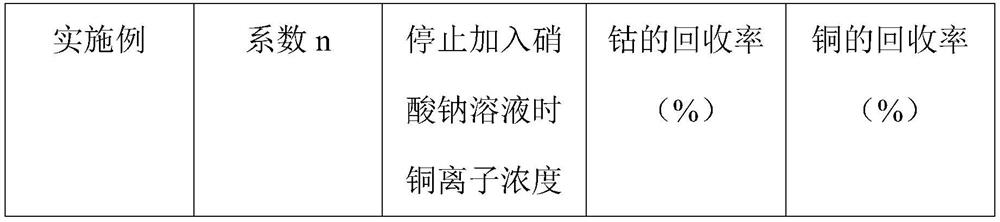

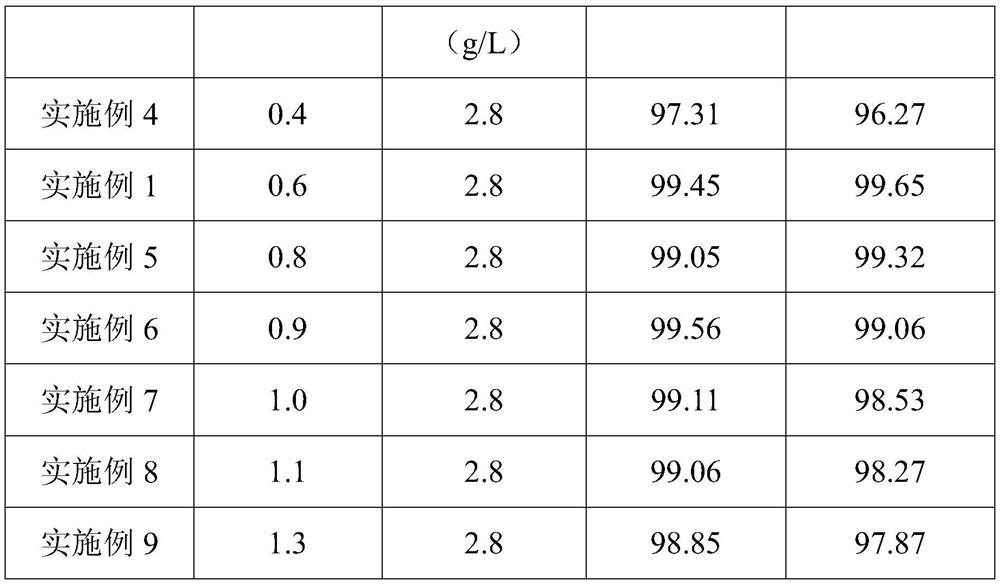

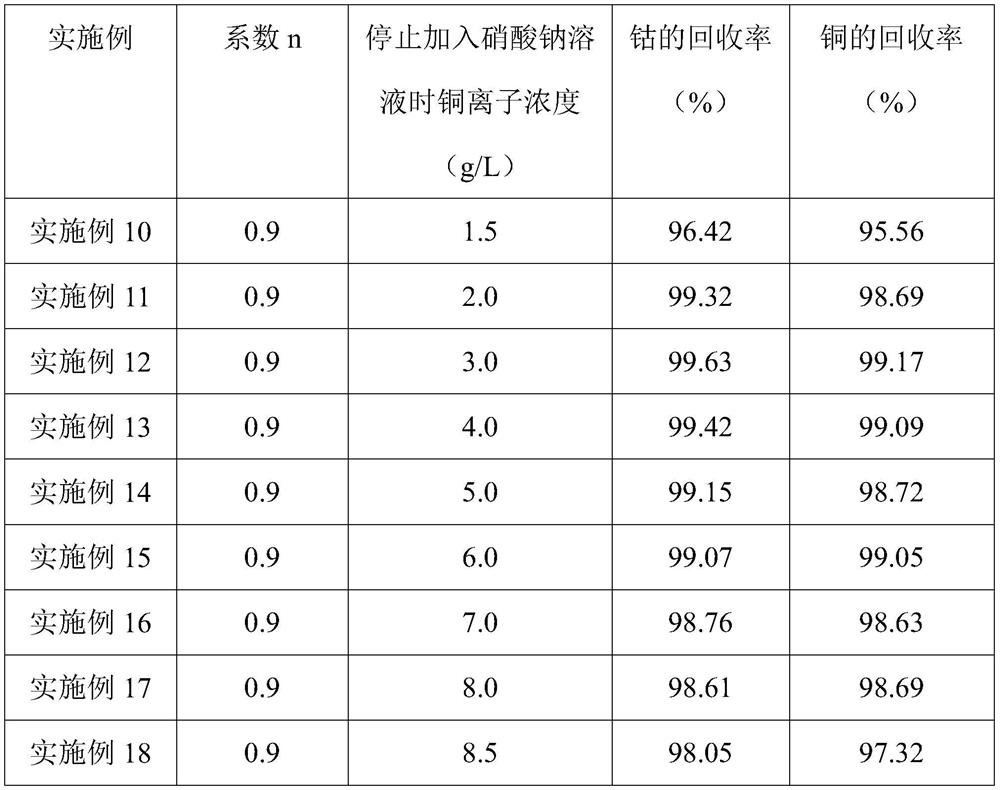

Embodiment 1

[0031] Grind the purchased white metal into fine powder with a ball mill, pass through a 100-mesh sieve, pour 200g of white metal powder into a beaker, add 800ml of water, stir and slurry to obtain a slurry mixture, and then add it to the slurry mixture Slowly add concentrated sulfuric acid with a mass fraction of 98% to obtain the first solution, the coefficient n in the volume formula of the added concentrated sulfuric acid is 0.6, heat up to 75°C, and slowly add the sodium nitrate solution with a mass fraction of 10% while stirring. In a solution, react, detect the copper ion content in the solution during the reaction, when Cu 2+ When the concentration is 2.8g / L, stop adding sodium nitrate solution, continue to react for 30 minutes, then add iron powder for replacement, react for 10 minutes, and filter. The filter residue was washed twice. The slag is 107.92g of sponge copper slag, then add hydrogen peroxide to the filtrate, 0.8-1.8 kg of 27% industrial-grade hydrogen per...

Embodiment 2

[0034] Grind the purchased white metal into fine powder with a ball mill, pass through a 100-mesh sieve, pour 180g of white metal powder into a beaker, add 800ml of water, stir and slurry to obtain a slurry mixture, and then add it to the slurry mixture Slowly add concentrated sulfuric acid with a mass fraction of 98% to obtain the first solution, the coefficient n in the volume formula of the added concentrated sulfuric acid is 0.8, heat up to 