Electrode molybdenum sheet assembly for ultrahigh-voltage point light source and forming method thereof

A molding method and point light source technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of poor welding strength, and achieve the effect of ensuring bearing strength, avoiding over-welding or virtual welding, and ensuring linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

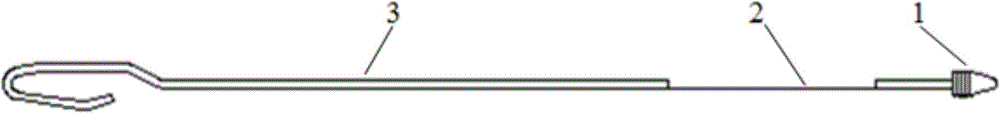

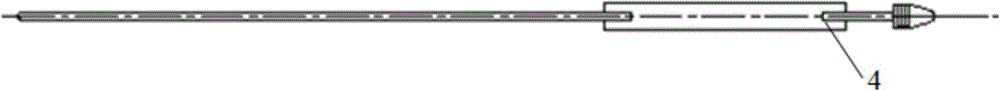

[0040] An electrode molybdenum sheet assembly for a point light source, its structure is as follows Figure 1-2 As shown, it is composed of emitter electrode 1, sealing molybdenum sheet 2 and lead wire 3, emitter electrode 1 is set at the front end, laser welding spot 4 is set on sealing molybdenum sheet 2, and emitter electrode 1 is welded and connected to laser welding spot 4 The top is connected with the sealing molybdenum sheet 2, and the lead wire 3 is connected to the other end of the sealing molybdenum sheet 2 by means of resistance spot welding, and is arranged coaxially with the emitter electrode 1. In this embodiment, the emitter electrode 1 is composed of a mandrel and a spring welded and sleeved on the front end of the mandrel. The extension at the front end of the mandrel is a bullet-shaped structure. -16mm, spring wire diameter is 0.1-0.4mm. The molybdenum sheet has a width of 1.2-4mm and a thickness of 0.02-0.04mm. The lead-out wire 3 is a molybdenum rod lead-...

Embodiment 2

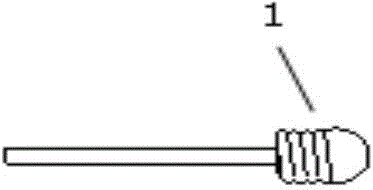

[0047] An electrode molybdenum sheet assembly for a point light source, consisting of an emitter electrode 1, a sealed molybdenum sheet 2 and a lead wire 3, the connection method is basically the same as that of embodiment 1, the difference is that the emitter electrode 1 has a structure such as image 3 As shown, it consists of a mandrel and a spring welded and sleeved on the front end of the mandrel. The extension at the front end of the mandrel is a round head structure. The structure of the sealed molybdenum sheet 2 is as follows: Figure 4-5 As shown, it is an arc-shaped structure, and the radian is controlled at 1.2-2.8rad. In this embodiment, it is controlled at 2rad. The structure of the lead-out line 3 is as follows Image 6 As shown, the tail is a diamond-shaped structure, and the middle part is a wave-shaped structure. The height of the middle wave-shaped structure is slightly smaller than the inner diameter of the glass tube, and the precision is controlled at 0.05m...

Embodiment 3

[0049] An electrode molybdenum sheet assembly for a point light source, consisting of an emitter electrode 1, a sealed molybdenum sheet and a lead wire 3, the connection method is basically the same as that of embodiment 1, the difference is that the emitter electrode 1 has a structure such as Figure 7 As shown, it is composed of a single mandrel, and the structure of the lead wire 3 is as follows Figure 8 As shown, the tail is a hook-shaped structure, and the middle part is a straight rod structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com