Overhead trestle structure built on non-covering steep bare rocks in deep rapids

A non-covering, steep technology, applied in infrastructure engineering, erecting/assembling bridges, bridges, etc., can solve the problems of high cost, heavy workload, long construction period, etc., to achieve low cost, short construction period, and reduced construction costs. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

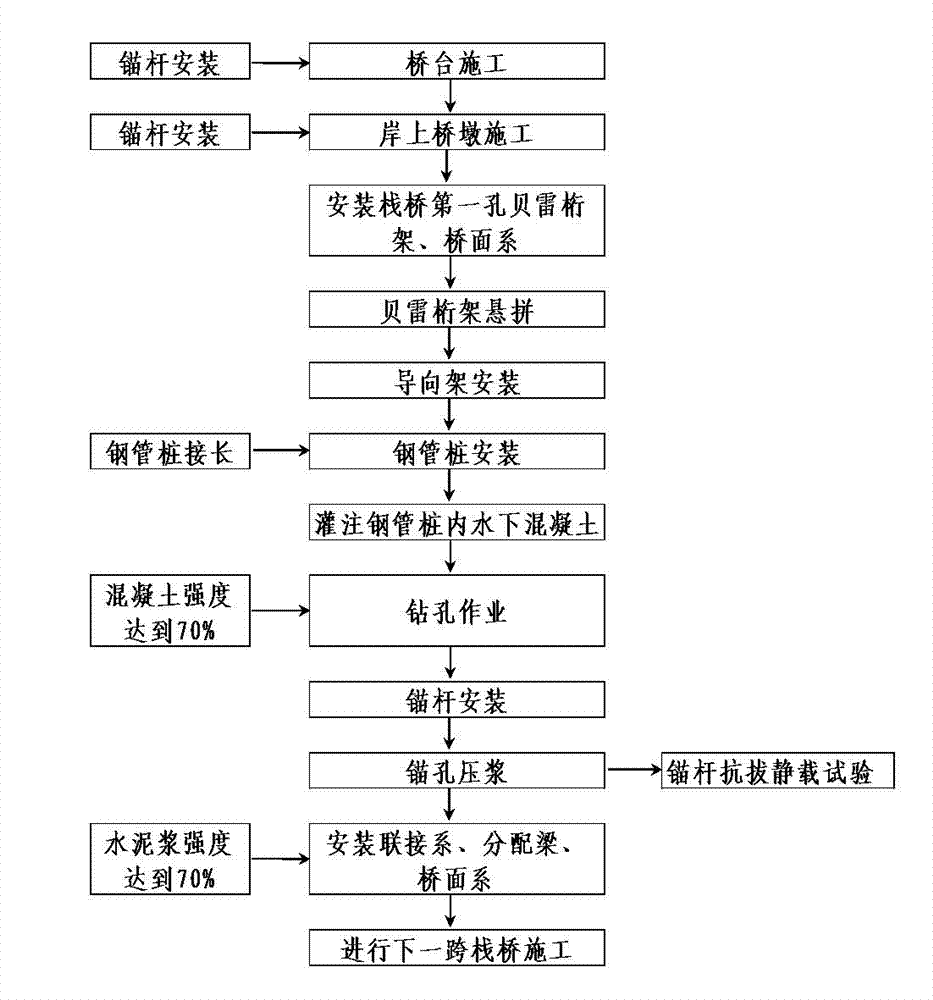

Method used

Image

Examples

Embodiment

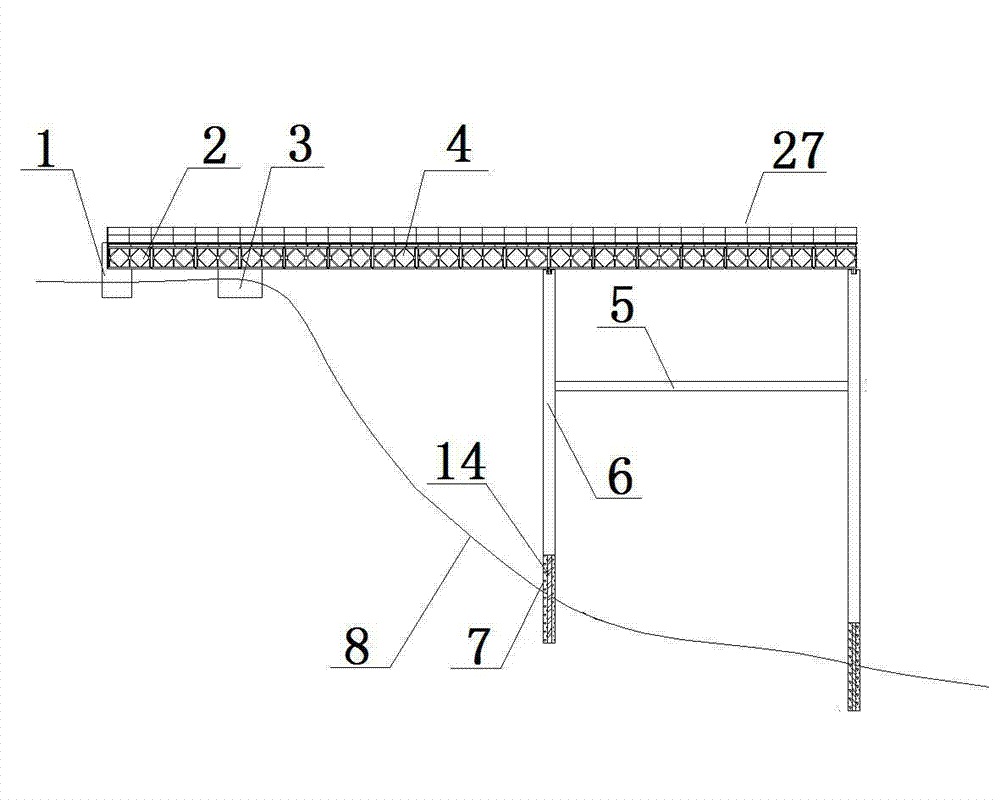

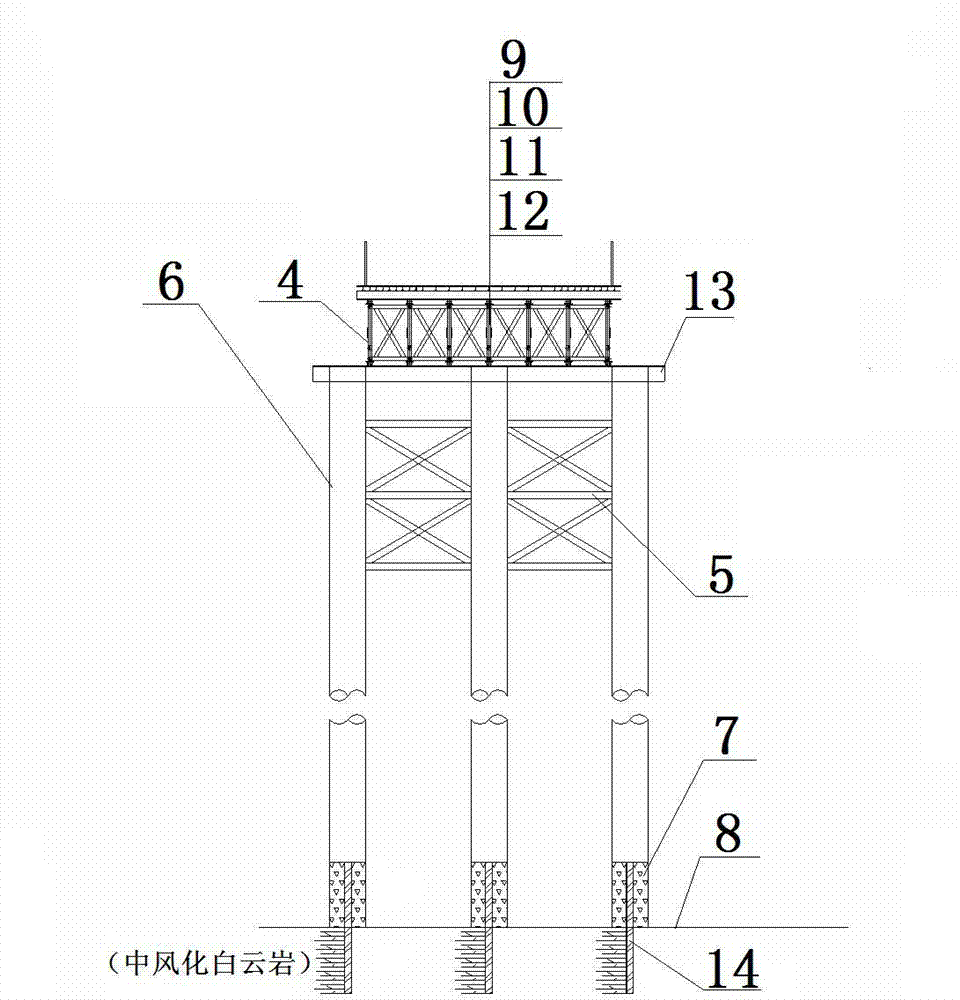

[0029] Embodiment: This embodiment specifically relates to a high-level trestle structure arranged on steep bare rock without covering in deep-water rapids. This kind of high-level trestle structure is suitable for deep-water rivers, high flow rates, mountainous rivers with high flood seasons, rivers without covering layers, and riverbeds. It is a steep or inclined hard bare rock hydrogeological condition. This embodiment will take the Qianjiang Super Bridge Project as an example to describe in detail. The Qianjiang River is a mountainous river with a large flow rate and rapid flow. The maximum flow rate reaches 3.21m / s. The riverbed has no cover layer. 80 MPa, extending all the way to the shore, the riverbed within 65m near the shore is steep, the rock face is inclined at 35-53°, and the rock face at the pier in the water is inclined at about 25°, and the river bed is undulating and full of stalagmites. In order to make it easier for construction workers to enter the bridge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com