75°C, and slowly add the sodium nitrate solution with a mass fraction of 10% while stirring. In a solution, react, detect the copper ion content in the solution during the reaction, when Cu 2+ When the concentration is 4.7g / L, stop adding sodium nitrate solution, continue to react for 30 minutes, then add iron powder for replacement, react for 10 minutes, and filter. The filter residue was washed twice.

[0035] The slag is 82.5g of sponge copper slag, then add hydrogen peroxide to the filtrate, 0.8-1.8 kg of 27% industrial-grade hydro...

Embodiment 3

[0038] Grind the purchased white metal into fine powder with a ball mill, pass through a 100-mesh sieve, pour 150g of white metal powder into a beaker, add 800ml of water, stir and slurry to obtain a slurry mixture, and then add it to the slurry mixture Slowly add concentrated sulfuric acid with a mass fraction of 98% to obtain the first solution, the coefficient n in the volume formula of the added concentrated sulfuric acid is 1.1, heat up to 75°C, and slowly add the sodium nitrate solution with a mass fraction of 10% while stirring. In a solution, react, detect the copper ion content in the solution during the reaction, when Cu 2+ When the concentration is 7.6g / L, stop adding sodium nitrate solution, continue to react for 30 minutes, then add iron powder for replacement, react for 10 minutes, and filter. The filter residue was washed twice.

[0039] The slag is 67.85g of sponge copper slag, then add hydrogen peroxide to the filtrate, 0.8-1.8 kg of 27% industrial-grade hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com